丝素蛋白材料制备及应用进展

明津法 黄晓卫 宁新 潘福奎 左保齐

摘要: 为深入了解丝素蛋白材料的制备技术及应用研究现状,文章介绍了湿法纺丝、干法纺丝等制备丝素蛋白纤维类材料的制备技术及纤维性能特点,发现湿法纺丝中纺丝液浓度普遍低于干法纺丝,且湿法纺丝过程中凝固浴对材料性能影响波动较大。冷冻干燥法、盐析法、发泡法等制备丝素蛋白支架类材料,冷冻干燥法获得丝素蛋白支架孔隙率可高达99%。同时,对不同制备技术获得的丝素蛋白材料性能进行分析,综述了丝素蛋白材料在智能纺织品、生物医药、光电学器件等领域应用研究。指出可通过再生制备技术进行结构设计和材料功能化,可提升蚕丝的附加值和拓宽其应用领域,实现蚕丝产品的多元化应用。

关键词: 湿法纺丝;蚕丝;丝素蛋白;智能可穿戴;生物医用

Abstract: In order to deeply understand the research status of the preparation and application of silk fibroin materials, this paper introduces the preparation techniques of silk fibroin fibers, such as wet spinning and dry spinning and the properties of such fibers. It is found the concentration of spinning solution in wet spinning is generally lower than that in dry spinning, and the coagulation bath in wet spinning has a great impact on the properties of materials. Silk fibroin scaffolds are prepared by freeze-drying, salting out and foaming etc. The porosity of silk fibroin scaffolds obtained by freeze-drying can be up to 99%. At the same time, the properties of silk fibroin materials obtained by different preparation techniques are analyzed. The applications of silk fibroin materials in intelligent textiles, biomedicine and optoelectronic devices, etc. are summarized. It is pointed out that the structural design and functionalization of silk by regenerative preparation technology can enhance the additional value of silk and broaden its application fields, so as to realize the diversified application of silk products.

Key words: wet spinning; silk; silk fibroin; intelligent wearable; biomedicine

蠶丝作为一种天然有机高分子材料,随着材料制备、表征等技术的应用和多学科的交叉融合发展,蚕丝研究已由宏观向微观分子水平方向发展,其应用领域也由单纯丝织物纺织产品向生物医药、光学、电学、智能可穿戴等领域延伸。蚕丝因其良好的生物相容性、生物降解性、优异的力学性能等特性,通过各种制备技术加工成纤维、长丝、膜、支架、凝胶等材料(图1),在生物医用领域特别是用作组织工程支架、药物缓释载体等已开展深入研究。除生物医用外,对蚕丝进行功能化探究,增加蚕丝本身不具有的功能,拓展其在智能纺织品、光电学器件等领域应用。

可穿戴技术于20世纪60年代由美国麻省理工学院媒体实验室提出,融合材料技术、信息技术等对人体相关信息进行收集、处理和反馈。柔性可穿戴电子器件及相关产品不断涌现,引起学术界和工业界的广泛关注。目前,可穿戴电子设备主要依靠将电子装置黏合到织物上实现,缺乏柔性且易产生故障。纺织纤维具有柔韧性、舒适性、轻质性和耐用性,将可穿戴电子设备融入到纺织纤维、织物中,可改善其柔韧性,实现其产业化。蚕丝因显著的机械韧性、低成本、应用广泛且具有优异的可穿戴舒适性,在智能纺织品等领域的研究和应用日渐凸显[1-3]。

本文对丝素蛋白材料及其成型方法进行系统叙述,对丝素蛋白材料在智能可穿戴、生物医用、光学和电学领域发展进行分析,全面总结丝素蛋白材料的研究现状和最新进展,推动蚕丝成为研发和开发热点材料,为茧丝绸行业转型升级和产品开发提供借鉴。

1 丝素蛋白材料制备研究

1.1 纤维类材料

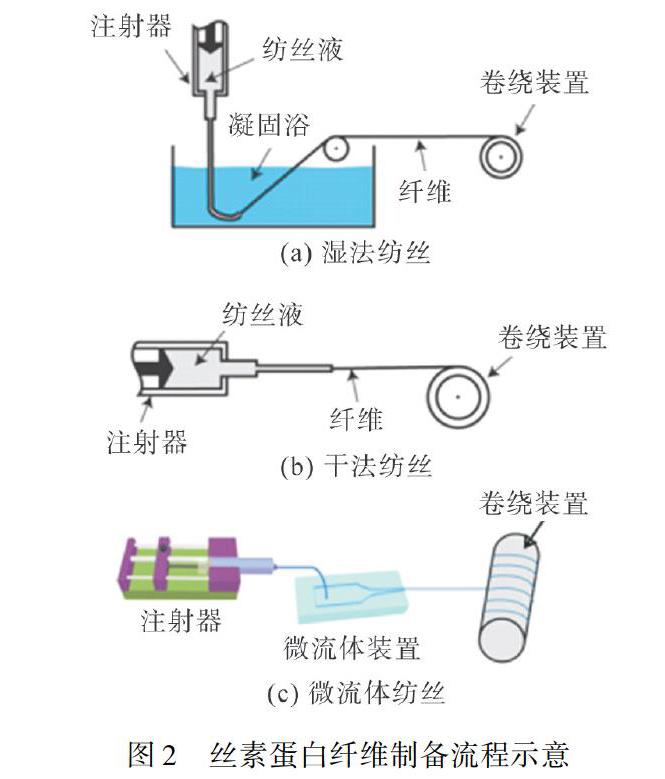

蚕吐丝过程是一个环保和低能耗的典范。蚕腺体内丝素蛋白(silk fibroin,SF)水溶液的流动过程中,受溶液质量分数、pH值、金属离子质量分数、剪切等作用共同影响[4]。近年来,人工模拟蚕吐丝过程制备高性能纤维已成为材料领域研究热点,主要制备方式有湿法纺丝(含干喷湿法纺丝)、干法纺丝和微流体纺丝等[5-8],具体制备流程如图2[9-10]所示。

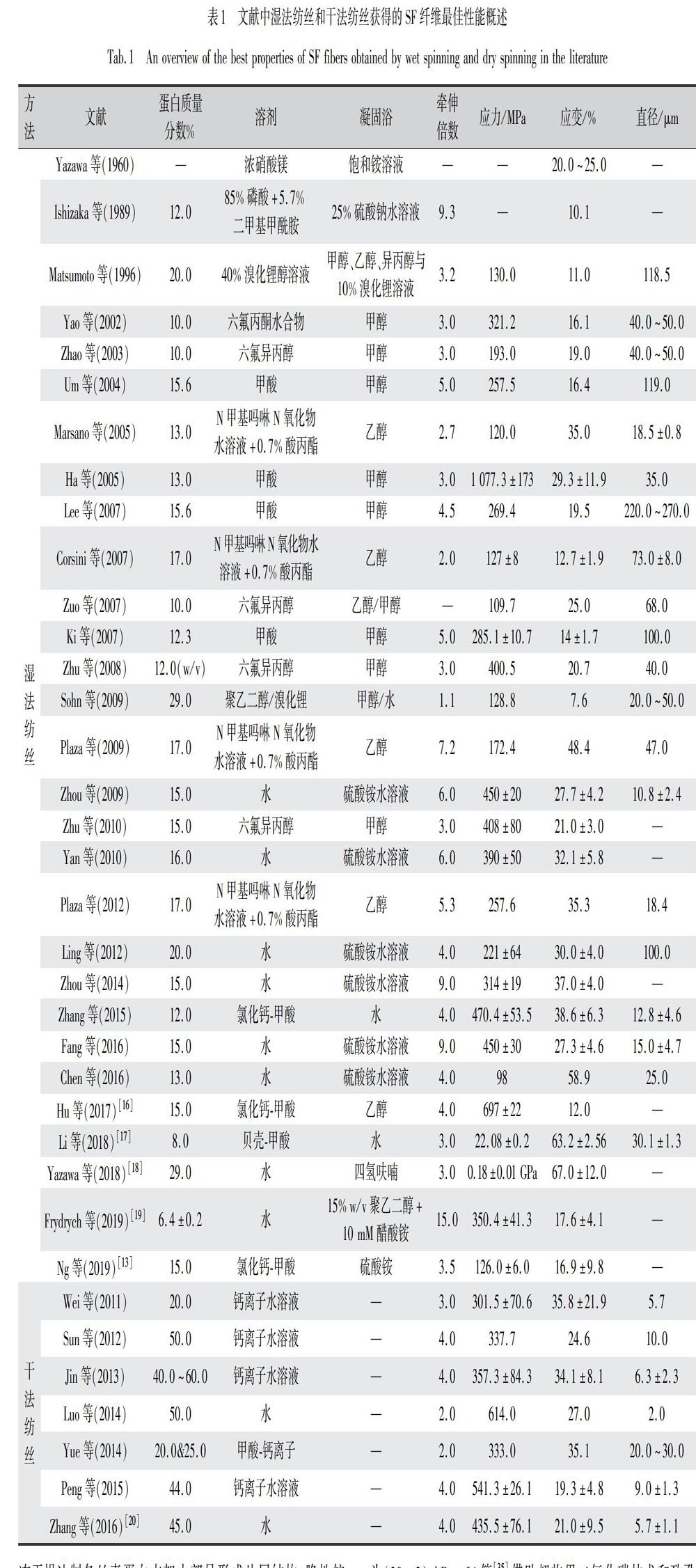

湿法纺丝(含干喷湿法纺丝)中用于制备SF纺丝液的溶剂主要有甲酸、六氟异丙醇、六氟丙酮和水等,所采用的凝固浴大多是醇类溶液,也有部分研究者采用N-甲基吗啉-N-氧化物及离子液体等为溶剂进行湿法纺丝(表1)。如:采用氯化钙-甲酸体系制备纺丝液,湿法纺丝经3倍牵伸获得直径(173±2.5) μm SF长丝[11]。湿法纺丝中SF纺丝液质量分数在13%~19%(w/w)、凝固浴为硫酸铵,可获得再生SF纤维,并经连续机械牵伸,可提高纤维强力[12],以及采用同轴湿法纺丝获得连续中空纤维[13]。基于Hansen溶解相对能差和动力学参数建立可选择预测模型,即建立湿法纺丝过程中三个变量:聚合物、溶剂和非溶剂类型,与湿法纺丝纤维直径和内部形貌的关系[14]。此外,高艳菲等[15]以六氟异丙醇溶解再生丝素膜,湿法纺丝制备再生丝素蛋白纤维,并经1-(3-二甲基氨基丙基)-3-乙基碳化二亚胺和N-羟基丁二酰亚胺作为交联剂进行后处理。研究发现,交联改性后纤维直径变细为87 μm,纤维内部结构以silk Ⅰ为主,纤维热稳定性提高,热分解温度由281 ℃提高至288 ℃,以及断裂强度和断裂伸长率增大到1.41 cN/dtex和11.38%。

干法纺丝与湿法纺丝流程相似,制备过程缺少凝固浴。Yue等[21]以甲酸/氯化钙为溶剂制备SF纺丝液,采用干法纺丝短流程加工制备再生SF纤维;Peng等[22]用Ca2+调控的38%~47%SF水溶液进行干法纺丝,初生纤维经4倍牵伸后应力可达541.3 MPa,伸长率19.3%。Zhang等[23]以45%的SF/石墨烯水溶液为纺丝液,干法纺丝制备再生纤维,经乙醇后处理,其断裂强度达到435.5 MPa;此外,通过给蚕喂食单臂碳纳米管和石墨烯,吐出的丝经测定得到纳米碳抑制SF结构从无规卷曲和α-螺旋到β-折叠的转变,同时提高了纤维断裂伸长率和韧性模量[24]。

微流体纺丝模仿蚕体内生物纺丝器结构进行纺丝[25-26]。Martel等[27]最先模拟蚕体内吐丝管道,设计了套管结构,内管截面圆形,外管截面正方形,壁厚50 μm,再生SF溶液和缓冲液在管内形成同轴流动,最终的混合溶液从套管内流出并在水中收集;Luo等[28]利用微流体技术用于再生SF水溶液组成的动态调控;Li等[29]借助计算流体动力学模拟剪切和离子变化对微流体纺SF纤维强力的影响;Kinahan等[8]采用微流体纺丝成功制得再生SF纤维,但纤维力学性能很差,低于10 MPa;Bettinger等[30]使用微流体技术将SF水溶液加工成具有层级结构SF膜,加工过程避免了有毒溶剂和复杂的加工过程;张耀鹏等[10]借助微流控纺丝方法采用高质量分数SF纺丝液制备高性能再生SF纤维;Michelle等[31]讨论了微流控溶液纺丝精确控制再生SF纤维形成和性能。此外,雷鸣等[32]利用微流体纺丝技术制备丝素纳米银/PVA共混纤维,当丝素纳米银/PVA共混溶液质量比为15,PVA甲酸溶液为25%,纺丝速度0.5 mL/h,步进平移频率30 Hz,旋转电机速率200 r/min时,制备纤维直径为13~14 μm,且纤维粘连断丝较少。

1.2 支架类材料

丝素蛋白支架材料的制备方法有冷冻干燥法、盐析法、发泡法等。丝素蛋白支架制备方法特点对比见表2[33],其中冷冻干燥法制备丝素蛋白支架内部易形成片层结构、脆性较大。盐析法通过致孔剂形状和粒径可调控支架中孔径分布,但孔的贯通性较差,且发泡法制备的丝素蛋白支架中孔径分布难以控制。Nazarov等[34]报道盐析法制备的SF支架孔隙率为84%~98%,压缩强度达(175±3) kPa。气泡法制备的SF支架孔隙率为87%~97%、压缩强度(280±4) kPa,然而冷冻干燥法制备的SF支架孔隙率可达99%、最大压缩强度为(30±2) kPa。Li等[35]借助超临界二氧化碳技术和致孔剂析出制备类细胞质结构的SF支架,研究表明SF溶液的压强和质量分数对SF支架的纳米结构没有明显影响,改变致孔剂含量可调控SF支架的孔隙率从(32.7±1.7)%到(821±2.3)%,力学强度从(237.0±2.2) kPa到(163.0±6.5) kPa,此外该材料还表现出良好的支持血旺细胞生长和黏附的能力。

2 丝素蛋白材料应用

2.1 智能可穿戴领域

蚕丝具有优异的机械稳定性和易再生加工等特点,成为可穿戴产品优选的热点材料[36]。李胜优等[37]总结近年来蚕丝材料在可穿戴传感器上的应用包括机械(应变、压力)、电生理、温度和湿度传感器等。蚕丝基材料在可穿戴传感器领域应用时,既可作柔性基底,提供良好的可拉伸性、生物相容性和可降解性,又可作介电层、摩擦层和中间介质。张莹莹团队将静电纺丝SF纳米纤维包缠在CNT纱线表面,制备成导电纱线。该导电纱线表现出优异导电性能(3.1×104 S/m)、良好机械强度(16 cN/tex)、良好的韧性和耐久性,以及经过后处理可以拒水,用于智能织物(包括电致变色和近场通信)[38]。Wang等[39]将SF纳米纤维衍生出柔性透明的碳纤维膜,制备成温度传感和压力传感的电子皮肤,且温度传感器的高温灵敏度为每度0.81%,压力传感器在应变50%条件下测量因子为8 350。

凌盛杰团队利用六氟异丙醇溶剂实现蚕丝表面温和可控溶解,实现蚕丝表面均匀负载碳纳米管,借助简单的浸泡-纺纱技术制备成高性能导电蚕丝[40]。导电蚕丝的拉伸强度和应变分别为(633±168) MPa和(12±4)%,与天然蚕丝相近,可实现工业加工,将导电蚕丝纱线用于可穿戴传感器、医疗监控及人机交互领域等。

毛翠萍[41]借助石墨烯层层包裹-还原方法制备导电蚕丝纤维,通过不断循环浸润-还原次数,得到蚕丝织物的薄片电阻为1.5 kΩ/Sq,单根蚕丝纤维的电导率高达3 595 S/m。同时,以高导电石墨烯修饰蚕丝织物为基底,将氧化锌纳米棒矩阵沉积到蚕丝织物上,利用氧化锌纳米棒的压电性质,将人体运动能量转化为电能,制作成压电式传感器,用于人体手指的按压、扭曲、弯曲等机械运动检测。

2.2 生物医学领域

丝素蛋白因良好的生物相容性和优异的物理、化学性能,在生物医学领域表现出极大的应用潜力。Vandana Soni团队综述了蚕丝作为前沿生物医学大分子用于提高药物释放[42]。朱良均团队关注SF复合纳米颗粒的制备方法和性能增强,特别是生物医用领域应用[43]。Subhas C.Kundu团队总结了制备各种SF仿生结构,如膜、凝胶、支架、納米纤维和纳米颗粒,以及这些仿生材料的功能化和生物医用[44],又综述了丝素蛋白基凝胶的生物医学应用[45]。

杨俊团队将疏水性单体甲基丙烯酸十八烷基酯(C18M)溶于丝素蛋白(SF)溶液中形成疏水缔合作用,引入海藻酸钠离子交联网络中,制备成多功能丝蛋白基天然高分子水凝胶[46]。该凝胶表现出剪切变稀行为,凝胶具有触变性,当剪切应力消除后,其网络结构可以快速恢复。此外,在模拟体液中矿化28 d后发现磷化钙纳米颗粒均匀分布于矿化后的凝胶表面,经细胞培养发现,小鼠成骨细胞(MC3T3-E1)在凝胶中存活率仍能达到48.62%。Muthumanickkam等[47]制备负载草药的SF纳米纤维网,研究表明:随着纳米纤维直径增加,热稳定性下降,纤维结晶度下降,以及随着草药负载量的增加抗菌性增强;同时,负载1.5%草药的纳米纤维比负载1.0%草药的纳米纤维表现出更持久的药物释放性能。Riccardo Raho等[48]采用绿色合成方式制备负载银纳米颗粒的丝素蛋白-纤维素钠凝胶,凝胶在不同生理溶剂中,溶胀率达到59 g/g;同时,在预防伤口感染和愈合方面表现出良好的抗菌性和生物相容性。凌盛杰团队通过速度可控的力缫丝,获得连续可纺均匀柞蚕丝纤维,用纺纱技术将强拉柞蚕丝组装成具有可编程驱动功率(0.77~2.1 W/kg)的双螺旋微驱动器[49]。借助表面粗糙度和形状梯度触发并促进水在微驱动器上的渗透,导致强拉柞蚕丝的膨胀和收缩,这种驱动作用可使强拉柞蚕丝微驱动器用于促进伤口愈合。

2.3 电学领域

蚕丝是电的不良导体,为拓展其在电学领域应用,赋予蚕丝新的功能。Vitor Sencadas等[50]用静电纺制备电极化的SF纳米纤维用于能量收集,研究表明,该纳米纤维压电常数(38±2) pm/V、机械灵敏度0.15 V/kPa、能量储存容量85 μJ、储能效率达21%,可用于智能服装中自供电人体电子监测。Manish Singh等[51]采用超临界二氧化碳浸渍聚吡咯和高锰酸盐赋予蚕丝纤维导电和催化功能,该复合材料作为生物传感器可用于检测双氧水及其降解。Xu等[52]通过浸渍和碳化相结合方式制备三维层状茧丝-Co-石墨烯复合材料,碳化茧丝拥有27 dB电磁屏蔽效率(12.4~18 GHz),在石墨烯和Co纳米颗粒存在下可增强至55 dB(18 GHz)。可见,茧丝-Co-石墨烯三维层状材料不仅具有优异的电磁屏蔽效能,同时还拥有优异的比屏蔽效能664 dB·cm3/g。

2.4 光学领域

近年来,蚕丝易加工成纤维、薄膜、凝胶等材料,通过改性和功能化使其可应用于光电学器件和生物成像等领域。Lawrence等[53]利用纳米形态学优化丝蛋白基生物材料系统的光学特性,将表面形貌控制在125 nm以下,纳米图案成形使丝蛋白形成衍射光学器件,如衍射光栅、模式发生器和透镜,这是材料形成过程中通过调控β-折叠结构结晶度获得的。Pal等[54]利用光刻技术,将经化学修饰的丝蛋白光阻剂制成二维周期性图形阵列和菲涅耳区域板。由于布拉格衍射,在这些周期性的微观图形中产生了依赖于角度的彩虹色。同时,材料完全可生物降解,可开发生物兼容的、可控制降解的软微光学设备。Lee等[55]报道由丝素蛋白和金纳米结构组成的生物相容性和高度可调等离子体生物/化学传感器,这种蚕丝等离子体吸收传感器可用作葡萄糖传感器具有1 200 nm/RIU高灵敏度和高相对强度变化。Bucciarelli等[56]优化了一种制备极低粗糙度丝蛋白薄膜的自旋涂覆方法,使其应用于光学领域;同时,采用椭圆偏振法对丝素蛋白和丝胶蛋白的折射率和光阻进行了表征。

3 结 语

本文对丝素蛋白材料的制备和应用进行综述,纤维类丝素蛋白材料的制备方法包括湿法纺丝、干法纺丝和微流控纺丝等;支架类丝素蛋白材料的制备方法包括冷冻干燥法、盐析法、发泡法等。每种制备技术各有优缺点,制备的材料性能和功能各异,拓展了蚕丝蛋白材料的研究开发和应用领域,除纺织领域应用外还可以用于生物医药、光电学器件等。

参考文献:

[1]SONG P, TAO J, HE X M, et al. Silk inspired stretchable fiber shaped supercapacitors with ultrahigh volumetric capacitance and energy density for wearable electronics[J]. Chemical Engineering Journal, 2020, 386(15): 124024.

[2]WANG C Y, LI X, GAO E L, et al. Carbonized silk fabric for ultrastretchable highly sensitive and wearable strain sensors[J]. Advanced Materials, 2016, 38(31): 6640-6648.

[3]NA D, CHOI J, LEE J, et al. Commercial silk based electronic yarns fabricated using microwave irradiation[J]. ACS Applied Materials & Interfaces, 2019, 11(30): 27353-27357.

[4]JIN H J, KAPLAN D L. Mechanism of silk processing in insects and spiders[J]. Nature, 2003, 424(6952): 1057-1061.

[5]ZHANG F, LU Q, YUE X X, et al. Regeneration of high-quality silk fibroin fiber by wet spinning from CaCl2 formic acid solvent[J]. Acta Biomaterialia, 2015, 12: 139-145.

[6]魏偉. 再生丝素蛋白水溶液的干法纺丝及后处理研究[D]. 上海: 东华大学, 2011.

WEI Wei. Studies on Dry Spinning of Regenerated Silk Fibroin Aqueous Solution and Post Treatment of the Resultant Fibers[D]. Shanghai: Donghua University, 2011.

[7]林永佳, 杨董超, 张佩华, 等. 再生丝素蛋白/脱细胞真皮基质共混纳米纤维膜的制备及其性能[J]. 纺织学报, 2019, 40(7): 13-18.

LIN Yongjia, YANG Dongchao, ZHANG Peihua, et al. Preparation and properties of regenerated silk fibroin acellular dermal matrix blended nanofiber membrane[J]. Journal of Textile Research, 2019, 40(7): 13-18.

[8]KINAHAN M E, FILIPPIDI E, KOSTER S, et al. Tunable silk using microfluidics to fabricate silk fibers with controllable properties[J]. Biomacromolecules, 2011, 12(5): 1504-1511.

[9]KOEPPEL A, HOLLAND C. Progress and trends in artificial silk spinning a systematic review[J]. ACS Biomaterials Science & Engineering, 2017, 3(3): 226-237.

[10]PENG Q F, SHAO H L, HU X C, et al. Microfluidic dry spinning and characterization of regenerated silk fibroin fibers[J]. Journal of Visualized Experiments, 2017(127): 56271.

[11]吳惠英, 左保齐. 氯化钙甲酸溶解体系再生丝素长丝的制备及其性能[J]. 纺织学报, 2016, 37(2): 1-6.

WU Huiying, ZUO Baoqi. Preparation and properties of regenerated silk fibroin filaments using CaCl2 formid acid system[J]. Journal of Textile Research 2016, 37(2): 1-6.

[12]YAN J P, ZHOU G Q, KNIGHT D P, et al. Wet spinning of regenerated silk fiber from aqueous silk fibroin solution discussion of spinning parameters[J]. Biomacromolecules, 2010, 11(1): 1-5.

[13]NG P F, LEE K I, MENG S F, et al. Wet spinning of silk fibroin based core sheath fibers[J]. ACS Biomaterials Science & Engineering, 2019, 5(6): 3119-3130.

[14]TRIPATHI A, RUTKEVICIUS M, BOSE A, et al. Experimental and predictive description of the morphology of wet spun fibers[J]. ACS Applied Polymer Materials, 2019, 1(6): 1280-1290.

[15]高艳菲, 明津法, 邓春闽, 等. 再生丝素纤维的湿法纺丝及其交联改性研究[J]. 丝绸, 2012, 49(4): 10-14.

GAO Yanfei, MING Jinfa, DENG Chunmin, et al. Wet spinning of the regenerated silk fibroin fibers and its cross linking modification research[J]. Journal of Silk, 2012, 49(4): 10-14.

[16]HU X J, LI J G, BAI Y X. Fabrication of high strength graphene regenerated silk fibroin composite fibers by wet spinning[J]. Materials Letters, 2017, 194: 224-226.

[17]LI X R, MING J F, NING X. Wet spun conductive silk fibroin polyaniline filaments prepared from a formic acid shell solution[J]. Journal of Applied Polymer Science, 2019, 136(9): 47127.

[18]YAZAWA K, MALAY A D, IFUKU N, et al. Combination of amorphous silk fiber spinning and postspinning crystallization for tough regenerated silk fibers[J]. Biomacromolecules, 2018, 19(6): 2227-2237.

[19]FRYDRYCH M, GREENHALGH A, VOLLRATH F. Artificial spinning of natural silk threads[J]. Scientific Reports, 2019, 9(1): 247-255.

[20]ZHANG C, ZHANG Y P, SHAO H L, et al. Hybrid silk fibers dry-spun from regenerated silk fibroin/graphene oxide aqueous solution[J]. ACS Applied Materials & Interfaces, 2016, 8(5): 3349-3358.

[21]YUE X X, ZHANG F, WU H Y, et al. A novel route to prepare dry-spun silk fibers from CaCl2 formic acid solution[J]. Materials Letters, 2014, 128: 175-178.

[22]PENG Q F, SHAO H L, HU X C, et al. Role of humidity on the structures and properties of regenerated silk fibers [J]. Progress in Natural Science Materials International, 2015, 25(5): 430-436.

[23]ZHANG C, ZHANG Y P, SHAO H L, et al. Hybrid silk fibers dry-spun from regenerated silk fibroin/graphene oxide aqueous solution[J]. ACS Applied Materials & Interfaces, 2016, 8(5): 3349-3358.

[24]WANG Q, WANG C Y, ZHANG M C, et al. Feeding single walled carbon nanotubes or graphene to silkworms for reinforced silk fibers[J]. Nano Letters, 2016, 16: 6695-6700.

[25]PENG Q F, SHAO H L, HU X C, et al. The development of fibers that mimic the core-sheath and spindle knot morphology of artificial silk using microfluidic devices[J]. Macromolecular Materials and Engineering, 2017, 302(10): 201700102.

[26]KONWARH R, GUPTA P, MANDAL B B. Silk microfluidics for advanced biotechnological applications a progressive review [J]. Biotechnology Advances, 2016, 34(5): 845-858.

[27]MARTEL A, BURGHAMMER M, DAVIES R, et al. A microfluidic cell for studying the formation of regenerated silk by synchrotron radiation small and wide angle X-ray scattering[J]. Biomicrofluidics, 2008, 2(2): 24104.

[28]LUO J, ZHANG Y P, HUANG Y, et al. A bio-inspired microfluidic concentrator for regenerated silk fibroin solution [J]. Sensors and Actuators B: Chemical, 2012, 162(1): 435-440.

[29]LI D, JACOBSEN M M, RIM N G, et al. Introducing biomimetic shear and ion gradients to microfluidic spinning improves silk fiber strength [J]. Biofabrication, 2017, 9(2): 025025.

[30]BETTINGER C J, CYR K M, MATSUMOTO A, et al. Silk fibroin microfluidic devices [J]. Advanced Materials, 2007, 19(19): 2847-2850.

[31]KINAHAN M E, FILIPPIDI E, KOSTER S, et al. Tunable silk using microfluidics to fabricate silk fibers with controllable properties[J]. Biomacromolecules, 2011, 12(5): 1504-1511.

[32]雷鸣, 张逸, 焦晨璐, 等. 微流体紡丝制备丝素纳米银/PVA共混纤维的研究[J]. 丝绸, 2018, 55(2): 1-7.

LEI Ming, ZHANG Yi, JIAO Chenlu, et al. Study on preparation of silk fibroin stabilized silver nanoparticles PVA composite microfibers by microfluidic spinning[J]. Journal of Silk, 2018, 55(2): 1-7.

[33]殷丽华, 牟星, 余占海, 等. 丝素蛋白及其复合支架制备方法的研究进展[J]. 材料导报, 2013, 27(17): 110-112.

YIN Lihua, MOU Xing, YU Zhanhai, et al. Research development in preparation of silk fibroin and its composite scaffolds[J]. Materials Reports, 2013, 27(17): 110-112.

[34]NAZAROV R, JIN H J, KAPLAN D L. Porous 3D scaffolds from regenerated silk fibroin[J]. Biomacromolecules, 2004, 5(3): 718-726.

[35]LI Z H, WANG L, DAI H L, et al. Fabrication characterization and in vitro evaluation of biomimetic silk fibroin porous scaffolds via supercritical CO2 technology[J]. The Journal of Supercritical Fluids, 2019, 150: 86-93.

[36]WANG C Y, XIA K L, ZHANG Y Y, et al. Silk based advanced materials for soft electronics[J]. Accounts of Chemical Research, 2019, 52(10): 2916-2927.

[37]李勝优, 刘镓榕, 文豪, 等. 蚕丝基可穿戴传感器的研究进展[J]. 物理学报, 2020, 69(17): 130-142.

LI Shengyou, LIU Jiarong, WEN Hao, et al. The recent advances of silk based wearable sensors[J]. Acta Physica Sinica, 2020, 69(17): 130-142.

[38]YIN Z, JIAN M Q, WANG C Y, et al. Splash resistant and light weight silk sheathed wires for textile electronics[J]. Nano Letters, 2018, 18: 7085-7091.

[39]WANG C Y, XIA K L, ZHANG M C, et al. An all silk derived dual mode E-skin for simultaneous temperature pressure detection [J]. ACS Applied Materials & Interfaces, 2017, 9(45): 39484-39492.

[40]YE C, REN J, WANG Y L, et al. Design and fabrication of silk templated electronic yarns and applications in multifunctional textiles[J]. Matter, 2019, 1(5): 1411-1425.

[41]毛翠萍. 纳米功能化蚕丝织物的制备及其在可穿戴领域的应用研究[D]. 重庆: 西南大学, 2016.

MAO Cuiping. Nanomaterial Functionalized Silk and Its Application in Wearable Electronics[D]. Chongqing: Southwest University, 2016.

[42]PANDEY V, HAIDER T, JAIN P, et al. Silk as a leading edge biological macromolecule for improved drug delivery[J]. Journal of Drug Delivery Science and Technology, 2020, 55: 101294.

[43]XU Z P, SHI L Y, YANG M Y, et al. Preparation and biomedical applications of silk fibroin nanoparticles composites with enhanced properties a review[J]. Materials Science and Engineering C, 2019, 95: 302-311.

[44]KUNDU B, KURLAND N E, BANO S, et al. Silk protein for biomedical applications bioengineering perspectives[J]. Progress in Polymer Science, 2014, 39(2): 251-267.

[45]KAPOOR S, KUNDU S C. Silk protein based hydrogels promising advanced materials for biomedical applications[J]. Acta Biomaterialia, 2016, 31: 17-32.

[46]MENG L, SHAO C Y, CUI C, et al. Autonomous self healing silk fibroin injectable hydrogels formed via surfactant free hydrophobic association[J]. ACS Applied Materials & Interfaces, 2020, 12(1): 1628-1639.

[47]MUTHUMANICKKAM A, SUBRAMANIAN S, SATHIYARAJ M, et al. Development of herb based Nigella sativa eri silk nanofibrous mat for biomedical applications[J]. Materials Today: Proceedings, 2020, 22(3): 585-588.

[48]RAHO R, NGUYEN N Y, ZHANG N Y, et al. Photo-assisted green synthesis of silver doped silk fibroin carboxymethyl cellulose nanocomposite hydrogels for biomedical applications[J]. Materials Science and Engineering C, 2020, 107: 110219.

[49]LIN S H, WANG Z, CHEN X Y, et al. Ultrastrong and highly sensitive fiber microactuators constructed by force reeled silks[J]. Advanced Science, 2020, 7(6): 201902743.

[50]SENCADAS V, GARVEY C, MUDIE S, et al. Electroactive properties of electrospun silk fibroin for energy harvesting applications[J]. Nano Energy, 2019, 66: 104106.

[51]SINGH M, BOLLELLA P, GORTON L, et al. Conductive and enzyme like silk fibers for soft sensing application[J]. Biosensors and Bioelectronics, 2020, 150: 111859.

[52]XU Z Q, LIANG M W, HE X H, et al. The preparation of carbonized silk cocoon Co graphene composite and its enhanced electromagnetic interference shielding performance[J]. Composites Part A: Applied Science and Manufacturing, 2019, 119: 111-118.

[53]LAWRENCE B D, GOLOMB M C, GEORGAKOUDI I, et al. Bioactive silk protein biomaterial systems for optical devices[J]. Biomacromolecules, 2008, 9(4): 1214-1220.

[54]PAL R K, KURLAND N E, WANG C Z, et al. Biopatterning of silk proteins for soft micro-optics[J]. ACS Applied Materials & Interfaces, 2015, 7(16): 8809-8816.

[55]LEE M, JEON H, KIM S. A highly tunable and fully biocompatible silk nanoplasmonic optical sensor[J]. Nano Letters, 2015, 15(5): 3358-3363.

[56]BUCCIARELLI A, MULLONI V, MANIGLIO D, et al. A comparative study of the refractive index of silk protein thin films towards biomaterial based optical devices[J]. Optical Materials, 2018, 78: 407-414.