BaTiO3-ZnNb2O6陶瓷介电及储能性能研究

王通, 王渊浩, 杨海波, 高淑雅, 王芬, 鲁雅文

BaTiO3-ZnNb2O6陶瓷介电及储能性能研究

王通1, 王渊浩1, 杨海波1, 高淑雅1, 王芬1, 鲁雅文2

(1. 陕西科技大学 材料科学与工程学院, 陕西省无机材料绿色制备与功能化重点实验室, 西安 710021; 2. 咸阳陶瓷研究设计院有限公司, 咸阳 712000)

采用固相法制备(1–)BaTiO3-ZnNb2O6(=0.5mol%, 1mol%, 1.5mol%, 2mol%, 3mol%, 4mol%) (简称BTZN)陶瓷, 研究了BTZN陶瓷的烧结温度、结构、介电性能和铁电性能。BTZN陶瓷烧结温度随着ZnNb2O6含量增加逐渐降低。XRD结果表明当ZnNb2O6含量达到3mol%时出现第二相Ba2Ti5O12。介电测试结果表明随ZnNb2O6含量的增加, BTZN陶瓷介电常数逐渐减小, 而介电常数的频率稳定性逐渐增强。介电温谱表明所有BTZN陶瓷均符合X8R电容器标准。BTZN陶瓷的极化强度值随着ZnNb2O6含量的增加逐渐降低。当=4mol%时, BTZN陶瓷获得240 kV/cm的击穿电场和1.22 J/cm3的可释放能量密度。

钛酸钡; 陶瓷; 介电性能; 储能性能

钛酸钡(BaTiO3)是一种典型的ABO3型钙钛矿结构的铁电体材料, 因其优良的介电、压电以及铁电性能[1]被广泛应用于多层陶瓷电容器[2], 铁电存储器[3], 传感器及非线性电光器件等[4-5]。BaTiO3(BT)陶瓷介电常数(r)非常高, 室温为1500~2000 ℃, 在居里温度(C)附近高达10000 ℃以上[6],r与温度呈非线性关系, 导致r随温度变化率较大, 此外r对电场、频率和压力等条件变化也非常敏感。BT陶瓷介电损耗(tan>0.05)相对较高。BT陶瓷饱和极化强度值(s>27 μC/cm2)高[7], 而剩余极化强度值(r> 14.7 μC/cm2)也很高[8]。BT陶瓷击穿电场(BDS< 100 kV/cm)较低[9]。

高r和大s使BT陶瓷成为一种非常有潜力的无铅陶瓷储能电容器材料[10-12], 可应用于激光脉冲武器和混合电动车等领域[13-19]。但高r和低BDS导致BT陶瓷储能性能并不良好[20-22]。近年来许多研究人员尝试在BT的A位和B位引入离子合成BT基弛豫铁电体陶瓷从而降低r: Huang等[23]用Sol-Gel法合成Ba0.4Sr0.6TiO3陶瓷, 在240 kV/cm电场强度下获得1.23 J/cm3能量存储密度(), 和94.52%能量存储效率()。Puli等[24]用固相法制备0.85Ba(Zr0.2Ti0.8)O3-0.15(Ba0.7Ca0.3)TiO3陶瓷, 在170 kV/cm下获得0.94 J/cm3的和94.52 %的。Sun等[25]用固相法合成Ba1–xSm2x/3Zr0.15Ti0.85O3陶瓷,当=0.003获得1.15 J/cm3可释放能量密度(rec)和92%的。此外, 在BT中加入Bi基化合物合成BT-Bi基弛豫铁电体陶瓷成为近几年研究热点: Wang等[26]用固相法合成(1–)BaTiO3-Bi(Mg2/3Nb1/3)O3陶瓷, 当=0.1在143.5 kV/cm下获得1.13 J/cm3的rec和92.4%的。Hu等[27]用固相法合成0.88BaTiO3- 0.12Bi(Mg1/2Ti1/2)O3陶瓷, 在224 kV/cm下获得1.81 J/cm3的rec和88%的。Yuan等[28]用固相法合成0.9BaTiO3-0.1Bi(Zn0.5Zr0.5)O3陶瓷, 在264 kV/cm下获得2.46 J/cm3的W和86.8%的。Li等[29]用固相法合成0.88BaTiO3-0.12Bi(Li0.5Nb0.5)O3陶瓷, 在270 kV/cm下获得2.03 J/cm3的rec和88%的。上述BT基和BT-Bi基弛豫铁电体陶瓷P均随着离子化合物含量增加逐渐减小, 储能性能得到明显改善, 然而s急剧降低成为储能性能提高的瓶颈。

为了提高BT基陶瓷BDS, 许多研究人员在BT基或BT-Bi基陶瓷中添加玻璃来提高致密度, 同时达到降低烧结温度的效果。Wang等[30]在BT陶瓷中添加BaO-SrO-TiO2-Al2O3-SiO2-BaF2玻璃, 当玻璃添加量为7wt%, BDS提高到94.6 kV/cm, 获得0.32 J/cm3的rec。Wang等[31]在Ba0.4Sr0.6TiO3陶瓷中添加BaO-B2O3-SiO2-Na2CO3-K2CO3玻璃, BDS提高到280.5 kV/cm, 获得0.72 J/cm3的rec。Yang等[32]在Ba0.4Sr0.6TiO3陶瓷中添加Bi2O3-B2O3-SiO2玻璃, 当玻璃添加量为9wt%, BDS提高到279 kV/cm, 获得1.98 J/cm3的rec和90.57%的。Yang等[33]在Ba0.85Ca0.15Zr0.1Ti0.9O3陶瓷中添加B2O3-Al2O3-SiO2玻璃, BDS提高到250 kV/cm, 当玻璃添加量为5wt%, 获得1.15 J/cm3的rec。Wu等[34]在Ba0.4Sr0.6Zr0.15Ti0.85O3陶瓷中添加SrO-B2O3-SiO2玻璃, BDS提高到220 kV/cm, 当玻璃添加量为5wt%, 获得0.45 J/cm3的rec和88.2%的。Wang等[35]在0.85BaTiO3-0.15Bi(Mg2/3Nb1/3)O3陶瓷中添加B2O3-Na2B4O7-Na2SiO3玻璃, BDS提高到240 kV/cm, 当玻璃添加量为3wt%, 获得1.26 J/cm3的rec和80.9%的。上述BT基和BT-Bi基玻璃陶瓷BDS均随着玻璃含量增加而增大, 但同样存在玻璃含量高时s大幅降低现象。此外在BT陶瓷中添加低温晶相助烧剂也可改善BT基陶瓷BDS。铌酸锌(ZnNb2O6)[36]是一种典型低温烧结微波介质陶瓷。Wang等[37]用固相法合成BaTiO3-ZnNb2O6(BT-ZN)陶瓷, 结果表明添加ZN显著降低BT陶瓷烧结温度。Yan等[38]和Yang等[39]分别用固相法和微波烧结法制备BT-ZN陶瓷, 结果表明添加ZN并未明显改变BT陶瓷C。上述研究发现添加ZN使BT陶瓷BDS和储能性能都得到改善, 但均未系统性研究ZnNb2O6含量对BT陶瓷介电常数频率稳定性和温度稳定性, 以及对极化强度值和储能性能的影响。

本工作用固相法制备了BaTiO3-ZnNb2O6(BT-ZN)陶瓷, 系统地研究了ZnNb2O6含量对BT-ZN陶瓷烧结温度、相结构、显微结构、介电常数的频率稳定性和温度稳定性、击穿电场、极化强度值和储能性能的影响。

1 实验方法

1.1 样品制备

以分析纯BaCO3、TiO2、ZnO和Nb2O5为原料, 固相法制备(1–)BaTiO3-ZnNb2O6(=0.5mol%, 1mol%, 1.5mol%, 2mol%, 3mol%, 4mol%) (BTZN1-6)陶瓷。先分别称料BaCO3、TiO2、ZnO和Nb2O5,球磨6 h, 然后分别在1150和900 ℃煅烧2 h合成BT和ZN预烧粉, 并将预烧粉二次球磨。将BT和ZN预烧粉按配比称料球磨6 h, 干燥后加入PVA (5wt%)造粒, 在150 MPa下压制成直径12 mm, 厚度1~ 2 mm圆片生坯。600 ℃排胶4 h后在1100~ 1350 ℃下烧结2 h成瓷。用被银法在850 ℃保温20 min制备厚度1 mm的介电性能测试样品。用喷金法制备厚度0.3 mm的铁电性能测试样品, 电极直径为6 mm。

1.2 性能测试

采用阿基米德排水法测试样品密度。采用X射线衍射仪(XRD, D8 Advance, Bruker, Germany)测试样品相结构。采用扫描电子显微镜(SEM, Verios 460, FEI, USA)观察抛光热腐蚀样品表面显微结构。采用阻抗分析仪(E4990A, Aglient, USA)测试样品介电性能频率稳定性, 频率范围为100 Hz~10 MHz。采用LCR电桥(E4980A, Aglient, USA)测试样品介电性能温度稳定性, 温度范围为–100~500 ℃, 升温速率3 ℃/min, 测试频率为100 Hz、1 kHz、10 kHz、100 kHz和1 MHz。采用铁电测试仪(Premier II, Radiant, USA)测试样品室温下电滞回线, 测试频率为10 Hz。

2 结果和讨论

2.1 BTZN陶瓷的结构分析

图1是BTZN陶瓷不同烧结温度的密度, 插图为不同ZN含量BTZN陶瓷最佳烧结温度和密度, BTZN陶瓷最佳烧结温度随ZN含量增加从1275 ℃ (BTZN1)降低到1200 ℃(BTZN6)。纯BT陶瓷烧结温度高达1375 ℃[3], 而ZN陶瓷烧结温度仅有1150 ℃[36], 说明添加ZN有效降低了BTZN陶瓷烧结温度。而最佳烧结温度下BTZN陶瓷密度随ZN含量增加从5.808 g/cm3(BTZN1)降低到5.701 g/cm3(BTZN6), 主要由于ZN陶瓷的理论密度(5.645 g/cm3)比BT陶瓷(6.018 g/cm3)低[37]。

图2(a)是BTZN陶瓷XRD图谱, 结果表明所有样品主晶相衍射峰为BaTiO3(No. 050626)。当ZN含量达到3mol%时出现ZnNb2O6(No. 371371)和第二相Ba2Ti5O12(No. 170661)的衍射峰[37]。

图2(b)是BTZN陶瓷31°到32°放大图谱, 衍射峰随ZN含量增加向低角度方向移动, 说明晶面间距变大。通常容差因子在0.79~1.1可形成稳定钙钛矿结构, 容差因子计算公式[40]:

式(1)中: rA——A位阳离子半径; rB——B位阳离子半径; rO——氧离子半径。Zn2+取代A位和B位容差因子分别为0.728和0.909, 而Nb5+分别为0.718和0.926。Zn2+(0.074 nm)和Nb5+(0.070 nm)远小于A位Ba2+(0.135 nm), 比B位Ti4+(0.068 nm)略大。所以Zn2+和Nb5有可能取代B位Ti4+, 增大B–O八面体体积, 导致晶面间距增大。

图2 (a)BTZN陶瓷XRD图谱和(b)31°~32°放大图谱

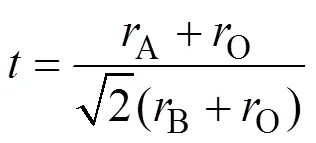

图3是BTZN陶瓷的抛光热腐蚀SEM照片, 从图中可见所有样品均很致密, 晶粒尺寸随ZN含量增加显著减小, 说明ZN抑制BTZN陶瓷晶粒生长, 晶粒尺寸减小非常有利于提高陶瓷BDS[35]。

2.2 BTZN陶瓷的介电性能

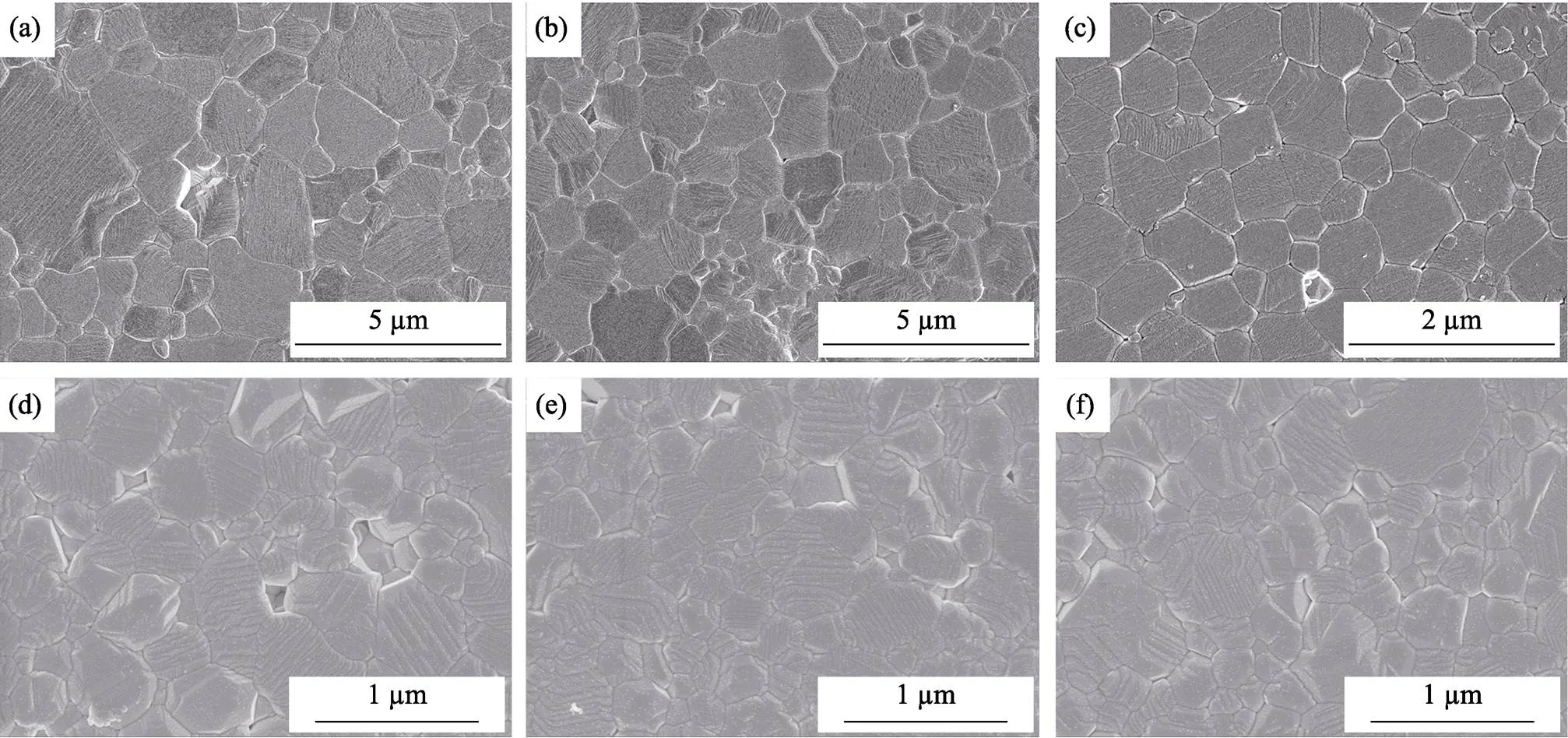

图4(a, b)是BTZN陶瓷介电常数(r)和介电损耗(tan)随频率变化的曲线, BTZN陶瓷r和tan都随ZN含量增加逐渐降低。100 Hz下r从3923 (BTZN1)降低到1604(BTZN6), tan从0.013(BTZN1)减小到0.006(BTZN6), 10 MHz下所有样品tan<0.05, 这是由于ZN的r和tan都远远低于BT[36]。所有BTZN陶瓷r随频率升高逐渐降低, 是由于不同极化机制响应频率不同造成的。低频下电子位移极化、离子位移极化和偶极子取向极化等各种机制都对r有贡献, 高频时只有电子位移极化和离子位移极化机制[35]。BTZN1陶瓷r随频率升高降低较为明显, 随ZN含量增加, BTZN陶瓷r表现出良好的频率稳定性, 说明ZN显著减弱了BTZN陶瓷介电极化。

图3 BTZN陶瓷热腐蚀的SEM照片

(a) BTZN1; (b) BTZN2; (c) BTZN3; (d) BTZN4; (e) BTZN5; (f) BTZN6

图4 BTZN陶瓷的介电性能频率稳定性

(a) Frequency dependence of dielectric constant (lines are linear fitting results) with inset showing the fitting values ofandwith different ZN content, and (b) frequency dependence of dielectric loss, (c), and (d)as a function of ZN content

为了进一步研究ZN含量对BTZN陶瓷ε随频率变化的影响, 我们定义了一个公式:

式(2)中:r()——频率为时的r;——测试频率。图4(a)中插图是线性拟合斜率和截距的拟合值与ZN含量关系。随ZN含量增加, 斜率从114.7(BTZN1)减小到26.6(BTZN6), 说明r随频率变化率越来越小。截距和r减小规律一致, 从4195(BTZN1)减小到1670(BTZN6)。

我们通过定义频率电容系数(Frequency coefficient of capacitance,)来描述BTZN陶瓷r频率稳定性:

式(3)中:100 Hz——频率为100 Hz时;C——频率为时图4(c)是随频率变化, 所有BTZN陶瓷均随频率升高逐渐减小, 是由于r随频率升高逐渐减小。为了进一步描述ZN含量对影响, 图4(d)是随ZN含量变化曲线, 在相同测试频率下均随ZN含量增加逐渐增大, 10 MHz下从–14.85%(BTZN1)提高到–8.45%(BTZN6), 说明ZN添加有利于提高BTZN陶瓷r频率稳定性。

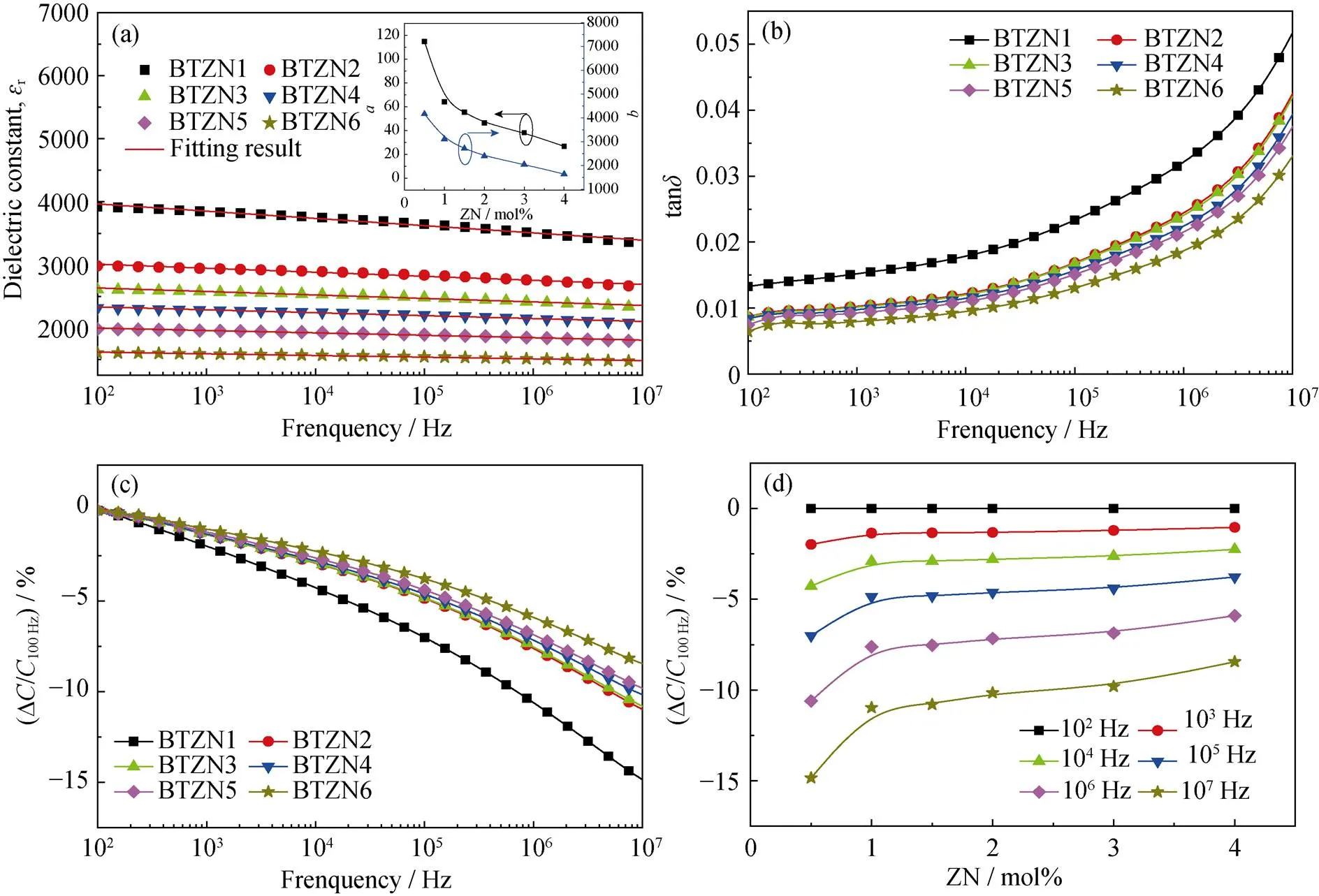

图5是BTZN陶瓷在–100~500 ℃范围内的介电常数和介电损耗与温度的关系。随着ZN含量增加, BTZN陶瓷居里温度(C)并没有明显变化, 而介电常数居里峰展宽较为明显。Yang等[39]采用TEM在BTZN陶瓷晶粒和晶界处都发现了Zn和Nb元素, 说明ZnNb2O6和BaTiO3形成了固溶体。但晶界处Zn和Nb元素含量明显高于晶粒内部, 且观察到BTZN陶瓷存在壳核结构。由于壳核结构的形成和Zn2+和Nb5+取代B位Ti4+造成BTZN陶瓷的化学成分不均匀, 引起弥散相变导致居里峰展宽[38]。C处最大介电常数(m)随ZN含量增加逐渐减小, 1 MHz下m从3956(BTZN1)降低到1694(BTZN6), 主要是由于ZN的r低于BT[36]。C和m的变化和其他在BT中添加ZN的文献报道结果一致[38-39]。用电容温度系数(Temperature Coefficient of Capacitance,)来进一步研究BTZN陶瓷r的温度稳定性[35, 41-42]:

式(4)中:25℃——25 ℃时的电容;T——温度时的电容。

图6是BTZN陶瓷基于25 ℃在1 MHz下的, 虚线表示范围是±15%, 25 ℃的为0, 位于两条虚线中间。从图中可以看出, 所有BTZN陶瓷均满足X8R(–55~150 ℃, ΔC/25℃≤±15%)[43]电容器标准。

2.3 BTZN陶瓷的储能性能

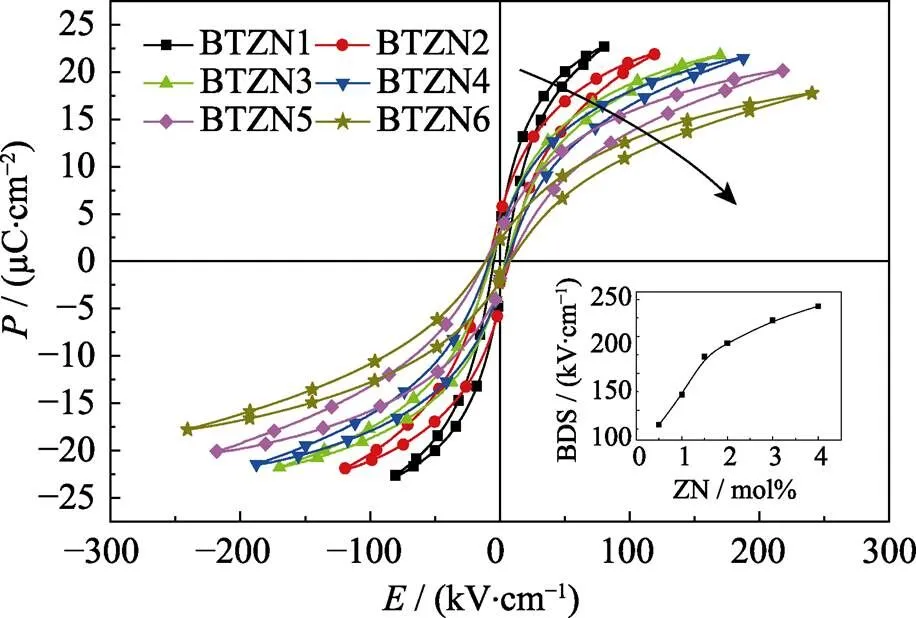

图7是BTZN陶瓷击穿电场下的室温电滞回线(10 Hz)。所有样品表现出瘦电滞回线, 高BDS, 大s和低r, 适合应用于能量存储领域[26]。插图是不同ZN含量的BTZN陶瓷的BDS, BDS随ZN含量增加而增大。从80 kV/cm(BTZN1)增大到240 kV/cm(BTZN6), BDS的提高主要是由于晶粒尺寸减小(图3)。

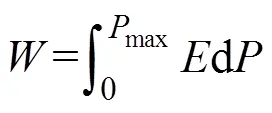

图8(a)是不同ZN含量BTZN陶瓷在100 kV/cm下(最大极化强度值)的max、r和max-r(BTZN1陶瓷的BDS为80 kV/cm, 所以并未出现)。max、r和max-r均随着ZN含量增加逐渐减小。max和r分别从20.26和4.48 μC/cm2(BTZN2)减小到11.67和1.37 μC/cm2(BTZN6), 这是由于添加ZN稀释了BTZN陶瓷的铁电性, 和其他BT-ZN陶瓷的结果一致[37-39]。用-曲线研究BTZN陶瓷储能性能, 曲线由于存在滞回, 充电曲线和放电曲线并不重合。能量存储密度()是充电电流曲线和极化强度轴包围的面积积分, 可释放能量密度(rec)是放电电流曲线和极化强度轴包围的面积积分, 损失掉能量密度(loss)是充放电电流曲线包围的面积积分, 能量存储效率()是rec/。因此,rec,loss和都是衡量能量存储性能的重要指标[35]:

图5 BTZN陶瓷–100~500 ℃的介电常数和介电损耗

(a) BTZN1; (b) BTZN2; (c) BTZN3; (d) BTZN4; (e) BTZN5; (f) BTZN6

图6 BTZN陶瓷1 MHz下基于25 ℃的TCC

图7 BTZN陶瓷击穿电场下室温电滞回线(10 Hz), 箭头方向为ZN含量增大方向, 插图为不同ZN含量BTZN陶瓷BDS

max,randmax-rof BTZN ceramics at 100 kV/cm; (b) Energy storage density (); (c) Recoverable energy storage density (rec); (d) Energy loss density (loss); (e) Energy storage efficiency () as a function of electric field; (f) Variations of,rec,lossandat critical electric field with different ZN contents

式(5~8)中:——电场强度;——极化强度值。

图8(b)~(e)是BTZN陶瓷不同电场强度下,rec,loss和。随ZN含量增加,rec和loss都逐渐增加, 而逐渐减小, 主要由于loss随电场强度增加显著增大[26, 35]。实际应用不仅需要高rec, 同时高也是必须的, 低材料在充放电过程中会将大量电能转换成热能, 导致材料性能恶化[35]。当ZN的含量为4mol%时, 不同电场下均高于77.6%。图8(f)是不同ZN含量BTZN陶瓷在各自BDS下的,rec,loss和, 随ZN含量增加,rec,loss和大体呈增大趋势, 当ZN含量4mol%, BTZN6陶瓷在240 kV/cm电场下获得1.22 J/cm3的rec和77.6%的。

3 结论

本研究采用固相法制备(1–)BaTiO3-ZnNb2O6(=0.5mol%, 1mol%, 1.5mol%, 2mol%, 3mol%, 4mol%)陶瓷。添加ZN有效降低了BTZN陶瓷的最佳烧结温度。XRD结果表明所有样品主晶相为BaTiO3, 当ZN含量达到3mol%时出现ZnNb2O6和第二相Ba2Ti5O12。BTZN陶瓷晶粒尺寸随ZN含量增加显著减小。r和tan随ZN含量增加逐渐降低, 100 Hz下r从3923降低到1604, tan从0.013减小到0.006, 10 MHz下所有样品tan<0.05。r频率稳定性随ZN含量增加逐渐增强, 10 MHz下从–14.85%提高到–8.45%。介电温谱结果表明所有BTZN陶瓷均符合X8R电容器标准。BDS随ZN含量增加而增大, 从80 kV/cm增大到240 kV/cm。极化强度值随着ZN含量的增加逐渐降低, 100 kV/cm下max和r分别从20.26和4.48 μC/cm2减小到11.67和1.37 μC/cm2。随ZN含量增加,rec,loss和大体上呈增大趋势, 当ZN含量为4mol%时, BTZN6陶瓷在240 kV/cm电场下获得1.22 J/cm3的rec和77.6%的。结果表明BTZN陶瓷有望应用于高温电容器和储能领域。

[1] ACOSTA M, NOVAK N, ROJAS V,BaTiO3-based piezoelectrics: fundamentals, current status, and perspectives., 2017, 4(4): 041305.

[2] HENNINGS D, ROSENSTEIN G. Temperature-stable dielectrics based on chemically inhomogeneous BaTiO3., 1984, 67(4): 249–254.

[3] JIANG X W, HAO H, ZHANG S J,Enhanced energy storage and fast discharge properties of BaTiO3based ceramics modified by Bi(Mg1/2Zr1/2)O3., 2019, 39(4): 1103–1109.

[4] HUANG Y A, LU B, YI X Z,Grain size effect on dielectric, piezoelectric and ferroelectric property of BaTiO3ceramics with fine grains., 2018, 33(7): 767–772.

[5] GHAYOUR H, ABDELLAHI M. A brief review of the effect of grain size variation on the electrical properties of BaTiO3-based ceramics., 2016, 292: 84–93.

[6] ZEB A, MILNE S J. Temperature-stable dielectric properties from −20 ℃ to 430 ℃ in the system BaTiO3-Bi(Mg0.5Zr0.5)O3., 2014, 34(13): 3159–3166.

[7] DAMJANOVIC D. Ferroelectric, dielectric and piezoelectric properties of ferroelectric thin films and ceramics., 1998, 61(9): 1267–1324.

[8] GUO F Q, ZHANG B H, FAN Z X,Grain size effects on piezoelectric properties of BaTiO3ceramics prepared by spark plasma sintering., 2016, 27(6): 5967–5971.

[9] YUAN Q B, LI G, YAO F Z,Simultaneously achieved temperature- insensitive high energy density and efficiency in domain engineered BaTiO3-Bi(Mg0.5Zr0.5)O3lead-free relaxor ferroelectrics., 2018, 52: 203–210.

[10] HAO X H. A review on the dielectric materials for high energy- storage application., 2013, 03(1): 1330001.

[11] DU H L, YANG Z T, GAO F,Lead-free nonlinear dielectric ceramics for energy storage applications: current status and challenges., 2018, 33(10): 1046–1058.

[12] YANG L T, KONG X, LI F,Perovskite lead–free dielectrics for energy storage applications., 2019, 102: 72–108.

[13] YAN F, YANG H B, LIN Y,Dielectric and ferroelectric properties of SrTiO3-Bi0.5Na0.5TiO3-BaAl0.5Nb0.5O3lead-free ceramics for high-energy-storage applications., 2017, 56(21): 13510–13516.

[14] YANG H B, YAN F, LIN Y,Novel strontium titanate-based lead-free ceramics for high-energy storage applications., 2017, 5(11): 10215–10222.

[15] YANG H B, YAN F, LIN Y,Lead-free BaTiO3- Bi0.5Na0.5TiO3-Na0.73Bi0.09NbO3relaxor ferroelectric ceramics for high energy storage., 2017, 37(10): 3303–3311.

[16] YAN F, YANG H B, YING L,Enhanced energy storage properties of a novel lead-free ceramic with a multilayer structure., 2018, 6(29): 7905–7912.

[17] LIU X Y, YANG H B, YAN F,Enhanced energy storage properties of BaTiO3-Bi0.5Na0.5TiO3lead-free ceramics modified by SrY0.5Nb0.5O3., 2019, 778: 97–104.

[18] YANG H B, LIU P F, YAN F,A novel lead-free ceramic with layered structure for high energy storage applications., 2019, 773: 244–249.

[19] YANG Z T, GAO F, DU H L,Grain size engineered lead-free ceramics with both large energy storage density and ultrahigh mechanical properties., 2019, 58: 768–777.

[20] WANG T, JIN L, TIAN Y,Microstructure and ferroelectric properties of Nb2O5-modified BiFeO3-BaTiO3lead-free ceramics for energy storage., 2014, 137: 79–81.

[21] JIN L, LI F, ZHANG S J. Decoding the fingerprint of ferroelectric loops: comprehension of the material properties and structures., 2014, 97(1): 1–27.

[22] WANG T, HU J C, YANG H B,Dielectric relaxation and Maxwell-Wagner interface polarization in Nb2O5doped 0.65BiFeO3-0.35BaTiO3ceramics., 2017, 121(8): 084103.

[23] HUANG Y H, WU Y J, LI J,Enhanced energy storage properties of barium strontium titanate ceramics prepared by Sol-Gel method and spark plasma sintering., 2017, 701: 439–446.

[24] PULI V S, PRADHAN D K, CHRISEY D B,Structure, dielectric, ferroelectric, and energy density properties of (1−)BZT–BCT ceramic capacitors for energy storage applications., 2012, 48(5): 2151–2157.

[25] SUN Z, LI L X, YU S H,Energy storage properties and relaxor behavior of lead-free Ba1-xSm2x/3Zr0.15Ti0.85O3ceramics., 2017, 46(41): 14341–14347.

[26] WANG T, JIN L, LI C C,Relaxor ferroelectric BaTiO3- Bi(Mg2/3Nb1/3)O3ceramics for energy storage application., 2015, 98(2): 559–566.

[27] HU Q Y, JIN L, WANG T,Dielectric and temperature stable energy storage properties of 0.88BaTiO3-0.12Bi(Mg1/2Ti1/2)O3bulk ceramics., 2015, 640: 416–420.

[28] YUAN Q B, YAO F Z, WANG Y F,Relaxor ferroelectric 0.9BaTiO3-0.1Bi(Zn0.5Zr0.5)O3ceramic capacitors with high energy density and temperature stable energy storage properties., 2017, 5(37): 9552–9558.

[29] LI W B, ZHOU D, PANG L X,Novel barium titanate based capacitors with high energy density and fast discharge performance., 2017, 5(37): 19607–19612.

[30] WANG X R, ZHANG Y, SONG X Z,Glass additive in barium titanate ceramics and its influence on electrical breakdown strength in relation with energy storage properties., 2012, 32(3): 559–567.

[31] WANG T, JIN L, SHU L L,Energy storage properties in Ba0.4Sr0.6TiO3ceramics with addition of semi-conductive BaO-B2O3-SiO2-Na2CO3-K2CO3glass., 2014, 617: 399–403.

[32] YANG H B, YAN F, LIN Y,Enhanced energy storage properties of Ba0.4Sr0.6TiO3lead-free ceramics with Bi2O3-B2O3-SiO2glass addition., 2018, 38(4): 1367–1373.

[33] YANG H B, YAN F, ZHANG G,Dielectric behavior and impedance spectroscopy of lead-free Ba0.85Ca0.15Zr0.1Ti0.9O3ceramics with B2O3-Al2O3-SiO2glass-ceramics addition for enhanced energy storage., 2017, 720: 116–125.

[34] WU T, PU Y P, CHEN K. Dielectric relaxation behavior and energy storage properties in Ba0.4Sr0.6Zr0.15Ti0.85O3ceramics with glass additives., 2013, 39(6): 6787–6793.

[35] WANG T, WANG Y H, YANG H B,Structure, dielectric properties of low-temperature-sintering BaTiO3-based glass-ceramics for energy storage., 2018, 8(6): 1850041.

[36] GAO F, LIU J J, HONG R Z,Microstructure and dielectric properties of low temperature sintered ZnNb2O6microwave ceramics., 2009, 35(7): 2687–2692.

[37] WANG T, WEI X Y, HU Q Y,Effects of ZnNb2O6addition on BaTiO3ceramics for energy storage., 2013, 178(16): 1081–1086.

[38] YAN Y, NING C, JIN Z Z,The dielectric properties and microstructure of BaTiO3ceramics with ZnO-Nb2O5composite addition., 2015, 646: 748–752.

[39] YANG Y, LIU K H, LIU X K,Electrical properties and microstructures of (Zn and Nb) co-doped BaTiO3ceramics prepared by microwave sintering., 2016, 42(6): 7877–7882.

[40] SPAGNOL P D, VARELA J A, ZAGHETE M A,Evidence of hetero-epitaxial growth of Pb(Mg1/3Nb2/3)O3on the BaTiO3seed particles of a citrate solution., 2002, 77(3): 918–923.

[41] YANG H B, YAN F, LIN Y,Enhanced energy-storage properties of lanthanum-doped Bi0.5Na0.5TiO3-based lead-free ceramics., 2018, 6(2): 357–365.

[42] JIA W X, HOU Y D, ZHENG M P,Superior temperature- stable dielectrics for MLCCs based on Bi0.5Na0.5TiO3-NaNbO3system modified by CaZrO3., 2018, 101(8): 3468–3479.

[43] SUN Y, LIU H, HAO H,Structure property relationship in BaTiO3-Na0.5Bi0.5TiO3-Nb2O5-NiO X8R system., 2015, 98(5): 1574–1579.

Dielectric and Energy Storage Property of BaTiO3-ZnNb2O6Ceramics

WANG Tong1, WANG Yuanhao1, YANG Haibo1, GAO Shuya1, WANG Fen1, LU Yawen2

1. Shaanxi Key Laboratory of Green Preparation and Functionalization for Inorganic Materials, School of Materials Science and Engineering, Shaanxi University of Science & Technology, Xi’an 710021, China; 2. Xianyang Research and Design Institute of Ceramics Co. Ltd, Xianyang 712000, China)

(1–)BaTiO3-ZnNb2O6(=0.5mol%, 1mol%, 1.5mol%, 2mol%, 3mol%, 4mol%) (BTZN) ceramics were synthesized by solid state method. The sintering temperature, structure, dielectric property and ferroelectric property of BTZN ceramics were systematically investigated. The sintering temperature of BTZN ceramics decreased with increasing ZnNb2O6content. XRD results show that the second phase Ba2Ti5O12was observed when the content of ZnNb2O6reached 3mol%. The dielectric measurements result showed that with increasing ZnNb2O6content, the dielectric constant of BTZN ceramics decreased gradually, while the frequency stability of dielectric constant increasedgradually. The temperature dependence of dielectric constant results showed that all BTZN ceramics met the characteristics of X8R capacitors.Polarization values of BTZN ceramics decreased with increasing ZnNb2O6content. The dielectric breakdown strength of 240 kV/cm and arecoverable energy density of 1.22 J/cm3were achieved in the sample of=4mol%.

BaTiO3; ceramics; dielectric property; energy storage property

TQ174

A

1000-324X(2020)04-0431-08

10.15541/jim20190170

2019-04-22;

2019-06-12

国家自然科学基金(51702196); 中国博士后科学基金(2017M620435); 陕西省自然科学基础研究计划(2017JQ5088); 陕西省教育厅专项科研计划(17JK0105); 陕西科技大学博士科研启动基金(BJ16-07)

National Natural Science Foundation of China (51702196); China Postdoctoral Science Foundation (2017M620435); Natural Science Foundation of Shaanxi Province (2017JQ5088); Scientific Research Program Funded by Shaanxi Provincial Education Department (17JK0105); Research Starting Foundation of Shaanxi University of Science and Technology (BJ16-07)

王通(1985–), 男, 讲师. E-mail: andyton85@163.com

WANG Tong(1985–), male, lecturer. E-mail: andyton85@163.com

杨海波, 教授. E-mail: yanghaibo@sust.edu.cn

YANG Haibo, professor. E-mail: yanghaibo@sust.edu.cn