茶生物质填充高分子复合材料的研究进展

龚新怀,李明春,辛梅华,赵瑨云,赵晓杰,吕 橄

茶生物质填充高分子复合材料的研究进展

龚新怀1,2,李明春2※,辛梅华2,赵瑨云1,赵晓杰1,吕 橄1

(1. 武夷学院生态与资源工程学院,福建省竹生态产业协同创新中心,武夷山 354300;2. 华侨大学材料科学与工程学院,环境友好功能材料教育部工程研究中心,厦门 361021)

茶叶在种植、生产、加工及消费环节中会产生大量的茶剩余物,茶生物质呈中空多孔隙结构,富含纤维素、木质素、半纤维素及茶多酚、茶多糖等多种活性成分,在农牧业、医疗健康、食品、环境治理及复合板材领域具有广泛应用前景,尤其是茶生物质/高分子复合材料的研究与应用得到快速和广泛发展。该文首先概述了茶生物质资源特点及其化学组成,然后综述了茶生物质填充不同高分子复合材料的研究进展,并介绍了茶生物质填充高分子复合材料在刨花板、仿木材料、吸声材料、制浆造纸、环境治理及功能食品中的应用研究现状。并指出今后须加强:1)茶生物质中多种组分的综合化、集成化利用研究;2)茶生物质木塑复合材料在阻燃、电学、热学及抗菌除臭等性能研究;3)茶生物质填充高分子复合材料在旅游、养生、装修等领域的应用基础研究;4)茶生物质生化成分变化对茶食品口味、外观及保健功能的影响机制研究。

复合材料;茶;生物质;环境保护;资源循环利用;茶生物质填充高分子复合材料

0 引 言

茶饮是目前世界上除水之外最流行的饮品之一,目前全球每年茶叶消耗量近600万t[1]。中国是世界上茶叶种植、生产与消费第一大国。2019年中国茶园面积达290万hm2,占全球60%,茶叶产量260万余t,近全球茶叶产量的50%,皆占世界第一位[2]。茶叶在种植、生产、加工及消费环节中会产生大量的如茶树修剪枝叶、茶梗茶末、茶下脚料、低档茶叶、滞销茶等各种形式的茶产业剩余物,中国每年可产生500万t以上茶剩余物,是中国农林产品余料的重要组成部分[2]。废弃茶生物质大量堆积,造成环境的固废污染和资源的极大浪费。开展茶生物质资源化利用研究,对生态环境、茶产业发展及促进茶农增收具有积极意义。

目前茶生物质主要用于提取活性成分[3]、植物生长肥料[4]、动物饲料[5]及环保吸附材料[6]。相关研究开展较充分,相关报道也较多。随着对茶生物质资源的进一步研究及应用,茶生物质材料的一些新型使用形式及应用领域得以发展,如茶塑复合材料、茶刨花板材料等。通常而言,单纯一种材料的使用性能存在一定局限,通过不同种材料间的交叉与融合,可发展协同优势和新型材料[7]。高分子树脂具有长链桥联作用、成型方式多样化及机械性能优良等优势,将茶生物质与高分子树脂复合,可融合茶生物质及高分子树脂的双重优势,开发新型茶生物质填充高分子复合材料及其应用领域。相关研究已呈蓬勃发展之势,但也存在诸如茶生物质综合化与集成化利用程度不够、茶生物质填充高分子复合材料的基础和应用研究不够深入及茶生物质功能特性的发挥有待进一步挖掘等问题。因此为了明晰当前茶生物质填充高分子复合材料的研究现状,本文首先研究茶生物质资源的生化成分,然后综述了茶生物质填充高分子复合材料的研究及其应用进展,总结了其研究不足,并探讨了茶生物质填充高分子复合材料进一步发展的对策。

1 茶生物质组成及结构特点

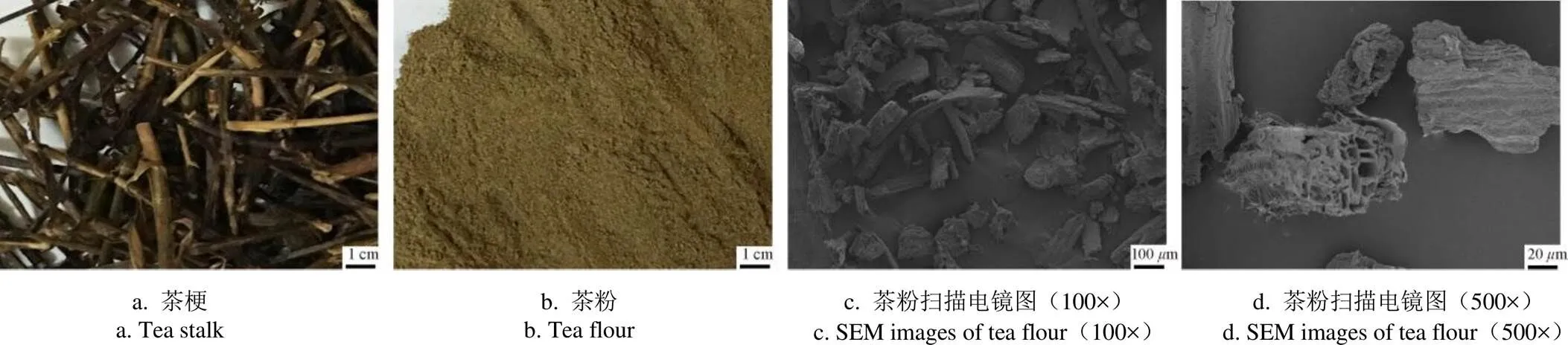

茶生物质种类有很多,其来源主要可分为茶树枝、茶梗及茶叶类。图1为茶梗茶末形式的茶生物质实物及其微观形态图。图1a为茶叶加工制作工程中产生的茶梗茶末,将其用粉碎机研磨得到茶粉(图1b),图1c和图 1d为茶粉的扫描电镜图片,可见粉碎后的茶渣微观形态有纤维状、片状及颗粒状等,纤维性较差,在横截面上有多孔道结构,呈中空多孔隙特性。

茶生物质中含有丰富的纤维素、木质素、半纤维素、茶氨酸、茶蛋白、茶多酚、咖啡因及微量元素等有用成分[8],其与木材及草本植物等主要化学成分含量对比如表 1所示[9]。从表1可知,茶生物质中纤维素含量更低,但木质素和各种抽提物含量要明显高于木材及草本植物,而各种抽提物含量是木材和草本植物的数倍甚至数十倍。这些抽提物主要由茶多酚、茶氨酸、茶色素及咖啡碱等组成。茶饮具有特殊的香气、口味和抗癌、抗老化及预防心血管疾病等医疗保健功能,受到人们的追捧。由此可知,有别于其他农林生物质材料,茶生物质具有独特的结构与组成特点,因此基于茶生物质自身特点,开展茶生物质资源高值化利用具有重要意义。

图1 茶生物质形态图

表1 茶生物质与阔、针叶木材及草本植物主要化学成分含量对比[9]

2 茶生物质/高分子复合材料的制备与性能

2.1 茶生物质/脲醛树脂复合材料

脲醛树脂是各种人造板中广泛使用的黏合剂,以茶生物质来部分替代或者完全替代各种木质材料,与脲醛树脂复合后,有望制备一种新的茶复合板材料。Yalinkilicy等[10]以废茶叶为填料,以脲醛树脂为黏合成分,经热压工艺制备得到一种茶复合板,发现与木刨花复合板相比,茶复合板具有更好的耐老化防腐蚀性能,作者分析认为这与其含有较多的多酚组分有关,茶多酚作为一种天然的抗氧剂和抗菌剂,对茶复合板起到防老化抗腐蚀作用。Batiancela等[11]采用同样方法制备了茶/脲醛树脂复合板,在浸水24 h后其表现出较低的吸水率和吸水膨胀性;在废茶中加入20%~50%的菲律宾楹木粉后,制备的复合板具有更低的吸水膨胀性和更高的刚度、强度,远高于刨花板的最低使用要求。Hanmin等[12]将木粉、绿茶粉和锯末用于制备复合植物纤维刨花板,在质量配比木粉∶茶粉∶锯末为50∶40∶10下,压制的刨花板动态弹性模量最大,为1.41~1.65 GPa。苏团[13]则制备了茶梗刨花板,并系统研究了工艺与其甲醛释放量的关系,研究结果显示,茶梗的加入能够明显降低刨花板甲醛释放量,茶梗中的茶多酚、茶黄素及茶氨酸等活性成分可与甲醛发生化学反应,可化学吸附刨花板中的部分甲醛,使其甲醛释放量下降,此外,茶梗碎料本身的多孔隙性,可对刨花板中的甲醛发生物理吸附,共同来降低茶梗刨花板的甲醛释放量。

2.2 茶生物质/热塑性树脂复合材料

2.2.1 茶生物质/聚丙烯复合材料

Mattos等[14]将一定比例的茶废弃物和桉树粉混合用作植料,与聚丙烯熔融热压制备了聚丙烯基木塑复合材料。De Cademartori等[15]将马黛茶和木粉混合作为植物填料,制备了聚丙烯基木塑复合材料,考察了植物填料配比及用量对复合材料表面粗糙度和颜色的影响。研究结果表明,马黛茶粉的添加,使复合材料外观呈现黑色状态,且茶粉含量越多,黑色越明显;当马黛茶粉∶木粉∶PP的质量配比为30∶30∶40时,复合材料的表面粗糙度最高。Rathod等[16]采用苯乙烯处理茶粉,用于改善其与PP的界面相容性。Lanjewar等[17]采用马来酸酐处理茶粉,用于改善其与PP的界面相容性,取得较好效果。Hassan等[18]则以茶末为植物填料,甲基丙烯酸缩水甘油酯接枝PP(glycidyl methacrylate grafted to PP,GMA-g-PP)为增容剂,热压制备了茶末/GMA-g-PP/PP复合材料,结果显示GMA-g-PP增容剂添加量为2%以内时,可改善茶末/PP复合材料的拉伸强度及界面相容性。Bari等[19]采用硅烷偶联剂改善茶粉与聚丙烯的界面结合,并添加氧化石墨烯粒子制备了石墨烯/茶粉/PP三元复合材料;发现硅烷偶联剂及氧化石墨烯添加有效改善了茶粉/聚丙烯复合材料的机械性能和热性能。龚新怀等[20]和王兆礼等[21]采用密炼-注塑工艺制备了茶渣/PP复合材料,考察了茶生物质填料种类、处理方式及其添加量对复合材料结构、形态及性能的影响;发现以茶树枝为生物质填料制备的复合材料力学性能最佳,茶梗次之,茶叶最差;茶梗填料经水煮和马来酸酐接枝聚丙烯增容处理后,复合材料的拉伸强度、弯曲强度、拉伸模量及弯曲模量分别提高了23.4%、9.0%、16.9%和13.9%。此外,龚新怀等[22-23]采用户外自然老化和冻融加速老化形式研究了茶渣/PP复合材料的户外应用及老化机制,发现自然老化和冻融老化后茶渣/PP复合材料表面均存在褪色现象,形态变粗糙,出现裂纹或孔洞及力学性能下降;且随老化进程增加,材料表观褪色程度越明显,表面形态更粗糙,裂纹和孔洞尺寸变大,力学性能损耗增加,其中以户外自然老化后变化更明显。

2.2.2 茶生物质/聚乙烯复合材料

于学领等[24-25]研究了茶粉粒径和硅烷偶联剂添加对茶粉/HDPE复合材料结构与性能的影响,发现KH550用量为1.8%,茶粉目数为150m时,复合体系的综合性能较好。宋剑斌等[26]以茶叶梗为填料,HDPE为基体树脂,制备了茶梗/HDPE复合材料,并研究了无机碳纳米管引入对复合材料结构、性能的影响,发现其添加在一定范围内时可改善复合材料的流动性、力学及热性能。He等[27]以茶渣为填料,HDPE为基体,制备了茶渣/HDPE复合材料,发现复合材料的刚度随茶渣用量增加而明显提高,但强度和韧性下降;马来酸酐接枝聚乙烯增容剂可改善复合材料的界面粘结;纳米填料的加入可提高复合材料的热稳定性和维卡耐热性。Cavdar等[28]将茶渣作为木质纤维填料填充于热塑性树脂中制备茶塑复合材料,考察了茶渣添加量和树脂种类对复合材料性能的影响。Cavdar等[29]还以氢氧化铝和硼酸锌为阻燃添加剂,生产阻燃性茶渣/HDPE复合材料,发现铝系阻燃剂引入对复合材料的拉伸模量有利,而引入硼酸锌不利;氢氧化铝和硼酸锌阻燃剂添加后复合材料的强度性能略有下降,但提高了复合材料的热及阻燃性能。

2.2.3 茶生物质/可降解树脂复合材料

以石化资源为原料制备的聚烯烃类为不可降解树脂,以其为基体制备的茶塑复合材料实际上属于部分可降解复合材料,仍然会造成塑料的“白色污染”问题。随着石化资源的日益减少和人们环保意识的提高,以环保、可降解树脂为基体,制备完全可降解茶塑复合材料是未来发展趋势之一。

Wu等[30]以茶渣(Tea Waste,TW)为填料,聚羟基脂肪酸酯(Polyhydroxyalkanoates,PHA)为基体,采用混炼及模压工艺制备了TW/PHA可降解复合材料,用马来酸酐(Maleic Anhydride,MA)接枝PHA改善TW与PHA的界面相容性;结果显示,MA的接枝反应明显提高了复合材料的机械强度,吸水性下降,而加工性提高;TW的引入提高了PHA材料的降解性能。Xia等[31]采用溶液浇铸法制备了TW/聚碳酸亚丙酯(Poly(propylene Carbonate),PPC)复合膜;发现TW添加改善了PPC膜的力学性能和热性能,在TW添加质量分数为25%时,复合膜的拉伸强度和拉伸模量分别提高了86.6%和66.4%,最快热分解失重温度提高了13 ℃。

龚新怀等[32-33]以TW为填料,聚乳酸(Polylactic Acid,PLA)为基体,经密炼、注塑工艺制备了环境友好型TW/PLA复合材料。并为改善二者的界面相容性,分别以亚甲基二苯基二异氰酸酯(Methylene Diphenyl Diisocyanate,MDI)和自制的甲基丙烯酸缩水甘油酯接枝聚乳酸(Glycidyl Methacrylate Grafting PLA,GMA-g-PLA)为界面改性剂,考察了其添加对TW/PLA复合材料结构与性能的影响。结果表明,GMA-g-PLA的添加显著改善了TW与PLA的界面相容性,提高了复合材料的力学性能和热稳定性,降低了吸水率,其界面增容效果明显优于MDI。在GMA-g-PLA添加质量分数为10%时,复合材料的力学性能最佳,与未增容TW/PLA复合材料相比,其拉伸强度、弯曲强度及缺口冲击强度分别提高43.8%、42.1%和24.1%,拉伸模量和弯曲模量提高26.5%和10.4%,断裂伸长率提高26.1%。

龚新怀等[34]采用冻融循环加速老化方式进一步研究了TW/PLA复合材料的老化性能及行为,发现TW/PLA复合材料老化后表面出现略微褪色现象,复合材料相界面处出现裂纹或孔洞,在12次冻融循环老化后,复合材料的弯曲、冲击及拉伸强度分别下降了29.19%、22.92%及24.15%。

此外,龚新怀等[35-36]为进一步改善TW/PLA复合材料脆性大问题,以甘油(Glycerol,GL)、聚乙二醇400、环氧大豆油(Epoxidized Soybean Oil,ESO)和乙酰柠檬酸丁酯(Acetyl Butyl Citrate,ATBC)为增塑剂,制备了可降解TW/PLA增韧增塑复合材料。发现ESO增韧增塑效果最佳,其添加制备的复合材料断裂伸长率及缺口冲击强度分别提高了154.23%和65.53%。

2.3 茶生物质/橡胶复合材料

橡胶在加工中受热、光及自由基等影响易老化,为此需要添加防老化剂。茶生物质含有较多的茶多酚,是一种天然的抗氧化、抗老化剂[37]。将低成本的茶生物质刚性填料与生胶混炼,不仅可以降低成本、改善力学性能,还有望改善橡胶加工中的抗老化性能[38]。

Riyajan等[39]将茶渣经甲基丙烯酸甲酯(Methyl Methacrylate,MMA)和硅烷改性后,与炭黑一起填充到天然橡胶中进行炼胶。发现随茶渣用量增加,复合橡胶的模量,硬度和耐油性增加,热稳定性提高;在添加30份茶渣和30份炭黑后的复合橡胶具有最好的综合性能,茶渣的添加还赋予了复合橡胶特殊的茶香味。Masek等[40]发现将从绿茶叶中提取得到的多酚物质添加于乙丙橡胶中,可以有效抑制乙丙橡胶的老化过程。

2.4 茶生物质/其他高分子复合材料

Ekici等[41-42]将用茶叶纤维与聚氨酯树脂复合制备泡沫材料,发现茶叶纤维的添加,显著提高了聚氨酯泡沫的吸声性能。Rodney等[43]则以废茶叶、茶梗及茶树枝3种茶生物质为增强材料,以木薯淀粉为基体,制备了完全可降解茶生物质/淀粉复合材料。结果显示,在加入质量分数为5%的茶生物质填料后,复合材料的力学性能都获得不同程度提高,茶叶、茶梗及茶树枝增强木薯淀粉复合材料的拉伸强度比淀粉分别提高了34.39%、82.80%和203.18%。Auta等[44]将废茶叶制备成活性炭后,以壳聚糖为包埋基质,采用溶胶凝胶法制备得到茶碳/壳聚糖复合凝胶微球,用于吸附水溶液中的亚甲基蓝和AB29染料,发现微球在循环使用5次以后,其对2种染料的吸附去除率仍维持在50%以上。Cai等[45]将废茶叶负载水合氧化铝后,用阴离子聚丙烯酰胺将其絮凝桥联后得到茶粉/聚丙烯酰胺/水合铝氧化物三元复合吸附材料,用于吸附水溶液中氟离子。Zhang等[46]以PVA为聚合物基质来包埋废茶叶,并通过碳酸钙和盐酸反应产生二氧化碳气体,制备得到一种多孔复合凝胶球。

3 茶生物质/高分子复合材料的应用

3.1 刨花板

刨花板主要是以植物填料如竹木屑、稻壳稻草、麦草、甘蔗渣及玉米芯等,与脲醛树脂经热压得到的一种建筑用板材料,广泛应用于镶板、台面、橱柜、门皮及家具构件等[47]。但刨花板中存在甲醛释放问题,严重限制了其广泛使用。茶生物质中的多酚组分可与甲醛按酚醛树脂机理发生反应,降低刨花板中的甲醛释放量[48-49]。Yalinkilicy等[10]制备的茶叶刨花板表现出较好的耐白蚁和真菌性能。Yel等[50]以杨木粉、纸板及茶渣为原料,以Al2(SO4)3和Na2SiO3为粘结剂,压制了5种木质纤维刨花板,系统分析了不同木质纤维材料制备的刨花板力学、吸水性能。苏团[13]系统研究了传统刨花板中茶梗替代量与刨花板甲醛释放量之间的关系,发现茶梗碎料具有多孔性,有利于其对甲醛的吸附,同时茶梗中的茶多酚、茶黄素等活性成分能与甲醛发生化学反应,从而降低刨花板中的甲醛释放量。

3.2 仿木材料

仿木材料又名木塑复合材料(Wood Plastics Composites,WPC),是以植物纤维或粒料为增强相,热塑性树脂如PP、PE及PVC等为基体,经混炼、模压、挤出或注塑等工艺制备得到的一种新型环保复合材料,可应用于建筑市场、家居装修、包装运输及汽车内饰等领域[51]。

茶渣作为一种廉价易得的生物质纤维材料,其与木材纤维材料类似,可用于仿木材料制造。目前茶生物质填充高分子仿木复合材料研究主要以PP[14-23]和PE[24-29]为主,主要开展茶生物质填料特性影响[14-15,20,27]、复合材料界面改善及力学性能优化[16-21,24-25]、阻燃抑烟[29]及老化应用[22-23]等研究。茶生物质填充可降解树脂复合材料近年来已有研究者开展研究,并在界面调控[30,32-33]、力学性能优化[32-33]、老化应用及功能改性[34-36]上取得一定进展。随着对茶生物质结构、性能的进一步认识,茶生物质填充高分子仿木复合材料研究将取得更大进展。

3.3 吸声材料

具有优良吸声效果的隔音材料,对于控制环境噪音,提高人们工作或生活环境的舒适度具有重要意义。工业应用中常将玻璃纤维棉、矿物纤维、泡沫塑料及其复合材料用于制备吸声材料[52]。随着人们环保要求的提高,开发天然植物纤维如竹纤维、麻纤维及茶叶纤维等来制备环保吸声材料,成为趋势之一。

Ersoy等[53]比较了茶叶纤维、机织棉纱和聚丙烯无纺纤维3种纤维层的吸声性能,研究结果表明,茶叶纤维具有优良的吸声性能,1 cm厚有背衬的茶叶纤维层吸声性能相当于6层机织棉纱的吸声效果,20 mm厚无背衬茶叶纤维层与无纺纤维在500~3 200 Hz频率范围内几乎具有等同的吸声效果。Ekici等[41]用天然茶叶纤维和丝瓜泡沫填充聚氨酯制备软质吸声泡沫复合材料,发现随着茶叶纤维添加量增加,复合材料吸声效果提高。Celebi等[42]将天然茶叶纤维与聚氨酯树脂复合,制备了软、硬质聚氨酯复合泡沫塑料,并测试了2种复合泡沫材料的吸声性能。发现在硬质聚氨酯泡沫塑料中天然茶纤维的添加对吸声性能影响较小,而对软质聚氨酯泡沫塑料的吸声性能改善效果显著;在茶叶纤维添加质量分数为24%时,软质聚氨酯复合泡沫塑料具有最佳的吸声性能。Ahsan等[54]则以废弃茶叶为原料,制备了3种不同等级的茶纤维材料,填充于聚氨酯中制备复合吸声材料,结果表明以废弃茶叶为原料制备的茶纤维/聚氨酯复合材料的吸声效果最好,而以颗粒状填充的茶/聚氨酯复合材料吸声效果最差。Wong等[55]同样将不同形态的茶叶纤维填料与聚酯复合制备吸声材料,发现纤维形态的茶纤维/聚氨酯复合材料的吸声系数最大,传输损耗最低。

3.4 制浆造纸

木材、竹材及草类等含有丰富的纤维素、半纤维素及木质素等,是制浆造纸的主要原料来源。茶生物质作为一种木质纤维材料,其与木材含有类似的化学成分,理论上也可以用于制浆造纸生产。

Tutus等[9]探讨了茶渣用于制浆造纸的可行性,研究结果显示,茶废弃物制浆的最大得率为33.26%,小于木材制浆得率。此外,由于茶渣纤维素、半纤维素、α-纤维素含量较低而木质素含量较高,茶纤维较粗短等,以茶渣为原料制备的纸张强度并不理想,但添加部分松木浆后可以改善纸张性能。Takahashi等[56]将废茶叶与纸浆、丁苯胶乳混匀,室温下压成100 mg/m2的纸张,然后在120 ℃旋转干燥器中硬化,测试纸张的抗菌及除臭性能。发现经短时间的紫外照射可大幅增加纸张的抑菌性能,而可见光照射对纸张抑菌性能没有影响[57]。茶叶的添加可显著提高纸张的除臭能力,当纸张中废茶叶质量分数达60%时,在30 min内可使氨气浓度下降至1×10-3mg/m3,即使添加质量分数10%的废茶叶,也可脱除95%的气味,这是由于茶叶中儿茶素与气味分子间的化学反应所致[47]。

3.5 环境治理

茶生物质具有多孔微观形态,富含各种活性成分及极性基团,在废水、废气等治理上具有广泛应用[58-60]。但各种茶生物质基吸附材料主要以粉末状形式应用,存在吸附材料强度和吸附容量低、易分散、难以脱离水体及回收利用等问题。在茶生物质上引入磁性纳米Fe3O4粒子和具有良好分子长链桥联作用的高分子化合物,将有效解决这个问题[60-62]。

龚新怀等[62]采用简易化学共沉淀技术制备了磁性茶渣吸附材料(Magnetic Tea Waste,MTW),在303 K下其对亚甲基蓝(Methylene Blue,MB)的最大吸附量提高了9.93%,并具有良好的回收与再生性能。龚新怀等[63]进一步将其与高吸附容量的海藻酸钙(Calcium Alginate,CA)复合,制得磁性茶渣/海藻酸钙(MTW/CA)复合微球,发现在303 K下,质量配比为MTW∶CA=4∶1的复合微球对MB的最大吸附量为272.5 mg/g,比TW提高86.7%。唐跃武等[61]则将制备的磁性茶用于水溶液中铜铅离子的吸附处理。

张素玲等[64]用孔径为0.5~2 μm的多孔性亲水性聚丙烯膜包覆废弃叶制备成一种铬离子吸附用茶叶包,具有使用方便、回收容易等特点。Auta等[44]先将废茶叶制备成活性炭,再用溶胶凝胶法制备得到茶活性炭/壳聚糖复合凝胶微球,用于水溶液中MB和AB29染料的吸附处理。Cai等[45]通过无机、有机及生物质杂化,制备得到茶叶/水合铝氧化物/聚丙烯酰胺三元复合吸附材料,用于吸附水溶液中氟离子,其对氟离子的Langmuir最大吸附量为42.14 mg/g,离子交换是其吸附主要驱动力。Zhang等[46]则制备了一种多孔茶渣/PVA复合凝胶球,用于吸附水溶液中的Pb2+、Hg2+和Cu2+。研究结果显示,在298 K时多孔凝胶对Pb2+、Hg2+和Cu2+的Langmuir最大吸附量分别为81.56、175.68和49.08 mg/g,优于大多数其他生物质材料;凝胶中的–COOH、–NH2及O–CH3基团可与Pb2+、Hg2+和Cu2+发生络合作用,是其吸附主要驱动力。龚新怀等[59]基于酚醛缩合机理和反应,将茶多酚原位聚合于茶生物质内部,得到茶渣/茶多酚-醛缩聚物复合材料,可降低多酚组分的析出,保留多酚组分的活性官能团,提高茶生物质对金属离子的吸附能力,在重金属离子废水中具有较好的应用前景。

3.6 食品加工

茶叶富含茶氨酸、茶多糖、儿茶素及膳食纤维等功能成分,将茶叶粉碎得到超微茶粉,能保留茶叶的的色泽、营养及药理成分。用于食品加工中,则可赋予食品茶味、茶色、茶香和茶的功效,不仅改善感官和营养,还能延长食品保质期[65]。

即食冲调型食品是抹茶粉应用于食品的常用种类,通过简单的调配和混匀即可制作抹茶即食冲调型食品。刘欣等[66]将绿茶粉加入到黑色冲调粉中,发现绿茶粉添加有助于提高黑色冲调粉的抗氧化能力,降低消化特性的功能。王秀兰[67]则研究了绿茶粉添加对玉米即食性冲调粉挤压膨化加工过程中营养成分、口感风味等的影响及其机制。茶叶中最重要活性成分茶多酚具有抗菌抗氧化功能,但易受环境影响而变性。牛奶富含蛋白质,可可与茶多酚通过分子间作用力及氢键等结合在一起,有效防止茶多酚的变性、失效。因此,奶茶能最大程度保留茶多酚的功效[68]。刘媛等[69]通过响应曲面法优化得到了一种抹茶牛奶,抹茶添加量仅为0.81%所得抹茶牛奶饮料具有浓郁的绿茶感官,口感细腻,茶香醇厚。段雪梅等[70]则将抹茶粉添加于一种牛奶布丁制备过程,发现抹茶粉添加,改善了布丁质构和风味,储存稳定性得到提高。

茶多酚在热作用下会部分氧化,因此热烘焙食品对抹茶粉应用提出了更高要求。食品中氧化产物含量和组成决定了食品的健康和应用状况。Zbikowska等[71]比较了蛋糕中添加天然抗氧剂绿茶粉和人工合成抗氧剂对氧化产物含量影响,发现虽然绿茶粉添加后,蛋糕中氧化产物含量要略高于合成抗氧剂的蛋糕,但与未添加抗氧剂的蛋糕比较,添加绿茶粉质量分数为1%的蛋糕中氧化产物质量分数减少了82.3%。Ivanišová等[72]制作了一种含抹茶粉小麦饼干,以未添加茶粉的饼干为对照,研究分析了茶粉添加对饼干味道、香气、粗纤维含量、酚类及黄酮含量和抗氧化功能的差异;结果显示,添加茶粉后,饼干的口感、气味等感官更好,饼干中酚类及黄酮类组分含量更高,其抗氧化功能也更强;此外,含绿茶粉饼干的粗纤维含量更高,而含红茶粉饼干的酚类和黄酮含量更高。

4 结论与展望

茶产业是中国特色的重要经济产业,茶产业中形成的茶渣剩余物是中国农林生物质的重要组成部分。茶生物质呈中空多孔隙结构,并富含纤维素、木质素、半纤维素、茶多酚及茶蛋白等多种有用成分。茶生物质填充高分子复合材料在刨花板、仿木材料、吸声材料、制浆造纸、环境治理及功能食品中具有广泛应用前景。今后开展茶生物质资源的高值化利用及茶生物质填充高分子复合材料研究应注意以下几点:

1)基于茶生物质中生化成分特点,应发展茶生物质中多种组分的集成、一体化利用新技术研究,如对茶生物质先开展茶多酚、茶氨酸及茶皂素等活性成分提取,然后将提取后的茶渣改性用作废水吸附材料或者仿木材料的填料,这样可对茶生物质资源物尽其用,提高其利用率和价值。

2)目前茶生物质/高分子仿木复合材料的研究主要集中在力学性能改善上,后期需要进一步拓展茶生物质/高分子仿木复合材料在阻燃、电学、热学及抗菌除臭等性能研究,拓深其应用基础研究。

3)茶生物质填充高分子复合材料融合了植物材质、高聚物及茶文化元素功能,在建筑、交通、旅游及养生等具有很好应用前景,目前研究主要集中在实验室开展茶生物质填充高分子复合材料的工艺改进及机械性能优化,后期需要开展茶生物质高分子复合材料在旅游、养生、装修等领域的应用基础研究,为产业化奠定基础。

4)健康产业有着巨大的市场需求。茶生物质中富含茶多酚、茶氨酸、茶皂素等营养成分,且茶多酚还具有抗菌抗氧化、防衰老及预防心脑血管疾病等保健功能,将茶生物质与食品融合具有美好前景。但是在食品的烘焙过程中,茶生物质中活性成分含量变化、结构变化及其对食品口味、外观品质及其保健功能的影响机制还有待进一步完善,这对夯实茶功能食品行业发展和科学理论建立具有重要意义。

[1] Batiancela M A, Acda M N, Cabangon R J. Particleboard from waste tea leaves and wood[J]. Journal of composite materials, 2014, 48(8): 911-916.

[2] 王刻铭,黄勇,刘仲华. 中国茶叶国际竞争力分析[J]. 农业现代化研究,2020,41(1):45-54. Wang Keming, Huang Yong, Liu Zhonghua. Empirical analysis of the international competitiveness of China’s tea industry[J]. Research of Agricultural Modernization, 2020, 41(1): 45-54. (in Chinese with English abstract).

[3] Maraschi F, Rivagli E, Sturini M, et al. Solid-phase extraction of vanadium(V) from tea infusions and wines on immobilized nanometer titanium dioxide followed by ICP-OES analysis[J]. Arabian Journal of Chemistry, 2019, 12(8): 1902-1907

[4] Patil P A, Mane S, Wakse A, et al. Evaluation of tea waste for nitrogen, phosphorous, potassium (NPK) as organic fertilizer[J]. Asian Journal of Research in Pharmaceutical Science, 2018, 8(4): 217-218.

[5] Chen Y, Ni Ji, Li Hongwei. Effect of green tea and mulberry leaf powders on the gut microbiota of chicken[J]. BMC Veterinary Research, 2019, 15(1): 77-80

[6] Savas Y, Yavuz G, Emine Y, et al. The performance of sulphur doped activated carbon supercapacitors prepared from waste tea[J]. Environmental Technology, 2020, 41(1): 36-48

[7] 于长江,王苗,董心雨,等. 海藻酸钙@Fe3O4/生物碳磁性复合材料的制备及其对Co(Ⅱ)的吸附性能和机制[J]. 复合材料学报,2018,35(6):1549-1557. Yu Changjiang, Wang Miao, Dong Xinyu, et al. Preparation and characterization of calcium alginate@ Fe3O4/biochar magnetic microsphere and its adso[J]. Acta Materiae Compositae Sinica, 2018, 35(6): 1549-1557. (in Chinese with English abstract).

[8] 谢枫,金玲莉,涂娟,等. 茶废弃物综合利用研究进展[J]. 中国农学通报,2015,31(1):140-145. Xie Feng, Jin Lingli, Tu Juan, et al. Comprehensive utilization of tea waste: A review[J]. Chinese Agricultural Science Bulletin, 2015, 31(1): 140-145. (in Chinese with English abstract).

[9] Tatus A, Kazaskeroglu Y, Cicekler M. Evaluation of tea wastes in usage pulp and paper production[J]. Bio- resources, 2015, 10(3): 5407-5416.

[10] Yalinkilicy M K, Imamuraa Y J, Takahashi M. Biological, physical and mechanical properties of particleboard manufactured from waste tea leaves[J]. International Biodeterioration & Biodegradation, 1998, 41(1): 75-84.

[11] Batiancela M A, Acda M N, Cabangon R J. Particleboard from waste tea leaves and wood particles[J]. Journal of Composite Materials, 2014, 48(8): 911-916.

[12] Hanmin P, Sookyeong L, JiHoon S, et al. Effect of green tea and saw dust contents on dynamic modulus of elasticity of hybrid composite boards and prediction of static bending strength performances[J]. Journal of Agriculture & Life Science, 2012, 46(2): 9-17.

[13] 苏团. 茶梗碎料板工艺及甲醛释放量控制机理的研究[D]. 福州:福建农林大学,2012. Su Tuan. Research on the Technology and Control Mechanism of Formaldehyde Emission from Tea Stalk Particlboard[D]. Fuzhou: Fujian Agriculture and Forest University, 2012. (in Chinese with English abstract).

[14] Mattos B D, Misso A L, De Cademartori P H G. et al. Properties of polypropylene composites filled with a mixture of household waste of mate-tea and wood particles[J]. Construction and Building Materials, 2014, 61: 60-68.

[15] De Cademartori P H G, Missio A L, Mattos B D, et al. Roughness and color evaluation of wood polymer composites filled by household waste of mate-tea[J]. Maderas-Cienciay Tecnologia, 2015, 17(3): 457-468.

[16] Rathod Y, Bari P, Hansora D P, et al. Elaboration of performance of tea dust–polypropylene composites[J]. Journal of Applied Polymer Science, 2017, 134(17): 44750-44758.

[17] Lanjewar S R., Bari P S, Hansora D P, et al. Preparation and analysis of polypropylene composites with maleated tea dust particles[J]. Science and Engineering of Composite Materials, 2018, 25(2): 1-9.

[18] Hassan M Masudul, Mueller Marco, Tartakowska Diana J, et al. Role of compatibilizers on the physicomechanical performance of tea dust polypropylene composites[J]. Journal of Applied Polymer Science, 2012, 125(S1): 413-420.

[19] Bari P, Lanjewar S, Hansora D P, et al. Influence of the coupling agent and graphene oxide on the thermal and mechanical behavior of tea dust-polypropylene composites[J]. Journal of Applied Polymer Science, 2016, 133(4): 42927-42936.

[20] 龚新怀,赵升云,陈良璧,等. 茶生物质/聚丙烯复合材料的制备与性能研究[J]. 材料导报,2016,30(24):48-53. Gong Xinhuai, Zhao Shengyun, Chen Liangbi, et al. Preparation and properties of wasted tea biomass/polypropylene composites[J]. Materials Review, 2016, 30(24): 48-53. (in Chinese with English abstract).

[21] 王兆礼,赵升云,赵缙云,等. 不同界面改性茶粉/聚丙烯复合材料的制备与性能研究[J]. 塑料工业,2018,46(3):33-37. Wang Zhaoli, Zhao Shengyun, Zhao Jinyun, et al. Preparation and properties of tea dust/polypropylene composites through different interface modification[J]. China Plastics Industry, 2018, 46(3): 33-37. (in Chinese with English abstract).

[22] 龚新怀,赵升云,陈良璧. 茶粉/聚丙烯复合材料加速老化性能[J]. 农业工程学报,2015,31(12):308-314. Gong Xinhuai, Zhao Shengyun, Chen Liangbi. Properties of accelerated weathering of tea stalk/polypropylene composites[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(12): 308-314. (in Chinese with English abstract).

[23] 龚新怀,陈良壁. 茶粉/聚丙烯复合材料自然老化性能[J]. 复合材料学报,2016,33(6):1437-1445. Gong Xinhuai, Chen Liangbi. Performances of tea dust/polypropylene composites under natural weathering[J]. Acta Materiae Compositae Sinica, 2016, 33(6): 1437-1445. (in Chinese with English abstract).

[24] 于学领,杨江帆,杨文斌,等. 茶粉粒径对茶塑复合体系流变性能的影响[J]. 福建农林大学学报:自然科学版,2015,44(1):108-112. Yu Xueling, Yang Jiangfan, Yang Wenbin, et al. Effects of particle size of tea flour on rheological properties of tea plastic composite system[J]. Journal of Fujian Agriculture and Forestry Univeserity: Natural Science Edition, 2015, 44(1): 108-112. (in Chinese with English abstract).

[25] 于学领,宋剑斌,杨文斌,等. KH-550含量对茶梗粉/HDPE性能的影响[J]. 森林与环境学报,2015,35(1):92-96. Yu Xueling, Song Jianbin, Yang Wenbin, et al. Effects of KH-550 content on properties of tea stems flour/HDPE[J]. Journal of Froest and Environment, 2015, 35(1): 92-96. (in Chinese with English abstract).

[26] 宋剑斌,刘学莘,袁全平,等. 茶叶梗/HDPE/CNT复合材料的流变及力学性能研究[J]. 塑料工业,2015,43(4):79-82. Song Jianbin, Liu Xueshen, Yuan Quanping, et al. Rheological and mechanical properties of HDPE/tea stalk/CNTs composites[J]. China Plastics Industry, 2015, 43(4): 79-82. (in Chinese with English abstract).

[27] He Shuai, Zhou Lin, He Hui. Preparation and properties of wood plastic composites based on tea residue[J]. Polymer Composites, 2015, 36(12): 2265-2274.

[28] Cavdar A D, Kalaycioglu H, Mengeloglu F. Tea mill waste fibers filled thermoplastic composites: the effects of plastic type and fiber loading[J]. Journal of Reinforced Plastics and Composites, 2011, 30(10): 833-844.

[29] Cavdar A D, Kalaycioglu H, Mengeloglu F. Technological properties of thermoplastic composites filled with fire retardant and tea mill waste fiber[J]. Journal of Composite Materials, 2016, 50(12): 1627-1634.

[30] Wu Chinsan. Preparation, characterization and biodegradability of crosslinked tea plant-fibre-reinforced polyhydroxyalkanoate composites[J]. Polymer Degradation and Stability, 2013, 98(8): 1473-1480.

[31] Xia Guangmei, Reddy K O, Maheswari C U, et al. Preparation and properties of biodegradable spent tea leaf powder/poly(propylene carbonate) composite films[J]. International Journal of Polymer Analysis and Characterization, 2015, 20(4): 377-387.

[32] 龚新怀,辛梅华,李明春,等. MDI增容茶粉/聚乳酸生物质复合材料的制备与性能[J]. 塑料工业,2016,44(11):127-131,151. Gong Xinhuai, Xin Meihua, Li Mingchun, et al. Preparation and properties of tea waste/polylactic acid biomass composites compatibilized with MDI[J]. China Plastics Industry, 127-131, 151. (in Chinese with English abstract).

[33] 龚新怀,辛梅华,李明春,等. 增容剂改善茶粉/聚乳酸生物质复合材料性能[J]. 农业工程学报,2017,33(2):308-314. Gong Xinhuai, Xin Meihua, Li Mingchun, et al. Compatibilizer improving properties of tea dust/polylactic acid biomass composites[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(2): 308-314. (in Chinese with English abstract).

[34] 龚新怀,戴忠豪,王兆礼,等. 冻融循环老化对PLA/TW生物质复合材料性能的影响[J]. 工程塑料应用,2018,46(10):39-43. Gong Xinhuai, Dai Zhonghao, Wang Zhaoli, et al. Effects of freeze-thaw cycling accelerated weathering on properties of poly (lactic acid)/tea waste[J]. Engineering Plastics Application, 2018, 46(10): 39-43. (in Chinese with English abstract).

[35] 龚新怀,辛梅华,李明春,等. 茶粉/聚乳酸复合材料的增韧改性[J]. 化工进展,2016,35(10):3273-3280. Gong Xinhuai, Xin Meihua, Li Mingchun, et al. Toughening of tea dust/poly(lactic acid) composites[J]. Chemical Industry and Engeering Progress, 2016, 35(10): 3273-3280. (in Chinese with English abstract).

[36] 龚新怀,辛梅华,李明春,等. 环氧大豆油增塑聚乳酸/茶渣生物质复合材料的制备与性能研究[J]. 塑料科技,2019,47(4):54-58. Gong Xinhuai, Xin Meihua, Li Mingchun, et al. Study on Preparation and properties of PLA/TW biocomposites plasticized with ESO[J]. Plastics Science and Technology, 2019, 47(4): 54-58. (in Chinese with English abstract).

[37] Li Xuedou, Ba Fangli, Kai Zhang, et al. Physical properties and antioxidant activity of gelatin‑sodium alginate edible films with tea polyphenol[J]. International Journal of Biological Macromolecules: Part B, 2018, 118: 1137-1183.

[38] 王丽丽. 茶多酚基多功能橡胶助剂的制备及其在胎面胶中的应用[D]. 青岛:青岛科技大学,2018. Wang Lili. The Preparation of Multifunction Acceierators Derived from Tea Phenol in Tread Compounds[D]. Qingdao: Qingdao University of Science and Technology, 2018. (in Chinese with English abstract).

[39] Riyajan S A, Sukhlaaied W. Influence of tea waste on the physical properties of natural rubber[J]. KGK-Kautschuk Gummi Kunststoffe, 2012, 65(3): 20-24.

[40] Masek A, Zaborski M, Kosmalska A, et al. Eco-friendly elastomeric composites containing Sencha and Gun Powder green tea extracts[J]. Comptes Rendus Chimie, 2012, 15(4): 331-335.

[41] Ekici B, Kentli A, Kucuk H. Improving sound absorption property of polyurethane foams by adding tea-leaf fibers[J]. Archives of Acoustics, 2012, 37(4): 515-520.

[42] Celebi S, Kucuk H. Acoustic properties of tea-leaf fiber mixed polyurethane composites[J]. Cellular Polymers, 2012, 31(5): 241-255.

[43] Rodney J, Sahari J, Kamal M S M, et al. Thermochemical and mechanical properties of tea tree () fibre reinforced tapioca starch composites[J]. E-Polymers, 2015, 15(6): 401-409.

[44] Auta M, Hameed B H. Coalesced chitosan activated carbon composite for batch and fixed-bed adsorption of cationic and anionic dyes[J]. Colloids and Surfaces B: Biointerfaces, 2013, 105: 199-206.

[45] Cai Huimei, Chen Guijie, Peng Chuanyi, et al. Enhanced removal of fluoride by tea waste supported hydrous aluminium oxide nanoparticles: anionic polyacrylamide mediated aluminium assembly and adsorption mechanism[J]. RSC Advances, 2015, 5(37): 29266-29275

[46] Zhang Yun, Li Xiaoli, Li Yanfeng. Influence of solution chemistry on heavy metals removal by bioadsorbent tea waste modified by poly (vinyl alcohol)[J]. Desalination and Water Treatment, 2015, 53(8): 2134-2143.

[47] Grigoriou A H. Straw-wood composites bonded with various adhesive systems[J]. Wood Science & Technology, 2000, 34(4): 355-365.

[48] 蔡晓红. 茶及茶制品废弃物对甲醛的吸附动力学与环保刨花板开发[D]. 杭州:浙江大学,2010. Cai Xiaohong. Research on the Kinetics of Tea and Waste Tea Products to Adsorb Formaldehyde and Development of the Environment-Friendly Flakeboards[D]. Hangzhou: Zhejiang University, 2010. (in Chinese with English abstract).

[49] Hou Lijie, Song Dinghe, Chen Tiantian, et al. Manufacture and properties of particleboards by mixing green tea leaves waste with wood-based particles[J]. Forest Product Industry, 2009, 28(1): 53-62.

[50] Yel H, Çavdar A D, Kalaycioğlu H. Mechanical and physical properties of cement-bonded perticleboard made from tea residues and hardboards[J]. Key Engineering Materials, 2011, 471: 572-577.

[51] Khalil H A, Tehrani M, Davoudpour Y, et al. Natural fiber reinforced poly(vinylchloride) composites: A review[J]. Journal of Reinforced Plastics and Composites, 2013, 32(5): 330-356.

[52] Yang T L, Chiang D M, Chen R. Development of a novel porous laminated composite material for high sound absorption[J]. Journal of Vibration & Control, 2001, 7(5): 675-698.

[53] Ersoy S, Kucuk H. Investigation of industrial tea-leaf-fibre waste material for its sound absorption properties[J]. Applied Acoustics, 2009, 70(1): 215-220.

[54] Ahsan Q, Ching C P, Yaakob M Y B. Physical and sound absorption properties of spent tea leaf fiber filled polyurethane foam composite[J]. Applied Mechanics and Materials, 2014, 660: 541-546.

[55] Wong K, Ahsan Q, Putra A, et al. Acoustic benefits of ecofriendly spent tea leaves filled porous material[J]. Key Engineering Materials, 2017, 739: 125-134.

[56] Takahashi T, Aso Y, Kasai W, et al. Effect of light irradiation on the antibacterial activity of compounded papers containing wasted tea leaves[J]. Journal of Wood Science, 2010, 56(4): 299-306.

[57] Takahashi T, Aso Y, Kasai W, et al. Improving the antibacterial activity against Staphylococcus aureus of composite sheets containing wasted tea leaves by roasting[J]. Journal of Wood Science, 2010, 56(5): 403-410.

[58] Takahashi T, Aso Y, Kasai W, et al. Synergetic deodorant effect and antibacterial activity of composite paper containing waste tea leaves[J]. Journal of Wood Science, 2011, 57(4): 308-316.

[59] 龚新怀,戴忠豪,李素琼,等. 多酚原位固化茶渣对水中Cr(Ⅵ)的吸附[J]. 化工环保,2017,37(6):655-660. Gong Xinhuai, Dai Zhonghao, Li Suqiong, et al. Removal of Cr(Ⅵ) from solution using polyphenol in-situ immobilized tea residue[J]. Environmental Protection of Chemical Industry, 2017, 37(6): 655-660. (in Chinese with English abstract).

[60] 姚时,张鸣帅,李林璇,等. 茶渣负载纳米四氧化三铁复合材料制备及其对亚甲基蓝的吸附机理[J]. 环境化学,2018,37(1):96-107. Yao Shi, Zhang Mingshuai, Li Linxuan, et al. Preparation of tea waste-nano Fe3O4composite and its removal mechanism of methylene blue from aqueous solution[J]. Environmental Chemistry, 2018, 37(1): 96-107. (in Chinese with English abstract).

[61] 唐跃武,江勇,杨英,等. 茶渣修饰磁性Fe3O4纳米粒子协同吸附铜铅离子的研究[J]. 环境污染与防治,2019,41(1):60-66. Tang Yuewu, Jiang Yong, Yang Ying, et al. Study on synergistic adsorption of copper and lead ions by magnetic Fe3O4nanoparticles decorated by[J]. Environmental Pollution & Control, 2019, 41(1): 60-66. (in Chinese with English abstract).

[62] 龚新怀,辛梅华,李明春,等. 磁性响应茶渣制备及其对水溶液中亚甲基蓝的吸附[J]. 化工进展,2019,38(2):1113-1121. Gong Xinhuai, Xin Meihua, Li Mingchun, et al. Preparation of magnetically responsive tea waste and it's adsorption of methylene blue from aqueous[J]. Chemical Industry and Engineering Progress, 2019, 38(2): 1113-1121. (in Chinese with English abstract).

[63] 龚新怀,李明春,杨坤,等. 纳米Fe3O4@茶渣/海藻酸钙磁性复合材料制备及其对亚甲基蓝的吸附性能与吸附机制[J]. 复合材料学报:2020,38(2):1451-1465. Gong Xinhuai, Li Mingchun, Yang Kun, et al. Preparation of nano-Fe3O4@tea waste/calcium alginate magnetic composited bead and it’s adsorption characteristics and mechanisms for methylene blue from aqueous solution[J]. Acta Materiae Compositae Sinica, 2020, 38(2): 1451-1465. (in Chinese with English abstract).

[64] 张素玲,张春晓,姚志通. 一种用于吸附废水中铬离子的茶叶包:CN201320774086. 4,[P]. 2013.

[65] 龙登星,黄忠,刘伟梅,等. 超微茶粉在食品加工中的应用[J]. 食品工程,2020,155(1):5-7. Long Dengxing, Huang Zhong, Liu Weimei, et al. Application to ultra-micro tea powder as a new food resource in food processing[J]. Food Engineering, 2020, 155(1): 5-7. (in Chinese with English abstract).

[66] 刘欣,何新益,刘斌,等. 绿茶粉添加对黑色冲调粉抗氧化及消化特性的影响[J]. 食品研究与开发,2019,49(17):64-68. Liu Xin, He Xinyi, Liu Bin, et al. Effect of green tea powder addition on antioxidant and digestive properties of black powder[J]. Food Research and Development, 2019, 49(17): 64-68. (in Chinese with English abstract).

[67] 王秀兰. 夏秋绿茶复合玉米粉挤压加工及其冲调特性研究[D].合肥: 安徽农业大学,2018. Wang Xiulan. Research on Extrusion Processing and Solubility of Extruded Summer and Autumn Green Tea Compound Corn Flour[D]. Hefei: Anhui Agricultural University, 2018. (in Chinese with English abstract).

[68] Bhagat A R, Delgado A M, Issaoui M, et al. Review of the role of fluid dairy in delivery of polyphenolic compounds in the diet: Chocolate milk, coffee beverages, matcha green tea, and beyond[J]. Journal of Aoac International, 2019, 102(5): 1365-1372.

[69] 刘媛,贾志磊,李启明,等. 抹茶牛奶饮料配方优化[J]. 食品工业科技,2019,40(14):100-107. Liu Yuan, Jia Zhilei, Li Qiming, et al. Formula optimization of Matcha milk beverage[J]. Science and Technology of Food Industry, 2019, 40(14): 100-107. (in Chinese with English abstract).

[70] 段雪梅,徐诗涵,李启明,等. 抹茶风味牛奶布丁的研制[J].中国乳品工业,2019,47(6):60-64. Duan Xuemei, Xu Shihan, Li Qiming, et al. Development of matcha flavored milk pudding[J]. China Dairy Industry, 2019, 47(6): 60-64. (in Chinese with English abstract).

[71] Zbikowska A, Kowalska M, Rutkowska J, et al. Impact of green tea extract addition on oxidative changes in the lipid fraction of pastry products[J]. Acta Scientiarum Polonorum Technologia Alimentaria, 2017, 16(1): 25-35.

[72] Ivanišová E, Mickowska B, Socha P, et al. Determination of biological and sensory profiles of biscuits enriched with tea (L) powder[J]. Proceedings of the Latvian Academy of Sciences. Section B: Natural, Exact, and Applied Sciences, 2018, 72(2): 113-117.

Research progress of polymer composites filled with tea biomass

Gong Xinhuai1,2, Li Mingchun2※, Xin Meihua2, Zhao Jinyun1, Zhao Xiaojie1, Lyu Gan1

(1.,,,354300,; 2.,,,,361021,)

The researches and applications of biomass materials have always been the interest of people, due to the advantages of low-cost, non pollution, regeneration and so on. Tea biomass is the general name of waste dominated during the cultivation, processing, deep processing and consumption processes of tea. The tea biomass includes 1)dead-wood, fallen leaves, pruning branches and leaves, seed shells and other tea residues produced during tea cultivation; 2)fannings, thick stems, old stems and tea ash produced during tea processing; 3)tea residues and tea oil cakes produced during deep processing of tea beverage, instant tea, tea polyphenols and tea oil; 4)tea leaves after drinking of tea. A large number of tea residues are produced during the process of planting, production, processing and consumption of tea. China is the biggest producer and consumer of tea all over the world. The cultivation area and yield of tea of China were more than 2.9×106hm2and 2.6×106t in 2019, respectively, which accounts for 60% and 50% of the world’s area harvested and yield of tea. The worldwide consumption of tea is about 6 million tons annually, and the amount of tea biomass produced during the tea industry reached up to 5×106t per pear merely in china, most of which were treated as agricultural waste, resulting in both environmental pollution and enormous natural resource waste. Therefore, the research and application of tea waste would be great benefit to the environment management and developpment of tea industry. The tea biomass resources showed a hollow porous structure and were rich in cellulose, lignin, hemicellulose, tea polyphenols, theanine and other useful components. Traditionally, the tea biomass were mainly used as raw materials to extract active components, plant growth fertilizers, animal feeds and environmental adsorption materials. It has extensive application potential in agriculture and animal husbandry, health care, food processing, environmental protection and composited materials. With the developpment of research focused on the tea biomass, the composites prepared by the combination of tea biomass with polymers have been developped rapidly and widely in recent years because of their excellent processing and application performance, and have became the most important part of tea biomass based materials. In order to clarify the current research status of the tea biomss/polymer composites, this paper introduced the characteristics and chemical composition of the tea biomass resources first, and then the advances in research of tea biomass filled different polymers composites were recommended, and the progress of application in particleboard, wood-plastic materials, sound-absorbing materials, rubber based composites, pulp and paper making, wastewater treatment and functional food of polymer composites filled with tea biomass were also overviewed. In addition, the future research of tea biomass resources are pointed out, which includes 1)developing comprehensive and integrated utilization technology of tea biomass; 2)exploiting the research in flame retardant, electrical, thermal, antibacterial and deodorizing properties of the tea biomass filled resin materials; 3)enhancing the application research in tourism, health preservation, decoration and other fields of the tea biomass filled polymer composites; 4)studying the influence and mechanism of the biochemical components changes of tea biomass on the taste, appearance and health performances of the tea functional foods.

composites; tea; biomass; environmental protection; resource recycled utilization; polymer composites filled with tea biomass

龚新怀,李明春,辛梅华,等. 茶生物质填充高分子复合材料的研究进展[J]. 农业工程学报,2020,36(18):283-291.doi:10.11975/j.issn.1002-6819.2020.18.033 http://www.tcsae.org

Gong Xinhuai, Li Mingchun, Xin Meihua, et al. Research progress of polymer composites filled with tea biomass[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(18): 283-291. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.18.033 http://www.tcsae.org

2020-05-21

2020-07-19

福建省自然科学基金项目(2018J01445);福建省高校杰出青年科研人才计划(闽科教[2018]47号);福建省中青年教师教育科研项目(JAT170594,JT180555);武夷学院引进人才科研启动项目(YJ201810);福建省生态产业绿色技术重点实验室项目(WYKF2018-5);武夷学院师生共创科研团队项目(2020-SSTD-009)

龚新怀,博士,副教授,主要从事生物质资源利用与高分子复合材料研究。Email:wyu_gxh@163.com

李明春,教授,博士生导师,主要从事功能高分子材料研究。Email:mcli@hqu.edu.cn

10.11975/j.issn.1002-6819.2020.18.033

TB322

A

1002-6819(2020)-18-0283-09