Effect of acidity on the catalytic performance of ZSM-5 zeolites in the synthesis of trioxane from formaldehyde

YE Yu-ling, FU Meng-qian, CHEN Hong-lin, ZHANG Xiao-ming

(1.Chengdu Institute of Organic Chemistry, Chinese Academy of Sciences, Chengdu 610041, China;2.College of Chemical Engineering, Sichuan University of Science & Engineering, Zigong 643000, China;3.University of Chinese Academy of Sciences, Beijing 100049, China)

Abstract: ZSM-5 zeolite is considered as an effective catalyst in the synthesis of trioxane from formaldehyde.In this work, a series of ZSM-5 zeolites with different SiO2/Al2O3 molar ratios were used in the synthesis of trioxane from formaldehyde; through characterization by XRF, XRD, SEM, NH3-TPD, Py-FTIR and 27Al MAS NMR, the effect of acidity including the Brønsted and Lewis acid sites on the catalytic performance of ZSM-5 zeolites in the trioxane synthesis was investigated.The results indicate that the ZSM-5-250 zeolite with a SiO2/Al2O3 molar ratio of 250 exhibits excellent catalytic performance in the synthesis of trioxane.The ZSM-5-250 zeolite owns sufficient amount of Brønsted acid sites which are active for the synthesis of formaldehyde to trioxane; meanwhile, it has few Lewis acid sites and can then effectively inhibit various side-reactions like the Cannizzaro or Tishchenko reactions.Moreover, the ZSM-5-250 zeolite displays high stability with a single-pass lifetime of 114 h and can be regenerated easily through calcination at 550 ℃.

Key words: trioxane; ZSM-5 zeolite; formaldehyde; acidity; Brønsted acid; Lewis acid

Trioxane(TOX,(CH2O)3), a cyclic trimer, is an anhydrous form of formaldehyde(FA, CH2O).Trioxane can be used as a substitute for formaldehyde in the synthesis of polyoxymethylene(POM)[1,2]and poly(oxymethylene)dimethyl ethers(PODE)[3,4].80% of the world’s POM is now produced via TOX, whilst PODE is considered a promising diesel additive which can be efficiently synthesized with TOX.The dramatic increase in the demand for POM and PODE has prompted the exploration of a more environmentally benign and practical route to synthesize TOX.

TOX is commercially produced by cyclotrimerization of high concentrations of aqueous formaldehyde with sulfuric acid as a catalyst(Eq.(1))[5-8].Unfortunately, numerous side reactions may occur under acidic conditions.For example, methanol(MeOH, CH3OH)and formic acid(HCOOH)are formed via the Cannizzaro reaction(Eq.(2))and subsequently, methyl formate(MF, HCOOCH3)is produced via esterification(Eq.(3))[9].In addition, MF can also be obtained via the Tishchenko reaction(Eq.(4)).Meanwhile, a small amount of dimethoxymethane(DMM, CH3OCH2OCH3)can be detected in the reaction mixture, which is propoably produced by the condensation of formaldehyde with methanol(Eq.(5))over acidic catalysts.

3CH2O=(CH2O)3

(1)

2CH2O+H2O=CH3OH+HCOOH

(2)

CH3OH+HCOOH=HCOOCH3+H2O

(3)

2CH2O=HCOOCH3

(4)

CH2O+2CH3OH=CH3OCH3OCH3+H2O

(5)

In general, a variety of homogeneous catalysts including sulfuric acid, heteropolyacid[10], and acidic ionic liquid[11,12]exhibit excellent performance in the synthesis of TOX via the cyclotrimerization of formaldehyde.However, such homogeneous catalysts are often limited in practice by a series of problems like equipment corrosion and difficulty in product separation.In contrast, solid Brønsted and/or Lewis acids, such as FeCl3[13], acidic resin[14], montmorillonite[15], ferrierite[16], ZSM-5[17,18], Beta and mordenite[19], are considered as alternative catalysts for the cyclotrimerization of formaldehyde.In particular, for the TOX synthesis over ZSM-5 zeolite, the influence of catalyst amount, reaction temperature and raw materials concentration on the formaldehyde conversion and selectivity to TOX have been investigated[20].However, the relation between the acidity of ZSM-5 zeolites and their catalytic performance in trioxane synthesis has yet to be clarified.

In this work, a series of acidic ZSM-5 zeolites with different SiO2/Al2O3molar ratios were used as the catalyst in the cyclotrimerization of aqueous formaldehyde; the effect of acidity including the Brønsted and Lewis acid sites on the catalytic performance of ZSM-5 zeolites in the trioxane synthesis was then investigated through various characterization tests.

1 Experimental

1.1 Materials and catalyst preparation

All H-type ZSM-5 zeolites with nominal SiO2/Al2O3ratios of 30, 100, 180, 250 and 400 were provided by Qilu Huaxin Industry Co.(Shandong, China), which were designated as ZSM-5-x, wherexrepresents the SiO2/Al2O3molar ratio.For comparison, acid resin andγ-Al2O3were also used.

Al-ZSM-5 zeolites were prepared via liquid ion-exchange method.Briefly, ZSM-5-100(10 g)was added to Al2(SO4)3solution(40 mL)of desired concentration and stirred at 80 ℃ for 3 h.After that, the solid sample was filtered, washed with distilled water, and dried at 110 ℃.Subsequently, the solid sample was calcined at 550 ℃ for 2 h in a muffle furnace.By adjusting the concentration of Al2(SO4)3, Al-ZSM-5-100 samples with different amounts of Al2(SO4)3were prepared and denoted asyAl-ZSM-5-100, whereyrepresents the concentration of Al2(SO4)3solution.

The deactivated catalyst after the reaction was designated as ZSM-5-x-D.The deactivated ZSM-5-x-D catalysts were then regenerated through calcination in the muffle furnace at 550 ℃ for 3 h and the recovered catalysts were designated as ZSM-5-x-R.

Industrial formaldehyde solution(37%, MeOH<0.8%, HCOOH<0.003%)was supplied by Weite Plastic Co.(Chengdu, China).Before use in the reaction tests, the formaldehyde solution was concentrated to 60%(MeOH<0.2%, HCOOH<0.004%)via evaporation, in which trace amounts of MeOH and HCOOH had little effect on the trioxane synthesis.Chromatographically pure 1,4-dioxane was used as an internal standard in analysis by gas chromatography; other analytical grade reagents were supplied by Aladdin Industrial Corporation(Shanghai, China).

1.2 Catalytic reaction tests

The same reactor with a reactive distillation column, as described in our previous report[18], was used for the synthesis of trioxane with formaldehyde.For the batch operation, the reaction mixture containing formaldehyde(100.0 g)and solid catalyst(5.0 g)was first placed in the reactor and then heated in an oil bath with magnetic stirring.The reaction began when the temperature reached ca.100 ℃ and continued for 2 h.For the continuous operation to evaluate the catalytic stability and lifetime of zeolites, the reaction mixture containing formaldehyde(100.0 g)and solid catalyst(5.0 g)was also placed in the reactor at the begin.After the temperature reached ca.100 ℃, the formaldehyde solution was continuously pumped into the reactor and the formaldehyde solution feed rate was adjusted to ensure a constant level for the reaction solution in the reactor.Distillate analysis was conducted every 8 h and the reaction test halted when the conversion of formaldehyde decreased by 10%.

The esterification of MeOH and HCOOH was also conducted under the batch reaction conditions.The reaction solution(100.0 g)was composed of water, MeOH, and HCOOH.The influence of MeOH concentration was investigated in the range of 0.50%-2.00% with a constant MeOH/HCOOH molar ratio of 1.3.

TOX, MeOH, MF and DMM were analyzed by a gas chromatograph with an FID detector and HP-1 capillary column.The inlet and detector temperatures were kept at 230 and 250 ℃, respectively, and the column temperature was programmed from 40 ℃(held for 5.8 min)at a rate of 30 ℃/min to 200 ℃(held for 5.8 min).Formaldehyde and HCOOH were analyzed by titration method according to the GB/T 9009—2011 standard.The arithmetic mean value of two parallel analysis results was adopted as the final result; the difference between the two parallel results was in general less than 0.005%.It was estimated that the carbon loss of all reactions over different catalysts was below 3.0%.The conversion(x)of formaldehyde and formic acid and selectivity(s)to a specific product were calculated on the basis of carbon molar quantity:

xCH2O=

(6)

xHCOOH=

(7)

sproduct=

(8)

1.3 Catalyst characterization

Elemental analysis was performed on a PANalytical Axios X-ray fluorescence(XRF).

N2adsorption-desorption measurements were performed on a Gold App V-Sorb 2800.Specific surface areas were calculated according to the BET equation and the total pore volume was calculated as the nitrogen adsorption volume at a relative pressure of 0.99.The average pore size was calculated by BJH method forγ-Al2O3and acid resin and byt-plot method for ZSM-5 zeolites.

Electron micrographs were taken on a JEOL JEM-5410LV scanning electron microscope(SEM).

The crystalline structures were determined by a Bruker D8 ADVANCE X-ray diffractometer(XRD)with CuKαradiation.

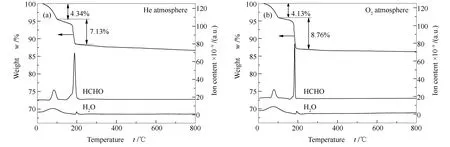

Thermogravimetric measurements(TG-MS)was performed on a QMS 403/5 Skimmer instrument with a heating rate of 10 ℃/min under He or O2atmosphere.

The temperature-programmed desorption of ammonia(NH3-TPD)profiles were recorded on a chemisorption instrument from Micromeritics(AutoChem II 2920), as described in reference[18].

Infrared spectra of adsorbed pyridine(Py-FTIR)were collected at 2 cm-1resolution on a Nicolet FT-IR 6700 spectrometer.The catalyst samples were directly pressed into self-supporting wafers without any dilution.The quantities of Brønsted and Lewis acid sites were calculated from the bands at 1540 and 1450 cm-1in the Py-FTIR spectra by using extinction coefficients of 1.88 and 1.42, respectively[18].

27Al MAS NMR spectra were recorded on a Bruker AVANCE III NMR spectrometer that operated at 600 MHz and spinning rate of 14 kHz.The spectra were acquired with aπ/12 pulse width of 0.65 μs and the recycle delay of 1 s.The27Al chemical shifts were referenced to 1 mol/L Al(NO3)3aqueous solution.The relative amounts of tetrahedrally coordinated framework aluminum(AlF)and octahedrally coordinated extra-framework aluminium(AlEF)were determined by peak integration.

The acid amount of sulfonic acid resin was determined by acid-base titration method, which was first impregnated with a certain amount of sodium hydroxide standard solution to over-neutralize the acid sites and then titrated back with a hydrochloric acid standard solution.

2 Results and discussion

2.1 Characterization of catalysts

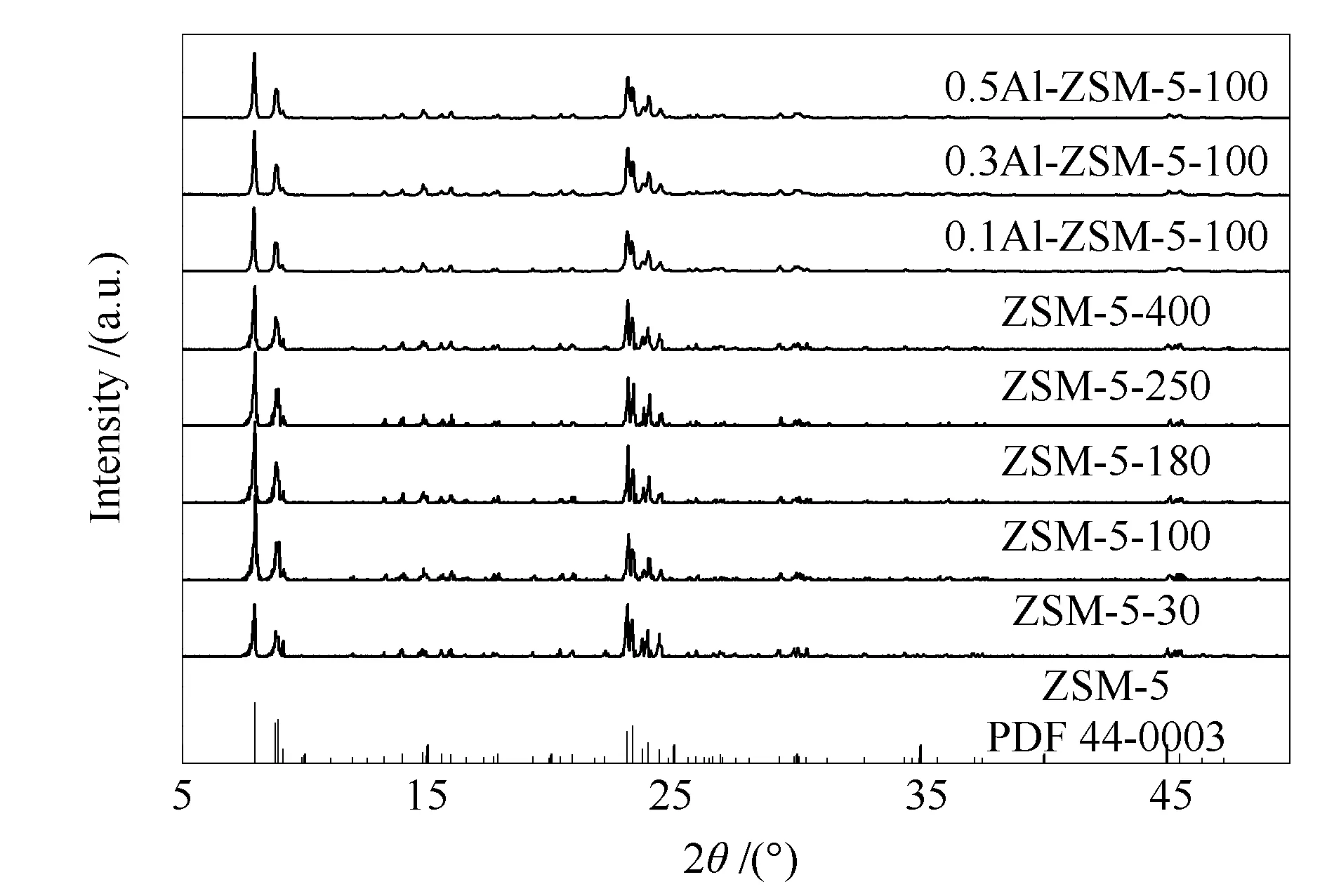

As shown by the XRD patterns in Figure 1, all ZSM-5 zeolites with different SiO2/Al2O3molar ratios possess the MFI structure.Similarly, theyAl-ZSM-5-100 zeolites also display the characteristic XRD patterns of typical MFI structure, whereas no Al oxides or sulfates are observed, indicating the high dispersion of additional Al species inyAl-ZSM-5-100.Moreover, Figure 2 shows that all the ZSM-5 zeolites with different SiO2/Al2O3molar ratios have similar crystal morphologies and particle sizes(1.0-2.0 μm).

Figure 1 XRD patterns of ZSM-5 zeolites with different SiO2/Al2O3 molar ratios

The Al content and textural properties of ZSM-5 zeolites,γ-Al2O3and resin are given in Table 1.The Al content of ZSM-5-xzeolites decreases with an increase in the SiO2/Al2O3molar ratio, whereas for theyAl-ZSM-5-100 zeolites, the loading of Al increases with the increase of Al2(SO4)3solution concentration.The ZSM-5 zeolites with different SiO2/Al2O3molar ratios have similar specific surface area, total pore volume and average pore size.Furthermore, theyAl-ZSM-5-100 zeolites with different Al loadings also display similar specific surface area, total pore volume and average pore size; that is, small amounts of additional Al species loaded on the ZSM-5 zeolites have little impact on the textural structure.Unlike the microporous ZSM-5 zeolites,γ-Al2O3and resin show mesoropores with the average pore size of 5.23 and 19.27 nm, respectively.

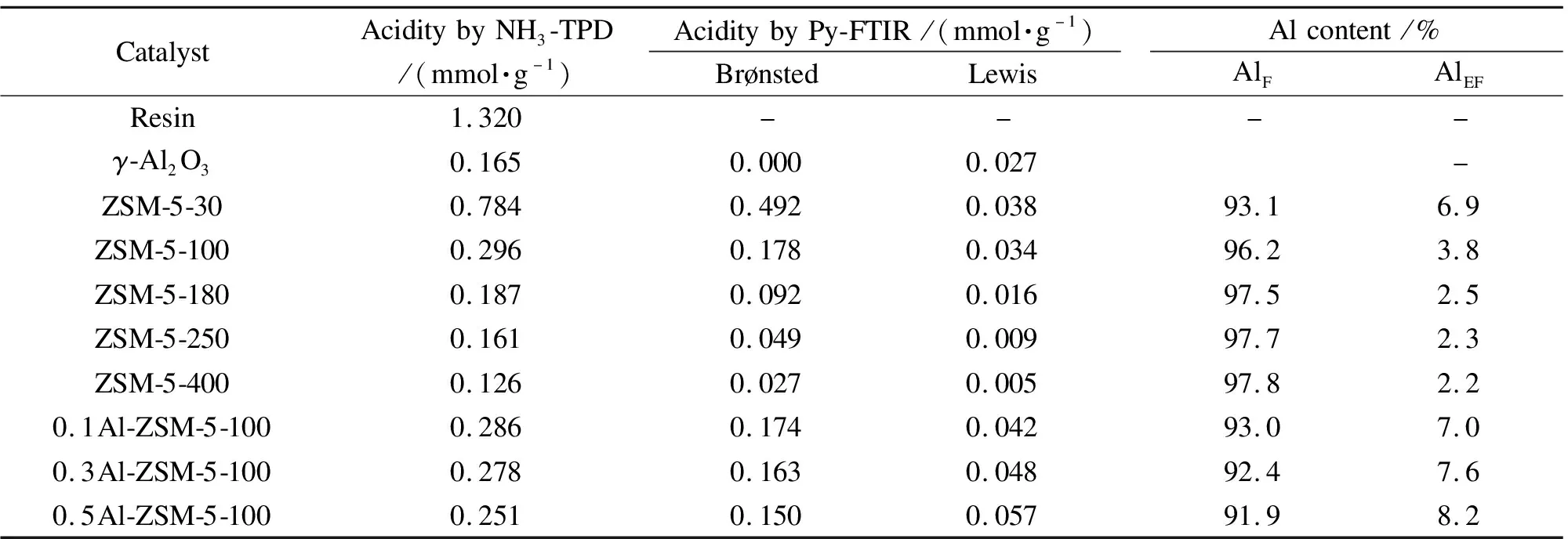

The acidity of ZSM-5 zeolites andγ-Al2O3was first characterized by NH3-TPD, as shown in Figure 3 and Table 2.Two desorption peaks are observed for the ZSM-5 zeolites at 190-240 and 350-430 ℃, corresponding to weak and strong acid sites, respectively[21].With an increase in the SiO2/Al2O3molar ratio, two desorption peaks(the high temperature peak in particular)shift to lower temperatures, meaning a decrease in the acid strength.Moreover, the amounts of acid sites decrease with the increase of SiO2/Al2O3molar ratio, consistent with the decrease of Al concentration in the zeolite framework.ForyAl-ZSM-5-100, the total acid amounts show only a slight decrease with the increase of Al loading.The NH3-TPD profile ofγ-Al2O3displays a wide peak at 150-420 ℃, meaning thatγ-Al2O3also has considerable weak and strong acid sites.In contrast, the amount of Brønsted acid sites on the acid resin is 1.30 mmol/g[22].

note: Al content was measured by XRF, the surface area(ABET)was determined from nitrogen sorption isotherms by BET method; the total pore volume(vtotal)was obtained at a relative pressure of 0.99; the average pore diameter(D)was derived by using BJH method for resin andγ-Al2O3and usingt-plot method for the ZSM-5 zeolites

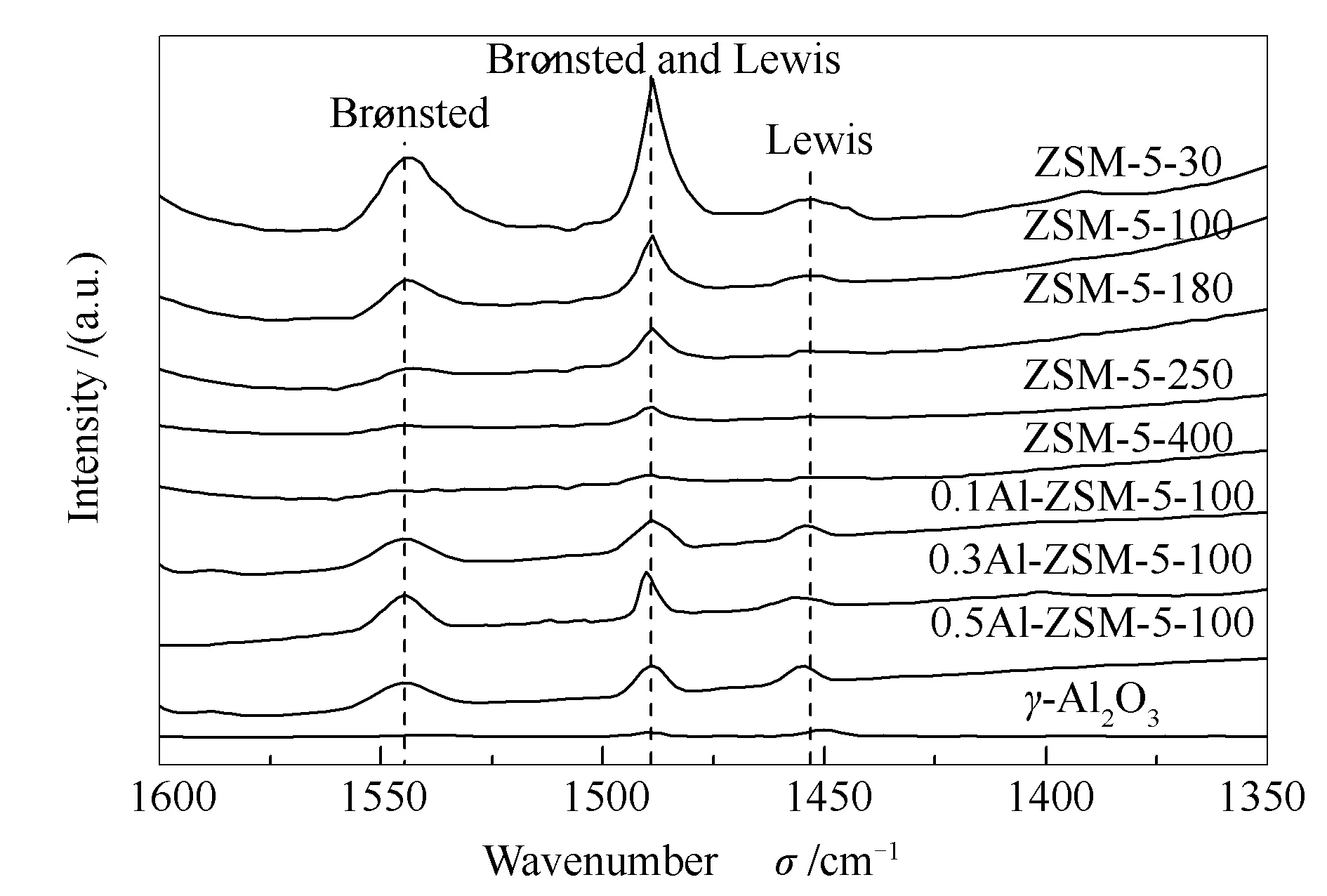

The Brønsted and Lewis acidity of ZSM-5 zeolites andγ-Al2O3was then determined by Py-FTIR, as shown in Figure 4 and Table 2.Two absorption peaks in the Py-FTIR spectra located at 1540 and 1450 cm-1correspond to the Brønsted and Lewis acid sites, respectively, whereas the peak at 1490 cm-1represents both types of acid sites[23-25].γ-Al2O3only possesses 0.027 mmol/g Lewis acid sites, whereas ZSM-5 zeolites have both the Brønsted and Lewis acid sites.By increasing the SiO2/Al2O3molar ratio from 30 to 250, the amounts of Brønsted acid and Lewis acid sites in ZSM-5 zeolites decrease from 0.492 and 0.038 mmol/g to 0.049 and 0.009 mmol/g, respectively.It is known that the Lewis acid sites next to Brønsted acid sites increase the acid strength[24], consistent with the NH3-TPD results.For theyAl-ZSM-5-100 zeolites, the amount of Brønsted acid sites decreases slightly from 0.178 to 0.150 mmol/g, whereas the amount of Lewis acid sites increases from 0.034 to 0.057 mmol/g, with the increase of Al loading.

Table 2 Acidity and Al content of various ZSM-5 zeolites and γ-Al2O3 and resin

note: the acidity of resin was determined by the acid-base titration method, the contents of framework Al(AlF)and extra-framework(AlEF)were determined by27Al MAS NMR

Figure 4 Py-FTIR spectra of various ZSM-5 zeolites and γ-Al2O3

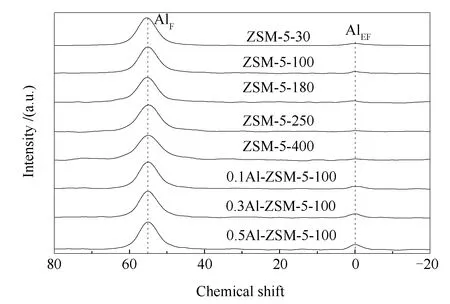

To further examine the Lewis acid sites on the ZSM-5 zeolites, the environments of Al atoms, which affect the acid types, were characterized by27Al MAS NMR, as shown in Figure 5.An intense and sharp peak at ca.56 and a less intense peak at ca.0 are observed, indicating that all these zeolites are dominated by tetrahedrally coordinated framework aluminum(AlF), though a very small amount of octahedrally coordinated extra-framework aluminium(AlEF)is present in ZSM-5 zeolites[26].As given in Table 2, with the increase of SiO2/Al2O3molar ratio from 30 to 250, the relative AlEFcontent decreases from 6.9% to 2.3%.Moreover, the relative AlEFcontent ofyAl-ZSM-5-100 increases from 7.0% to 8.2% with the increase of Al loading.By referring to the Py-FTIR results, it is observed that the decrease in the amount of Lewis acid sites in the ZSM-5 zeolites is related to the decrease of relative AlEFcontent, according with the usual viewpoint that the AlEFatoms localized adjacent to Brønsted acid sites acts as the Lewis acid sites[27,28].

Figure 5 27Al MAS NMR spectra of the ZSM-5 zeolites with different SiO2/Al2O3 molar ratios

2.2 Catalytic activity of ZSM-5 zeolites in TOX synthesis

The catalytic performance of ZSM-5 zeolites with different SiO2/Al2O3molar ratios was compared with that of acid resin,γ-Al2O3and blank test under identical batch reaction conditions, as demonstrated in Figure 6.In the absence of any catalyst or withγ-Al2O3as the catalyst, only a small amount of MeOH originated from the formaldehyde raw material was detected, meaning that the Lewis acid sites alone inγ-Al2O3has almost no catalytic activity in the trioxane synthesis under current reaction conditions.When acid resin is employed as the catalyst, the conversion of formaldehyde and selectivity to TOX reach 16.1% and 93.1%, respectively.In contrast, the ZSM-5 zeolites with less acid sites display higher formaldehyde conversions than acid resin.Moreover, the formaldehyde conversion decreases whereas the selectivity to TOX increases with the increase of SiO2/Al2O3molar ratio.Interestingly, the ZSM-5 zeolites with a low SiO2/Al2O3molar ratio(< 250)show lower selectivity to TOX than the acid resin; however, over the ZSM-5 zeolite with a SiO2/Al2O3molar ratio of 250, the conversion of formaldehyde and selectivity to TOX are 17.2% and 93.4%, respectively, slightly higher than those over the acid resin.Over the ZSM-5 zeolites with a SiO2/Al2O3molar ratio above 250, the selectivity to TOX levels off whereas the conversion of formaldehyde decreases drastically.Moreover, the ZSM-5 zeolites display much higher stability than the resin for TOX synthesis[19], due to the poor thermal stability and swelling of acid resin in the liquid phase[29].As a result, ZSM-5 zeolite with a SiO2/Al2O3molar ratio of 250 is a suitable catalyst for the TOX synthesis.

Figure 6 Formaldehyde conversions and product selectivity for TOX synthesis over different catalysts the reactions were carried out under 100 ℃ for 2 h, with 100 g CH2O solution(60%)and 5 g catalyst

Furthermore, an analysis on the acidity and textural properties suggests that the catalytic activity for TOX synthesis should be mainly related to the acidity; the Brønsted acid sites in the ZSM-5 zeiolites are probably the active centers for promoting the TOX formation, similar to the acid resin catalytic system.The Lewis acid sites alone inγ-Al2O3shows almost no activity for the synthesis of TOX, but likely acts together with the Brønsted acid sites and promotes the side reactions, such as Cannizzaro or Tishchenko reactions, consistent with previous studies[30-32].In particular, over the ZSM-5-30 zeolite with a SiO2/Al2O3molar ratio of 30, which contains a large amount of Brønsted acid sites but only 0.038 mmol/g of Lewis acid sites, the selectivity to TOX is only 67.99%.It indicates that besides the amount of Lewis acid sites, the selectivity to TOX is also greatly influenced by the SiO2/Al2O3molar ratio.That is, a good ZSM-5 zeolite catalyst for TOX synthesis should have an appropriate SiO2/Al2O3molar ratio, containing a suitable amount of Brønsted acid sites and as few as possible Lewis acid sites.

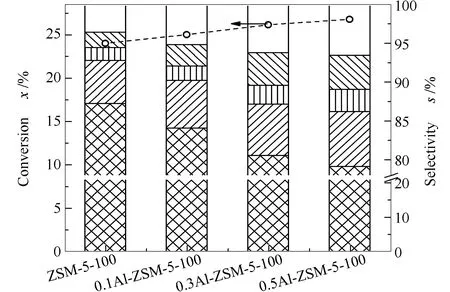

The Lewis acid and Brønsted acid sites decrease synchronously with the increase of the SiO2/Al2O3molar ratio in ZSM-5; therefore, it is arguable whether the decrease of Lewis acid sites favors a decrease in side reactions.To clarify this issue,yAl-ZSM-5-100 zeolites containing different amounts of Lewis acid sites were used in TOX synthesis, as shown in Figure 7.

Figure 7 Formaldehyde conversions and product selectivity for TOX synthesis over the yAl-ZSM-5-100 zeolites the reactions were carried out under 100 ℃ for 2 h, with 100 g CH2O solution(60%)and 5 g catalyst

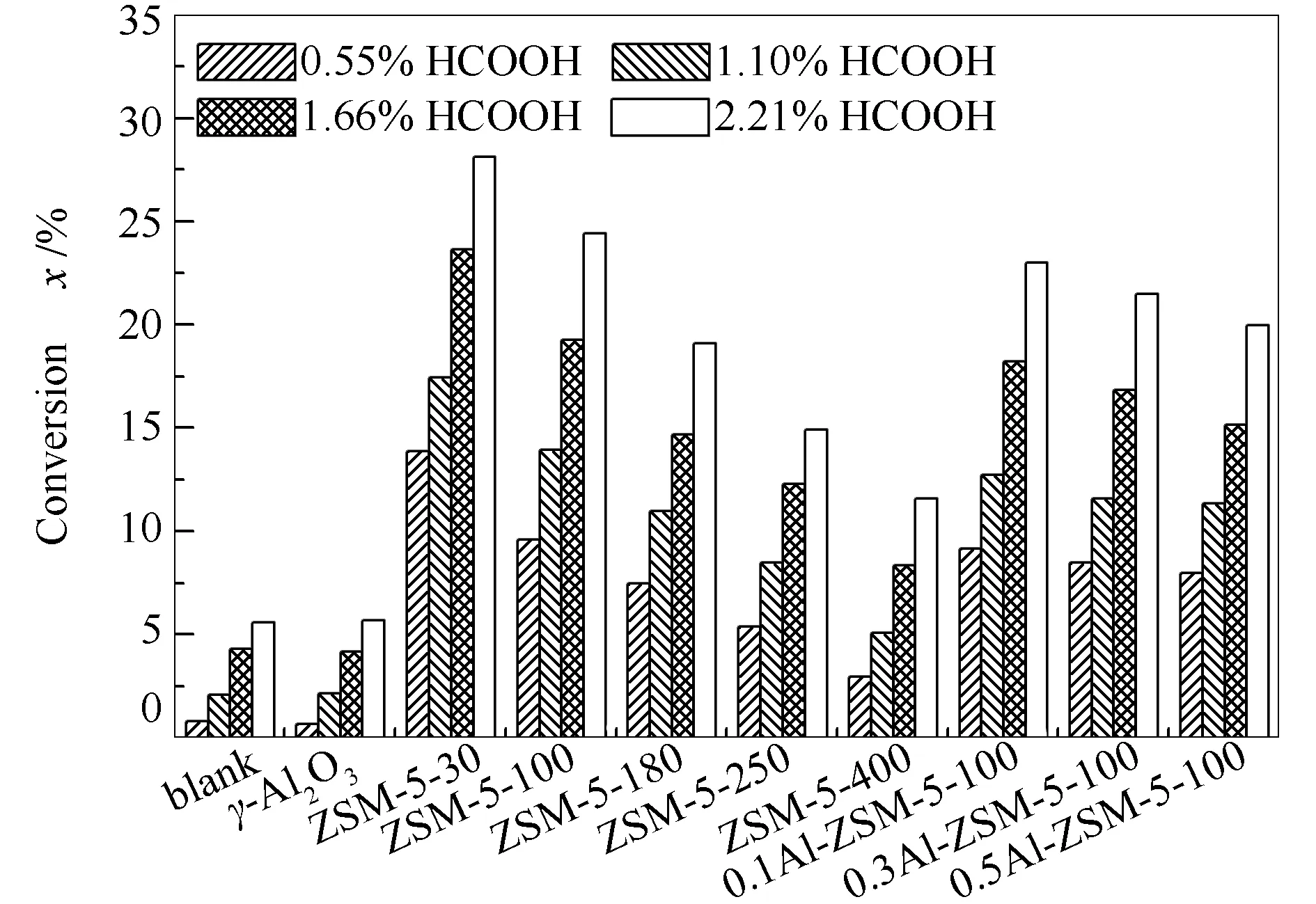

Figure 8 Conversion of HCOOH in the esterification of MeOH and HCOOH over various catalysts the reactions were carried out at 100 ℃ for 1 h, with 100 g reaction mixture solution and 5 g solid catalyst(or 2 g H2SO4)

The conversion of formaldehyde increases slightly with the increase of Al loading; however, the selectivity to TOX decreases whereas the yield of byproducts increases gradually with the increase of Al loading, due to the increase of the Lewis acid sites.That is, the coexistence of Lewis acid sites and Brønsted acid sites may promote unwanted side reactions such as Cannizzaro and Tishchenko reactions, resulting in lower selectivity to TOX.

To clarify the origin of byproducts, the esterification of MeOH and HCOOH(Eq.(3))was simulated with low raw material concentrations in water under the same conditions.As shown in Figure 8, the esterification of MeOH and HCOOH can even take place in the absence of acidic catalyst[33].Furthermore,γ-Al2O3shows similar conversion of HCOOH to the blank result, indicating that the Lewis acid sites are inessential for the esterification of MeOH and HCOOH.Over the ZSM-5 zeolites with different SiO2/Al2O3molar ratios, the conversion of HCOOH decreases with the increase of SiO2/Al2O3molar ratio.Additionally, the conversion of HCOOH decreases in order of ZSM-5-100 > 0.1Al-ZSM-5-100 > 0.3Al-ZSM-5-100 > 0.5Al-ZSM-5-100 > ZSM-5-180, which is consistent with the order of the amounts of Brønsted acid sites.That is, the esterification of MeOH and HCOOH can occur easily in this reaction system; the conversion of HCOOH increases with the increase of Brønsted acid sites amount but is not related to Lewis acid sites.Therefore, it is speculated that MeOH and HCOOH are formed via Cannizzaro reaction catalyzed by synergy of Brønsted acid and Lewis acid sites in the formaldehyde solution and MF is generated via the esterification catalyzed by Brønsted acid sites.However, the Tishchenko reaction(Eq.(4))may also occur over the catalyst where the Lewis acid and Brønsted acid sites coexist[34,35].Moreover, the hydrolysis of MF, which is the reverse reaction of(Eq.(4)), takes place easily in aqueous solution[36].Therefore, the formation of MF from formaldehyde(Eq.(4))via Tishchenko reaction should also be considered in current reaction system.

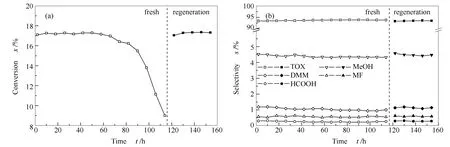

2.3 Catalytic stability of ZSM-5 zeolites in TOX synthesis

To consider the catalytic stability of ZSM-5 zeolites in TOX synthesis, ZSM-5-250 was tested under continuous operation.As demonstrated in Figure 9, the conversion of formaldehyde and the selectivity to TOX and byproducts under continuous operation are similar to those obtained under batch operation.Furthermore, the single-pass lifetime of ZSM-5-250 zeolite is about 114 h.After calcination in the muffle furnace at 550 ℃ for 3 h, the catalyst activity of the deactivated ZSM-5 zeolite is fully recovered.All these suggest that ZSM-5 zeolite with a proper SiO2/Al2O3molar ratio is an effective catalyst for TOX synthesis.

Figure 9 Formaldehyde conversions and product selectivity for TOX synthesis over the ZSM-5-250 zeolite catalyst under continuous operation at 100 ℃, with 100 g CH2O(60%)and 5 g catalyst initially in the reactor and CH2O solution feed flow rate of 0.5-1.0 mL/min during the continuous reaction

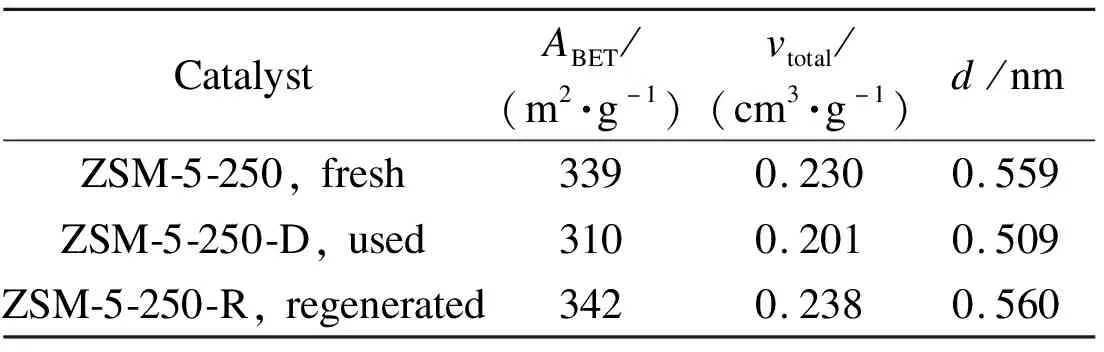

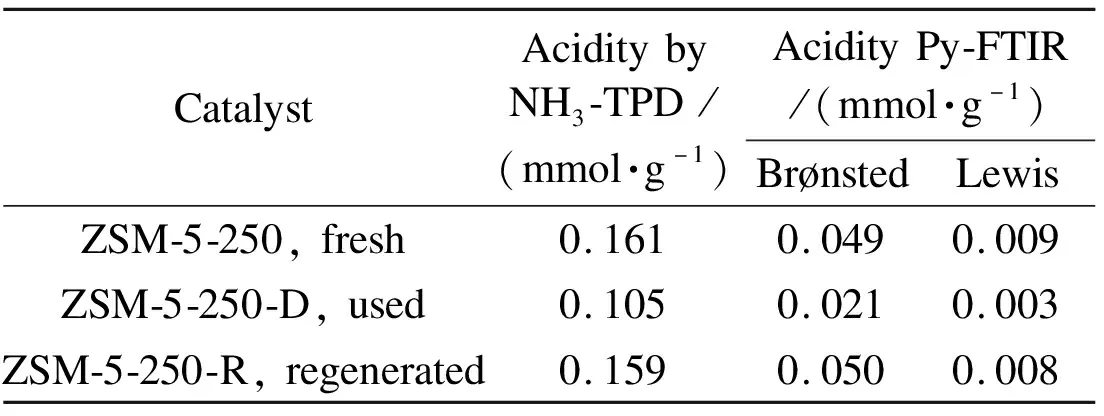

To clarify the causes of catalyst deactivation, the deactivated and regenerated ZSM-5-250 zeolites were characterized by nitrogen sorption, NH3-TPD, Py-FTIR and TG-MS.As given in Table 3, the specific surface area, total pore volume and average pore size of ZSM-5-250 zeolites decrease after the continuous reaction test; however, the textural characteristics can be recovered to the original state after regeneration by calcination.Moreover, as given in Table 4, the acidity of ZSM-5 zeolites can also be recovered to the original state after the regeneration by calcination.Hence, the carbonaceous deposition should be the main cause for the deactivation of zeolite catalyst, which can be easily regenerated by calcination to eliminate the carbonaceous deposits.

TG-MS analysis under He and O2atmosphere was employed to characterize the carbon deposits on the deactivated ZSM-5-250 zeolite surface after reaction.As shown in Figure 10, under He atmosphere, two degradation stages are observed, with the weight loss of 4.34% at ca.90 ℃ and 7.13% at ca.190 ℃.The substances desorbed at ca.90 ℃ are formaldehyde and water preserved on the inner surface of ZSM-5 zeolite channels, whereas the high content of formaldehyde released at ca.190 ℃ may arise from the decomposition of formaldehyde polymer, as the high concentration of formaldehyde may condense easily to formaldehyde polymer.

The TG-MS profiles under O2atmosphere are consistent with those under He atmosphere.Since the thermal oxidation of formaldehyde is initiated at ca.330 ℃[37-39], the formaldehyde polymer is completely decomposed to formaldehyde gas before oxidation; there is almost no other substances deposited on the surface of ZSM-5 zeolite after the reaction tests.It suggests that the main cause of deactivation is the covering of the ZSM-5 zeolite surface by the formaldehyde polymer; the deactivated ZSM-5 zeolite can be easily regenerated by calcination in air at high temperature.

Table 3 Textural properties of the ZSM-5-250 catalyst before and after reaction test

note: the surface area(ABET)was determined from nitrogen sorption isotherms by BET method; the total pore volume(vtotal)was obtained at a relative pressure of 0.99; the average pore diameter(d)was derived by using thet-plot method

Table 4 Acidity of the ZSM-5-250 catalyst before and after reaction test

Figure 10 TG-MS curves of the spent ZSM-5-250 catalyst after continuous reaction test

3 Conclusions

A series of ZSM-5 zeolites with different SiO2/Al2O3molar ratios were used in the synthesis of trioxane from formaldehyde and the effect of acidity including the Brønsted and Lewis acid sites on the catalytic performance of ZSM-5 zeolites in the trioxane synthesis was investigated.

The results indicate that the ZSM-5-250 zeolite with a SiO2/Al2O3molar ratio of 250 exhibits excellent catalytic performance in the synthesis of trioxane; the conversion of formaldehyde and selectivity to TOX are 17.2% and 93.4%, respectively.The ZSM-5-250 zeolite owns sufficient amount of Brønsted acid sites which are active for the synthesis of formaldehyde to trioxane; meanwhile, it has few Lewis acid sites and can then effectively inhibit various side-reactions like the Cannizzaro or Tishchenko reactions.Moreover, the ZSM-5-250 zeolite displays high stability with a single-pass lifetime of 114 h and can be regenerated easily through calcination at 550 ℃; the deactivation is mainly caused by the covering of catalyst surface with the formaldehyde polymer.The results suggest that ZSM-5 zeolites with an appropriate SiO2/Al2O3molar ratio can be an efficient catalyst for the TOX synthesis.