SF2104拖拉机自主行驶与作业控制方法

吴才聪,王东旭,陈智博,宋兵兵,杨丽丽,杨卫中

SF2104拖拉机自主行驶与作业控制方法

吴才聪1,2,王东旭1,陈智博1,宋兵兵1,杨丽丽1,杨卫中1※

(1. 中国农业大学信息与电气工程学院,北京 100083;2. 农业农村部农业信息获取技术重点实验室,北京 100083)

针对农业机械无人化作业的应用需求,该研究基于SF2104动力换向线控底盘拖拉机和全球卫星导航系统(Global Navigation Satellite System,GNSS),研发了拖拉机自主行驶与作业控制系统。该系统针对田内直线作业与地头转弯,采用分层控制思想,将控制系统划分为规划层、控制层和执行层。规划层生成U形转弯所需的路网数据,控制层进行拖拉机横向控制、速度控制、转弯控制、机具升降控制、当前路径更新及终止作业等行为决策;执行层负责以上行为的配置执行。拖拉机挂载深松机进行深松作业,并与有人驾驶深松作业进行对照。结果表明,拖拉机自主行驶与作业控制系统横向偏差的平均标准差为4 cm,平均作业速度及其平均标准差分别为1.66和0.09 m/s,稳定作业时发动机转速的平均标准差为7.9 r/min,平均机具位置的极差为23.8,均优于有人驾驶。该研究初步实现了拖拉机的自主行驶与作业,有助于解决农村劳动力紧缺问题。

农业机械;试验;自动驾驶;自主作业;控制系统

0 引 言

中国农业劳动力数量不断减少,用工成本日益增长。“一人多机”作业模式可有效减少驾驶员数量,具有良好的经济效益[1-4],而线控底盘和自动导航技术为该模式提供了基础支撑[5-8]。“一人多机”首先要求实现单机的无人驾驶[9],但由于感知与避障等技术尚未成熟[10-12],研发基于近距离人工遥控的单机自主作业控制技术是当前的重点。在该领域,国内外学者以无人驾驶与自主作业为目标开展了系列研究,取得了一定的进展。

Zhang等[13-16]基于传统拖拉机,利用GNSS(Global Navigation Satellite System)、惯性导航、激光雷达等研发的自动化拖拉机,可初步实现道路行驶和田内作业的无人操作。凯斯纽荷兰研发的无驾驶室Magnum和有驾驶室NHDriveTM等无人驾驶概念车辆配备了感应和探测装置,能够感知并避开障碍物[17-18]。近年来,国内有关机构基于PZ-60型水稻插秧机[19-20],利用工况状态逻辑控制等方法进行行驶机构和插植机构的联合控制,实现了准无人驾驶作业,插秧机未配置感知系统,由操作员监视作业环境和紧急制动;这种作业模式将单机所需的劳动力从3人减至1人,有效节约了用工成本,在黑龙江等地得到了应用推广。为减少施药过程中对人的危害,刘兆朋等[21]基于ZP9500高地隙喷雾机,利用查询表方法进行直线跟踪、地头转弯和喷雾作业的自动控制,初步实现了自主喷雾作业。陈黎卿等[22]基于纯电动型喷雾机,设计了信息采集与通信系统,实现了喷雾机的自主行驶与作业控制。李云伍等[23]基于丘陵山地电动转运车,基于GNSS、视觉传感器及毫米波雷达,实现了转运车的自主行驶。

农机自主作业还需做好地头转弯的路径规划和跟踪,其核心在于选择转弯模式和平滑转弯路径。Sabelhaus等[24-25]基于Dubins曲线和Reeds-Shepp曲线,设计了连续曲率掉头路径生成算法,并分析了Ω式、自相交式和鱼尾式转弯的特点及其时间特性。Paraforos等[26]为了找出最佳的跳过路径数,针对历史作业数据,设计了转弯方式自动判别方法及转弯时间自动分析方法,通过对800 hm2地块连续4 a的数据分析,得出了最佳跳过路径数为3条的结论。Yin等[27]针对SPV-6C插秧机作业路径规划与跟踪控制系统,基于平滑最小转向圆完成了小幅宽相邻路径地头转弯,实现了插秧机转弯的自动化。Cariou等[28-29]以移动机器人小车为平台,针对相邻路径掉头问题,通过基于基本图元的轨迹规划和基于轮胎侧偏角监督估计的模型预测,优化了掉头时间和掉头区面积。

综上可知,农机无人驾驶与自主作业的研究尚处于起步阶段。本文拟基于SF2104动力换向线控底盘拖拉机和GNSS,开发拖拉机自主行驶与作业控制系统,并通过深松作业验证其性能。

1 材料与方法

1.1 作业机组

拖拉机自主行驶与作业机组的组成如图1,主要包括拖拉机、深松机、导航系统、车载控制器和监控终端。

A.WAS-3106角度传感器 B.电动方向盘 C.ZC30基准站 D.SF9507车载控制器 E.ZC200天线控制器一体机 F.深松机

拖拉机型号为SF2104,后轮驱动,阿克曼转向,支持SAE J1939协议。轴距为2 894 mm,轮距为1 750 mm,转弯半径为7 150 mm,标定转速为2 200 r/min,标定功率为154 kW。深松机型号为1SZ-230,幅宽为2.5 m,深松铲数量为4铲。导航系统型号为FARMSTAR F2BD-2.5RD,包括电动方向盘(MDU180)、角度传感器(WAS-3106)、天线控制器一体机(ZC200)等。车载控制器型号为SF9507,输入/输出通道总计24路,可通过控制局域网(Controller Area Network,CAN)控制发动机、变速箱及液压提升系统。监控终端采用手机或电脑,4G通信,可实现拖拉机的远程启停及数据可视化。

1.2 控制系统

1.2.1 系统组成

控制系统的结构见图2,包括数据获取单元、规划控制单元及动作执行单元。

图2 控制系统结构

数据获取单元通过ZC200内置的GNSS天线和陀螺仪获取拖拉机的实时坐标与航向;通过角度传感器获取拖拉机前轮(转向轮)的实时角度。GNSS基准站为ZC200播发差分改正数,实现厘米级定位。

规划控制单元为ZC200内置的导航控制器,是实现导航与控制的核心部件。该单元通过标准串口与电动方向盘进行通信,通过CAN与车载控制器进行通信。

动作执行单元接收控制单元指令并执行相应动作。电动方向盘负责控制前轮转动,车载控制器通过CAN控制发动机转速、变速箱挡位和悬挂装置位置。

1.2.2 导航与控制方法

导航与控制的数据流图如图3,数据来自用户输入和实时获取。导航控制器按分层思想设计,包括导航规划层、行为控制层和行为执行层。

至于灌区内部、城镇内部的水权分配采用何种方式,可以交由各地自行探索、自主选择。或许可以采用灌区用水协会集体所有的形式,也可能在灌区内部采用进一步分解到农户的形式。在城镇内部,水权或许可以属于城镇政府,而委托给供水公司和自供水单位使用。

图3 导航与控制数据流图

导航规划层:有研究表明[25],一般情况下,单弧转弯时间最短。为此,本文的路径规划算法采用FSP(First Turn Skip Pattern)[30],该模式将农田划分为多个标准区块和1个剩余区块,可进行单弧转弯及套行作业。该算法通过迭代生成路径编号,见式(1)。

式中q表示第个区块内的第个顺序号的路径编号;为跳过路径数。

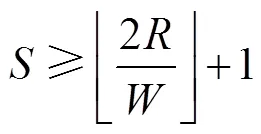

考虑到拖拉机最小转弯半径,单弧转弯跳过的路径数按式(2)计算。

式中为作业幅宽,m;为最小转弯半径,m。

导航规划的最终输出为路网数据S,形式如式(3)。

式中A、B为序号为的作业路径的起点和终点坐标(坐标系为WGS84),包含经度和纬度2个参数;为该区块最后一条作业路径的序号。

式中d为相对于11的延展方向,向右侧延展时d=1,向左侧延展时d=-1。

考虑到序号有奇偶之分,A和B的计算见式(5)。

然后,将生成的A和B的UTM坐标转换为WGS84坐标。经以上步骤,便可获得最终的导航路径,即路网数据,规划结果如图4。

注:No.表示该路径的路径编号为,=1,2,3,…;i表示该路径的作业顺序号为,=1,2,3,…;A和B表示作业顺序号为的路径的起点和终点坐标。下同。

Note: No.indicates that the No. of the path is=1,2,3,…;iindicates that the operation sequence No. of the path is,=1,2,3,…;AandBindicate the start and end coordinates of the path with operation sequence No.. The same as below.

图4 路径规划结果

Fig.4 Result of route planning

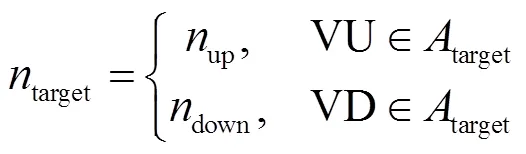

行为控制层:行为控制层输入为S和拖拉机实时位置now,输出为执行层的目标行为,即target,该行为的分类见表1。

表 1 目标行为分类

target的选择与now有关,见式(6)。

式中为拖拉机实时位置与作业路径起终点间距的判断阈值,综合考虑定位精度与跟踪精度,本文取0.1 m。

行为执行层:横向控制由农机自动导航系统实现,其算法业已成熟。当OP∈target时,直线跟踪行为线程启动,并向该模块传递now和now的坐标,该模块将基于轴距ab和拖拉机位置now动态调整目标前轮转角,最终将该值通过标准串口传递给电动方向盘执行。

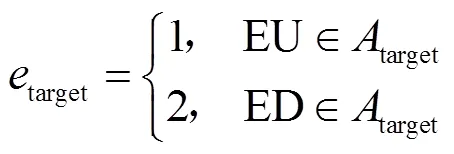

速度控制通过调节发动机转速target实现,由车载控制器通过CAN传递给发动机。为满足深松作业的农艺和转弯要求,设置高转速状态up和低转速状态down,分别对应升速与降速行为,target满足式(7)。

机具升降包括机具提升和机具降落,定义开关量target,满足式(8),即当target为1时机具提升,当target为2时机具降落。

对于深松作业,机具降落点down和机具上升点up需要在作业前完成配置,均由无量纲的机具位置表示,范围为[0, 1 000],其中,0表示最低位置,1 000表示最高位置。导航控制器将以上参数通过CAN总线发送至车载控制器,由车载控制器控制电液提升系统。

地头转弯采用单弧转弯(图5),此时的目标前轮转角为定值。考虑对行与转向要求,应满足式(9)。

式中ab为轴距,m;为转弯距离,m。

注:为目标前轮转角,(°);ab为轴距,m;为转弯距离,m。

Note:is the target front wheel turning angle, (°);abis the wheelbase, m;is the turning distance, m.

图5 转向示意图

Fig.5 Diagram of turning

1.3 试验设计

为验证自主行驶与作业系统的精度与稳定性,本文设计自动驾驶组和有人驾驶组开展对比试验。试验地块位于北京市顺义区(40°12'48.32"N,116°33'13.43"E),南北长约90 m,东西宽约35 m。

对于自动驾驶组,将=7.15及=2.5代入式(2)可得为6;由于地块限制,设置作业路径数为10条,速度控制和升降控制参数见表2。有人驾驶组由机手自行操作,实际作业路径数为11条。

表2 速度和升降控制参数

2 结果与讨论

2.1 行驶轨迹

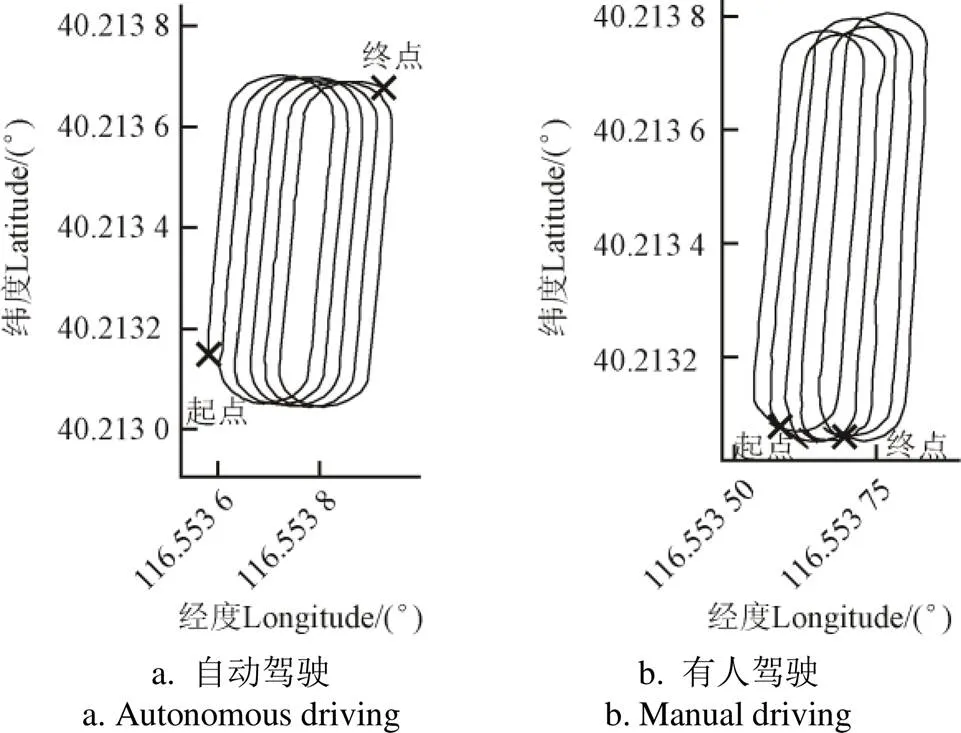

自动驾驶和有人驾驶的行驶轨迹如图6。直观来看,在直线作业段,自动驾驶的行驶轨迹更平直;在地头转弯段,自动驾驶只存在前进轨迹,且轨迹均为U形,而有人驾驶存在部分倒车轨迹。

图6 行驶轨迹对比

2.2 横向偏差

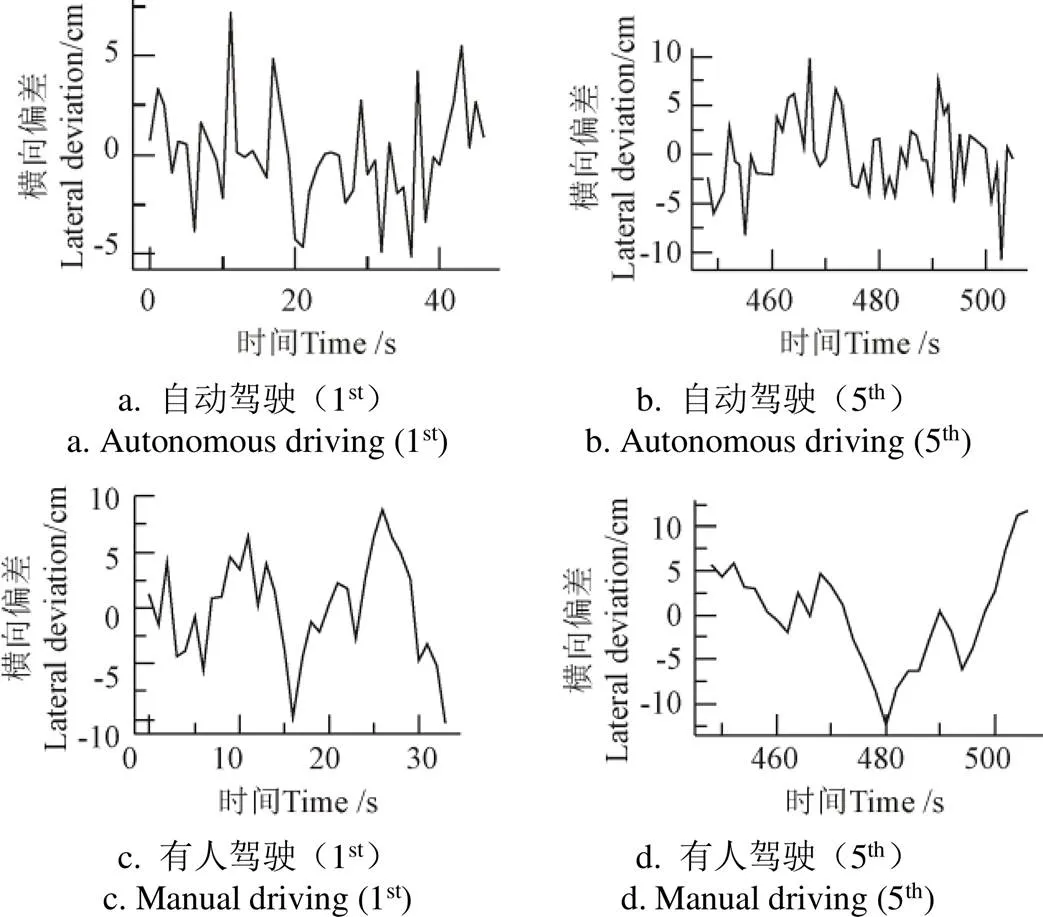

在作业阶段,自动驾驶和有人驾驶的拖拉机横向偏差的平均标准差分别为4和8 cm。其中,图7所示为第1和第5条作业路径的横向控制偏差。显然,自动驾驶的拖拉机横向偏差标准差降低了50%,作业性能更稳定。

图7 第1和第5条作业路径的横向控制偏差

2.3 作业速度

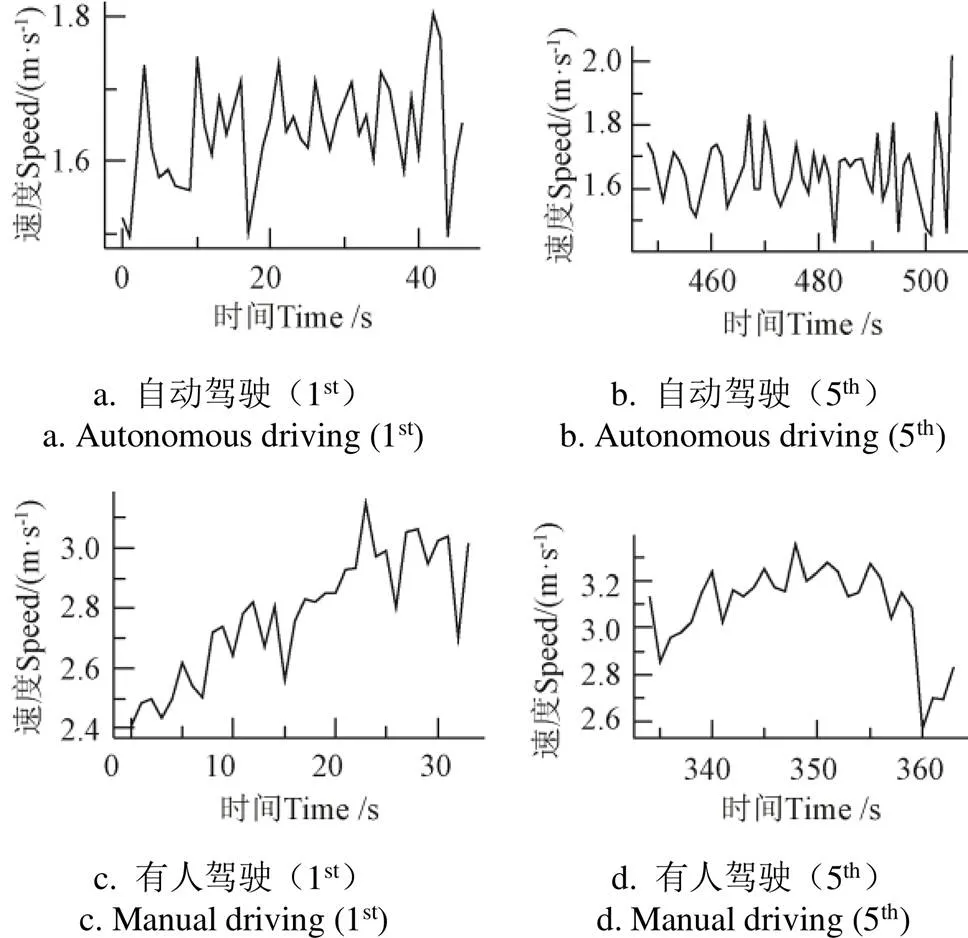

自动驾驶和有人驾驶的平均作业速度分别为1.66和2.98 m/s,平均标准差分别为0.09和0.27 m/s。自动驾驶的控制误差降低了约67%,表明自动驾驶的作业速度更为平稳(图8)。

图8 拖拉机作业速度对比

2.4 发动机转速

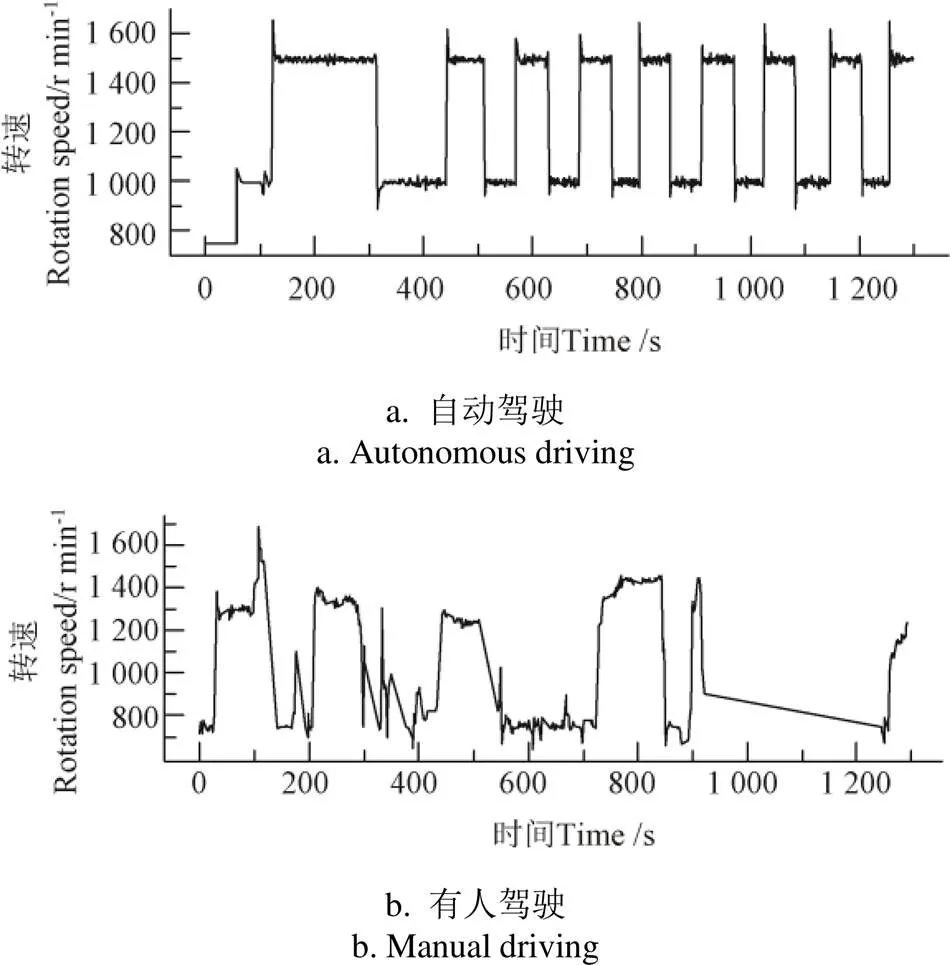

图9为拖拉机的发动机转速对比。自动驾驶的发动机转速有2个稳定点,作业阶段稳定在1 500 r/min附近,转弯阶段稳定在1 000 r/min附近,与设定值一致,仅在直线作业开始或结束时出现超调现象,而有人驾驶的发动机转速没有出现稳定点,自动驾驶在作业阶段(以130~300 s为例)和掉头阶段(以335~425 s为例)的发动机转速的标准差分别为7.9和9.1 r/min,拖拉机动力控制性能更优。

图9 拖拉机发动机转速对比

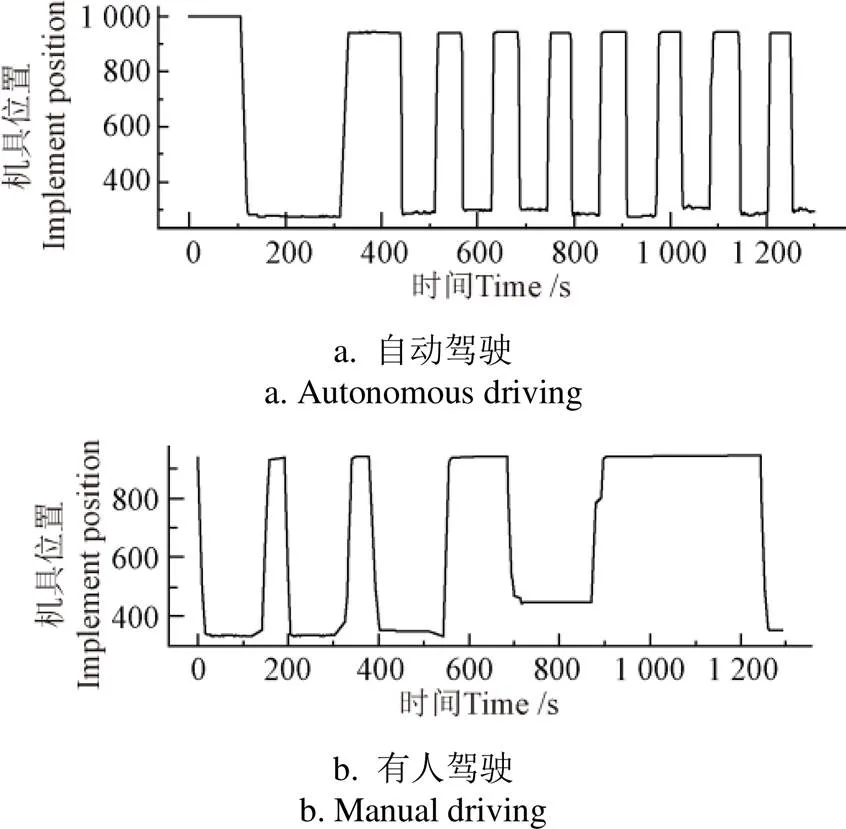

2.5 机具升降

图10为机具位置对比。对前4个稳定作业阶段(自动驾驶:130~300 s、450~500s、675~725 s、690~740 s;有人驾驶:20~130 s、205~300 s、405~535 s、720~800 s)的机具升降情况进行分析,自动驾驶平均机具位置的极差为23.8,有人驾驶平均机具位置的极差为113.3。较小的极差反映了自动驾驶的机具升降控制更为精确。

图10 机具位置对比

3 结 论

1)基于SF2104动力换向拖拉机、GNSS农机自动导航系统和深松机,设计了自主行驶与作业控制系统。采用分层控制思想,将控制系统划分为规划层、控制层和执行层。规划层生成路网数据,控制层进行横向控制、速度控制、转弯控制和机具升降控制等行为决策,执行层负责配置执行。

2)田间对照试验表明,自动驾驶和有人驾驶的横向偏差的平均标准差分别为4和8 cm,作业速度的平均标准差分别为0.09和0.27 m/s。自动驾驶稳定作业时发动机转速的平均标准差为7.9 r/min,平均机具位置极差23.8,均优于有人驾驶作业的对应指标,说明自主作业控制技术具有较高的作业精度和稳定性。

[1]Lowenberg-DeBoer James, Huang Iona Yuelu, Grigoriadis Vasileios, et al. Economics of robots and automation in field crop production[J]. Precision Agriculture, 2020, 21(2): 278-299.

[2]Pedersen Søren Marcus, Fountas Spyros, Sørensen Claus G, et al. Robotic seeding: Economic perspectives[M]. Precision Agriculture: Technology and Economic Perspectives. Springer, 2017: 167-179.

[3]Marinoudi Vasso, Sørensen Claus, Pearson Simon, et al. Robotics and labour in agriculture: A context consideration[J]. Biosystems Engineering, 2019, 184: 111-121.

[4]Duckett Tom, Pearson Simon, Blackmore Simon, et al. Agricultural robotics: The future of robotic agriculture[EB/OL]. 2018-08-02 https://arxiv.org/ftp/arxiv/ papers/1806/1806.06762.pdf.

[5]韩树丰,何勇,方慧. 农机自动导航及无人驾驶车辆的发展综述[J]. 浙江大学学报:农业与生命科学版,2018,44(4):381-391. Han Shufeng, He Yong, Fang Hui. Recent development in automatic guidance and autonomous vehicle for agriculture: A review[J]. Journal of Zhejiang University: Agriculture & Life Sciences, 2018, 44(4): 381-391. (in Chinese with English abstract)

[6]董胜,袁朝辉,谷超,等. 基于多学科技术融合的智能农机控制平台研究综述[J]. 农业工程学报,2017,33(8):1-11. Dong Sheng, Yuan Chaohui, Gu Chao, et al. Research on intelligent agricultural machinery control platform based on multi-discipline technology integration[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(8): 1-11. (in Chinese with English abstract)

[7]张漫,季宇寒,李世超,等. 农业机械导航技术研究进展[J]. 农业机械学报,2020,51(4):1-18. Zhang Man, Ji Yuhan, Li Shichao, et al. Research progress of agricultural machinery navigation technology[J]. Transactions of Chinese Society for Agricultural Machinery, 2020, 51(4): 1-18. (in Chinese with English abstract)

[8]Kelc Damijan, Stajnko Denis, Berk Peter, et al. Reduction of environmental pollution by using RTK-navigation in soil cultivation[J]. International Journal of Agricultural and Biological Engineering, 2019, 12(5): 173-178.

[9]刘小伟,吴才聪,车宇. 无人化农机技术与装备发展趋势[J]. 农机科技推广,2019(10):26-27. Liu Xiaowei, Wu Caicong, Che Yu. Development trend of unmanned agricultural machinery technology and equipment[J]. Agriculture Machinery Technology Extension, 2019(10): 26-27. (in Chinese with English abstract)

[10]何勇,蒋浩,方慧,等. 车辆智能障碍物检测方法及其农业应用研究进展[J]. 农业工程学报,2018,34(9):21-32. He Yong, Jiang Hao, Fang Hui, et al. Research progress of intelligent obstacle detection methods of vehicles and their application on agriculture[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(9): 21-32. (in Chinese with English abstract)

[11]薛金林,闫嘉,范博文. 多类农田障碍物卷积神经网络分类识别方法[J]. 农业机械学报,2018,49(S1):35-41. Xue Jinlin, Yan Jia, Fan Bowen. Classification and identification method of multiple kinds of farm obstacles based on convolutional neural network[J]. Transactions of Chinese Society for Agricultural Machinery, 2018, 49(S1): 35-41. (in Chinese with English abstract)

[12]薛金林,董淑娴,范博文. 基于信息融合的农业自主车辆障碍物检测方法[J]. 农业机械学报,2018,49(S1):29-34. Xue Jinlin, Dong Shuxian, Fan Bowen. Detection of obstacles based on information fusion for autonomous agricultural vehicles[J]. Transactions of Chinese Society for Agricultural Machinery, 2018, 49(S1): 29-34. (in Chinese with English abstract)

[13]Zhang Chi, Noguchi Noboru, Yang Liangliang. Leader–follower system using two robot tractors to improve work efficiency[J]. Computers and Electronics in Agriculture, 2016, 121: 269-281.

[14]Zhang Chi, Noguchi Noboru. Development of a multi-robot tractor system for agriculture field work[J]. Computers and Electronics in Agriculture, 2017, 142: 79-90.

[15]Wang Hao, Noguchi Noboru. Autonomous maneuvers of a robotic tractor for farming[C]// 2016 IEEE/SICE International Symposium on System Integration (SII). Sapporo, Japan: IEEE, 2016. 592-597.

[16]Wang Hao, Noguchi Noboru. Adaptive turning control for an agricultural robot tractor[J]. International Journal of Agricultural and Biological Engineering, 2018, 11(6): 113-119.

[17]关群. 凯斯纽荷兰工业集团推出无人驾驶概念拖拉机[J]. 农业机械,2016(9):40-43. Guan Qun. Case New Holland Industries launches driverless concept tractor[J]. Farm Machinery, 2016(9): 40-43. (in Chinese with English abstract)

[18]关群. 凯斯无人驾驶概念拖拉机荣获“最佳设计奖”[J]. 农业机械,2018(1):64. Guan Qun. Case driverless concept tractor won the “Best Design Award”[J]. Farm Machinery, 2018(1): 64. (in Chinese with English abstract)

[19]何杰,朱金光,罗锡文,等. 电动方向盘插秧机转向控制系统设计[J]. 农业工程学报,2019,35(6):10-17. He Jie, Zhu Jinguang, Luo Xiwen, et al. Design of steering control system for rice transplanter equipped with steering wheel-like motor[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(6): 10-17. (in Chinese with English abstract)

[20]何杰,朱金光,张智刚,等. 水稻插秧机自动作业系统设计与试验[J]. 农业机械学报,2019,50(3):17-24. He Jie, Zhu Jinguang, Zhang Zhigang, et al. Design and experiment of automatic operation system for rice transplanter[J]. Transactions of Chinese Society for Agricultural Machinery, 2019, 50(3): 17-24. (in Chinese with English abstract)

[21]刘兆朋,张智刚,罗锡文,等. 雷沃ZP9500高地隙喷雾机的GNSS自动导航作业系统设计[J]. 农业工程学报,2018,34(1):15-21. Liu Zhaopeng, Zhang Zhigang, Luo Xiwen, et al. Design of automatic navigation operation system for Lovol ZP9500 high clearance boom sprayer based on GNSS[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(1): 15-21. (in Chinese with English abstract)

[22]陈黎卿,许泽镇,解彬彬,等. 无人驾驶喷雾机电控系统设计与试验[J]. 农业机械学报,2019,50(1):122-128. Chen Liqing, Xu Zezhen, Xie Binbin, et al. Design and test of electronic control system for unmanned drive sprayer[J]. Transactions of Chinese Society for Agricultural Machinery, 2019, 50(1): 122-128. (in Chinese with English abstract)

[23]李云伍,徐俊杰,王铭枫,等. 丘陵山区田间道路自主行驶转运车及其视觉导航系统研制[J]. 农业工程学报,2019,35(1):52-61. Li Yunwu, Xu Junjie, Wang Mingfeng, et al. Development of autonomous driving transfer trolley on field roads and its visual navigation system for hilly areas[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(1): 52-61. (in Chinese with English abstract)

[24]Sabelhaus Dennis, Frank Roben, Lars Peter Meyer zu Helligen, et al. Using continuous-curvature paths to generate feasible headland turn manoeuvres[J]. Biosystems Engineering, 2013, 116(4): 399-409.

[25]Backman Juha, Piirainen Pyry, Oksanen Timo. Smooth turning path generation for agricultural vehicles in headlands[J]. Biosystems Engineering, 2015, 139: 76-86.

[26]Paraforos Dimitrios S, Hübner Robert, Griepentrog Hans W. Automatic determination of headland turning from auto-steering position data for minimising the infield non-working time[J]. Computers and Electronics in Agriculture, 2018, 152: 393-400.

[27]Yin Xiang, Du Juan, Noguchi Noboru, et al. Development of autonomous navigation system for rice transplanter[J]. International Journal of Agricultural and Biological Engineering, 2018, 11(6): 89-94.

[28]Cariou Christophe, Lenain Roland, Thuilot Benoit, et al. Motion planner and lateral-longitudinal controllers for autonomous maneuvers of a farm vehicle in headland[C]// 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems. St. Louis, MO, USA: IEEE, 2009. 5782-5787

[29]Cariou Christophe, Lenain Roland, Berducat Michel, et al. Autonomous maneuver of a farm vehicle with a trailed implement: motion planner and lateral-longitudinal controllers[C]// 2010 IEEE International Conference on Robotics and Automation. Anchorage, AK, USA: IEEE, 2010. 3819-3824

[30]Zhou Kun. Simulation Modelling for In-field Planning of Sequential Machinery Operations in Cropping Systems[D]. Aarhus: Aarhus University, 2015.

Autonomous driving and operation control method for SF2104 tractors

Wu Caicong1,2, Wang Dongxu1, Chen Zhibo1, Song Bingbing1, Yang Lili1, Yang Weizhong1※

(1,,100083,; 2,,100083,)

To solve the critical shortage and the increasing cost of rural labor, the concept of “one person, multiple machines” were proposed and an autonomous driving and operating system for SF2104 was developed. The hardware of the system included SF2104 tractor with a power reverser transmission and wire-controlled chassis, WAS-3106 angle sensor, 1SZ-230 subsoiler, GNSS (Global Navigation Satellite System) based auto-steering system for agricultural machinery (FARMSTARF2BD-2.5RD), SF9507 vehicle controller, and mobile monitor such as smartphone and PC (personal computer). The control system mainly included three function units, i.e., data acquisition unit, planning and control unit, and movement unit. The navigation and control method was deployed in the planning and control unit according to the hierarchical control method. The entire method constituted of the layer of navigation planning, the layer of behavior control, and the layer of behavior execution. The operation width, the turning radius and the first operation path (straight line) from user inputs were transferred to the layer of navigation planning, and it also used to calculate the path network data. The path network data, wheelbase from user inputs and the real-time data (i.e.,location, heading and front wheel angle), were transferred to the layer of behavior control involving the target behavior decision. The decision of the target behavior wouldl be transferred to the layer of behavior execution, which derived the target front wheel angle, the target engine rotation speed and the target implement position. The layer of navigation planning generated the path network data to meet the requirement of operating in the field and turning in the headland through the FSP (First Turn Skip Pattern). The layer of behavior control made the decisions of target behavior, including lateral control, speed control, turning control, lifting control, current path update and operation ending. When the tractor entered the operating strip, the system identified the starting point of the operation, and sequentially executed the behavior of implement lowering, the behavior of speed increase, and the behavior of tracking thestraight line. When the tractor finished the operation of the current path, the behaviors of implement lifting, speed reduction, and turning were executed sequentially. The behavior of speed control was executed by controlling the tractor’s engine rotation speed at a high value or a low value through the vehicle controller. The behavior of lifting control was executed by transmitting an implement status value to the controller of the hydraulic lifting system. The behavior of turning control was executed by transmitting a fixed front wheel angle which was calculated by tractor kinematics turning distance. The subsoil operation experiments were carried out in the Shunyi District of Beijing. The experiments included the manual driving group and the autonomous driving group. For the autonomous driving group, the operating trajectories were straight and smooth, the average standard deviation of lateral deviation was 4 cm, the average operating speed was 1.66 m/s, and the standard deviation of operating speed was 0.09 m/s. During the stable operating stage in the field, the standard deviation of engine rotation speed was 7.9 r/min, and the range of the average implement position was 23.8. For themanual driving group, the operating trajectories were not smoother than the trajectories of the autonomous driving group, and the average standard deviation of lateral deviation was 8 cm, the average operating speed was 2.98 m/s, and the standard deviation of operating speed was 0.27 m/s. The stability of engine rotation speed and the range of implement position were also poor in manual driving group. The results showed that the autonomous driving group outperformed the manual driving group in terms of operating accuracy and working stability, which can effectively reduce labor costs. This research provides a platform foundation and theoretical basis for the future research of multi-vehicle and multi-operation collaboration with less human operations.

agricultural machinery; experiments; automatic driving; autonomous operation; control system

吴才聪,王东旭,陈智博,等. SF2104拖拉机自主行驶与作业控制方法[J]. 农业工程学报,2020,36(18):42-48.doi:10.11975/j.issn.1002-6819.2020.18.006 http://www.tcsae.org

Wu Caicong, Wang Dongxu, Chen Zhibo, et al. Autonomous driving and operation control method for SF2104 tractors[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(18): 42-48. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.18.006 http://www.tcsae.org

2020-06-03

2020-08-01

国家重点研发计划项目(2016YFB0501805)

吴才聪,博士,副教授,博士生导师,主要从事农机导航与位置服务等研究。Email:wucc@cau.edu.cn

杨卫中,博士,副教授,主要从事农机导航与位置服务等研究。Email:ywz@cau.edu.cn

10.11975/j.issn.1002-6819.2020.18.006

S24

A

1002-6819(2020)-18-0042-07