Optimization of Steam Explosion Process Condition for Extracting Polysaccharides from Pseudostellaria heterophylla by Response Surface Methodology

PAN Hui-qing, ZHANG Zhao-kun, ZHANG Yan-da*, LIU Han-ru, YUAN Ji-duan, ZHAO Qi,

1. Municipal Enterprise Technical Center of Fujian Beidi Pharmaceutical Co., Ltd., Ningde 355300, PRC;

2. Henan Zhengdaoqibao Environmental Protection Technlology Co., Ltd., Hebi 458000, PRC;

3. School of Pharmacy Sciences, Southwest University, Chongqing 400715, PRC;

4. Zherong County Pharmaceutical Development Bureau, Ningde 355300, PRC;

5. Fujian Ningde Beidi Bio-technology Co., Ltd, Ningde 355300, PRC

Abstract 【Objective】To optimize the steam explosion process condition for extracting polysaccharides from Pseudostellaria heterophylla. 【Method】The effects of steam pressure, pressure-maintaining time and material moisture content on the extraction of polysaccharides from Pseudostellaria heterophylla were studied by response surface methodology based on Box-Behnken design. 【Result】The findings showed that each factor could significantly affect the test index, and the optimum condition was as follows: steam pressure 1.50 Mpa, pressuremaintaining time 46 s and material moisture content 46%. Under this condition, the verified experimental value of polysaccharides from Pseudostellaria heterophylla was 39.32%, indicating a relative standard deviation of 2.73% from the predictive value. Meanwhile, scanning electron microcopy (SEM) images showed that the surface physical structure of Pseudostellaria heterophylla was irregularly broken and cracked, which means the physical structure of Pseudostellaria heterophylla was changed and destroyed at the cellular level. 【Conclusion】This experiment provides a new approach for the extraction of polysaccharides from Pseudostellaria heterophylla, as well as a reference for the resource utilization of Pseudostellaria heterophylla.

Key words Pseudostellaria heterophylla; Polysaccharides; Extraction technology; Steam explosion; Response surface optimization

1. Introduction

Pseudostellaria heterophylla, commonly known as Tai Zi Shen in China, is the dry roots of Hai Er Shen in Caryophyllaceae family and a famous tonic herb originally included in the New Compilation of Materia Medica of Qing Dynasty. It mainly grows in Fujian, Guizhou, and Jiangsu[1-2], and is widely planted in Zherong of Fujian Province[3]. The medical ingredients of Pseudostellaria heterophylla are rich in polysaccharides, saponins, and cyclopeptides, providing valuable medical and nutritive efficacy[4]. According to clinical trials, Pseudostellaria heterophylla is beneficial to our spleens and lungs[5]; it is oxidation resistant[6-7], anti- inflammatory[8], and applicable to immune regulation[9]and probiotic strains[10]. Clinical studies of modern Chinese medicine have verified the multiple biological activities of polysaccharides in most herbs. It is also reported that the polysaccharides of Pseudostellaria heterophylla are highly conducive to immunity[11], cell differentiation[12], antioxidation[7], and adjuvant diabetes treatment[13]. The extraction of polysacc- harides from Pseudostellaria heterophylla is mainly done by ultrasonic waves or microwave-assisted hot water treatment, and there are no reports on steam explosion process (SEP) on this respect. Response surface methodology (RSM) explores the optimal technological parameters by mathematical modeling and statistical regression analysis based on definitive tests[14]. In this paper, RSM is used to optimize the technological parameters of SEP in the extraction of polysaccharides from Pseudostellaria heterophylla and to evaluate the feasibility of SEP in Pseudostellaria heterophylla processing, thus offering a new thought and a novel technological approach for the resource utilization of Pseudostellaria Heterophylla.

2. Materials and Methods

2.1. Materials and apparatus

In June 2019, fresh Pseudostellaria heterophylla were collected from the hilly land in Xiacun village of Zherong (119°52′01.9″E, 27°13′34.5″N), where hilly red earth was the main soil species. After removing the impurities, the samples were dried in an oven at 60℃. The reagents (i.e. anhydrous glucose, phenol, and absolute ethyl alcohol) were homemade and analytically pure.

The laboratory apparatus included a steam explosion bench (Henan Zhengdaoqibao Environ- mental Protection Technology Co., Ltd), an ultraviolet spectrophotometer (Shanghai Metash Instruments Co., Ltd), a thermostat water bath (Tianjin Taisite Instruments Co., Ltd), a pulverizer (Wuhan Haina Electric Appliance Co., Ltd), a drying oven (Beijing Kewei Yongxing Instruments Co., Ltd), an electronic balance (Shimadzu), a horizontal rapid detector (Shanghai Yoke Instrument Co., Ltd), and a scanning electron microscope (Hitachi Limited).

2.2. Experimental procedures

Dry the samples in the oven and grind into fine powder by the pulverizer; accurately weigh 1 g of the powder; measure the initial moisture content (H1) of the substrate by the horizontal rapid detector; take the designed moisture content (H2) as the final value; the difference (H2-H1) between H2and H1indicates the amount of purified water needed for steam explosion; spray this required amount of purified water onto the corresponding mass of Pseudostellaria heterophylla substrate for infiltration in a plastic bag; seal the bag and let it stand for 24 h. Set the steam pressure and the pressure-maintaining time for steam explosion experiment; add 100 g of the material into the explosion cavity each time; collect all the processed material in the cavity at the completion of the explosion experiment; dry the collected materials at constant temperature; measure the indexes of the dried materials and record the data.

2.3. Analytical method

The polysaccharide content in Pseudostellaria heterophylla was determined by the method of LIN Q M[15]et al. Anhydrous glucose was used as the control to plot the standard curve of polysaccharides. The regression equation of the standard curve was y=6.14x+0.035, where R2=0.995 2, y denoted the absorbance value, and x denoted the concentration of glucose.

The operation of scanning electron microscope and the calculation of related measurements were in accord with the method of PAN H Q[10]et al.

2.4. Experimental design

Before starting the steam explosion test, it is necessary to define the steam pressure (X1), pressuremaintaining time (X2), and substrate moisture content (X3) according to the Box-Behnken Design (BBD) and the results of factorial experiment in the early stage of this research. The content of polysaccharides in Pseudostellaria heterophylla was taken as the indexing factor. Design-Expert 8.0.6 was used for response surface analyses. Each factor included three levels (coded as -1, 0, and 1). The factors and levels for response surface experiment were listed in Table 1.

3. Results and Analysis

3.1. Design and results of response surface experiment

In Table 2 there are the results and predictive indexes of the response surface experiment for extracting polysaccharides from Pseudostellaria heterophylla substrates by steam explosion process.

3.2. Mathematical modeling and variance analysis

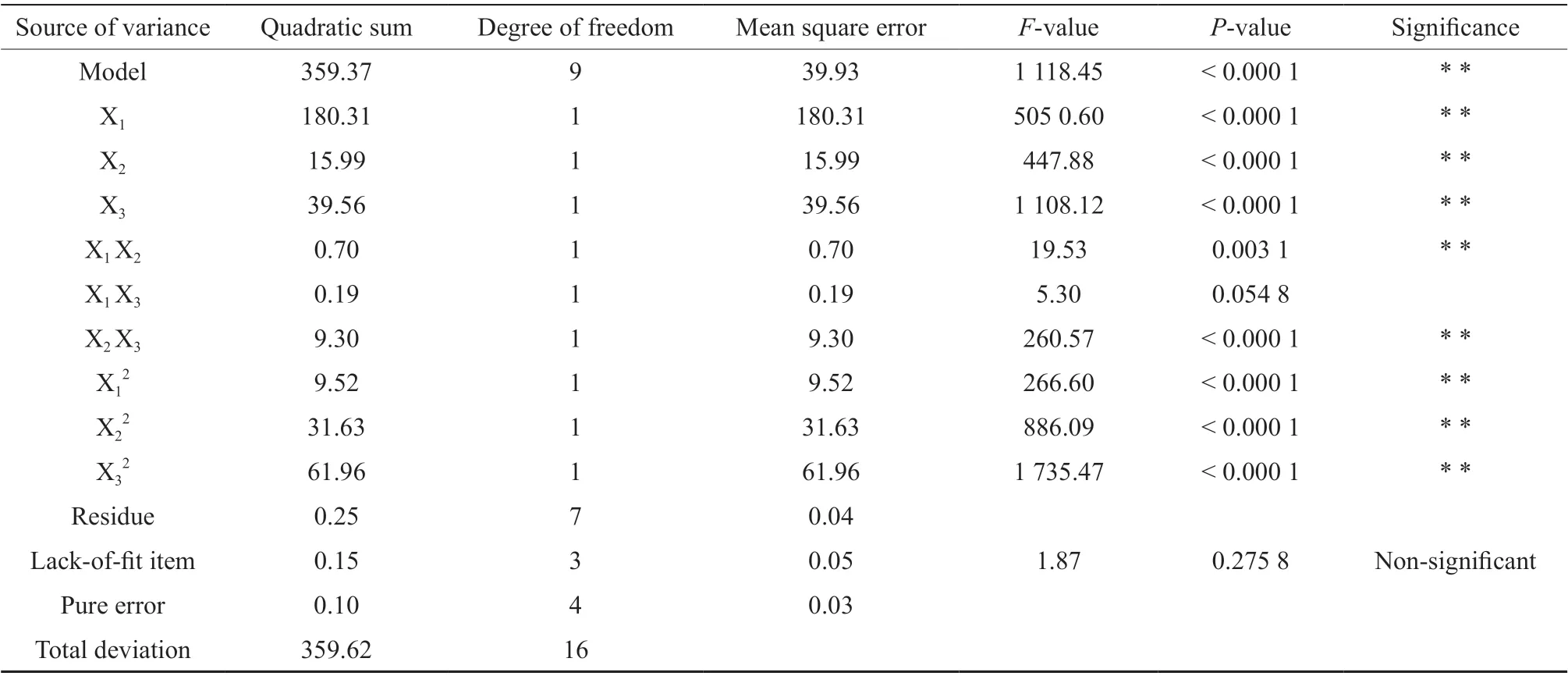

The fit regression and calculation of the measured polysaccharide contents were done by Design-Expert 8.0.6. A quadratic response surface regression model was built based on Y=37.03+4.75X1+1.41X2- 2.22X3-0.42X1X2-0.22X1X3-1.52X2X3-1.50X12- 2.74X22-3.84X32, and R2=0.998 4. Significancetests and variance analyses were conducted (Table 3). According to the data in Table 3, P<0.000 1 indicated extremely significant regression effects of the model; if the lack-of-fit item was nonsignificant (P=0.275 8 >0.05), it meant the model is statistically meaningful. Stable analytical results could better predict the variation of polysaccharide contents in Pseudostellaria heterophylla substrates by steam explosion process. “R2=0.998 4” indicated high degree of fitting and relatively small errors. The P-values of the steam pressure (X1), pressuremaintaining time (X2), and substrate moisture content (X3) were below 0.000 1, indicating highly significant differences. There was a positive correlation between the F-value of the factor and the polysaccharide content in Pseudostellaria heterophylla substrates. Therefore, the influence of X1, X2and X3on the content of polysaccharide ranked in descending order would be: X1>X3>X2. Among the interactive effects of these three factors, only the effects of factor X1X3(P=0.054 8>0.05) were non-significant. The interactive effects followed the order of X2X3>X1X2>X1X3. The results have proved that this model is applicable to analyze the contents of polysaccharides from Pseudostellaria heterophylla.

Table 2 Experimental design and results of Box-Behnken

Table 3 Variance analysis of the regression model

3.3. Response surface analysis

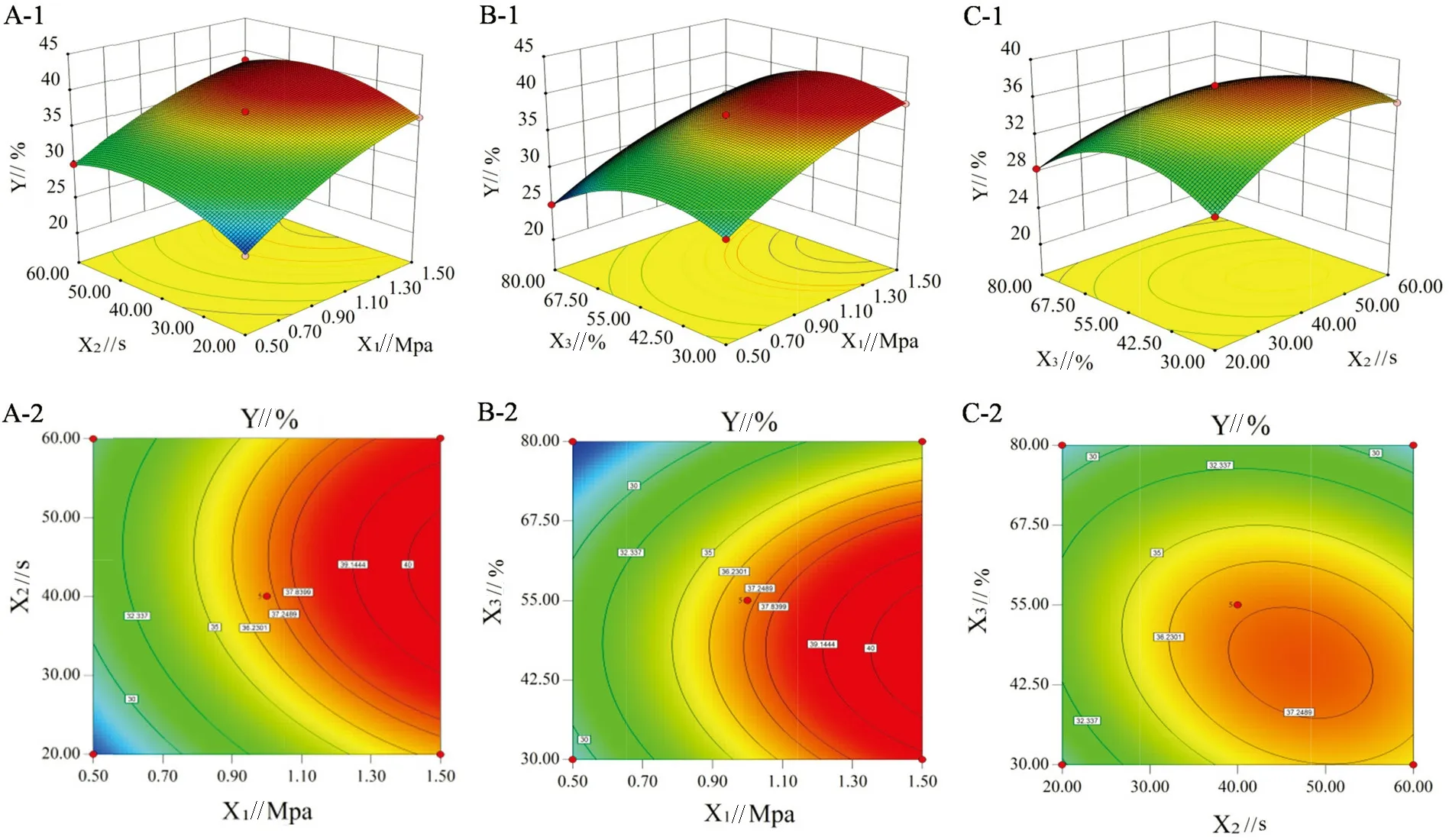

The response surfaces and contours among the factors were plotted in Fig.1 (A-C) based on the regression model to evaluate the pairwise correlations of the three factors with polysaccharide contents and to determine the ranges of their optimal levels. The properties of contours in Fig.1 (A-2, B-2, and C-2) directly reflected the strength of interaction between two factors. Particularly, elliptical contours indicated significant interactions between factors, while the rounded ones represented non-significant interactions[14].

The interaction effects of X1and X2to Y were plotted in Fig.1 (A-1 and A-2). The interaction between X1and X2was quite obvious, and the effect of X1was much stronger than that of X2. The value of Y reached rock bottom at low X1and X2levels, and increased gradually with the rise of factor levels.

As shown in Fig.1 (B-1 and B-2), there were no significant interactions of X1and X3with Y. When X3remained constant, Y tended to increase with X1. Whereas when X3rose, the value of Y would decrease.

Fig.1 (C-1 and C-2) showed the interaction effects of X2and X3to Y. According to the figures, there were significant interactions between these two factors and Y, and the effect of X3was a bit stronger than that of X2. The value of Y tended to increase with the rise of X2and X3level.

3.4. Optimization of process conditions and verification

Based on the analytical results of the experimental data and the Design-Expert model, the conditions of steam explosion process were optimized into steam pressure 1.50 Mpa, pressuremaintaining time 45.75 s, and substrate moisture content 45.62%. These parameters were then modified as follows to conveniently verify their operability: steam pressure 1.50 Mpa, pressure-maintaining time 46 s, and substrate moisture content 46%. A mean polysaccharide content of 39.32% was obtained under the optimized condition. This result approximated to the predictive value (40.87%) of the mathematical model and presented a relative standard deviation of 2.73%, suggesting good reliability of the optimization model. And the polysaccharide content under optimized conditions was 1.41 times of that in the control (raw materials of Pseudostellaria heterophylla).

3.5. SEM analyses of Pseudostellaria heterophylla substrate

Fig.1 Response surface and contour of two-factor interaction to polysaccharide content

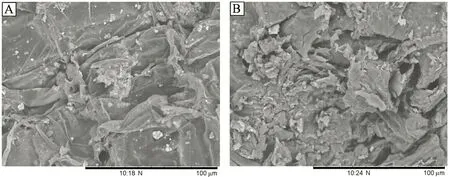

The Pseudostellaria heterophylla substrates were analyzed by SEM to further investigate the possible cause of improved polysaccharide contents under optimized steam explosion condition and the consequent changes in Pseudostellaria heterophylla’s physical properties. Fig.2-A and B were the SEM images of the control and the materials processed by optimized steam explosion, respectively. In Fig.2-A, the surface structure of the unprocessed Pseudostellaria heterophylla was smooth, compact and well-organized without a crack. Whereas in Fig.2-B, the materials treated by optimized steam explosion process were broken with obvious cracks on the surface. This means the optimized steam explosion process could effectively change and destroy the physical structure of Pseudostellaria heterophylla’s biomass at the cellular level.

4. Conclusion and Discussion

Fig.2 SEM images of Pseudostellaria heterophylla (A) before and (B) after response surface optimization (1 000×)

In this paper, a mathematical model was constructed based on Box-Behnken Design to investigate the extraction of polysaccharides from Pseudostellaria heterophylla. According to the results, all the experimental factors could significantly affect the contents of polysaccharides and the optimized process condition was: steam pressure 1.50 Mpa, pressure-maintaining time 46 s, and substrate moisture content 46%. The tested value of polysaccharide content in Pseudostellaria heterophylla was 39.32% under this condition, which was 1.41 times of that in the control and indicated a relative standard deviation of 2.73% to the predictive value. Meanwhile, the optimized steam explosion process could effectively change and destroy the physical structure of Pseudostellaria heterophylla’s biomass at the cellular level. The steam explosion process was commonly divided into two stages as vapor-phase cooking and instantaneous explosion[16]. The high-pressure steam in the first stage formed an energy field, thus maintaining a dynamic balance of energy inside and outside the cell wall during the pressure-maintaining process. In the second stage, the shielding effect of cell wall would accelerate the formation of pressure difference inside and outside the cell wall, easily leading to the fracture of cell wall under radial shear force and expansive force. This is theoretically conducive to the dissolution of polysaccharide components and thus improves the contents of polysaccharides. This research provides a new way to extract polysaccharides from Pseudostellaria heterophylla and a theoretical support for the industrial application of resources.

Agricultural Science & Technology2020年2期

Agricultural Science & Technology2020年2期

- Agricultural Science & Technology的其它文章

- Effects of γ Irradiation on Microorganisms in Edible Fungi Matrix

- Investigation of Salt Stress Response Mechanisms Using Mirna Sequencing of Salt Tolerant and Salt Sensitive Jute Genotypes

- Study on Extraction Method of Carotenoids from Citrus Leaves

- Analysis of Rhizosphere Microbial Community Structure in Different Pathogenesis Stages of Watermelon Fusarium Wilt

- A Study on Planting Adaptability of Various Soybean Varieties in Hengyang

- Analysis on Some Agronomic Characters and Pedigree in Hezihao Series Peanut Varieties