高升压DC/DC变换器的研究

李冬辉 刘玲玲 姚乐乐

摘 要:提出了一种高升压DC/DC(简称HS)变换器,它利用一种特殊的结构来实现升压,这种升压结构是由两个电感、一个电容和两个二极管构成.将这种特殊的升压结构和双开关升压直流变换器相结合,就构成了HS变换器,通过电感电容充放电来实现升压功能.另外,本文还提出了(Repeated HS,Re-HS)和(Generalized HS,G-HS)变换器.分析了HS变换器在CCM模式下的电压增益,并对其电压增益、开关应力以及电流尖波进行了深入研究,并与其他电路进行了比较,对比分析验证了HS变换器具有高电压增益、低电压应力和低电流尖波的特点.通过搭建HS变换器的实际电路,验证了所提拓扑的正确性.

关键词:高升压;HS变换器;升压结构;电压增益;开关应力;电流尖波

中图分类号:TM131.3 文献标志码:A

Research of High Step-up DC/DC Converters

LI Donghui,LIU Lingling?覮,YAO Lele

(College of Electrical Automation and Information Engineering,Tianjin University,Tianjin 300072,China)

Abstract:A High Step-up DC/DC (HS) converter was proposed. It steps up the voltage by using a special structure, and the boost structure is composed of two inductors, a capacitor and two diodes. Combing the special boost structure with the double-switch boost DC converter, HS converter is obtained, which depends mainly on charging and discharging of the inductors and capacitors to realize the step-up function. In addition, Repeated HS (Re-HS) and Generalized HS (G-HS) converters were proposed. The voltage gain of the Continuous Conduction Mode (CCM) for HS converter was analyzed. The voltage gain, voltage stress and ripple current of HS converter was deeply studied and compared with other converters. The comparative analysis shows that the HS converter has the characteristics of high voltage gain, low voltage stress, and low current ripple. By building the actual circuit of the HS converter, the correctness of the proposed topology is verified.

Key words: high step-up;HS converter;boost structure;voltage gain;switching stress;current ripple

近年来,随着高压直流开关电源的应用,升压型DC/DC变换器在许多工业领域内越来越受欢迎. DC/DC变换器分为隔离型和非隔离型变换器. 与非隔离型变换器相比,隔离型变换器更容易实现升压,然而隔离型变换器开关浪涌能量损失大,体积和重量相对较大,这些都增加了直流变换器的成本,所以非隔离型变换器越来越受到研究者的青睐[1].

基本的非隔离型变换器主要有Buck[2]、Boost[3-6]、Buck-Boost[7-9]、Cuk[10]、Zeta [10]和Sepic[10]变换器.上述变换器中,Buck和Buck-Boost变换器可以降压,Boost、Buck-Boost、Cuk、Zeta和Sepic变换器可以实现升压. 不过,Boost、Buck-Boost、Cuk、Zeta和Sepic变换器,只有当占空比为极大值时,它的电压增益才可以达到最大.然而,由于电子元器件的限制,占空比通常不超过0.9,因此,直流升压变换器需要更高的电压转换增益[11-15].

文献[16]提出了升压型变换器,可以实现较高的电压转换增益.与其他的变换器相比,它有较少的开关,然而输出电压为负,这在应用中是不利的. 文献[17-18]分别提出了分割电感式升压变换器和高增益升压开关型变换器. 然而,它们开关较多,增加了控制的难度,并降低了工作效率.

目前,经典的非隔离型DC/DC拓扑结构有几种先进的电路拓扑结构,如Switched-capacitor Boost(SC-Boost)、Switched-inductor Boost(SL-Boost)[19]、Asymmetrical Hybrid Switched- inductor converter(AH-SLC)和Symmetrical Hybrid Switched-inductor converter (SH-SLC)[20]變换器. 虽然SL-Boost、SC-Boost、AH-SLC和SH-SLC变换器可以实现比较高的电压增益,但仍然有限,并不能满足许多行业的需求.

故本文提出了一种高升压DC/DC(简称HS)变换器,它是将特殊的升压结构与双开关直流变换器结合,这种特殊的升压结构是由两个电感、一个电容和两个二极管构成.另外,本文还提出了(Repeated HS,Re-HS)和(Generalized HS,G-HS)变换器.HS变换器在性能上具有以下优势:1)比已存在的升压变换器电压增益更高;2)具有更低的电压应力,提高了电路的转换效率;3)具有更低的电流尖波,降低了输出电压纹波.

1 HS变换器的工作模式

本文提出了一种高升压DC/DC变换器:HS变换器,它的拓扑结构如图1所示(L1 = L2 = L3 = L4 = L,C1 = C2).

HS变换器在CCM模式下的工作情况如图3所示(图中实线部分表示电路处于工作状态,虚线部分表示电路不工作). 图3(a)是开关导通时的等效电路图,在Ton时间段内,直流电源给L1、L2、L3、L4、C1 和C2充电,输出电容给负载供电;图3(b)是开关关断时的等效电路图,在Toff时间段内,直流电源、L1、L2、L3、L4、C1 和C2给负载供电.

1)在图3(a)中,开关S1、S2在t0-t1时间段内导通, L1、L2、L3、L4、C1 和C2的电压是:

VL1 = VL2 = VL3 = VL4 = VC1 = VC2 = Vi (1)

2)在图3(b)中,开关S1、S2在t1-t2时间段内关断, L1、L2、L3和L4的电压是:

根據电感L1、L2、L3和L4的电压在一个周期内充放电相等,可以得到下面的公式:

根据图2和等式(3),HS变换器在CCM模式下的输出电压为:

在CCM模式下的电压增益为:

这里D1 = 1 - D.

2 Re-HS和G-HS变换器

在HS变换器的基础上提出了Re-HS和G-HS变换器,其中Re-HS变换器增加了4个二极管、2个电感和2个电容,它的的拓扑结构如图4所示(L1 = L2 = L3 = L4 = L5 = L6 = L,C1 = C2 = C3 = C4).

1)开关S1、S2在t0 - t1时间段内导通, L1、L2、L3、 L4、L5、L6、C1、C2、C3和C4的电压是:

VL1 = VL2 = VL3 = VL4 = VL5 = VL6 =

VC1 = VC2 = VC3 = VC4 = Vi (6)

2)开关S1、S2在t1 - t2时间段内关断, L1、L2、L3、 L4、L5和L6的电压是:

根据电感L1、L2、L3、 L4、L5和L6的电压在一个周期内充放电相等,可以得到下面的公式:

根据图2和等式(8),Re-HS变换器在CCM模式下的输出电压为:

Re-HS变换器在CCM模式下的电压增益为:

G-HS变换器的拓扑结构如图5所示(L1 = L2 =… =Ln-1 = L,C1 = …= Cn-2).

同理得,G-HS变换器在CCM模式下的电压增益为:

3 对HS变换器的理论分析

3.1 电压增益对比分析

SH-SLC变换器的电压增益为[20]:

AH-SLC变换器的电压增益为[20]:

SL-Boost变换器的电压增益为[20]:

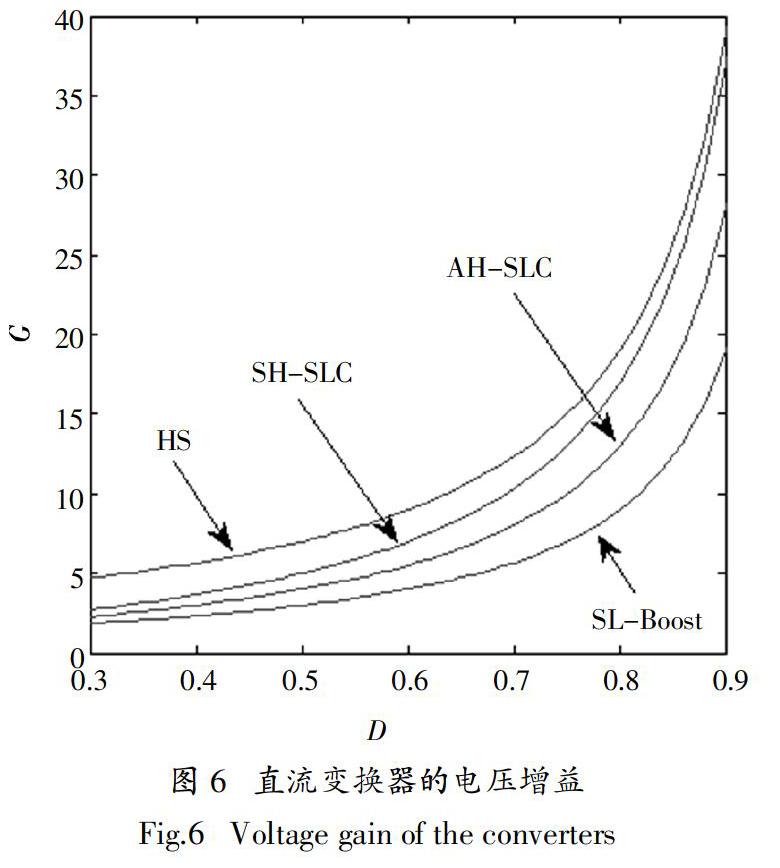

HS、SL-Boost、SH-SLC和AH-SLC变换器的电压增益如图6所示.通过图6可看出,HS变换器的电压增益明显高于SL-Boost、AH-SLC和SH-LDC变换器,所以本文提出的HS变换器具有更高的电压增益.

3.2 开关电压应力对比分析

当开关S1和S2关断时,HS变换器开关S1的电压应力是:

VS1 = 2Vi + VL1 + VL2 (15)

HS变换器开关S2的电压应力是:

VS2 = 2Vi + VL3 + VL4 (16)

HS变换器S1和S2的电压应力为:

SL-Boost变换器的电压应力为[20]:

VS = GVi (18)

SH-SLC变换器的电压应力为[20]:

AH-SLC变换器S1和S2的电压应力为[20]:

直流变换器的电压应力如图7(与公式(17)~(21)一致)所示. 通过图7,可以看出,本文提出的HS变换器的电压应力与SH-SLC变换器的电压应力相同,并明显比AH-SLC和SL-Boost变换器的低,这改善了电路的工作效率.

3.3 HS变换器的电流尖波对比分析

电感峰值电流的表达式可以表示为:

Ipeak-L = (1+ Ki)IL∝IL (22)

式中:Ki是电流尖波参数.由于尖波电流与电感电流成正比,故电感电流越小,尖波电流越小,输出电压纹波越小.

HS变换器在一个周期的平均电感电流与输出电流的比值IL /Io的表达式:

SL-Boost变换器IL /Io为[20]:

AH-SLC变换器IL /Io为[20]:

SH-SLC变换器IL /Io为[20]:

直流变换器的平均电感电流与输出电流比值如图8(与公式(23)~(26)一致)所示,通过图8,可以看出HS变换器的IL /Io明显低于SL-Boost、AH-SLC和SH-SLC变换器,故电感电流尖波较SL-Boost、AH-SLC和SH-SLC变换器更小,这增加了输出电压的稳定性.

3.4 HS变换器二极管的电压应力

当开关S1和S2关断时,HS变换器二极管D1的电压应力是:

VD1 = VL2 + VC1 (27)

二极管D2的电压应力为:

VD2 = VL1 + VC1 (28)

二极管D3的电压应力是:

VD3 = VL4 + VC2 (29)

二极管D4的电压应力为:

VD4 = VL3 + VC2 (30)

联立公式(2)(5)(27)(28)(29)和(30),得到二极管D1、D2、D3和D4的电压应力为:

VD1 = VD2 = VD3 = VD4 = Vi (31)

当开关S1和S2关断时,HS变换器二极管S1和Do的电压应力是:

VDo = Vi + Vo (32)

聯立公式(5)和(31),二极管Do的电压应力是:

VDo = (G + 1)Vi (33)

4 实验结果

为了验证HS变换器拓扑的正确性,以HS变换器为例,搭建了其电路实验平台,电路参数如表1所示.

图9为HS变换器开关S1和S2的驱动信号,频率为24 kHz.当Vi = 5 V时,HS变换器的实验波形如图10所示. 由图10可知:当输入电压为5 V(D=0.5)时,输出电压约为30.5 V,理想值为35 V. 二极管D1、D2、D3和D4的电压应力如图11所示,四个二极管在电路拓扑中的位置对称,故它们的电压应力相同,实验中电压应力约8.5 V,理论分析值为10 V.二极管Do的电压应力如图12所示,电压应力约为35 V,理论值为40 V. 开关S1和S2的电压应力如图13所示,实验值约为18.5 V,理论分析值为20 V.电容C1和C2电压实验图如图14所示,从图14可看出电容在开关导通和关断过程中的充放电过程.

5 结 论

本文首先提出了高升压DC/DC变换器:HS、Re-HS和G-HS变换器,分析了三种变换器在CCM模式下的电压增益,并重点对HS变换器的电压增益、电压应力以及电流尖波进行了分析,同时与其他电路进行了比较,证明了HS变换器具有更高的电压增益,更低的电压应力和电流尖波.最后搭建了HS变换器的实际电路,实验验证了所提拓扑的正

确性.

参考文献

[1] LI W,HE X. Review of nonisolated high-step-up DC/DC converters in photovoltaic grid-connected applications[J]. IEEE Transactions on Industrial Electronics,2011,58(4):1239—1250.

[2] SEBASTIAN J,VILLEGAS P J,NUNO F. High-efficiency and wide-band width performance obtainable from a two-input buck converter[J]. IEEE Transactions on Power Electronics,1998,13(4):706—717.

[3] TSENG K,HUAN C,SHIH W. A high step-up converter with a voltage multiplier module for a photovoltaic system [J]. IEEE Transactions on Power Electronics,2013,28(6):3047—3057.

[4] WU T,LAI Y,HUNG J,et al. Boost converter with coupled inductors and buck-boost type of active clamp [J]. IEEE Transactions on Industrial Electronics,2008,55(1):154—162.

[5] WU T,LAI Y,HUNG J,et al. An improved boost converter with coupled inductors and buck-boost type of active clamp[C]//IEEE Industry Application Society Annual Meeting. 2005:639—644.

[6] KAO S K,WU J H,CHENG H C. All-digital controlled boost DC-DC converter with all-digital DLL-based calibration[J]. Microelectronics Journal,2015,46:970—980.

[7] BENAVIDES N D,CHAPMAN P L. Power budgeting of a multiple-input Buck-Boost converter [J]. IEEE Transactions on Power Electronics,2005,20(6):1303—1309.

[8] SAMAVATIAN V,RADAN A. A novel low-ripple interleaved buck-boost converter with high efficiency and low oscillation for fuel-cell applications[J]. Electrical Power and Energy Systems,2014,63:446—454.

[9] CU K S,MIDDLEBROOK R D. A new optimum topology switching dc-to-dc converter[C]//IEEE Power Electronics Specialists Conference. 1977:160—179.

[10] AXELROD B,BERKOVICH Y,IOINOVICI A. Hybrid switched-capacitor-Cuk/Zeta/Sepic converters in step-up mode[C]// IEEE International Symposium on Circuits and Systems. 2005:1310—1313.

[11] WAI R J,DUAN R Y. High step-up converter with coupled-inductor [J]. IEEE Transactions on Power Electronics,2005,20(5):1025—1035.

[12] MARTINEZ-SALAMERO L,VALDERRAMA -BLAVI H,GIRAL R,et al. Self-oscillating DC-to-DC switching converters with transformer characteristics [J]. IEEE Transactions on Aerospace and Electronic Systems,2005,41(2):710—716.

[13] BRYANT B,KAZIMIERCZUK M K. Voltage-loop power-stage transfer functions with MOSFET delay for boost PWM converter operating in CCM [J]. IEEE Transactions on Industrial Electronics,2007,54(1):347—353.

[14] LU D D C,CHENG D K W,LEE Y-S. A single-switch continuous-conduction-mode boost converter with reduced reverse-recovery and switching losses [J]. IEEE Transactions on Industrial Electronics,2003,50(4):767—776.

[15] ZHOU D Y,PIETKIEWICZ A. A three-switch high-voltage converter [J]. IEEE Transactions on Power Electronics,1999,14(1):177—183.

[16] ZHU M,LUO F L. Voltage-lift-type Cúk converters: topologyand analysis [J]. IET Power Electronics,2009,2(2):178—191.

[17] JIAO Y,LUO F L,BOSE B K. Voltage-lift split-inductor-type boost converters [J]. IET Power Electronics,2011,4(4):353—362.

[18] ABUTBUL O,GHERLITZ A,BERKOVICH Y,et al. Step-up switching-mode converter with high voltage gain using a switched-capacitor circuit [J]. IEEE Transactions on Circuits and Systems-I: Fundamental Theory and Applications,2003,50(8):1098—1102.

[19] AXELORD B,BERKOVICH Y,IOINOVICI A. Switched-capacitor/switched-inductor structures for getting transformerless hybrid DC-DC PWM converters[J]. IEEE Transactions on Circuits and Systems-I: Fundamental Theory and Applications,2008,55(2):687-696.

[20] TANG Y,FU D J,WANG T,et al. Hybrid Switched-inductor converters for high step-up conversion [J]. IEEE Transactions on Industrial Electronics,2015,62(3):1480—1490.