Geomechanics involved in gas hydrate recovery☆

Zhiqiang Liu,Yunxiao Lu,Jiuhui Cheng,Qiang Han,Zunjing Hu,Linlin Wang,*

1 State Key Laboratory of Petroleum Resources and Prospecting,China University of Petroleum-Beijing,Beijing 102249,China

2 College of Petroleum Engineering,China University of Petroleum-Beijing,Beijing 102249,China

3 Downhole Service Company of Sinopec Shengli Oilfield Service Corporation,China

Keywords:Gas hydrate Phase transition THMC coupling Wellbore integrity Sand production

ABSTRACT Gas hydrate is regarded as a promising energy owing to the large carbon reserve and high energy density.However,due to the particularity of the formation and the complexity of exploitation process,the commercial exploitation of gas hydrate has not been realized.This paper reviews the physical properties of gas hydratebearing sediments and focuses on the geomechanical response during the exploitation.The exploitation of gas hydrate is a strong thermal-hydrological-mechanical-chemical(THMC)coupling process:decomposition of hydrate into water and gas produces multi-physical processes including heat transfer,multi-fluid flow and deformation in the reservoir.These physical processes lead to a potential of geomechanical issues during the production process.Frequent occurrence of sand production is the major limitation of the commercial exploitation of gas hydrate.The potential landslide and subsidence will lead to the cessation of the production and even serious accidents.Preliminary researches have been conducted to investigate the geomechanical properties of gas hydrate-bearing sediments and to assess the wellbore integrity during the exploitation.The physical properties of hydrate have been fully studied,and some models have been established to describe the physical processes during the exploitation of gas hydrate.But the reproduction of actual conditions of hydrate reservoir in the laboratory is still a huge challenge,which will inevitably lead to a bias of experiment.In addition,because of the effect of microscopic mechanisms in porous media,the coupling mechanism of the existing models should be further investigated.Great efforts,however,are still required for a comprehensive understanding of this strong coupling process that is extremely different from the geomechanics involved in the conventional reservoirs.

1.Introduction

Gas hydrate,a kind of clathrates,is a non-stoichiometric crystalline compound in which gas molecules fit in cavities composed of hydrogen-bonded water molecules.It is widespread in the permafrost and deep oceans where the necessary conditions of low temperature and high pressure exist for their formation and stability[1,2].As the most extensive distribution of organic carbon (over 50%)in the world,gas hydrate is closely involved in environment and energy domains[3].In particular,the carbon reserve of gas hydrate estimated is more than twice the total carbon amount of the proved conventional fossil fuel worldwide,approximately 18000Gt[4].Besides,gas hydrate owns high energy density,that is,1m3of gas hydrate could produce as much as 164 SCM (standard cubic meters)gas [5].Due to these advantages,gas hydrate is considered as a promising substitute of conventional energy[6].

Since the Soviet Union exploited hydrate resources in 1969,the United States,Japan,China and other countries have also carried out pilot recovery.Three main methods are applied:depressurization,thermal stimulation and chemical injection[7,8].All the three methods are based on decomposing hydrate solids into gas and water for the recovery.The depressurization method consists of reducing pressure lower than the hydration pressure at the prevailing temperature.Temperature is raised above the hydration temperature at the prevailing pressure in the thermal stimulation.Chemical injection invokes chemical inhibitors to shift the P-T equilibrium for the hydrate decomposition[7-9].Of these possible methods,the depressurization method appears to be the most effective and economical one[10].The thermal stimulation or chemical injection is usually combined with depressurization to prevent the secondary formation of hydrate during the production[11].

Certain geomechanical issues,however,seriously limit the longterm gas production during the pilot recovery.Sand production is recognized as the most critical one (Table 1).The hydrate-bearingreservoirs are fine-grained and poorly consolidated,and sand is easily produced and subsequently blocks the wellbore.Besides,the solid hydrate decomposes into gas and water during the exploitation,reducing the strength of reservoirs.The occurrence of large quantities of gas increases pore pressure dramatically and thus decreases the effective stress.These factors also favor the sand production in the gas hydratebearing reservoir [12].In addition to sand production,long-term production of gas hydrate may lead to a significant subsidence,which will lead to wellbore instability and even cause production accidents.These geomechanical issues should be considered primarily for the commercial exploitation of gas hydrate.

Table 1 Cases of trial production[12,13]

Compared with conventional oil and gas production,the exploitation of gas hydrate is characterized by a phase transition process[15-20].The temperature,pore pressure,and stress fields are all disturbed when hydrate transits into water and gas.The decomposition of gas hydrate is an endothermic process,leading to a variation in temperature.The gas and water produced by the phase transition cause a multiphase flow in the reservoir.Meantime,the transport properties(e.g.,permeability)vary dramatically with the loss of hydrate solid skeleton,which makes the transport phenomenon more complicated.The decomposition of hydrate also leads to the deformation or even the collapse of the reservoir because of 1)variation of pore pressure,2)loss of solid skeleton,and 3)temperature change.In addition,the physical properties of hydrate-bearing reservoirs also vary during the phase transition process.For instance,the specific heat of water is about twice that of gas hydrate.The loss of solid skeleton increases the permeability and also reduces the strength of reservoir rock.

This paper seeks to summarize the state-of-art of knowledge on the geomechanics behaviors of the gas hydrate-bearing reservoir.After the introduction,investigations on the evolution of physical fields(i.e.,temperature,pore pressure and stress)during the production processes are reviewed.Experiments and numerical simulations on the THMC coupling process during the exploitation of gas hydrate are discussed in the following section.Then,several typical geomechanical issues(i.e.,sand production,subsidence)during the exploitation and their influences on the well integrity are discussed.The final part is the summary.

2.Physical Properties of Gas Hydrate-Bearing Sediments

2.1.Thermal properties

Compared with conventional reservoirs,phase transition is the most prominent feature during the exploitation of gas hydrate.Phase transition refers to the conversion between solid hydrate and gas/water during the formation and decomposition of gas hydrate.Because the decomposition of hydrate is an endothermic reaction,the temperature field is disturbed dramatically during the hydrate recovery.For instance,when applying the depressurization method for decomposing the gas hydrate,the specific heat is exhausted rapidly due to the strong endothermic effect[21].The gas production rate will obviously decrease to a low level when the specific heat is not enough for dissociating the existing gas hydrate.Additional heat from the surrounding environment is needed for the continual gas production[22].

With the presence of phase transition,heat is actually stored not only in the form of specific heat but also in the form of latent heat.Accordingly,the heat transfer in solids with phase transition is described by a governing equation such that[23].

where T is temperature,t is time,ρ is the density of solid,kg·m-3,and k is the thermal conductivity,W·m-1·K-1.∇is the gradient operator,ρiis the density of PCM(phase change material,929 kg·m-3for methane hydrate at 263 K),and θiis the volumetric fraction of PCM.In Eq.(1),the first term in the left side refers to the heat that varies the temperature of the material,which is described by a coefficient c called the specific heat,kJ·kg-1·K-1.The specific heat of methane hydrate is 2.03 kJ·kg-1·K-1,about half that of water [24].The second term in the left side refers to the heat stored inside the material during the phase transition with constant temperature,which is described by a coefficient L called the latent heat of PCM,kJ·mol-1.The latent heat of methane hydrate is approximately 52-60 kJ·mol-1at T~0°C[25-28].

As for the governing equation,thermal conductivity is the key property that controls the heat transfer processes in gas hydrate-bearing sediments.Researches were concentrated on the thermal conductivity of pure hydrates and hydrate-bearing sediments.Experiments confirm that the thermal conductivity of pure hydrate has a negative,weak temperature dependence[29].The difference of thermal conductivity between methane hydrate and the water is less than 10%[30].Accordingly,the presence of hydrate alters little to the thermal conductivity in water-saturated sediments and may not be detectable in field measurements[31].

For hydrate-bearing sediments,the coexistence of multiple phases(i.e.,hydrate,water,mineral grain)complicates the measurement and prediction of thermal conductivity.With methane hydrate content increased,Waite[29]found that the effective thermal conductivity of the mixture of sand and methane hydrate increases first and then decreases.The maximum thermal conductivity of the mixture occurs when the solid hydrate accounts for 33%.The increase of thermal conductivity is due to the fact that hydrate in pore will increase grain-tograin heat transfer [32].When hydrate fills the pores and gradually replaces the sand,the thermal conductivity decreases then because of its lower thermal conductivity in comparison with that of mineral grains.The thermal conductivity of fully hydrate-bearing sediments is controlled primarily by porosity[32,33].Besides,the confining stress and the phase transition process also influence the thermal conductivity.The effective confining stress increases both the number and the quality of contacts,causing a rise in thermal conductivity.When hydrate decomposes into water and gas,water migration will improve the contact quality and thus increases the thermal conductivity[34].In addition,experiments have shown a hysteresis in the thermal conductivity of sediments during the formation and dissociation of gas hydrate.When water and hydrate coexist in the pores,the thermal conductivity along the dissociation path is slightly higher than that along the formation path[34].In a word,the thermal conductivity of saturated hydrate-bearing sediments is controlled by lithological stress,while that of unsaturated hydrate-bearing sediments is largely affected by the volume fraction and pore-scale distribution of the hydrate and water phases.

Based on the researches above,the effective thermal conductivity of hydrate-bearing sediments is related to the thermal conductivity of each component.Rather than explicitly calculating the contribution of each heat transfer path,a two-phase mixing model is commonly used to estimate the thermal conductivity considering both the contributions of the sediment grains and the pore fluid[35].Classical thermal conductivity models were established and applied to calculate the thermal conductivity of gas hydrate-bearing sediments(Table)[28].Simple mixing models provide a reasonable bound on the value of the thermal conductivity.As shown in Table 2,the arithmetic model(heat travels simultaneously through pores and particles)and the harmonic model(heat is alternated between flowing through the pore and particles)provide the upper and lower bounds of thermal conductivity,respectively.The other models produce similar results between two bounds.

Table 2 Thermal conductivity mixing models

2.2.Fluid transport

Understanding the permeability characteristics is critical when determining a reservoir production potential[40].Permeability controls fluid transport in pore,which also plays an important role in the thermal and chemical transfer.Darcy's law is commonly used to describe fluid flow in the pores of sediments.

where q(m·s-1)is the single-phase flow rate,P(Pa)is the pressure at elevation,k(m2)is the intrinsic permeability of the porous medium.

The presence of hydrate alters the permeability by reducing the pore size and changing the pore shape.When hydrate forms within pore spaces,the channels for the fluid transport reduce,and the permeability accordingly decreases[41,42].The permeability is also governed by the distribution of gas hydrate in pore spaces[43,44].If the forming hydrate cements the grain contacts or grain surfaces,the permeability is expected to reduce gradually,whereas the permeability decrease will be more pronounced if the hydrate is formed in the middle of the pores.Drastic reduction in permeability occurs if the hydrate forms at pore throat[45,46].According to previous studies,the dependences of permeability k on porosity φ and hydrate saturation SHcan be formulized as[47].

where k0is the absolute permeability without hydrate,φ0is the initial porosity,and n is the reduction factor representing the dependence of permeability on porosity or hydrate deposition.In addition to the influence of hydrate saturation,gas produced during phase transition obviously affects the permeability of sediments.Konno et al.[42]showed that depressurization-induced gas production has the potential to reduce absolute permeability due to high effective stress and water generation.With high effective stress of 10 MPa,absolute permeability of sediments decreased to approximately half of the initial level.

It should be noted that there are both water and gas seepage in hydrate-bearing sediments when hydrate decomposes [48,49].The main properties needed for the flow model are the formation k,the relative permeabilities krwand krgof the water and gas phases,respectively,and the relation between the capillary pressure Pcapand the saturations of the fluid phases[11].This multiphase flow can be modeled as multi-phase Darcy's flow

where Pcap,0is the capillary pressure under the reference conditions.The dimensionless relative permeabilities krwand krgvary from 0 to 1 and depend on phase saturations,the spatial distribution of the phases,mineral wettability,and pore space geometry[35].The dissociation of solid hydrate will generally increase the pore size of the porous media and decrease capillary pressure[50],leading to an increase of the absolute permeability(Eq.(6))[41].

However,it is not enough for the research of the flowing law in hydrate-bearing reservoir.The seepage of water and gas influences the temperature field through heat transfer,while the variation in temperature and pressure fields affects the decomposition and formation of hydrate.Especially for hydrate-bearing sediments with high porosity,the dissociation of hydrate leads to a sharp increase in flow passage and pore pressure.The fluid seepage in pore is enhanced,and even the tube flow is formed.Accordingly,Darcy's law is no longer applicable.The mechanism needs to be studied,and the coupling needs to be investigated.

2.3.Deformation

The mechanical behavior of hydrate-bearing sediments is crucial for analyzing the geohazards[51-53]and well instability[54,55].Hydrate is commonly compared with ice in mechanical properties[56,57].The experimental studies showed that Young's moduli,bulk moduli,and shear moduli of pure hydrate are all approximately 15%smaller than those of ice at nature condition[35].Two key reasons are provided by Sloan and Koh [5]for these differences.One is that the diffusion of water molecules in hydrate is nearly two orders of magnitude lower than in water under the same stress conditions,that is,hydrate should be more creep resistant than ice[58].Another is that the sI-type hydrate cell unit is almost twice the magnitude of that of ice.Besides,compared with ice,methane hydrate is found to exhibit almost isotropic elasticity based on velocity measurements of Brillion spectroscopy at high pressure(0.02-0.6 GPa)[59].This is attributed to the void-rich network of cavities and larger deviations from an ideal tetrahedral geometry.Therefore,it might be unsuitable to use ice as a reference for mechanical properties of pure hydrate.Under extremely high pressure(over 1 GPa),however,the difference between ice and hydrate is limited because of the structural transitions of gas hydrate[60,61].

The presence of hydrate can alter the mechanical properties of the sediment dramatically[62].Systematic laboratory tests of hydrate are concentrated on the effects of the confining pressures,soil types,saturation of hydrate and temperature[63,64].It reveals an increase in the peak strength when the confining pressure varies from 15 to 20 MPa.The presence of hydrate increases interparticle coordination and fills the pore space,enhancing the strength and stiffness[65].A clear yield point is identified related to the hydrate and particle de-bonding before the peak strength for full saturated(Shyd=100%)hydrate-bearing sand and crushed silts[63].Besides,the range of deviatoric stress values at failure under different confining pressures becomes narrower as the degree of saturation of hydrate increases,that is,the stress-strain response becomes less sensitive to confining pressure.It concludes that soil skeletal stiffness and frictional strength dominate the mechanical properties of hydrate-bearing sediments at low hydrate concentration(Shyd<40%).The behavior,however,becomes more independent of stress at high hydrate concentration (Shyd>50%).In addition,the strength of hydrate-bearing sand increased with temperature decreased according to the tests on the mechanical properties and dissociation characteristics[35].The main reason is that the solubility of methane in water is primarily controlled by temperature and the presence of hydrate.With the temperature increased from 0 to 15°C,more energetic methane molecules can break out of the solid hydrate and enter the liquid water.

The mechanical behavior of hydrate-bearing sediments with phase transition is unique [66].According to the Bishop's effective stress[67],the effective stresses σij′of hydrate soil is obtained on partially saturated porous medium

where S is the saturation and δijis Kronecker's delta(1 if i=j,0 if i ≠j).In addition to the coexistence of multi-phase,the effect of fluid flow and the thermal effect should be considered in mechanical formulation.Considering the influence of fluid flow on the mechanical behavior,Klar et al.[68]established a fluid-mechanical formulation.However,the energy flow and the endothermic nature of the hydrate dissociation are not taken into consideration.He then extended the formulation considering the non-isothermal conditions[69].

3.THMC Coupling in the Hydrate-bearing Reservoirs during the Gas Recovery

Numerous experiments and simulations are conducted to investigate the thermal-hydrological-mechanical-chemical(THMC)coupling process during the exploitation of gas hydrate.A series of experiments showed that the decomposition rate of hydrate and gas production rate depend on the formation characteristics and the initial temperature and pressure[70-76].With size effect eliminated[77],Li et al.[78-80]conducted the depressurization experiment in different volume reactors.It concludes that production rate and cumulative production will increase with the decrease of the pressure.As shown by Zhang et al.[81],the average production rate increases first and then decreases with the increase of hydrate saturation.In the heat injection experiments,it showed that the energy efficiency increases with the increase of hydrate saturation and formation temperature,but decreases with the increase of injection temperature and pressure[82-87].Compared with most conventional experimental researches,the nuclear magnetic resonance(NMR)can not only obtain experimental parameters such as pressure and temperature,but also observe the evolution of each phase during the phase transition[88,89].

The physical experiments are time consuming and costly.Numerical simulations are also widely used to analyze the exploitation of gas hydrate [90].Several numerical simulators have been developed to evaluate gas production values in the past few years[91,92].The exploitation of gas hydrate is an issue of fluid-solid coupling field.Significant errors can be resulted in the simulation modeling if the fluid transport phenomena are not adequately represented[93].Assumed the solid phase was immobile,Masuda et al.[94]and Ahmadi et al.[95]created numerical models using the finite difference method to predict flows of gas and water.The deformation of methane hydrate-bearing sand due to the dissociation of gas hydrates were rarely studied because the solid phase was assumed to be rigid in most simulators[96-98].Oka et al.[99]and Kimoto et al.[100]developed a numerical simulator to analyze it based on the chemo-thermo-mechanically coupled mixture theory.In addition,a numerical simulator for analyzing geomechanical performance of hydrate-bearing permafrost was presented combined numerical simulators of hydraulic behavior and mechanical behavior by the staggered technique[101,102].Kim et al.[103]further combined Tough software with geomechanical simulation software ROCMECH to match the real condition.

4.Geomechanical Issues during the Exploitation of Gas Hydrate

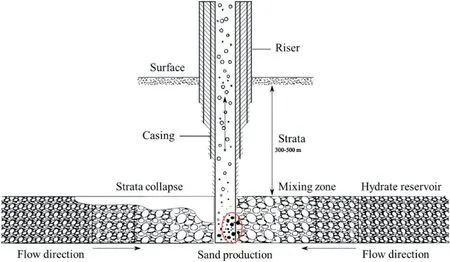

As mentioned above,the wellbore integrity is a key factor should be ensured in the commercial exploitation of gas hydrate.By definition,well integrity is the application of technical,operational,and organizational methods to reduce the risk of fluids being leaked out of control throughout the life cycle of the well in the reservoir [104,105].The main risk lies in geomechanical issues,such as sand production and subsidence.The exploitation of gas hydrate is often accompanied by sand production(Fig.1),which is the critical issue that leads to the failure of pilot recovery.During the gas recovery,the dissociation of hydrate may cause the significant subsidence of the reservoir,leading to wellbore instability and seriously breaking the integrity of the production wellbore[106-108].

4.1.Sand production

Sand production is the process that formation sand and gravel migrate into the wellbore by the flow of reservoir fluids.It commonly occurs due to the large pressure difference and the loose cementation during the exploitation of gas hydrate [12].Three sand production modes are distinguished:continuous collapse,earthworm cavities and pore liquefaction.Most particles are not cemented in the quicksand formation,and the fluid easily carries the sand out the well,causing continuous collapse.In the formation with intergranular pore,the permeability is high and the flow rate is fast.In addition to the free sand,the fluid with large drag force can even strip the consolidated sand,and the formation gradually forms a form similar to the earthworm cavities.Pore liquefaction refers to that the drag of the fluid is insufficient to strip the consolidated sand and can only carry free sand and unconsolidated particles in the microporous formation.Loss of solid structure and variation of the permeability are two consequences of the sand production [109].The pore structure changes significantly and depends on the type of sand production.Moreover,the dissociation of gas hydrate and the production of gas and water make sand production more severe during the exploitation.

Fig.1.Schematic of gas production from hydrate-bearing sediments.

In previous experimental investigations,the importance of fine sand production had been noted during the exploitation of gas hydrate,even when the content of fine sand was relatively low[109].But the influence of wellbores or temperature gradient was not taken into consideration in these tests.Researches have indicated that sand production typically occurs in the unstable depressurization stage.The water flow in pore is the driving force of the sand production [110],and the dissociation of hydrate increases the production volume of sand.Besides,the flow rate has a strong influence on the amount of sand produced by the water flow[12].The flowing gas bubbles and water due to the decomposition of hydrate enhanced the sand carrying capacity[111].To date,the mechanisms of sand production may be related to the porosity and confining pressure of sediments[112].Loose sand seems to produce a uniform flow of sand,where the formation moves as a whole,and the sand structure is preserved.In contrast,dense sand shows more localized production by creating larger voids.

In addition to experiment,numerical analysis is also widely applied in the investigation and prediction of sand production.A simple wellbore-scale numerical analysis showed that grain detachment occurs primarily near the wellbore.Besides,the sensitivity analyses in the simulation indicated that the critical gradient dominantly affects the sand production [12].Lowering depressurization rate is proved more effective in reducing sand production(by 60%)than well heating(by 10%).Moreover,the THMC model of sand production reveals that the shear deformation of hydrate-bearing reservoirs owes to the uneven stress distribution [113-115].TOUGH&HYDRATE model was used to simulate the depressurization process of gas production.The results showed that the increase of pressure difference in bottom hole will lead to the occurrence of settlement and an increase in sand production,but it has little influence on short-term pilot recovery.For long-term production,it is necessary to balance the relation among the production capacity,reservoir stability and sand production.

4.2.Landslide and subsidence

In addition to sand production,the exploitation of gas hydrate may cause geological disasters such as subsidence and landslide.There are two main reasons contributing to it:the most hydrate-bearing reservoirs have no complete trap structures and tight caprocks in submarine;and the gas and water produced by the dissociation of hydrate permeate into the surrounding formation under high pressure.It forms a dissociative surface that is easy to slide,creating conditions for landslide and subsidence[116].Although the pilot recovery of hydrate has not been discovered,it must be considered for the serious impact on the wellbore integrity.

The stability of hydrate-bearing sediments in the vicinity of warm pipes may be affected significantly,especially around the ocean floor where the sediments are unconsolidated and more compressible[51].Gas hydrate is released in the form of bubbles when decomposed.It creates favorable conditions for the formation of weak layers,which leads to the decrease of the shear strength of sediments,resulting in submarine landslide[117].Moreover,due to the gas solubility,the failure interface is initiated at the top of the hydrate layer and not at the bottom of the hydrate stability zone.Simulation results also showed that melting of gas hydrate can be at the origin of a retrogressive failure over the slope[54].A parametric study indicated that the factor of safety for a submarine slope will decrease with water depth decreased[55].Besides,long-term production leads to large deformation of the formation,causing the settlement and a wide range of landslide of hydratebearing reservoir.Large settlements in the formation will cause serious deformation and even buckling of the casing.It will result in the relative slippage between the formation and the wellbore,forming a high flow path for gas and liquid leakage.Serious leakage of gas during the production may occur,resulting in drilling accidents and even exacerbating environmental problems.

4.3.Wellbore instability

Sand production and subsidence may both induce the wellbore instability,seriously breaking the integrity of the production wellbore.The wellbore integrity is necessary for the safety and efficiency in gas recovery.Therefore,the wellbore instability,the bottleneck that restricts the economical production of gas hydrate,should be first clarified during the exploitation of gas hydrate.Considering the complexity of the multi-process during the exploitation,studies are concentrated on the variation of physical fields in the hydrate-bearing reservoirs.Moreover,the weakening of the interface and the role of multiphase flow in the wellbore are both necessary taken into consideration[118,119].

Investigations have conducted on the THM coupling model of hydrate-bearing reservoirs.Only a few coupling models,however,have been proposed and have been served in geotechnical analysis[120].Kimoto et al.[121]attempted to couple the geotechnical mechanics with fluids to analyze the effects of hydrate decomposition on soil deformation and strength.But the model is lacking for the analysis of the strain softening caused by the decomposition of hydrate.Combining TOUGH+HYDRATE and FLAC for a semi-coupling calculation,the decomposition process of hydrate and the geomechanical response involved can be simulated.However,the model is difficult to accurately simulate the stress release caused by the decomposition.Besides,this semi-coupling model only considers the effects of heat and fluid on the mechanics of hydrate-bearing sediments,without considering the effects of its inverse process[101].Klar and coworkers[68]established a four-field(heat transfer,seepage,deformation and phase transition)multiphase coupling model to analyze the mechanical behavior of hydrate-bearing sediments during the exploitation.This model can well simulate the stress release caused by the decomposition of hydrate,but strain softening was not taken into consideration.The current research on hydrated soil,in fact,is generally a simple superposition of theoretically existing multi-processes(phase transition,heat transfer,seepage).The interaction between various physical fields and its microscopic mechanism should be sufficiently studied for the wellbore stability.

5.Conclusions

The current paper reviews the physical properties of gas hydratebearing sediments and summarizes the state-of-art of knowledge on the geomechanical responses during the exploitation.Compared to conventional oil and gas reservoirs,gas hydrate-bearing reservoir is shallow and unconsolidated.Hydrate filling in sediments plays a role of a loadbearing component,decreasing the permeability while increasing the stiffness and strength.Besides,the phase transition involved in the exploitation leads to a richly complex system of interdependent physical properties of hydrate-bearing sediments.Understanding these characteristics can provide a basis for assessment of wellbore integrity,contributing to production strategies and preventing geomechanical issues(i.e.,sand production and settlement).

Accurate description of the multi-field coupling process with phase transition in hydrate-bearing sediments is the key point for the evaluation of wellbore integrity.With the presence of phase transition,hydrate decomposes into gas and water and absorbs heat,leading to a disturbance of temperature field.The heat transfer depends on both specific heat and latent heat,and the conductivity of hydrate-bearing sediments is related to temperature,confining pressure and content of hydrate.Moreover,the decomposition of solid hydrate and the sharp variation of pore pressure alter seepage characteristic and may even change the seepage law.The permeability of hydrate formations is affected by particle size,porosity,and hydrate saturation.Besides,unconsolidated structure and the variation of effective pressure result in the deformation and even damage in the formation.

The interaction of multi-physics processes remains a nodus for the exploitation of gas hydrate.The increase of temperature induces the dissociation of gas hydrate in formation.The seepage of water and gas affects the temperature field through thermal convection,while variations in temperature and pressure fields influence the decomposition and formation of hydrates.The phase transition of hydrate alters the pore structure and leads to the variation of effective pressure in hydrate-bearing sediments,redistributing the stress field.The current investigations,however,remain focus on a simple interaction of multi-physics processes in THMC coupling simulation,without fully considering the influence of the microscopic mechanism in porous media during the exploitation.

Unconsolidated structure and dramatical variation in physical fields are likely to cause several geomechanical issues during the exploitation of gas hydrate,such as sand production and subsidence.Sand production has been the critical issue that restricts the large-scale commercial exploitation of gas hydrate.Fine-grained and poorly consolidated reservoirs make sand production more severe.The potential of subsidence may lead to severe deformation of the formation and a high probability of accidents during the exploitation.With the effect of phase transition,there needs a further systematic and in-depth analysis to reveal the regularity and main control factors of geomechanical issues during the exploitation of gas hydrate.

These issues are the bottleneck of maintaining the wellbore integrity and thus should be prevented during the exploitation of gas hydrate.To date,the mechanism of multi-physics processes in hydrate-bearing formation has been extensively investigated.However,the variation of physical parameters (e.g.,conductivity,permeability,strength),therefore,is hard to be predicted around the wellbore.The precise description of these factors affects the accuracy of analysis of wellbore integrity.It is critical to reveal the geomechanical response of hydratebearing reservoirs under large-scale,long-term exploitation.Accurate prediction of sanding,sedimentation,etc.should be made to achieve safe and efficient production.

Chinese Journal of Chemical Engineering2019年9期

Chinese Journal of Chemical Engineering2019年9期

- Chinese Journal of Chemical Engineering的其它文章

- Decomposition behaviors of methane hydrate in porous media below the ice melting point by depressurization☆

- Research progress in hydrate-based technologies and processes in China:A review☆

- Fundamental mechanisms and phenomena of clathrate hydrate nucleation☆

- Methane hydrates:A future clean energy resource

- Progress and trends in hydrate based desalination(HBD)technology:A review☆

- Extraction of methane hydrate energy by carbon dioxide injection-key challenges and a paradigm shift