磁电弹结构多场耦合分析的稳定Node-based光滑径向基点插值法

任书慧 孟广伟 王吉贤 周立明?

摘 要:为提高磁电弹结构分析的精度,提出稳定Node-based光滑径向基点插值法(SNS-RPIM). 基于传统Node-based光滑径向基点插值法(NS-RPIM),引入与场变量梯度方差有关的稳定项,消除不确定参数,推导了多场耦合问题的SNS-RPIM方程,求解了磁电弹结构静力响应问题,并与有限元法计算结果进行比较. 数值算例结果表明,SNS-RPIM能够得到更加接近真实解的结果,有效解决了有限元系统刚度偏硬的问题;在精度与收敛性方面,SNS-RPIM比有限元法表现得更加出色,从而为磁电弹材料的进一步应用提供了有效的分析方法.

关键词:稳定光滑径向基点插值法;磁电弹材料;复合材料;梯度光滑技术;数值方法

中图分类号:TB115 文献标志码:A

Stabilized Node-based Smoothed Radial Point Interpolation Method

for Multi-field Coupling Analysis of Magneto-electro-elastic Structures

REN Shuhui,MENG Guangwei,WANG Jixian,ZHOU Liming?

(School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130025,China)

Abstract: In order to improve the accuracy in analyzing magneto-electro-elastic (MEE) structures, a stabilized node-based smoothed radial point interpolation method (SNS-RPIM) was proposed. Based on the traditional node-based smoothed radial point interpolation method, the stable item related to the gradient variance of the field variables was introduced to eliminate the uncertain parameter. The SNS-RPIM equations for multi-field coupling problems were derived, and the static responses of MEE structures were also solved. The results of SNS-RPIM were compared with those of finite element method. Numerical examples showed that SNS-RPIM can provide the result closer to the real solution and effectively solve the problem of 'overly-stiff' of finite element method. SNS-RPIM is better than FEM in terms of accuracy and convergence, which provides an effective analysis method for further application of MEE materials.

Key words: stabilized smoothed radial point interpolation method; magneto-electro-elastic(MEE) material;composite material;gradient smoothing technique;numerical methods

磁電弹材料是一种由压电相(BaTiO3)与压磁相(CoFe2O4)复合而成的智能材料,能够将机械能、电能与磁能相互转化[1-2]. 磁电弹材料因其具有力电、力磁、磁电效应而被广泛应用于智能结构中,引起了国内外学者的广泛关注[3-4]. Jiang等[5]推导了在均布载荷作用下磁电弹悬臂梁响应的解析解,为未来磁电弹结构的设计与分析奠定了基础. Wang等[6]求解了三维磁电弹圆柱板的自由振动问题,得出了频率方程. Ebrahimi等[7-8]利用Hamilton原理推导了磁电弹纳米板的非局部控制方程,研究了纳米板的屈曲行为.

由于传统有限元法(FEM)在求解中存在“过刚”、体积自锁等问题,导致结果不准确. 近年来,Liu等[9]提出了广义梯度光滑技术,并基于该方法构造出了一系列光滑有限元法(S-FEM)[10]和光滑径向基点插值法(S-RPIM)[11]. 何智成等[12-13]和陈泽聪等[14]将光滑有限元应用到声学模拟中. 周立明等[15-16]将光滑有限元扩展到了求解裂纹问题和多场耦合问题中,验证了光滑方法的准确性. 在S-RPIM中,Node-based光滑径向基点插值法(NS-RPIM)能够消除FEM中“过刚”的问题,为所求解问题提供能量范数的上界解[9].该方法使用径向基函数对场函数进行近似,其形函数具有Kronecker Delta函数属性,边界条件可以如FEM一样直接施加. 基于伽辽金弱形式与节点积分技术,推导出系统方程. 基于这些优点,NS-RPIM在求解静力学以及多场耦合问题中得到了广泛的应用. Li等[17]采用NS-RPIM分析了二维、三维固体力学问题,验证了此算法的准确性与优越性. Zhou等[18]将NS-RPIM引入多场耦合问题的研究中,结果表明,NS-RPIM对于求解磁电弹结构的响应问题是有效且可靠的.

尽管NS-RPIM在求解许多问题时表现良好,但研究表明[11,19],由于NS-RPIM的模型过于柔软,会令其在求解动态问题时产生伪非零能量模式,导致算法存在时间不稳定性. 为增强系统刚度,解决时间不稳定性,Wang等[20]提出了一种稳定算法,解决了Node-based光滑有限元方法中的缺陷并且减少了求解声学问题中的色散误差. Feng等[21]提出了一种稳定的节点积分方法,分析了电磁问题. Yang等[22]解决了Node-based光滑有限元方法中的时间不稳定性,更准确的求解了金属成型问题.

本文提出了稳定NS-RPIM (SNS-RPIM),基于傳统NS-RPIM方法,引入与场变量梯度方差相关的稳定项,消除了不确定参数,推导了求解多场耦合问题的SNS-RPIM方程,分析了磁电弹结构在静力作用下的响应,并将所得结果与有限元法计算结果进行了对比.

1 基本方程

磁电弹材料平衡方程如下:

σij,j = 0,(i,j = 1,2,3) (1)

Dl,l = 0,(l = 1,2,3) (2)

Bl,l = 0,(l = 1,2,3) (3)

式中:σij、Dl、Bl分别为应力分量、电位移分量、磁感应强度分量.

磁电弹材料的几何方程如下:

Sij = (ui,j + uj,i),(i,j = 1,2,3) (4)

Ek = -Φ,k,(k = 1,2,3) (5)

Hk = -Ψ,k,(k = 1,2,3) (6)

式中:Sij为应变分量;Ek为电场强度分量;Hk为磁场强度分量;Φ与Ψ为电势与磁势.

磁电弹材料的本构方程如下:

σi = Cij Sj - eki Ek - qki Hk (7)

Dl = elj Sj + εlk Ek + mlk Hk (8)

Bl = qlj Sj + mlk Ek + μlk Hk (9)

式中:Cij、eki、qki 分别为弹性常数、压电系数与压磁系数;εlk、mlk、 μlk 分别为介电常数、磁电耦合系数与磁导率. i,j = 1,2,… ,6; l = 1,2,3; k = 1,2,3.

边界条件为:

ui = [u][~]i,在Γd上 (10)

σij nj = [β][~]i,在Γs上,Γ = Γd ∪Γs (11)

Φ = [Φ][~],在Γe上 (12)

Dl nl = [Q][~]i,在Γt上,Γ = Γe ∪Γt (13)

Ψ = [Ψ][~],在Γm上 (14)

Bl nl = [R][~],在Γi上,Γ = Γm ∪Γi (15)

式中:Γd与Γs分别为位移边界与力边界;Γe与Γt分别为电势边界与电位移边界;Γm与Γi分别为磁势边界与磁通量边界;[u][~]为Γd上给定的位移;[β][~]为Γe上给定的面力;[Φ][~]为Γe上给定的电势;[Q][~]为Γt上给定的电位移;[Ψ][~]为Γm上给定的磁势;[R][~]为Γi上给定的磁通量.

2 稳定Node-based光滑径向基点插值法

2.1 Cell-based T2L方案

Cell-based T2L方案[9]为计算xQ的形函数值选择合适的局部支持节点. 该方案选择xQ周围的两层节点作为局部支持节点. 第一层节点为xQ所在三角形单元的顶点;第二层节点为与第一层节点直接连接的那些节点,如图1所示.

2.2 Node-based光滑径向基点插值法

二维问题域Ω被离散为ne个三角形单元,包含nn个节点. 通过将节点xi = [xi,zi]T周围三角形的边中点与质心依次相连,构造以xi为中心的光滑域Ωi,如图2所示.

问题域内任一点xi处的近似位移u、近似电势Φ与近似磁势Ψ可表示为:

式中:Nu(xi)、NΦ(xi)与NΨ(xi)分别为NS-RPIM的位移形函数、电势形函数与磁势形函数;ns为局部支持节点的数量;u、Φ和Ψ分别表示位移向量、电势向量和磁势向量.

通过引入梯度光滑技术,根据式(16)~(18),节点xi处的光滑应变S、光滑电场强度E与光滑磁场强度H分别为:

式中:Bu(xi)、BΦ(xi)与BΨ(xi)分别为节点光滑应变矩阵、节点光滑电场强度矩阵和节点光滑磁场强度矩阵,其表达式为:

式中:nG为高斯点的数量;nseg为光滑域边界的数量; n t

l,p为光滑域第p段边界中单位法向量矩阵的分量; N t

l,p,q为第p段边界上第q个高斯点处的形函数值; WG

q为第q个高斯点处的权值;Ai为光滑域的面积.

二维磁电弹的NS-RPIM静力学方程可表示为:

式中:等效力向量Feq、等效刚度矩阵Keq以及电势Φ和磁势Ψ的求解公式见参考文献[18].

2.3 稳定Node-based光滑径向基点插值法

为了在提高NS-RPIM计算精度的同时消除时间不稳定性,在该算法中引入与场变量梯度方差相关的稳定项来提高模型的刚度,令其更接近真实情况.

以二維问题为例,如图3所示,光滑域Ωi被近似为具有相同面积的圆,将近似域进一步划分为4个子光滑域. 局部坐标系与光滑域的交点Gk

i(k = 1,2,3,4; i = 1,2,3,…,nn)作为补充积分点,nn为结构包含节点数. 积分点与节点xi之间的距离lc相等,大小为近似域的半径. lc的计算公式为:

假设场变量的梯度在光滑域Ωi中连续且一阶可导,其在4个积分点处的泰勒展开式分别为:

3 数值算例

3.1 算例1

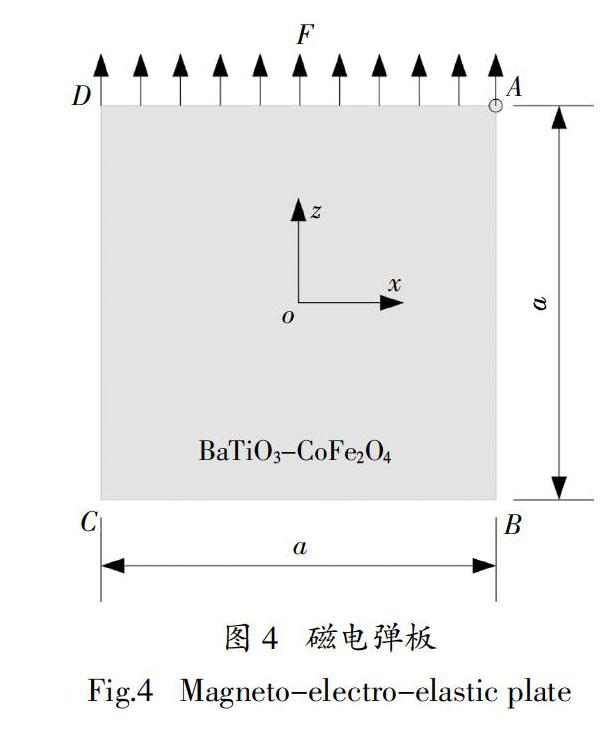

磁电弹材料(BaTiO3-CoFe2O4)板在边AD受100 N/m2的均布载荷作用,为平面应变问题,如图4所示,边长a = 2.0 m. 表1给出了磁电弹板的材料参数,质量密度为5 730 kg/m3,边界条件为:ux = 0(边CD),uz = Ф = Ψ = 0(边BC),每个边界的表面电荷与表面磁感应强度均为零.

采用不同节点数量(121、441和1 681个)求解磁电弹板的广义位移(位移ux、uz,电势Φ,磁势Ψ),验证SNS-RPIM的正确性以及收敛性. 表2给出了文献[23]中A点处位移、电势与磁势的解析解,以及SNS-RPIM在不同节点数量下的计算结果. 可见,SNS-RPIM的结果与解析解误差很小,随着节点数量的增加,误差减小,验证了SNS-RPIM求解磁电弹结构多场耦合问题的正确性、有效性.

3.2 算例2

磁电弹材料悬臂梁如图5所示,长度L=0.030 m,宽度h=0.002 m,在B点承受200 N的静力,为平面应力问题. 悬臂梁在固定端处满足ux=uz=Φ=Ψ =0. 悬臂梁材料属性见表1,质量密度为5 730 kg/m3.

在证明了SNS-RPIM正确性的基础上,对磁电弹悬臂梁在静力作用下的响应进行研究. 图6给出了边AB处的广义位移,SNS-RPIM与FEM采用三角形单元,节点数量为305个. 其中,参考解为FEM采用180×12个四边形单元的结果. 图7给出了静力作用下悬臂梁的云图. 由结果可知,在所用节点数量相同的情况下,SNS-RPIM的计算结果比FEM的结果更加接近参考解. 算例结果验证了SNS-RPIM的高精度、正确性和有效性.

在节点数为305 、637和1 089个时,对比了SNS-RPIM与FEM的能量误差[24],如图8所示. 可知在节点数相同的情况下,SNS-RPIM的能量误差远远低于FEM,并且随着所用节点数的增加,能量误差逐渐降低. 从而进一步验证了SNS-RPIM的精确性,高收敛性与有效性.

4 结 论

本文基于场变量梯度方差构造了稳定项,并将其引入了传统Node-based光滑径向基点插值法,提出了稳定Node-based光滑径向基点插值法. 随后求解了磁电弹结构在静力作用下的响应,得出以下结论:

1)将SNS-RPIM的结果与解析解进行对比,

二者吻合良好,说明了本方法的正确性及有效性.

2)计算了SNS-RPIM与FEM在不同节点数量

下的能量误差,结果显示SNS-RPIM具有良好的收敛性与准确性.

3)SNS-RPIM利用较少的节点能够达到更高的精度,消除了FEM模型刚度过硬的问题.

4)通过考虑SNS-RPIM与FEM对不同模型的

求解结果,表明SNS-RPIM在求解磁电弹结构多场耦合问题时的可靠性和适用性.

参考文献

[1] BOOMGAARD J V D,VAN RUN A M J,SUCHTELEN J V. Magnetoelectricity in piezoelectric-magnetostrictive composites [J]. Ferroelectrics ,1976,10(1): 295—298.

[2] LU X Y,LI H,WANG B. Theoretical analysis of electric,magnetic and magnetoelectric properties of nano-structured multiferroic composites [J]. Journal of the Mechanics and Physics of Solids,2011,59(10):1966—1977.

[3] FETISOV L Y,SEROV V N,CHASHIN D V,et al. A magnetoelectric sensor of threshold DC magnetic fields [J]. Journal of Applied Physics,2017,121(15):154503.

[4] 李帛书,钟轶峰,罗丹,等. 涂层-纤维增强磁电弹性材料的变分渐近细观力学模型 [J]. 复合材料学报,2018,35(10): 2823—2831.

LI B S,ZHONG Y F,LUO D,et al. Variational asymptotic micromechanics model of coating-fiber reinforced magneto-electro-elastic materials [J].Acta Materiae Compositae Sinica,2018,35(10): 2823—2831. (In Chinese)

[5] JIANG A M,DING H J. Analytical solutions to magneto-electro-elastic beams [J]. Structural Engineering and Mechanics,2004,18(2):195—209.

[6] WANG Y,XU R Q,DING H J,et al. Three-dimensional exact solutions for free vibrations of simply supported magneto-electro-elastic cylindrical panels[J]. International Journal of Engineering Science,2010,48(12):1778—1796.

[7] EBRAHIMI F,BARATI M R. An exact solution for buckling analysis of embedded piezoelectro-magnetically actuated nanoscale beams [J]. Advances in Nano Research,2016,4(2):65—84.

[8] EBRAHIMI F,BARATI M R. Static stability analysis of smart magneto-electro-elastic heterogeneous nanoplates embedded in an elastic medium based on a four-variable refined plate theory [J]. Smart Materials and Structures,2016,25(10):105014.

[9] LIU G R,ZHANG G Y. Smoothed point interpolation methods G space theory and weakened weak forms[M]. Singapore: World Scientific,2013: 403—578.

[10] 崔向陽,李光耀. 基于边光滑有限元法的剪切变形板几何非线性分析 [J]. 计算机辅助工程,2011,20(1): 155—162.

CUI X Y,LI G Y.Geometric nonlinear analysis on shear deformation plates using edge-based smoothed finite element method [J].Computer Aided Engineering,2011,20(1): 155—162. (In Chinese)

[11] LIU G R,LI Y,DAI K Y,et al. A linearly con-forming radial point interpolation method for solid mechanics problems[J]. International Journal of Computational Methods,2006,3(4):401—428.

[12] 何智成,李光耀,成艾国,等. 光滑有限元的声学研究:时域和频域分析 [J]. 振动与冲击,2012,31(16):122—127.

HE Z C,LI G Y,CHENG A G,et al.Acoustic analysis using edge-based smoothed finite element method: time and frequency domain analysis[J]. Journal of Vibration and Shock,2012,31(16): 122—127. (In Chinese)

[13] 何智成,李光耀,成艾国,等. 基于边光滑有限元的声固耦合研究 [J]. 机械工程学报,2014,50(4): 113—119.

HE Z C,LI G Y,CHENG A G,et al.Coupled edge-based smoothing finite element method for structural acoustic problems [J]. Journal of Mechanical Engineering,2014,50(4): 113—119. (In Chinese)

[14] 陈泽聪,陈毓珍,何智成,等. 应用混合单元基光滑点插值法的声固耦合分析 [J]. 振动与冲击,2019,38(8): 238—245.

CHEN Z C,CHEN Y Z,HE Z C,et al.A hybrid cell-based smoothing point interpolation method for solving structural-acoustic problems [J]. Journal of Vibration and Shock,2019,38(8): 238—245. (In Chinese)

[15] 周立明,孟廣伟,李锋. 界面裂纹的Cell-Based光滑有限元法研究 [J]. 湖南大学学报(自然科学版),2016,43(6): 34—39.

ZHOU L M,MENG G W,LI F.Research on cell-based smoothed finite element method of interface cracks [J].Journal of Hunan University (Natural Sciences),2016,43(6): 34—39. (In Chinese)

[16] 周立明,蔡斌,孟广伟,等. 含裂纹压电材料的Cell-Based光滑扩展有限元法 [J]. 复合材料学报,2016,33(4): 929—938.

ZHOU L M,CAI B,MENG G W,et al.Cell-based smoothed extended finite element method for piezoelectric materials with cracks [J].Acta Materiae Compositae Sinica,2016,33(4): 929—938. (In Chinese)

[17] LI Y,LIU G R,YUE J H. A novel node-based smoothed radial point interpolation method for 2D and 3D solid mechanics problems [J]. Computers & Structures,2018,196:157—172.

[18] ZHOU L M,REN S H,MENG G W,et al. A multi-physics node-based smoothed radial point interpolation method for transient responses of magneto-electro-elastic structures [J]. Engineering Analysis with Boundary Elements,2019,101:371—384.

[19] FENG H,CUI X Y,LI G Y,et al. A temporal stable node-based smoothed finite element method for three-dimensional elasticity problems [J]. Computational Mechanics,2014,53(5):859—876.

[20] WANG G,CUI X Y,FENG H,et al. A stable node-based smoothed finite element method for acoustic problems [J]. Computational Methods in Applied Mechanics and Engineering,2015,297:348—370.

[21] FENG H,CUI X Y,LI G Y. A stable nodal integration method for static and quasi-static electromagnetic field computation [J]. Journal of Computational Physics,2017,336:580:594.

[22] YANG H,CUI X Y,LI S,et al. A stable node-based smoothed finite element method for metal forming analysis [J]. Computational Mechanics,2019,63(6):1147—1164.

[23] ZHU X Y,HUANG Z Y,JIANG A M,et al. Fast multipole boundary element analysis for 2D problems of magneto-electro-elastic media [J]. Engineering Analysis with Boundary Elements,2010,34: 927—933.

[24] ZHOU L M,REN S H,LIU C Y,et al. A valid inhomogeneous cell-based smoothed finite element model for the transient characteristics of functionally graded magneto-electro-elastic structures [J]. Composite Structures,2019,208:298—313.