Comprehensive Evaluation Method for Safety Performance of Automobile Textiles

XUEWenliang(薛文良)1,2,ZHANGChuanxiong,SHENTing(申婷)1,2,ZHANGZhichang(张芝畅)1,2,DINGYi(丁亦)1,2

1 Key Laboratory of Textile Science & Technology, Ministry of Education, Donghua University, Shanghai 201620, China2 College of Textiles, Donghua University, Shanghai 201620, China3 Science and Technology Development Center of Textile Industry, Beijing 100005, China

Abstract: With the gradual increase of car ownership in China and the continuous expansion of travel radius, traffic accidents caused by car safety are also increasing. As far as automobile safety itself is concerned, its evaluation method is constantly evolving, but the safety of automobile textiles, which is an important part of it, is still in its infancy. The article starts from the factors that affect the safety performance of automobiles such as automobile safety theory, vehicle ergonomics and automobile textile performance. Then, the methods of expert investigation, analytic hierarchy process, fuzzy comprehensive evaluation and data analysis are used. In this way, we obtain a grade set for a multi-level index system and determine the weight of each index. Finally, we establish a comprehensive evaluation system for safety of the automobile textiles and select parameters under extreme conditions to verify the system, which proves to be effective and feasible.

Key words: automobile textiles; automobile safety performance; fuzzy comprehensive evaluation; analytic hierarchy process

Introduction

In recent years, with the automobile production and sales increasing year by year, the automobile industry has been burgeoning. The textile materials also become more and more widely used in the automobile industry, and automobile textiles consequently developed as an important support for industrial textiles. Nowadays, there are more than 80 kinds of parts using textile materials in automobiles, mainly including interior fabrics for seats in the car, other textile materials in the car such as airbags, seat belts, cushioning mufflers, interior filter materials, and thermal insulation filling materials[1-4]. At the same time, with the increasing number of cars, traffic problems have become increasingly prominent. Therefore, there is still a long way to go to reduce the hazards of traffic accidents and improve the safety performance and comfort performance of automobiles. It is particularly important to establish a mature overall evaluation method for the safety performance of automotive textiles.

At present, the automobile safety technology laws and regulations system mainly include the United States Federal Motor Vehicle Safety Standard used in European countries, the automobile regulations designated by the United Nations Economic Commission, and the regulations formulated by the European Union. Japan has relatively mature regulations according to the “Road Transport Vehicle Law”. China’s automotive safety standards are mainly divided into national standards, automotive industry standards, local standards and enterprise standards[5]. The new car evaluation system mainly includes the Insurance Institute for Highway Safety(IIHS) safety standard provided by the American Highway Safety Insurance Association, which is an important part of the world’s car safety standard. In addition, the new car evaluation procedure new car assessment program(NCAP) scores the comprehensive performance of the tested vehicle and sortes to stars level, thereby letting the public know the performance level of the car among similar products in the market[6].

Automobile experimentation divides the car safety into active and passive safeties, of which active safety is the performance of cars to prevent and avoid traffic accidents, and passive safety is the protection effect of relevant personnel after accidents[7]. Through comprehensive analysis of China’s NCAP safety evaluation method, it can be found that the research of vehicle safety has been constantly improving and becoming more and more detailed, but the focus is still on the evaluation of passive safety. In fact, the scope of automobile safety goes far beyond active safety and passive safety. It shall be noted that post-accident safety and ecological safety involved in textiles should also attract people’s attention. Post-accident safety refers to whether the vehicle can quickly eliminate the consequences of the accident[8]and the performance in avoiding new accidents. Among them, textiles are mainly related to the flame-retardant function of automotive textiles in automobile fires. Ecological safety refers to the impact of engine exhaust pollution, car driving noise and electromagnetic waves on the environment. Among them, textiles are mainly related to the air quality in the car[9].

For the above content, there is currently no uniform quality standard in the automotive industry. Different automobile companies use different quality systems and the evaluation indicators are not yet perfect. This article studies the overall evaluation method of the safety performance of automotive textiles, uses the analytic hierarchy process and fuzzy comprehensive evaluation method for sorting and analysis, establishes a suitable evaluation index system, and sets the test parameters under extreme conditions to verify the evaluation model to analyze the feasibility and effectiveness of the system. The research results provide a theoretical basis for the overall evaluation method of the safety performance of automotive textiles, which has a certain reference value for improving the scientificity of regulatory agencies, market managers and automobile manufacturers, and also provides more effective experience for evaluation in other fields. The evaluation method for automotive textiles established in this study was not only limited to the detection of individual components, but also analyzed on the hazard probability and degree of hazards of individual components and found that there was correlation between multiple components. A star rating system for the safety performance of vehicle textiles was formed.

1 Research Methods

In this paper, expert survey, analytic hierarchy process, fuzzy comprehensive evaluation and data statistical analysis were used to select evaluation indicators, determine evaluation levels and index weights, analyze and calculate membership, and finally establish a comprehensive evaluation model of automobile safety performance.

The safety performance of automotive textiles involves many parts inside the car and involves a high degree of professionalism. Therefore, expert investigation is needed to obtain professional opinions[10]. While using the expert survey method, due to the wide range of indicators and the large number of indicators, analytic hierarchy process and fuzzy comprehensive evaluation were combined. At the same time, statistical analysis of the data was carried out so as to establish a suitable evaluation index system more effectively and to make the evaluation results work better in objectively evaluating the safety performance of automotive textiles[11].

Before using the expert survey method for system consultation, the relevant indicators needed to be systematically sorted out to obtain a rough indicator framework for the overall evaluation of the safety performance of automotive textiles for the experts to provide reference. The target-level indicators were the safety of automotive textiles; the criterion-level focused on considering the safety of textiles in the automotive environment, including passive, post-accident, and ecological safety; the indicator-level contained some aspects of the three criterion levels; the program-level considered the specific reflection on the indicators. And the framework as shown in Fig. 1.

A total of 7 experts in the textile industry were invited who were from professional fields of automotive, functional textiles, composite materials, industrial fiber products, chemical fibers, textile testing, textile chemistry and dyeing and finishing engineering. The author conducted the survey by issuing expert questionnaires to experts, sorted and analyzing the recovered questionnaires, summarized the recommendations and correction results of the experts, and used the final indicator system to determine the evaluation level.

After the evaluation level set was established, referring to relevant standards and test methods, a single index evaluation was conducted again through expert surveys, the index weights were determined, and a vector matrix was obtained. Then a certain evaluation model was used to get the membership vectorSof automotive textiles with respect to each evaluation star as a whole. The process of establishing a comprehensive evaluation model of automobile safety performance will be described in detail below.

2 Establishment of the Evaluation Model

2.1 Selection of the evaluation methods

The overall evaluation of the safety performance of automotive textiles has the characteristics of multiple attributes, multiple levels and ambiguity. The use of the fuzzy comprehensive evaluation method for fuzzy synthesis is more comprehensive, accurate and intuitive, and the evaluation results can take into account all levels of indicators, which is conducive to formulating an overall evaluation plan; the use of analytic hierarchy process has a good applicability to the combination of quantitative and qualitative problems, and the accuracy of the results is high[12]. The combination of the two simplifies the mathematical model, makes it easier to master and the weights more reasonably to be distributed, thereby improving the enthusiasm and accuracy of various indicators.

2.2 Determining the evaluation level set

In this paper, there were a total of 46 program-level indicators used to characterize the safety performance of automotive textiles, and the resulting evaluation index set can be expressed asU={u1,u2, …,u46}. For each factor, there can be several reviews or evaluation levels, usually an odd integer in the range of [3, 7][13]. The star rating system here is divided into five levels: one- star, two-star, three-star, four-star, and five-star. Each star level is described in plain language. One-star

Fig.1 Framework for evaluating the safety performance of automobile textiles

means poor, unqualified, and sample denied by the “one vote veto” principle would fall into this level; two-star means just passing the qualified line; three-stars means generally passed the qualified line; four-star means relatively good; five-star means the best.

For each indexui(i=1, 2,…, 46) in the evaluation factor set, its membership degrees to the evaluation level setvj(j=1, 2, 3, 4, 5), andri, jis analyzed, getting the single index evaluation result of thei-th index[14]:

ri= (ri, 1,ri, 2,ri, 3,ri, 4,ri, 5 ).

Therefore, firstly, the frequency method was used to divide the change range of the index value at each level. Then the frequency of the historical data appearing in the variation range of each level was used as the membership of the fuzzy subset of each level. Finally, the expert survey was used to define the test methods that each index in the system shall be followed and the variation range of each index value in each level, including qualitative indexes and quantitative indexes.

The results of the five-star evaluation rating set are summarized as follows.

2.2.1Passivesafety

Passive safety includes the performance of airbags and seat belts. The indicators of the airbags are interrelated and affect each other. It is not reasonable to extract the individual indicators to divide the grade interval. It is more reasonable to judge its safety from the working efficiency of the entire airbag module. According to the opinions of experts, the safety of airbags should be combined with the degree of its assistance to the performance of the vehicle, such as the installation position, number of airbags, and cooperation with other safety devices. Then the performance is comprehensively judged and set as a qualitative index. If the basic requirements of national standards are not met, then “one vote veto” shall be implemented.

Regarding the performance of seat belts, in view of their importance in passive safety of automobiles, it is advisable to make “star downgrading” conditions restriction on seat belt indicators based on expert opinions. The rating down conditions are: if the safety belt performanceC11fuzzy comprehensive result is two-star or more lower than the automotive textile safety performance overall evaluation A fuzzy comprehensive result, then the overall evaluation result shall be lowered by one star. The grade indexes can be divided into qualitative indexes and quantitative indexes, and the quantitative index among them can be fixed and graded to obtain the grade interval as shown in Table 1. Among them, the tensile strength, which is more important in practical applications, is determined as the “one vote veto” indicator according to expert recommendations.

Table 1 Evaluation index grade division of seat belts

2.2.2Post-accidentsafety

For the post-accident safety, including the flame retardancy of interior parts and the toxicity of smoke and gas generated during the combustion process, combined with expert opinions, the three evaluation indicators of flame spread rate, smoke generation index and smoke production concentration were graded according to the national standard, and the classification is shown in Table 2.

Table 2 Evaluation index grade division of post-accident safety

2.2.3Ecologicalsecurity

The indicators included in ecological safety, combined with expert opinions, are graded according to national standards and test methods, as shown in Tables 3-4, including the noise reduction coefficient, atomization value, waterproof performance, strength retention in physical safety, odor characteristics, formaldehyde content in chemical safety, color fastness, anti-moth strength in biological safety, stain resistance, antibacterial property, mildew resistance.

Table 3 Evaluation index(u25-u43) grade division of ecological safety

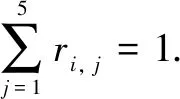

Table 4 Evaluation index(u44-u46) grade division of ecological safety

2.3 Determining weight vectors and fuzzy synthesis

From the conclusion drawn in the previous section, for a certain automotive textile, after completing the single index evaluation of these 46 indexes related to safety performance, the indexes are arranged withrias thei-th row, and the following fuzzy matrixRcombining 46 indexes and 5 evaluation levels was obtained[15].

2.3.1Determiningweightvector

In general, the importance of the indicators characterizing the evaluated objects is relative, and the importance of characterizing a certain indicator is the weight,i.e., the indicator weight vector is determined, and the determination method is divided into the subjective weighting method and the objective weighting method according to the degree of subjectivity and objectivity.

Take the weight of factoruiaswi, then the weight vector corresponding to factorUcan be expressed as

W= (w1,w2, …,w46),

wherewi≥0 and ∑wi=1.

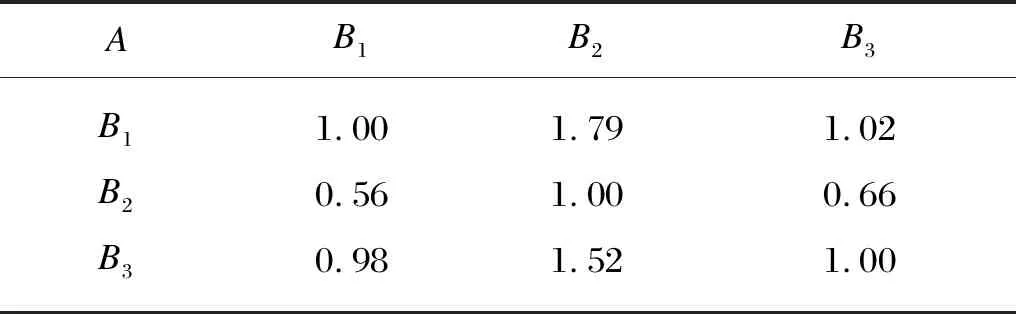

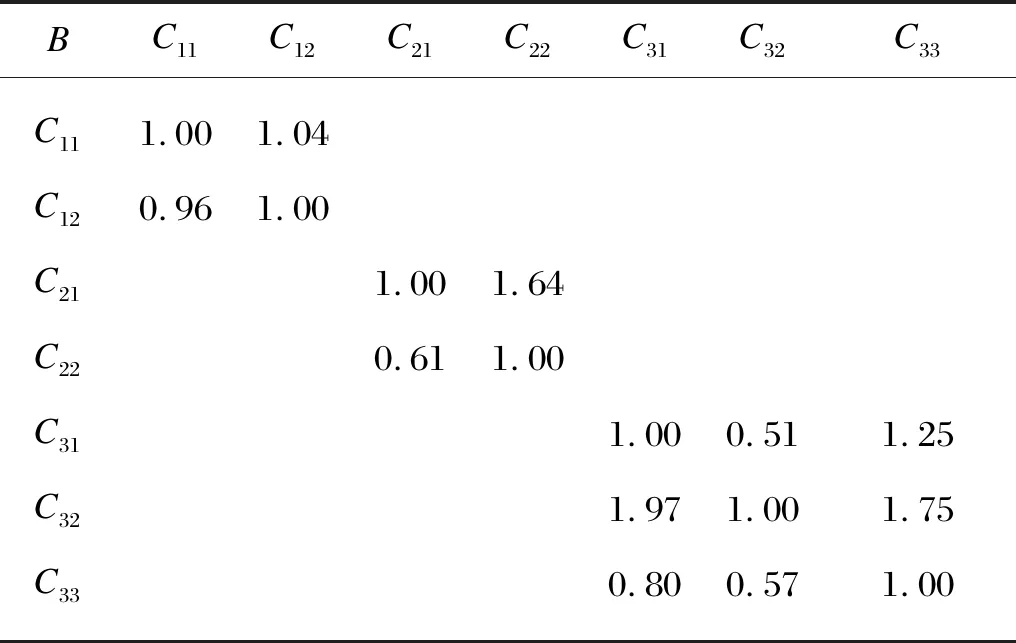

The safety of automotive textiles is a complex system, which is interwoven with various system indicators. The method of combining analytic hierarchy process and expert investigation is used to determine the weight of the evaluation indicators. After two rounds of questionnaires, expert opinions tend to be unified. The final weight result statistics are shown in Tables 5-10.

Table 5 Weight table of A

Table 6 Weight table of B

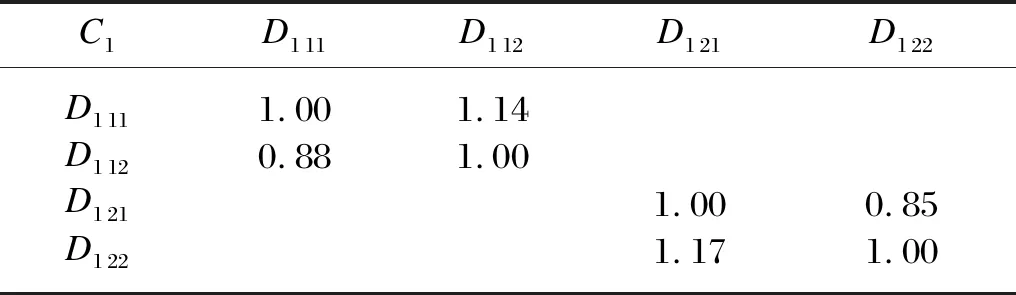

Table 7 Weight table of C1

Table 8 Weight table of C2

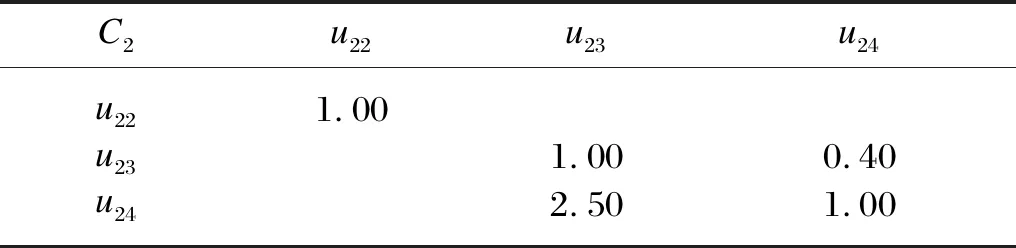

Table 9 Weight table of D1

Table 10 Weight table of C3

(Table 10 continued)

(1) Consistency test

Consistency test on the evaluation matrix was performed, according to the matrix theory, using the following test to evaluate:

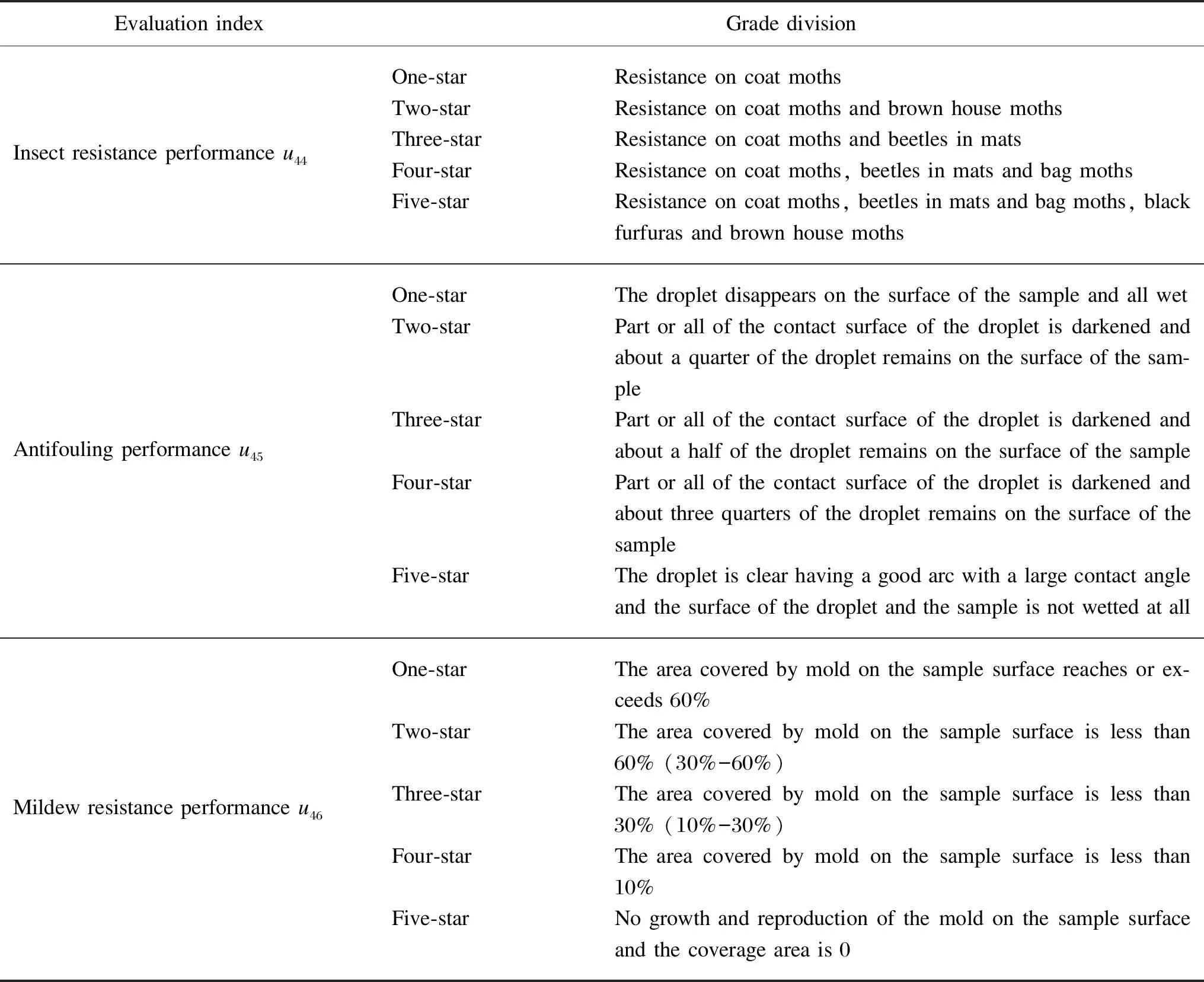

Generally, as the order of the evaluation matrix increased, the difficulty of the matrix having complete consistency also increased. In order to measure the satisfactory consistency of evaluation matrices of different orders, the ratioCr, which is equal toCiand divided by, the average random consistency index of the same orderRi, is introduced andCris called as the random consistency ratio. IfCr≤0.1, the consistency of the evaluation matrix is determined to be satisfactory; ifCr>0.1, the matrix needs to be further revised to achieve satisfactory consistency[16]. Among them, the value ofRiis only related to the dimension of the matrix. The results of theRivalue of the judgment matrix of the 3rd to 15th order are shown in Table 11. Based on this, we obtain Table 12, and the results show that they all have satisfactory consistency.

Table 11 Ri values of the matrix of 3rd-15th order

Table 12 Results of consistency test

(2) Hierarchical single ordering

For each index except the plan level, the relative weight between the corresponding lower level indexes was calculated. Specifically, to the calculation process, it comes down to calculating the maximum feature root of the evaluation matrix and its corresponding eigenvector. In order to facilitate the solution process, the eig function in MATLAB is used to directly calculate the feature root and eigenvector, and the involved format is:

[V,D]=eig (A).

The matrix corresponding toVis composed of the eigenvectors of matrixA, and the matrix corresponding toDis composed of the eigen roots of matrixA; where the diagonal elements in matrixDare the eigen roots, and the remaining elements are 0. After normalizing the column of elements with the maximum feature root inD, the result is the weight of the corresponding element.

(3) Hierarchical total ordering

Repeat the hierarchical single ordering, along with the hierarchical structure of the index system from top to bottom, the eigenvectors and feature roots of each evaluation matrix layer by layer are calculated, and this is used as the basis to calculate the total layer ranking, and then the relative weight of the lowest level index to the highest layer indicator. Thus, the weight vector corresponding to the index setUcan be obtained, expressed asW= (w1,w2, …,w46). The obtained weights are shown in Table 13.

Table 13 Results of consistency test

2.3.2Fuzzysynthesis

After obtaining the evaluation model data of matrixRand weight vectorW, the fuzzy synthesis method is used to analyze the data of the vector matrix and mathematically synthesize it to obtain the overall view membership of the automotive textiles relative to each evaluation star grade.

Take the fuzzy comprehensive evaluation result vector asS=(s1,s2,s3,s4,s5), which can be expressed as

S=W∘R=(b1,b2,b3,b4,b5),

ChooseM(,⨁) fuzzy synthesis operator to calculateS, and normalizeS,i.e., let ∑sj=1.

The result of the fuzzy comprehensive evaluation finally obtained was observed, and the vectorS= (s1,s2,s3,s4,s5), wheresjindicates that the automotive textile belongs to the measurement of the evaluation levelvj. Since the composition of the membership results is a fuzzy vectorS, rather than a point value, it can provide more abundant information than other methods.

3 Case Study

In order to verify the reliability, stability and adaptability of the overall evaluation model of the safety performance of automotive textiles, the above system model was verified as follows. The verification principle mainly considered the effectiveness of the model in extreme cases. Therefore, three sets of verification tests Ⅰ, Ⅱ and Ⅲ were set, in which Ⅰ was a “one vote veto” sample for airbags, Ⅱ was a “star downgrading” sample for seat belts, and Ⅲ was a conventional sample.

3.1 Cases index evaluation

As can be seen from the content of the previous chapter, the indicators of “one vote veto” indicators and their veto conditions, as well as the qualitative “star downgrading” indicators, are shown in Table 14 and Table 15 respectively.

Table 14 One vote veto indicators and conditions

Table 15 Qualitative indicators

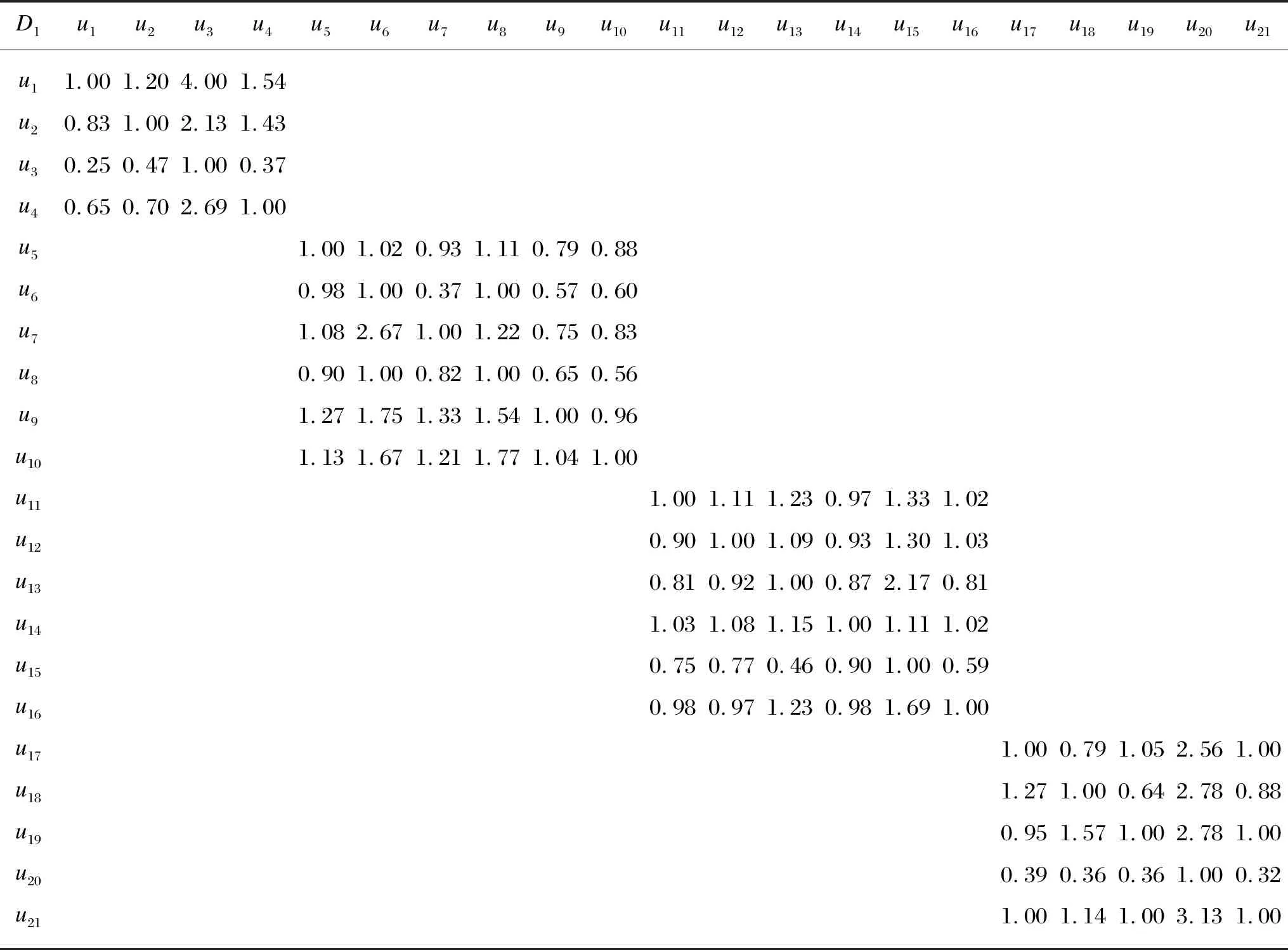

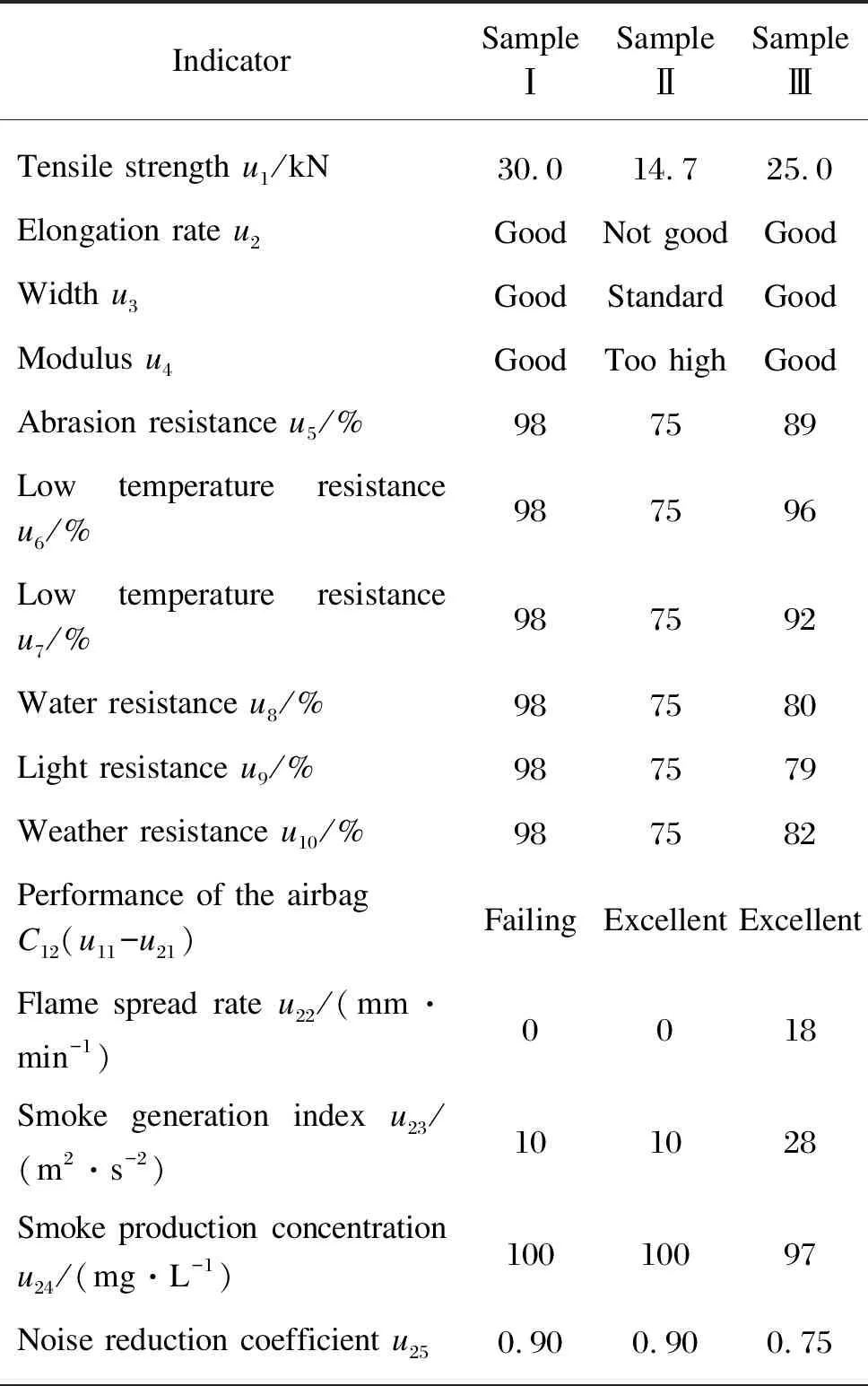

The indicators are now evaluated according to the case verification requirements. The specific evaluation values are shown in Table 16.

Table 16 Evaluation values of the three samples

(Table 16 continued)

3.2 Membership function calculation

After completing the single index evaluation on the 46 indexes of samples Ⅰ, Ⅱ and Ⅲ, respectively, takingrias theith line, the membership level matrix is obtained for the index of the plan layer of the criterion layersB1,B2andB3, and three fuzzy matrices are recorded asRb1,Rb2andRb3. Among them, sample Ⅰ is directly rated as one star because the airbag index meets the “one vote veto” condition. The membership matrices of sample Ⅱ and sample Ⅲ are shown as follows.

sample Ⅱ sample Ⅲ

3.3 MATLAB fuzzy synthesis

The determination of the weight vector of factors adopts Delphi method and analytic hierarchy process. The process of using MATLAB software is described in section 1 of this article. Thus, the weight vector and membership matrix of the indexes are obtained. The following will be mathematical synthesis using MATLAB.

Firstly, input vectors and matrices in MATLAB, includingRb1,Rb2, andRb3, and weightsWb1,Wb2, andWb3.

Secondly, enter the MATLAB programming code for calculatingS1,S2, andS3as

S1=Wb1×Rb1,

S2=Wb2×Rb2,

S3=Wb3×Rb3.

Then, the obtainedS1,S2, andS3are combined to obtain a fuzzy comprehensive evaluation matrixR, which is used as a first-level index evaluation matrix, as follows:

R=[S1S2S3].

Finally, according to the calculation principle of the fuzzy operator, the multiplication in MATLAB is used to mathematically synthesize the weight vectorWand the evaluation matrixR, and the result vectorSof the fuzzy comprehensive evaluation can be obtained.

S=W×R.

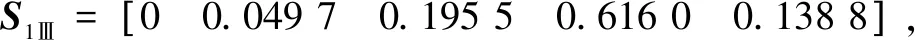

The calculated result vector of sample Ⅱ is

Similarly, the result vector of sample Ⅲ is

From the above results, it can be found that for sample Ⅱ, the evaluation level belonging to the evaluation level of “five-star” is the highest, which is 0.642 4. However, considering that the highest evaluation level of its seat belt performance indexC11is “two-star”, which is three stars less than the overall evaluation star grade, the star grade award of the sample is rated as “four-star”. For the sample Ⅲ, the measure of the evaluation level belonging to the level of “four-star” is the highest,i.e., 0.767 2, and the measure of the performance indexC11of the seat belt is also the highest at the level of the “four-star”, so the sample Ⅲ can be rated as “four-star”. From this cases analysis, it can be seen that this comprehensive system can effectively evaluate the safety performance of automotive textiles with good practicality, can intuitively provide consumers with information on the vehicle’s textile safety performance level, and can effectively promote car manufacturers to improve the safety performance of textiles.

4 Conclusions

This article studies the overall evaluation method of the safety performance of automotive textiles. In the condition that the field of the evaluation of the safety performance of automotive textiles is almost blank, the developed analytic hierarchy process and fuzzy evaluation are introduced into the evaluation system, and the “one vote veto” and “star downgrading” methods are also introduced, so that the evaluation of individual safety devices that is particularly important for automotive textiles can be more comprehensive and objective. At the same time, MATLAB mathematical tools are also used in the implementation process for related mathematical calculations, simplifying the calculation of the overall evaluation process of the safety performance of automotive textiles, and a complete overall evaluation system of the safety performance of automotive textiles was finally obtained. The test parameters under extreme conditions were selected for fuzzy synthesis through case analysis. The calculation of the evaluation results verified the feasibility and effectiveness of the system.

At present, the overall evaluation of the safety performance of automotive textiles is still blank in the research field, and there are many methods in the field of comprehensive evaluation, each with its own strengths and its own characteristics. This study uses the method combining the analytic hierarchy process and the fuzzy comprehensive evaluation method. Although this method is relatively mature in theory and application, there are still some problems that need to be further studied. For example, the division of evaluation levels is not rigorous and needs improvement; the citation of foreign standards is not comprehensive yet, and the technical indicators of the 46 indicators at home and abroad cannot be compared one by one; the number of sample questionnaires for experts is not sufficient, and the evaluation methods and the results may not have strong representation,etc. The above-mentioned problems require further research for further correction and improvement.

Journal of Donghua University(English Edition)2020年4期

Journal of Donghua University(English Edition)2020年4期

- Journal of Donghua University(English Edition)的其它文章

- Preparation of ZnO Nanomaterials and Their Photocatalytic Degradation of Organic Pollutants

- Improved Fibroblast Adhesion and Proliferation by Controlling Multi-level Structure of Polycaprolactone Microfiber

- Zero-Sequence Current Suppression Strategy for Open-End Winding Permanent Magnet Synchronous Motor Based on Model Predictive Control

- Preserving Data Privacy in Speech Data Publishing

- Method for Detecting Fluff Quality of Fabric Surface Based on Support Vector Machine

- Undrained Stability Analysis of Three-Dimensional Rectangular Trapdoor in Clay