Integration CSTR-UASB Two-phase Anaerobic System for Organic Removal Applied to Sugary Wastewater

LIU Jia-qi,LI Ya, LI Yong-feng

(School of Forestry, Northeast Forestry University, Harbin 150040)

Abstract: The earth contains human population, flora and fauna, ocean, land, etc. Most the human lives use abundantly natural resources. The industry evolves along with the increase of the human population. It is obvious that there are some plants industries which discharge their waste into rivers or streams. It might be damaging aquatic ecosystem and organisms, such as water pollution, eutrophication and diseases infecting the communities who live nearby watershed area. Human life is interdependent with water. The awareness of limited water resources incited researchers and experts attempt to invent new technology to treat wastewater. Therefore the wastewater can be reduced, recycled, even reused. Anaerobic digestion (AD) is one known of popular wastewater treatment technology due to its significant achieving waste management and renewable energy targets. CSTR was known for its ability to recover energy, while UASB was known for its methane production and its ability to achieve high COD removal rate. The study of the integration of CSTR-UASB is attempted to improve energy recovery and COD removal. COD removal rate reaches maximum 72% when the organic load was 28 kg/(m3·d).

Key words:CSTR-UASB; hydrogen production; organic removal; sugary wastewater

Introduction

The demography increasing and the expansion of land for industrial and residential activities have a significant impact on natural resources. These can be seen from the demand for petroleum, gas, coal which has increased from year to year. The fuel’s need for transportation, such as gasoline and diesel, heating devices fuel and power plants such as coal has also increased. Countries with big population or little population will carefully utilize their natural resources as wise and sustainable. They will also be looking for a viable and promising new resource alternative that can be utilized in the future (Chowdhury et al. 2013). Although fossil fuels are not expected to run out for the next 100 years, along with the increasing demand for fossil fuels, it is inevitable that scarcity of natural resources will occur (Logan 2008).

Recently, it has been known that hydrogen becomes a promising alternative source of energy, environmentally friendly and can be produced from organic raw materials through biological processes. In this term, raw materials derived from industrial waste such as cow dung, chicken manure, municipal wastewater, and sugar cane industry wastewater. The biological process refers to an anaerobic digestion (AD) process that takes place in chemical reactors such as up-flow anaerobic sludge blanket (UASB) as well as continuous stirred tank reactor (CSTR). The working principle of the CSTR reactor is to convert the influent comes into the CSTR reactor into hydrogen. On the other hand, the working principle of the UASB reactor is to convert the organic compound from the influent comes into the CSTR reactor to the methane. At the end of the process, methane-producing organisms produce methane from acetate or hydrogen and carbon dioxide (Weiland 2010). In the recent years, methane has also become a promising biogas for the next generations. Awareness of the limited natural resources, the continual increasing number of human populations, generate ideas for finding alternative solutions for new energy sources.

Sugar is one of the most important products of human life. Sugar is also a primary human need in addition to food and shelter. There are so much of food products that contain sugar, both for cooking and/or snacks in the market. The sugar is mostly produced from sugarcane. The milling processed sugarcane also generates ethanol, rubbing alcohol as well as industrial waste instead of sugar. To grind a ton of sugarcane, it needs 1500-2000 liters of water and generates 1000 liters of wastewater for per ton of cane crushed (Sahu and Chaudhari 2015). It can be imagined how much water is wasted into the river or stream with a high content of organic compounds. Sugarcane industry wastewater is known as wastewater contain high organic matter. If wastewater directly discharges into the river or stream, it can harm the water ecosystem and the microorganisms that live inside. It can also cause eutrophication, which is indicated by algae blooming. These algae blooming can obstruct sunlight into the bottom of the water, thus inhibiting the process of photosynthesis that should be done by aquatic organisms. In addition, it also causes the death of aquatic organisms (Nwaigwe et al. 2017). The process of the experiment was, waste or commonly called the substrates which are obtained from local sewage plant was inoculated for several days. The aim of inoculation was to enhance the number of hydrogen producing microorganisms much than before inoculated. The inoculation process will be completed if it has been separated from the water and the substrate. After inoculation has been done, the substrate is ready to become influent of CSTR reactor. In this research, a substrate which is used as CSTR influent was sugar wastewater.

CSTR and UASB are two reactors that have been widely used to treat waste (Cairns and Mead 2017; Kjorlaug et al. 2017). In the previous research, UASB was used to treat chicken manure waste (Yangin-Gomec et al. 2017), vinasse wastewater (Cruz-Salomón et al. 2017), and municipal wastewater (Quek, Yeap, and Ng 2017). This research was conducted by combining or integrating the two reactors, that are, the CSTR-UASB reactor. The integration of these two reactors is based on the principle work of both reactors. The CSTR reactor can generate a recovery of energy and the UASB reactor can generate methane biogas. The temperature which is imposed on the two reactors is different. The temperature commonly used in CSTR is mesophilic (35-42℃). While in the UASB reactor is thermophilic (45-60℃). This difference is caused by microorganisms in the biological process on the reactor are able to survive in this temperature range. Thus, the temperature stability of the reactor keeps being maintained.

Some parameters measured in this study include chemical organic demand (COD), biological organic demand (BOD), and the amount of hydrogen produced. The number of COD explains organic content is in the wastewater. Industries usually focus on COD and municipal usually focus on BOD (Nwaigwe et al. 2017).

Materials and Methods

IntegrationCSTRandUASB

The CSTR often refers to a model used to estimate the key unit operation variables when using a continuous agitated tank reactor to reach a specified output. The mathematical model works for liquids, gases, and slurries (Nwaigwe et al. 2017). CSTR has been also used in anaerobic fermentation processes due to their design simplicity and ease of monitoring important parameters (Jung, Kim, Kim, & Shin 2011). This reactor is the most commonly used reactor type, as the biomass is suspended and well mixed in the fermentation liquid, this configuration guarantees an efficient substrate uptake by the anaerobic bacteria (Braguglia et al. 2018). AD in CSTR of the sludge produced by wastewater treatment is the most common way to recover energy (Kjorlaug et al. 2017).

UASB reactor has successfully been used to produce methane directly from the sewage entering some wastewater treatment plants, while CSTR reactor was the most common way to recover energy (Kjorlaug et al. 2017). UASB reactors reduce pollution load and provide good stabilization of solids (Yasar 2018). UASB reactor has been widely applied to treat industrial effluent including vinasse wastewater (Cruz-Salomón et al. 2017), sugarcane syrup wastewater (Nualsri et al. 2016), sugary wastewater (Wang et al. 2013), municipal wastewater (Quek et al. 2017) and chicken manure (Yangin-Gomec et al. 2017). Based on AD process two-phase fermentation consists of acidogenesis and methanogenesis phases. In the acidogenesis process, acidogenic bacteria converted organic compounds to hydrogen, carbon dioxide, and volatile fatty acids (VFAs). In the methanogenesis process, the effluent that primarily composed of VFAs from the first phase was converted to methane and carbon dioxide (Nualsri et al. 2016).

This study used integration of CSTR and UASB two-phase anaerobic system reactor. The CSTR reactor was used as an acidogenic reactor. While UASB reactor was used as a methanogenic reactor. Effective volume and the total volume of CSTR is 7.0 litres and 19.4 litres, respectively. Effective volume and the total volume of UASB reactor is 21.2 litres and 16.8 litres, respectively. CSTR reactor used the compound brown sugar water as an influent. Effluent that derived from CSTR was used as influent of UASB reactor. Sludge from sewage treatment plant was the starting sludge of the reactor. After reactor ran stable, it could be investigated the effect of the integration of CSTR-UASB two-phase anaerobic system reactor applied to wastewater treatment by changing the organic load. The reactor has a stirring device, thereby microbes can be completely mixed with water. CSTR-UASB is located in gas-liquid-solid separation device. It has a reaction and settling zone integrated structure. The integration of CSTR-UASB two-phase anaerobic system is designed for simultaneous hydrogen and methane production (Wang et al. 2013). On the other hand, two-phase anaerobic system reactor is proposed to improve energy recovery and COD removal. Therefore, the benefits of using two-phase fermentation process are also the high stability of the whole process caused by a separation of the fermentation process into two phases (Nualsri et al. 2016).

Measurementsmethods

Volatile fatty acids (VFAs) was measured by HT-502 gas chromatography. pH and oxidation-reduction potential (ORP) was measured by PHS-25. The rate of hydrogen and methane production was measured by LML-1. Chemical oxygen demand (COD) was measured by ray magnetic COD-571 detector with the national standard method.

Inoculationandoperationalcontrolparameters

After precipitation and filtration process, sludge was inoculated in the reactor for 20 days. It was used as inoculum for hydrogen production. It is purposed to remove debris and large particles. Brown sugar water with COD 10 000 mg/l was used as a substrate. A certain quantity of NH4Cl and KH2PO4was added to the substrate. The fact of adding NH4Cl and KH2PO4was purposed to ensure the demand for nitrogen, phosphorus as a nutrient for microbes in the growth process. All anaerobic microorganisms require nitrogen in the form of nitrates, or ammonium salts for their growth. Nitrogen in the form of NH4Cl serves as nitrogen source as well as electron donor. Like nitrogen, phosphorus is also an essential nutrient for the growth and maintenance of bacterial cells. In many nutrient formulations considered, phosphorus is supplemented in the form of KH2PO4and K2HPO4which serves as phosphate buffer (Singh, Kumar, & Ojha 1999). Sludge was enriched by aerating intermittently to inactivate hydrogen-consuming bacteria, methanogens bacteria (Wang et al. 2013). The process should stop aeration for one hour and be settle every day. The sludge which is acclimated maturely has a yellowish color. These inoculation processes is aimed to provide nutrients for fermentative microorganisms.

When sludge reached steady condition, it was used as CSTR reactor’s influent and start running by hydraulic retention time 7 hours with the temperature 36℃ (mesophilic temperature) and pH 7.0, the organic load was 12 kg/(m3·d), suspended solid (SS) was 12.81 g/l, volatile suspended solid was 8.35 g/L, VSS/SS was 0.65. After 30 days, reactor reached steady condition. The type of fermentation was ethanol fermentation. Effluent that derived from CSTR reactor was used as influent in the UASB reactor. A certain amount of NH4Cl and KH2PO4was added to the substrate. After 50 days, sludge has been acclimated and began to produce methane. At the same time, SS was 16.28 g/l and VSS was 10.36 g/l. The reactor has a stable operation by HRT 6 hours with the temperature at 36℃, pH 8.0 after 20 days.

Result and Discussions

ChangesinpH

Figure 1 shows changes of pH in a CSTR-UASB two-phase anaerobic system during the study period. The changes of pH affect the activity of microorganisms in metabolism and the status as well as the number of dominant populations in the reactor. It also one of the important environmental factors that affect the hydrogen production process of anaerobic fermentation (Argun & Kargi 2011; Zhao et al. 2013). Methanogenic was sensitive to pH (Figure 1) and the methanogenic phase was controlled by adding a certain amount of NaHCO3to the substrate. These could make pH of methanogenic phase to be 6.5-7.5 and pH of acidogenic phase to be 4.5-6.0. It could ensure that anaerobic microorganisms were still moving. In this study, when organic load changed to 20 kg/(m3·d), the addition of NaHCO3was stopped. The accumulation of VFA in acidogenic phase results in pH effluent increased rapidly to 4.06. The VFAs present in hydrogen effluent fermentation process was utilized by methanogens in process of methane production (Wang et al. 2013).

Fig.1 Changes of pH in a CSTR-UASB two-phase anaerobic system

The change of environmental pH caused a certain impact on the acidogenic microorganisms. The activity of acidogenic microorganisms decreased, hence resulting in a downward trend in the biogas production rate and the hydrogen production rate. In this study, the hydrogen production still increased. It showed that acidogenic bacteria have adapted to the pH environment. When the organic load of CSTR influent changed into 28 kg/(m3·d), effluent’s pH descended to 5.94 because of accumulation of VFAs in the methanogenic phase. It showed that low pH could inhibit the metabolic activity of methanogenic microorganisms (Zhao et al. 2013). Methane production descended to 16,9 l/d. Several days after pH derivation, the effluent pH increased gradually to about 6.9 by raising the influent pH. It also showed that increasing pH in a certain range could enhance the metabolic activity of microorganisms (Elbeshbishy et al. 2017; Zhao et al. 2013).

Hydrogenandmethaneproduction

Hydrogen production in CSTR reactor mainly in a continued growth trend when organic loading is increasing continuously (Figure 2). In the UASB reactor, methane production increases and then decreases along with the increasing HRT. Methane production rate in UASB reactor is higher than the one of hydrogen, it was about 70 %. After increasing organic loading per-phase, the hydrogen content in the acidogenic phase raised at once. However, the growth of hydrogen production was faint contrarily. In the day one, the organic load was increased to 16 kg/(m3·d). The methane production increased from 6.2 l/d to 13.5 l/d. On the other hand, in the acidogenic phase, the content of acetic acid and ethanol was 392.7 mg/l and 56.1 mg/l, respectively. In the methanogenic phase, the content of acetic acid and ethanol was 0 mg/l and 95.4 mg/l. In the phase where the organic load was 28 kg/(m3·d) and 32 kg/(m3·d) the reactor show instability in hydrogen production. This phenomenon could be due to microorganisms in the reactor having insufficient time to hydrolyze sugar substrates. The reactor showed stability in methane content production. The stability of methanogenic process was assessed by volatile fatty acids (VFAs)/alkalinity ratio (Nualsri et al. 2016).

Fig.2 Hydrogen and methane production in a CSTR-UASB two-phase anaerobic system

On the first day, the organic load was increased to 16 kg/(m3·d). Subsequently, the methane production increased from 6.2 l/d to 13.5 l/d. On the other hand, ethanol and acetic acid content in the acidogenic phase were 392.7 mg/land 56.1 mg/l, respectively. While in the methanogenic phase, ethanol and acetic acid content were 0 mg/l and 95.4 mg/l, respectively. These explained that a certain number of acidogenic bacteria oxidized ethanol to be acetic acid in the acidogenic phase.

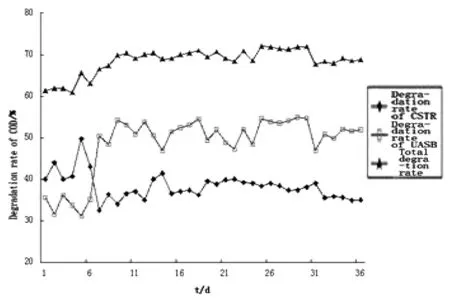

CODremovalrate

COD removal rate maximum from the acidogenic and methanogenic phase is 49.7% and 54.9% respectively (Fig.3.). Total COD removal rate maximum reaches 72% when organic load became 28 kg/kg/(m3·d). The increased COD removal rate during the reactor transition was related to an increase organic loading and influent COD concentrations (Hejnic et al. 2016; Mahmoud et al. 2003). Higher organic loading rate is preferred for energy-efficient operation of the fermentation process to minimize energy requirements for operation (primarily heating cost) (Elbeshbishy et al. 2017). The COD removal efficiency of most substrates varies between 51-79% (Nwaigwe et al. 2017). A high COD level of any organic waste depicts its toxicity and can be used as an index to state whether it is a pollutant or not. If effluent with high COD levels is discharged into a stream or river, it will accelerate bacterial growth in the river and consume the oxygen in the river. The oxygen might be lethal for most fish and many aquatic insects. The lower COD levels will be better. Hence waste utilized as a substrate in the bioreactor can be safely used as organic fertilizer (Nwaigwe et al. 2017).

Fig.3 Changes in COD removal in a CSTR-UASB two-phase anaerobic system

Thecontentoftheeffluent

There is no ethanol in the effluent of methanogenic phase (Fig.4. And Fig.5.), but it appeared as an effluent in the acidogenic phase. In the methanogenic phase, acetic acid descended rapidly then stable when the organic load in the CSTR reactor continuously increased. It caused by a number of microorganism activity which could change ethanol to be acetic acid worked at methanogenic phase. In the methanogenic phase, butyric acid decreased after organic load increased, then fluctuated about 100 mg/L. It might be a result of hydrogen production of acetogenic and methanogenic bacteria.

Fig.4 Changes in the concentration of fermentation liquid products of CSTR reactor

Fig.5 Changes in the concentration of fermentation liquid products of UASB reactor

Conclusion

The maximum COD removal rate that has been already achieved by using CSTR-UASB two-phase anaerobic system is 72%. Hydrogen and methane are also produced by these reactors. Organic load affects pH, hydrogen and methane production as well as COD removal. The integration of CSTR-UASB could enhance organic removal rate in sugary wastewater.