Overview of Vehicle AEB

Mingcheng Liu Rongwei Shen

Tianjin University of Technology and Education, Tianjin, 300222, China

ABSTRACT With the rapid development of China's economy and the continuous improvement of people's living standards, people pay more attention to the safety of cars.China's car sales and ownership is also rising, but also led to a lot of traffic accidents.With the continuous promotion of intelligent, electric and networked automobiles, Autonomous Emergency Braking system has become the focus of automobile enterprises in the active safety of automobiles.The overall scheme of auto emergency braking includes information acquisition module, control module and execution module.This paper briefly introduces the application status of this field at home and abroad, and discusses the function and implementation method of each module respectively.

Keywords:Active safety Vehicle intelligence Automatic emergency braking

1.Introduction

Since the birth of the automobile, the safety problem has been accompanied by around.With the rapid development of the automobile industry, the vehicle safety problem has once again become a problem of great concern to many consumers.

Automatic emergency braking system is a kind of vehicle active safety technology, which is mainly used to reduce vehicle collision accidents.At present, many automobile companies and research institutions in the world are developing automatic emergency braking systems with high reliability[1].When the vehicle is driving on the normal road, the auto emergency braking system can automatically detect the driving environment.If there is a collision risk in the current driving environment, the vehicle will remind the driver to pay attention through the form of sound and light.When the driver fails to take braking measures, the automatic emergency braking system will automatically take braking measures to avoid the occurrence of traffic accidents.

The National Highway Traffic Safety Administration (NHTSA) and the Insurance Institute for Highway Safety (IIHS) have set a September 1,2022 deadline for automakers to install automatic emergency braking systems in their vehicles.

According to a “report card”published by NHTSA, Tesla has equipped all four of its existing vehicles with automatic safety systems, including forward collision warning, urban emergency braking, high-speed emergency braking, and pedestrian emergency braking.Other U.S.automakers, such as Ford and General Motors, have also started to make good on their commitments, but have yet to equip all their vehicles with automatic braking.Ford makes automatic emergency braking a standard feature on its passenger vehicles such as the Edge, Escape, Expedition and Explorer, but makes it optional on vehicles such as the Mustang.Buyers of the F-250 and F-350 will also have the option of automatic braking.Emergency braking is optional on nearly all of GM’s Chevrolet vehicles, and the only model that comes standard with forward collision warning, predictive emergency protection and automatic emergency braking is the Equinox.This means that one in 17 Chevrolets will be equipped with automatic emergency braking, but it will still have to install it in all vehicles by September 1, Volkswagen, Audi, Mercedes-Benz and BMW are close to fulfilling that promise.Hyundai, Volvo, Toyota, Subaru and Mazda are also working hard to make good on their promises.The automated emergency system uses onboard sensors, such as radar, cameras or lasers to detect an impending collision and alert the driver, and is capable of braking if the driver does not brake quickly, IHS said.It is estimated that the system could reduce rear-end collisions by 40%[2].

2.Research Status of AEB at Home and Abroad

A prototype of automatic emergency braking first appeared in air vehicles in the1950s.At the end of 1980s, various research institutions and universities began to conduct in-depth research on collision warning and automatic emergency braking system.Since the 21st century, with the rapid development of sensor, computer and other technologies, AEB has attracted the attention of multinational automotive companies.Mercedes-Benz first introduced a collision warning system in 2002, introduced it in the S-class in 2003, and finally introduced its automatic emergency braking system in 2006.Honda introduced a collision warning system with automatic braking on its Inspire model in 2003, which was seen as the beginning of AEB.Subsequently, Volkswagen, Volvo, BMW, Ford Motor and other enterprises have been equipped with this technology on the high-end models.Currently, AEB is available on Audi A6 and QS, Volvo S60 and S80, BMW 5 Series, Ford Taurus and Reveille, and GM Cadillac.AEB has been gradually introduced to China.In China, C-NCAP has prioritized AEB research, which has attracted the attention of joint ventures and self-owned brands to the research, development and application of AEB, and the application models have been extended from high-end to mid-range models[3].

At present, low speed AEB, high speed AEB and AEB pedestrian functions have been achieved mass production, and equipped with medium and high-end models at home and abroad.AEB’s main suppliers include Bosch, Continental, Delphi, TRW and other multinational components companies.In addition, Magna, Valeo, Autoliv and other multinational component companies will also form supporting capabilities in the next few years.Domestic enterprises mainly focus on cameras, but there are still no mature products on the market.Hengrun Technology, Hangsheng Electronics, Neusoft Group, Desesiwei, Suzhou Zhihua and other enterprises have successfully developed camera-based FCW, while further AEB is still in the development stage.At the present stage, the cost of AEB for a single sensor scheme is RMB 1,000-2,000.With the continuous technological progress and the gradual expansion of the cost, the annual price reduction rate will be about 3% in the future.

At present, the main models of AEB are medium and high-end models launched by joint ventures such as Changan Ford, Beijing Benz, Dongfeng Nissan and FAWVolkswagen.The self-owned FAW sedans such as Hongqi H7 and Geely Bo Bei are also used.In recent years, AEB has experienced explosive growth due to the increasing maturity of AEB technology and the acceleration of the equipment process due to the inclusion of AEB in the Euro-NCAP evaluation process[4].

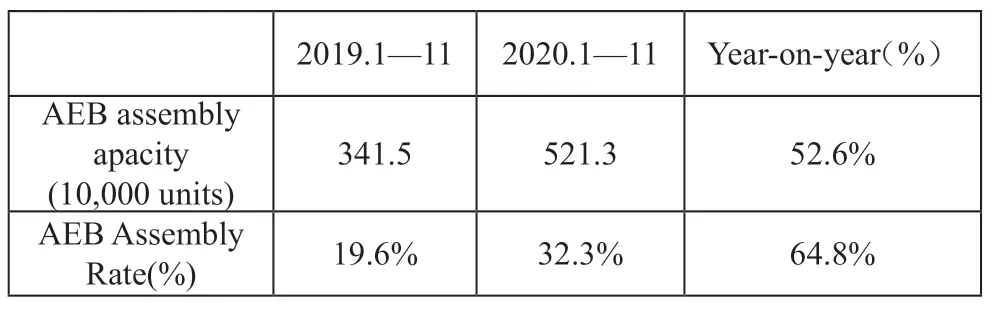

Table 1 shows the AEB assembly of new passenger vehicles in China from 2019 to 2020.From the perspective of various price ranges, the largest proportion of AEB assembly is 100,000-250,000 vehicles.Among them, the main brands are Toyota (Corolla, Leiling), accounting for 38%; Volkswagen (Bora, Lavida), accounting for 13%; 150-200,000 price range, the main brands are Toyota (Camry, RAV4 Rong Rong), accounting for 29%, Volkswagen (Lavida,T-ROC Tanjue), accounting for 20%; The price range is 200,000-250,000, and the main brands are Toyota (Camry, Asialong), accounting for 33%, and Volkswagen (Tanyue), accounting for 23%.

Table 1.AEB assembly in 2019-2020

3.Composition and Principle of AEB

The automatic emergency braking system uses radar (laser radar, millimeter wave radar) to measure the distance with the front vehicle, and then compares this distance with the alarm distance and the safety distance.If the distance between the two vehicles is less than the alarm distance, the alarm promptly will be started.If the distance between the two vehicles is less than the safety distance, the vehicle will automatically brake.The system mainly includes three modules: information acquisition module, control module and execution module.

3.1 Information Collection Module

The whole vehicle braking process can be divided into[5].The driver realizes the occurrence of a dangerous situation and then realizes that emergency measures should be taken.Then the driver raises his right foot and steps on the brake pedal to exert braking force on the vehicle.Finally, the vehicle stops under the action of maximum deceleration, which can be mainly divided into five periods: driver’s reaction time (t1), driver’s foot moving time (t2), braking coordination time (t3), braking deceleration constant time (t4).Generally, T1 value is 0.6-1s.Under the ideal condition of ABS, the braking distance of the vehicle can be calculated by the following formula:

Where S represents the braking distance, is the vehicle speed, and is the maximum adhesion coefficient of the road surface.

Vehicle braking distance is related to driving speed, driver reaction time, road adhesion coefficient and brake coordination time, etc.At present, the commonly used ranging methods for vehicles are as follows: ultrasonic ranging, infrared ranging, laser radar ranging, millimeter wave radar ranging, millimeter wave radar low cost, reliable performance, small environmental interference and other advantages, so the vehicle more use millimeter wave radar to measure the vehicle distance.

3.2 Control Model

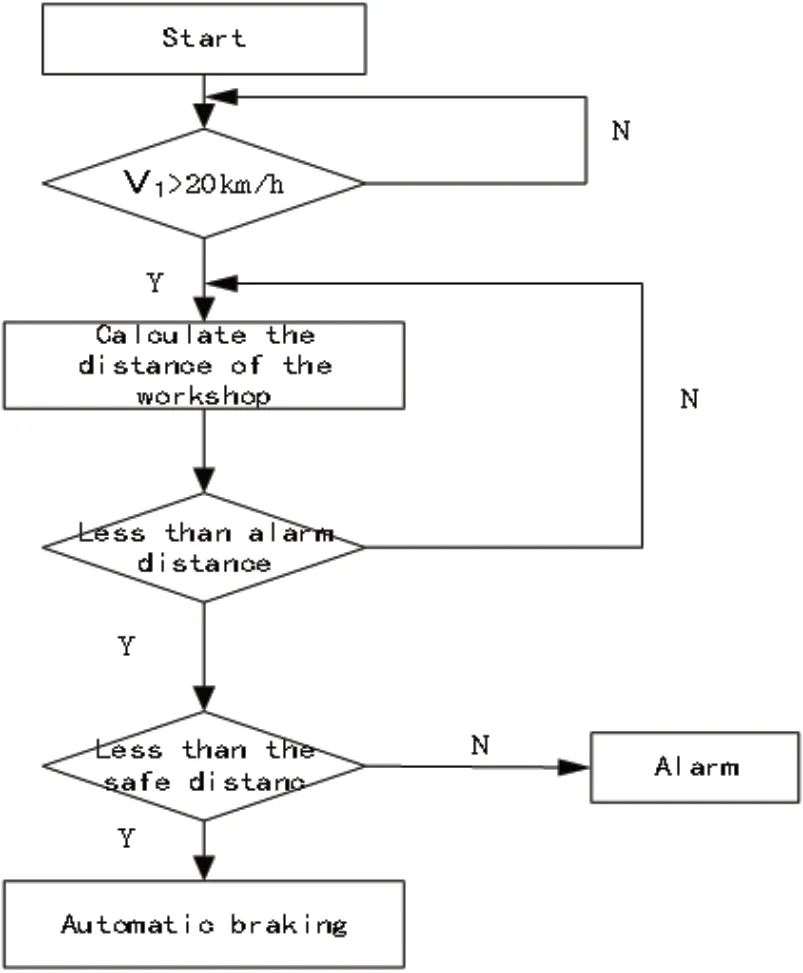

The control flow chart is shown in Figure 2.In the process of driving, the driver generally has enough time to brake, and the probability of traffic accidents is small.Therefore, the automatic emergency braking system shall first judge the current speed after starting.

Figure 1.Control flow

Measuring distance is actually measuring the time difference between the transmitting pulse and the echo pulse.Because the electromagnetic wave travels at the speed of light, it can be converted into the precise distance of the target.Because the relative speed between cars is much smaller than the speed of light, it is negligible.If the relative speed between cars is ignored, the distance between two cars can be expressed by Equation (2):

Where R is the relative distance between the two cars, c is the speed of light, and T is the time interval from transmitting signal to receiving signal.The calculation of the time interval can be done by the timer inside the control processor.Timer starts timing when the signal is transmitted and stops timing when the signal is received, and then reads the time interval numerical substitution Formula (2) of the data register of timer to calculate the vehicle distance.The alarm distance is calculated by Formula (3) and the safety distance is calculated by Formula (1).

Measured by the speed sensor and set as constant.Adhesion coefficient is selected according to the road conditions.When the system is working, the driver makes the selection according to the actual road conditions at that time and place, and then calculates the distance using Formula (1) and (3).In order to avoid the car in front of the overtaking and vehicles approached, in turn to enter the road cars, pedestrians, when changing lanes or around obstructions caused unnecessary risk, automatic braking and the car when the above situation, must make a turn, so the system control processor made linkage switch, power switch and turn signal switch when calling the turn signal switch.The power switch of the processor is disconnected, and the automatic braking system stops working, so that when overtaking, cornering, changing lanes or going around obstacles, the vehicle in front or its objects will not affect the normal running of the car.When the turn signal switch is turned off, the power switch of the processor is closed and the automatic braking system continues to work[6].

3.3 Perform Module

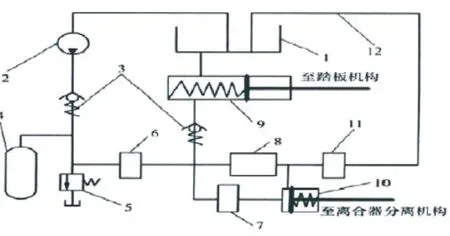

As shown in Figure 3, in order to simplify the figure, the vacuum main force is omitted.The hydraulic pump 2 is driven by the engine through the transmission mechanism and keeps working to produce high pressure.When the vehicle is running at a high speed, the brake fluid oil pressure is required to reach (10-12) MPa to generate the braking torque corresponding to the vehicle speed.Therefore, the brake fluid pressure of the energy storage tank 4 should be kept at 12 MPa, and the relief valve 5 should be set at 14 MPa[7].When the driver steps on the brake pedal, the high-pressure brake fluid flows into the brake wheel cylinder 8 and pushes the brake block to press the brake disc to realize braking.At this time, the solenoid valve 6, 7 and 11 are closed so that the oil inlet maintains high pressure.When the driver releases the brake pedal, the solenoid valve 6 and 7 are closed, the solenoid valve 11 is opened, and the high-pressure oil flows back to the oil storage room 1 through the oil return road 12.Under the action of the reset spring of the brake wheel cylinder 8, the brake block loosens, thus realizing manual braking.

Figure 2.Schematic diagram of automatic actuator

When the distance of the workshop measured by the system control processor is less than the alarm distance, the output signal of the processor drives the voice chip to give a voice prompt, reminding the driver to take the necessary deceleration operation.When the driver still does not take corresponding measures and the measured workshop distance is less than the safe distance, the output signal of the processor makes the solenoid valve 6 open, the solenoid valve 7, 11 close, the high pressure oil flow of the energy storage tank 4 into the wheel cylinder 8, to achieve automatic braking.At this point, check valve 3 to avoid high pressure oil flow to brake the main cylinder 9 role.If the driver step on the accelerator, the processor is detected after the accelerator pedal position switch signal, and output a high level signal, it has to do with driving solenoid valve 6 signal after and gate, the 7 open the solenoid valve, high pressure oil flow into the single-acting cylinder (10, driving the push rod connected to the clutch mechanism, make the clutch.After the driver releases the accelerator pedal, the solenoid valve 7 closes, until the danger disappears after the solenoid valve 6 closes, the solenoid valve 11 opens, and the high pressure oil in the brake wheel cylinder 8 and single acting cylinder 10 flows back to the oil storage room 1 under the action of the return spring.

4.Conclusions

This paper briefly introduces the current situation of AEB at home and abroad, and introduces the three main components and principles of AEB.

In the main information acquisition module, millimeter wave radar is used to measure the vehicle distance, which has strong environmental adaptability, weak environmental interference and suitable detection range.The safety distance and alarm distance of the brake module can be approximated according to the formula.Appropriate improvement of the automatic emergency braking structure can effectively avoid the danger caused by the misoperation.

Modern Electronic Technology2021年2期

Modern Electronic Technology2021年2期

- Modern Electronic Technology的其它文章

- Research on Direct Torque Control of Permanent Magnet Synchronous Motor for New Energy Vehicles

- A 4-element Rectangular Microstrip Patch Antenna Array

- A Review of Traffic Conflict Avoidance Methods at Intersection Using Vehicle-Infrastructure Cooperation System

- Design of a Submarine Pipeline Inspection Robot System Based on CT Technology

- Research on Thermal Management Control Strategy of Electric Vehicle Liquid Cooling Battery Pack