Hollow Nitrogen-Rich Carbon Nanoworms with High Activity for Metal-Free Selective Aerobic Oxidation of Benzyl Alcohol

Ping An , Yu Fu , Danlei Wei , Yanglong Guo , Wangcheng Zhan ,*, Jinshui Zhang ,*

1 State Key Laboratory of Photocatalysis on Energy and Environment, College of Chemistry, Fuzhou University,Fuzhou 350108, China.

2 Key Laboratory for Advanced Materials and Research Institute of Industrial Catalysis, School of Chemistry and Molecular Engineering, East China University of Science and Technology, Shanghai 200237, China.

Abstract:Carbon materials have become one of the research hotspots in the field of catalysis as a typical representative of non-metallic catalytic materials. Herein, a facile synthetic strategy is developed to fabricate a series of hollow carbon nanoworms (h-NCNWs)that contain nitrogen up to 9.83 wt% by employing graphitic carbon nitride (g-C3N4)as the sacrificing template and solid nitrogen source. The h-NCNWs catalysts were characterized by X-ray diffraction (XRD), high-resolution transmission electron microscope (HR-TEM), N2 adsorption-desorption, Fourier transform infrared spectroscopy (FT-IR), thermal gravimetric (TG), Raman spectra,and X-ray photoelectron spectroscopies (XPS). The catalytic activities of the h-NCNWs catalysts for selective oxidation of benzyl alcohol with O2 were also evaluated. The characterization results revealed that the h-NCNWs catalysts displayed a unique hollow worm-like nanostructure with turbostratic carbon shells.The nitrogen content and shell thickness can be tuned by varying the relative ratio of resorcinol to g-C3N4 during the preparation process. Furthermore, nitrogen is incorporated to the carbon network in the form of graphite (predominantly)and pyridine, which is critical for the enhancement of the catalytic activity of carbon catalysts for the selective oxidation of benzyl alcohol. At a reaction temperature of 120 oC, a 24.9% conversion of benzyl alcohol with > 99% selectivity to benzaldehyde can be achieved on the h-NCNWs catalyst prepared with a mass ratio of resorcinol to g-C3N4 of 0.5. However, the catalytic activities of the h-NCNWs catalysts were dependent on the amount of N dopants, in particular graphitic nitrogen species.The conversion of benzyl alcohol markedly decreased to 13.1% on the h-NCNWs catalyst prepared with a mass ratio of resorcinol to g-C3N4 of 1.5. Moreover, the h-NCNWs catalyst showed excellent stability during the reaction process. The conversion of benzyl alcohol and the high selectivity to aldehyde can be kept within five catalytic runs over the h-NCNWs0.5 catalyst. These results indicate that rationally designed carbon materials have great potential as highly efficient heterogeneous catalysts for oxidation reactions.

Key Words:Hollow nanostructure; Nitrogen doping; Metal-free catalyst; Selective oxidation; Benzyl alcohol

1 Introduction

Transition and noble metals are widely used as active components for most of the heterogeneous catalytic redox reactions, owing to their emptydorforbits that can be combined with the substrate molecules to form a low barrier transition state. Nevertheless, it was generally believed that nonmetallic substances are quite difficult to participate in the catalytic reactions due to the absence of empty orbits. In the last two decades, carbon nanomaterials (e.g., activated carbon, fullerene,carbon nanotubes, graphene, nanofibers, nanodiamond)have aroused extensive concern owing to their unique physical and chemical properties1–6, which give birth to moderate catalytic activity in many reactions, such as hydrogenation of acetylene and nitrobenzene7,8, oxidation of benzylamine and aromatic aldehyde9,10, hydroxylation of acetylene and benzene11,12, and as well as electrochemical oxygen reduction reaction (ORR)13–16.However, the activity of carbon materials in the reactions is typically several orders of magnitude lower than that of metallic materials. To improve the catalytic performance, carbon materials are generally modified with hetero-atom dopants, and then their catalytic behavior is closely depended on the kinds of hetero-atom dopants. For example, doping carbon materials with more electronegative nitrogen atoms (3.04 for Nvs2.55 for C)can induce positively charged carbon atoms, leading to novel functions for redox reactions17–20. Therefore, the control synthesis of carbon materials with doped foreign atoms is facile strategy to advance carbon materials for heterogeneous catalysis.

Hollow nanostructured carbon materials have gained significant interest for a variety of applications, including drug release, fuel cells, energy storage, gas storage and separation,lithium-ion batteries, and as well as catalysis21–25, because of their high surface area and surface-to-volume ratio. Recently, the preparation of hollow carbon materials with controlled size, wall thickness and geometry is extremely appealing, and several strategies have been adopted for their synthesis. For example,hard template methodology is a straightforward approach using silica or polymer nanoparticles to direct the formation of hollow nanostructured carbons26–29. However, it is formidable to combine the removal of hard template with the doping of heteroatoms during the preparation of hollow nanostructured carbon materials, and thus multi-step process is employed generally.Fortunately, using graphitic carbon nitride (g-C3N4)as the template is a feasible approach to achieve two things at one stroke. g-C3N4is a conjugated organic compound with N content of > 50%30,31. Therefore, g-C3N4 can be utilized as both sacrificing template and solid nitrogen source for the preparation of hollow carbon nanostructures with high content N dopants.

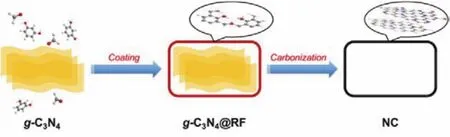

Herein, a hollow carbon material doped with N atoms was prepared by a facile approach based on carbonization of resins coated onto g-C3N4, in which g-C3N4was employed as the sacrificial template and solid nitrogen source. In Scheme 1,coating g-C3N4cores with resorcinol and formaldehyde precursors results in a thin layer of resins on their surfaces. The following thermal treatment under inert atmosphere decomposes g-C3N4to generate hollow carbon nanoworms with thin carbon shells containing nitrogen atoms up to 9.83% (w, mass fraction).The selective aerobic oxidation of benzyl alcohol molecules was selected as the model reaction to better evaluated their metal-free catalytic performance.

Scheme 1 Formation process of hollow nitrogen-rich carbon nanoworms.

2 Experimental section

2.1 Chemicals

AR grade powders of urea (CH4N2O, 99.5%), ethanol(C2H6O, 99.5%), ammonia aqueous solution (NH4OH, 28% (w))and formaldehyde solution (HCHO, 37% (w))in stoichiometric ratio were used without further purification.

2.2 Preparation of hollow nitrogen-rich carbon nanoworms (h-NCNWs)

2.2.1 Preparation of g-C3N4

10 g of urea was placed in a crucible covered with a lid and then heated at 550 °C for 4 h at a heating rate of 4 °C∙min−1. The light yellow solid obtained (designated as g-C3N4)was ground into powder before usage.

2.2.2 Preparation of g-C3N4@RF and h-NCNWs

Typically, 0.4 g of g-C3N4was first dispersed in the solution of 20 mL of deionized water and 8 mL of ethanol in a roundbottom flask. After sonicating for 2 h, the mixture was heated to 30 °C, and then 0.1 mL of ammonia aqueous solution (NH4OH,28% (w))was added followed by stirring at 600 r∙min−1for 30 min. Subsequently, 0.2 g of resorcinol was added and dissolved under stirring for 30 min. 0.28 mL of formaldehyde solution(HCHO, 37% (w))was then added to the reaction solution and further stirred for 24 h. Then the mixture was transferred into a 50 mL Teflon-lined autoclave and heated at 100 °C for 24 h. The as-prepared solid sample was separated by centrifugation and washed with water and ethanol. Finally, the solid was dried at 100 °C for 24 h to obtain g-C3N4@RF0.5.

The solid sample was also prepared without g-C3N4with the same procedures as mentioned above, the obtained sample was designated as RF0.5. Fig. S1 (in Supporting Information)shows the photos of the g-C3N4, g-C3N4@RF0.5 and RF0.5 samples,indicating that the color of g-C3N4template changed from light yellow to orange after coating with resins.

The g-C3N4@RF0.5 sample was then heated to 900 °C at a heating rate of 5 °C∙min−1under a gas flow of 30 mL∙min−1N2and kept at this temperature for 1 h. After cooled to room temperature, the sample obtained was designated as h-NCNWs0.5. Other g-C3N4@RFxand h-NCNWsxsamples were prepared by the same procedure except different amount of resorcinol and HCHO, in whichxrepresents the mass ratio of resorcinol to g-C3N4. In detail, h-NCNWs1 was prepared with 0.4 g of resorcinol and 0.56 mL of HCHO, while 0.6 g of resorcinol and 0.84 mL of HCHO were used for the preparation of h-NCNWs1.5. Carbon sample was also prepared from RF0.5 by the same procedure as a reference, and designated as C-RF.

2.3 Catalytic activity testing

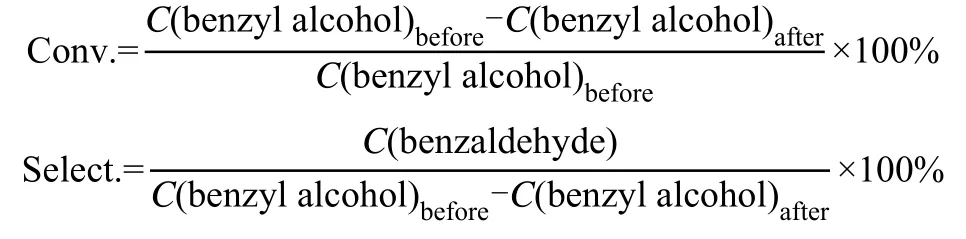

The selective oxidation of benzyl alcohol was carried out in a 50 mL autoclave lined with polytetrafluoroethylene (PTFE). 0.5 mmol of benzyl alcohol, 50 mg of catalyst and 3 mL of ethanol were added into the reactor. After purging with O2for three times, the pressure of O2 was adjust to 0.1 MPa, and then the reactor was heated to a certain temperature under stirring at 500 r∙min−1. After the reaction, the reactor was quenched with ice water to avoid the loss of volatile organics. The reaction mixture was diluted with ethanol to completely dissolve the side products. After the catalyst separated by centrifugation, a certain amount of cyclooctane was added as an internal standard substance. The reaction products were analyzed by Agilent gas chromatograph (GC)7890B equipped with an HP-5 capillary column and a flame ionization detector (7890B, Agilent Technologies, USA). In addition, the side products were further identified using Agilent 7890A-5975C gas chromatograph-mass spectrometry (GC-MS, Agilent Technologies, USA). The conversion of benzyl alcohol (Conv.)and the selectivity to benzaldehyde (Select.)were calculated as follows:

whereC(benzyl alcohol)before andC(benzyl alcohol)after are the concentrations of alcohol before and after reaction,respectively.C(benzaldehyde)is the concentration of benzaldehyde generated during the reaction process.

The recycling test of the catalyst was carried out and the catalyst was used for five times in the reaction. After every run,the catalyst was separated from reaction solution by centrifugation, washed with ethanol, and then dried in the air at 80 °C to constant weight.

2.4 Characterization

X-ray diffraction (XRD)data were collected on a D8 diffractometer (Bruker, Germany)using CuKαradiation (40 kV,40 mA)at room temperature. The high-resolution transmission electron microscope (HR-TEM)analysis were performed on the JEM-2100 microscope (JEOL, Japan)at an accelerating voltage of 200 Kv. N2adsorption-desorption isotherms of samples were obtained at −196 °C on a Micrometrics ASAP 2020M Sorptometer (Micromeritics, USA)using static adsorption procedures. Prior to the measurements, the sample was degassed at 120 °C for 12 h. The pore size distribution curves were calculated from the desorption branch by the Barrett-Joyner-Halenda (BJH)method. The FT-IR spectra of samples were recorded on a Nexus 670 FT-IR spectrometer (Nicolet, USA),and the samples were ground with anhydrous KBr and pressed into thin wafers. Elemental analysis of carbon was measured on a Vario EL III Analyzer (Elementar, Germany). The Raman spectra of samples were recorded on an Iuvia Reflequipment(Renishaw, England). X-ray photoelectron spectroscopies (XPS)were analyzed on an Escalab 250Xi photoelectron spectrometer(Thermo Scientific, USA)equipped with AlKαradiation as the excitation source. Thermal gravimetric (TG)analysis and the corresponding mass spectrometric (MS)signals were performed at a heating rate of 10 °C∙min−1from 40 °C to 800 °C in air using a Pyris 1 TGA thermogravimetric analyzer (PerkinElmer, USA)coupled with Hiden HPR 20 mass spectrometer.

3 Results and discussion

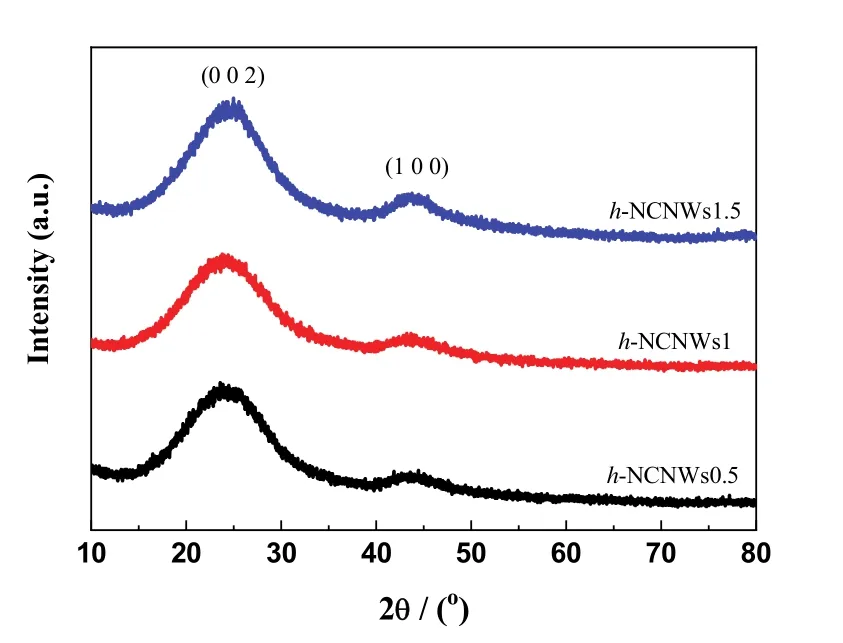

3.1 XRD

The powder XRD patterns of the h-NCNWs samples are depicted in Fig. 1. All the samples exhibited two broad diffraction peaks corresponding to the (002)and (100)diffraction modes at 24.1° and 43.9°, indicating the typical disordered carbonaceous structure. However, the interlayer spacing (d002)of all samples is about 0.368 nm, which is wider than that of classical graphite (0.336 nm). As a comparison, the precursor g-C3N4@RF0.5 sample, showed the typical diffraction peaks of g-C3N4 at 27.4° and 13.1° (Fig. S2, in Supporting Information). These results revealed that the thermal treatment can effectively decompose and carbonize the g-C3N4@RF0.5 sample.

Fig. 1 XRD patterns of the h-NCNWs samples.

3.2 TEM

The morphology and nanostructure of h-NCNWs were characterized by TEM experiments. In Fig. S3 (in Supporting Information), the g-C3N4@RF sample exhibited a typical coreshell structure, indicating that g-C3N4has been coated with resins. After being subjected to the thermal treatment, h-NCNWs samples displayed a unique hollow worm-like nanostructure with turbostratic carbon shells (Fig. 2). It should be pointed out that the preparation method makes it available to tune the shell thickness of h-NCNWs through adjusting the ratio of resorcinol to g-C3N4. The thickness of weakly ordered shell is determined to beca.6 nm, 9 nm and 14 nm for the h-NCNWs0.5, h-NCNWs1 and h-NCNWs1.5, respectively.

Fig. 2 HR-TEM images of the h-NCNW0.5 (a, b), h-NCNW1 (c, d),h-NCNW1.5 (e, f)samples

3.3 N2 adsorption-desorption

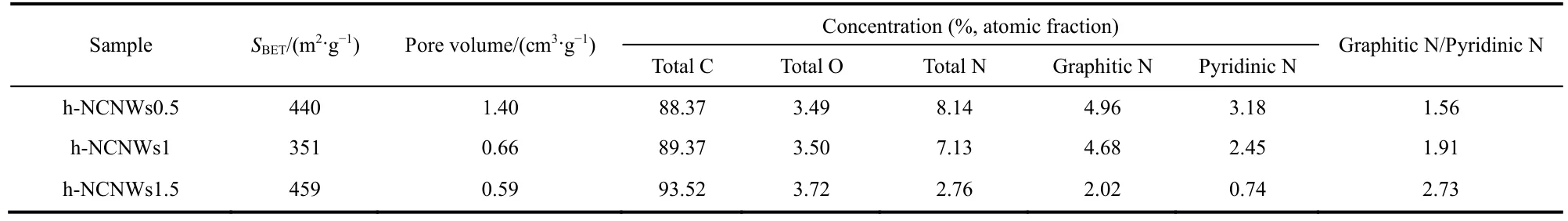

Fig. 3 shows N2adsorption-desorption isotherms and the corresponding pore size distribution curves of the h-NCNWs samples. All isotherms exhibited a typical IV type isotherm of mesoporous materials. The textural information of the h-NCNWs were summarized in Table 1. The Brunauer-Emmett-Teller (BET)surface areas of the h-NCNWs0.5, h-NCNWs1 and h-NCNWs1.5 samples are 440, 351, 459 m2∙g−1, respectively.The pore size of the h-NCNWs1 sample decreased from 9.4 to 5.5 nm compared to the h-NCNWs0.5 sample (Fig. 3b). The distribution at 3.8 nm for the h-NCNWs1 sample is due to the tensile strength effect32. However, the pore size was truly decreased to about 3.8 nm for the h-NCNWs1.5 sample.Meanwhile, the h-NCNWs0.5 sample exhibited a large pore volume (1.40 cm3∙g−1), which is more than two times of that of the h-NCNWs1 sample. In addition, the pore volume of the h-NCNWs1.5 sample further declined to 0.59 cm3∙g−1.

Table 1 Textural properties and the concentration of C, N and O atoms on the surface of the h-NCNWs samples detected by XPS.

3.4 FT-IR Spectroscopy

Fig. 4a shows FT-IR spectra of the g-C3N4, g-C3N4@RF0.5 and RF0.5 samples. The spectrum of g-C3N4@RF0.5 sample is similar with that of the g-C3N4sample. The strong absorption peaks between 1100 and 1700 cm−1observed from g-C3N4and g-C3N4@RF0.5 samples are attributed to the characteristic stretching modes of aromatic CN heterocycles in the polymeric melon network. Meanwhile, the strong peaks at 805 cm−1can be attributed to the typical stretching mode of the triazine units33,34.However, the FT-IR spectra of the h-NCNWs samples are rather different from that of g-C3N4@RF samples (Fig. 4b). Compared with the spectrum of the C-RF sample, two new peaks centered at 1596 and 1200 cm−1were present for all h-NCNWs samples,which can be assigned to the characteristic stretching modes of aromatic CN heterocycles in the networks. Significantly, the intensities of these two peaks decreased with an increase in the thickness of the shell, suggesting the different content of N species in the h-NCNWs samples.

Fig. 3 N2 adsorption-desorption isotherms (a)and the corresponding pore size distribution curves (b)of the h-NCNWs samples.

Fig. 4 FT-IR spectra of g-C3N4, g-C3N4@RF0.5 and RF0.5 samples (a)as well as the h-NCNWs samples (b).

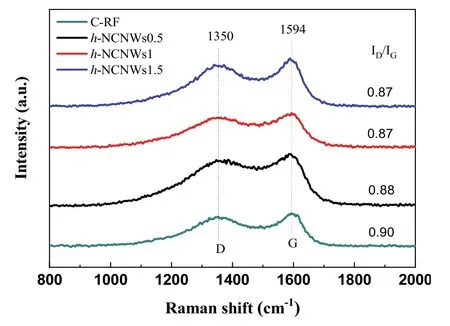

3.5 Raman spectroscopy

Raman spectra of the h-NCNWs samples are shown in Fig. 5.All h-NCNWs displayed two conspicuous bands centered at 1350 and 1594 cm−1, corresponding to the dispersive defectinduced vibrations (Dband)and the vibration of graphiticsp2-bonded carbon atoms (Gband), respectively. TheG-band indicates the graphitic structure of the samples, while theD-band demonstrates the presence of structural defects in the samples.Generally, the ratio of the intensity ofDto that ofGband (ID/IG)can represent intrinsic disorder of the carbon materials, and a higherID/IGvalue suggests the presence of more structural defects35,36. TheID/IGvalue of h-NCNWs0.5, h-NCNWs1 and h-NCNWs1.5 is determined to be 0.88, 0.87, and 0.87,respectively, which was close to that of C-RF (0.90). These results revealed that N-doping cannot affected the degree of graphitization.

Fig. 5 Raman spectra of the h-NCNWs samples.

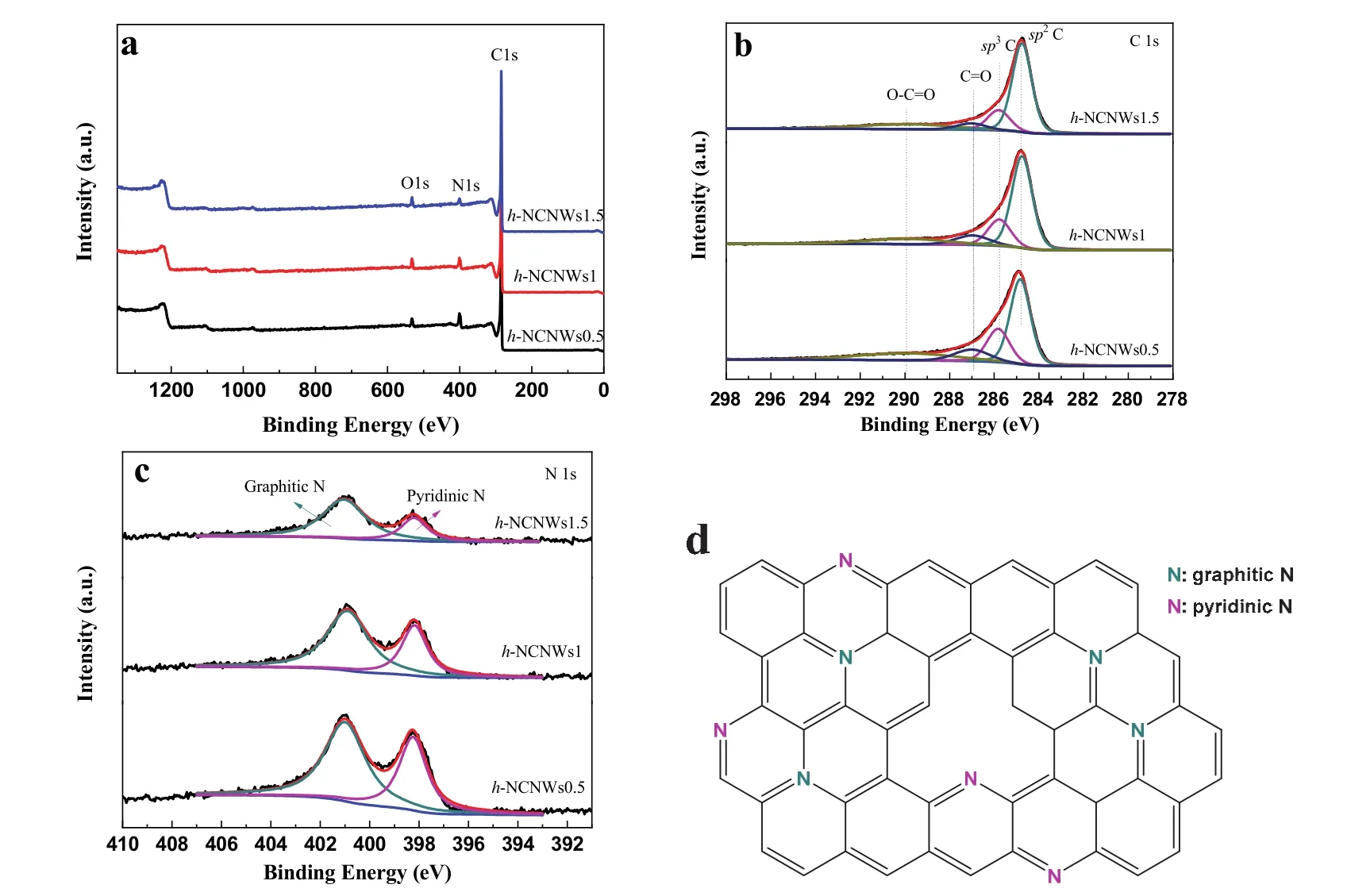

3.6 XPS

XPS spectra of the h-NCNWs samples are shown in Fig. 6.The XPS survey spectra of h-NCNWs samples displayed a strong signal relative to N 1sphotoelectron excitation peak (Fig.6a). The N content on the surface of the h-NCNWs samples is 8.14%, 7.13% and 2.76% (atomic fraction)for h-NCNWs0.5, h-NCNWs1 and h-NCNWs1.5 respectively, which is consistent with the FT-IR results. Fig. 6b shows the C 1sXPS spectra, where the peak is asymmetric and deconvoluted into four peaks. The peaks at 290.5, 287.3, 285.8 and 284.8 eV can be assigned to O-C=O, C=O,sp3C andsp2C species,respectively. Furthermore, as shown in Table S1 (in Supporting Information), the content of N in the h-NCNWs0.5, h-NCNWs1 and h-NCNWs1.5 samples are 9.83%, 6.94% and 3.76% (w)respectively, indicating N heteroatoms have be incorporated into the carbon network with a high content of N and the main structure ofsp2-carbon networks can be maintained when thesp2-hydridized nitrogen atoms are incorporated37. The two peaks at 398.2 and 400.9 eV corresponding to pyridinic and graphitic N can be observed in N 1sXPS spectrum of the h-NCNWs samples (Fig. 6c), and the detail structure is shown in Fig. 6d. As listed in Table 1, N atoms are preferentially at the graphitic sites for the h-NCNWs samples. Despite the ratio of graphitic N to pyridinic N for the h-NCNWs samples decreased with the increase in the content of N in the samples, graphitic N atoms are still the dominant species.

Fig. 6 XPS survey spectra (a)and O 1s (b), N 1s (c)XPS spectra of the h-NCNWs samples and schematic illustration of different types of nitrogen species (d)

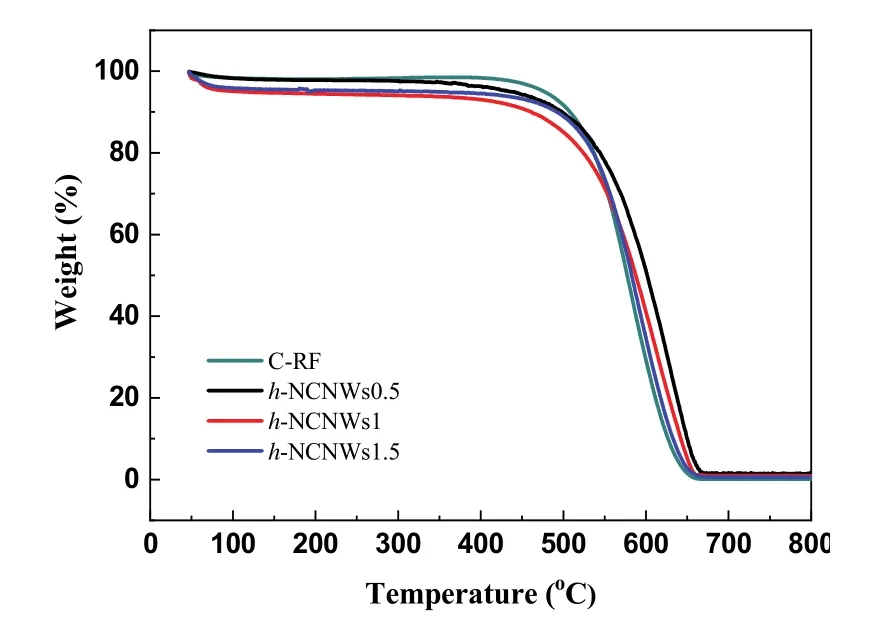

3.7 Thermal analysis

In Fig. 7, h-NCNWs samples were subjected to thermal gravimetric analysis (TGA)to study their thermal stability. All the samples were heated from room temperature to 800 °C in air at a heating rate of 10 °C∙min−1. There was an obvious weight loss occurring at 425–650 °C, due to the decomposition of the carbon framework. Furthermore, the decomposition temperature of N-rich h-NCNWs samples is close to that of the C-RF sample,indicating that the thermal stability of the samples can be preserved even after N-doping.

Fig. 7 TGA curves of the C-RF and h-NCNWs samples.

3.8 Catalytic performance

It is reported that graphitic nitrogen species can absorb and activate oxygen molecules, thereby showing the highest activity for the selective oxidation of benzyl alcohol among various types of N dopants38–42. Toward this end, the catalytic performances of h-NCNWs catalysts were systematically studied by the selective oxidation of benzyl alcohol with molecular oxygen.Owing to the well dispersion of h-NCNWs in ethanol (Fig. S4,Supporting Information), the selective oxidation of benzyl alcohol reaction was conducted in the solvent of ethanol. In Table 2, negligible conversion of benzyl alcohol was detected in the blank test, and only 1.73% conversion of benzyl alcohol was achieved over C-RF catalyst. As a comparison, the N-doped h-NCNWs catalysts exhibited a significantly enhanced activity.The conversion of benzyl alcohol increased markedly as increasing the reaction temperature, and was achieved to 24.9% at 120 °C with a high selectivity to benzaldehyde (> 99%).Furthermore, the catalytic performance of h-NCNWs was closely depended on the amount of N dopants, in particular graphitic nitrogen species. The catalytic activity decreased from 24.9% for h-NCNWs0.5 to 20.2% for h-NCNWs1 and 13.1% for h-NCNWs1.5. This finding strongly indicated the essential role of nitrogen dopants in redox reactions.

Table 2 Catalytic selective oxidation of benzyl alcohol over different catalysts under different conditions a.

To determine the role of O2in selective oxidation of benzyl alcohol, the reactions were performed with N2instead of O2for two runs. There is a dramatic decrease in the conversion of benzyl alcohol, suggesting that O2 is involved in the reaction as the oxidant. In addition, hydroquinone was added to the reaction system as a free-radical scavenger. As expected, a distinct decrease in the conversion of benzyl alcohol was also observed,demonstrating that the reaction may proceedviaa radical chain reaction mechanism.

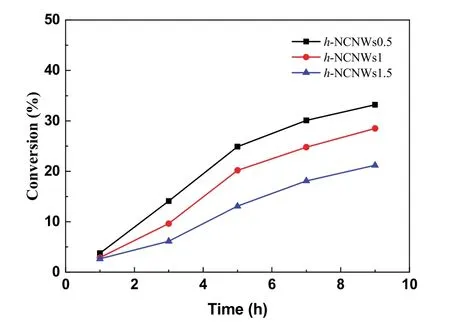

The effect of reaction time on the conversion of benzyl alcohol over the h-NCNWs catalysts was studied. In Fig. 8, the conversion of benzyl alcohol over the h-NCNWs catalysts increased as increasing the reaction time, while the high selectivity to benzaldehyde was preserved. Furthermore, the conversion of benzyl alcohol over the h-NCNWs0.5 catalyst was higher than that of the h-NCNWs1 and h-NCNWs1.5 catalysts,further demonstrating the important role of N dopants.

Fig. 8 Effect of reaction time on the conversion of benzyl alcohol over the h-NCNWs catalysts.

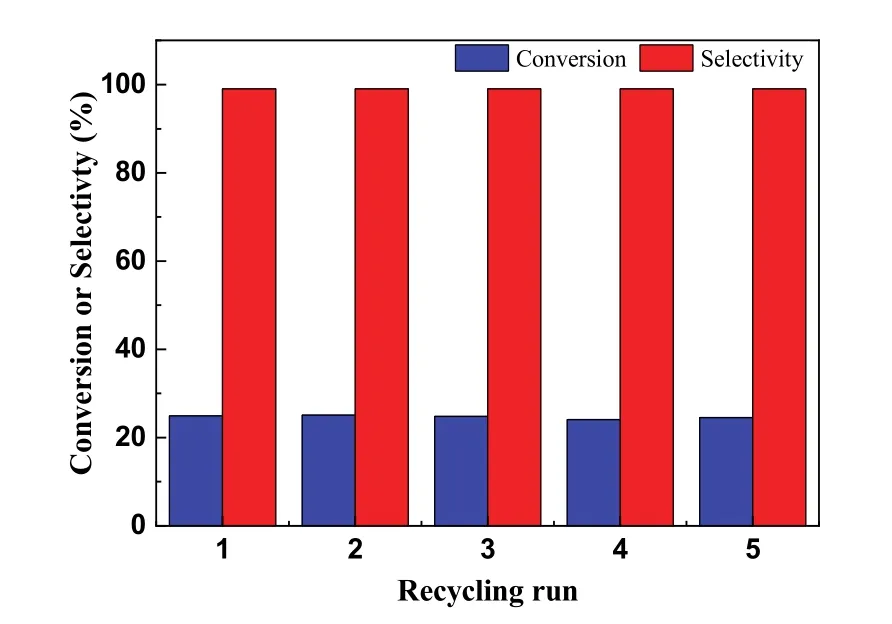

In addition to the catalytic performance of fresh catalyst,another important feature of the catalyst is its reusability. As shown in Fig. 9, both the conversion of benzyl alcohol and the high selectivity to aldehyde can be kept within five catalytic runs over the h-NCNWs0.5 catalyst. Furthermore, there is no significant change between the XRD patterns of fresh and recycled h-NCNWs0.5 catalyst (Fig. S5, Supporting Information), suggesting that the structure of the h-NCNWs0.5 catalyst can be retained during reaction process.

Fig. 9 Reusability of the h-NCNWs0.5 catalyst for benzyl alcohol oxidation

4 Conclusions

A facile synthetic strategy is developed for the fabrication of hollow carbon nanoworms with high nitrogen dopants. The resin coating on g-C3N4 can be directly carbonized to N-doped carbon materials without any additional etching process involving in synthesis. This strategy provides a new avenue for the development of tunable functional hollow carbon nanomaterials,where the ratio of precursors and template affords a route to control the shell thickness. These hollow carbon nanoworms possess a large fraction of mesopores, large surface area, and high nitrogen content up to 9.83% (w). Pyridinic and graphitic nitrogen species are incorporated in the carbon networks, leading to an excellent catalytic toward selective oxidation of benzyl alcohol to benzaldehyde under mild conditions. We hope that the hollow N-rich carbon nanoworms prepared by this strategy should have great potential for advanced applications in the fields of traditional heterogeneous catalysis.

Supporting Information:available free of chargeviathe internet at http://www.whxb.pku.edu.cn.