Determination of Paeonol in Detergent by High Performance Liquid Chromatography

Wang Juan, Lei Min, Yu Wen

Xi'an Kaimi Co., Ltd., China

Abstract

Keywords

detergent; paeonol; high performance liquid chromatography

With the rising emphasis on consumer product safety, it' s more likely to add natural plant extract fungicides to detergents.Paeonol is a medicine extracted from the root of flower peony, which can be used as an excellent fungicide in detergents.Methods for detecting paeonol include spectrophotometry,[1]high performance liquid chromatography[2,3]and others.[4]Most of the researches refer to the detection of paeonol in Chinese medicine preparations,[5-15]while less detection of paeonol in detergents is mentioned, and the maximum absorption wavelength of paeonol is usually selected as the detection wavelength to improve the detection sensitivity, but the detergent contains a large number of surfactants and functional ingredients with complicated composition, so there are many interference factors.The author adjusted the high performance liquid chromatography method to determine the paeonol content in the detergent, in order to find a detection method with high accuracy, high reliability and wide applicability.

Experiment

Reagents and instruments

UV6000LP (Diode Array Detector) Liquid Chromatograph, Thermo Finnigan;

Acetonitrile, HPLC grade, Merck, Germany;

Paeonol, standard product (purity ≥ 99.0%), Desit Chengdu;

Ultrapure water, homemade.

Chromatographic conditions

Chromatographic column: Kromasil 100-5 C18 column (150 mm × 4.6 mm, 5 μm);

Column temperature: 30 °C;

Sample injection method: 20 μL valve injection;

Detection wavelength: 274 nm;

Flow rate: 1 mL / min;

Mobile phase A: Ultra-pure water;

Mobile phase B: Acetonitrile;

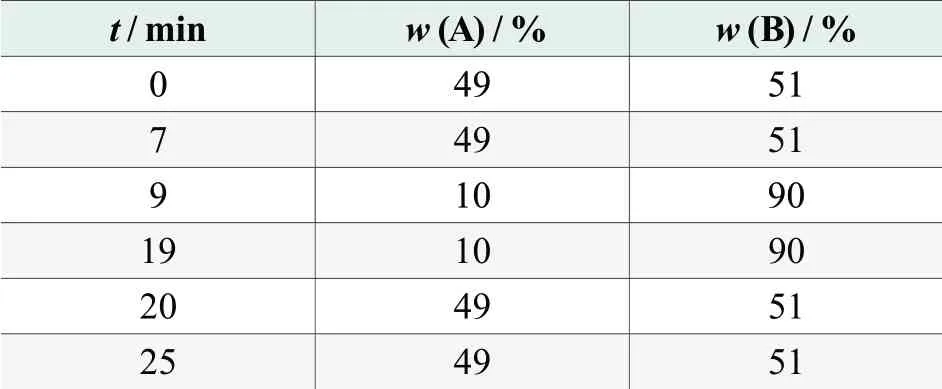

The gradient elution is shown in Table 1.

Table 1.The selection of mobile phase

Solution preparation and sample treatment

Preparation of mobile phase.Use ultrasonic vibration to degas acetonitrile and ultrapure water for 10 min and filter them through a 0.45 μm filter for use.In addition, mix acetonitrile and ultrapure water at a ratio of 51:49 (volume ratio), degas by ultrasonic vibration for 10 min, and filter them through a 0.45 μm filter membrane for use (for preparation of the standard solution and sample solution).

Preparation of standard solution.Weigh 0.100 0 g of paeonol in a 100 mL volumetric flask, dilute the mobile phase to the mark, and prepare a series of samples of different mass concentrations (0.1, 0.5, 1.0, 5.0, 10 and 20 μg / mL).

Preparation of sample solution.Accurately weigh 1.000 0 g sample in a 50 mL volumetric flask, dilute the mobile phase, and use ultrasonic vibration, and dilute to mark for use.

Results and discussion

Choice of mobile phase

Screen the methanol/water system and the acetonitrile/water system and adjust the ratio according to the practical situation to achieve the best separation effect and reduce interference.According to the experimental results, the isocratic elution separation is relatively preferable when the volume ratio of methanol to water is 70:30, at which the baseline is stable, but it takes longer time; gradient elution can better separate and shorten the time, but the baseline drift is severe so it' s not recommended.According to the experimental data comparison and analysis, when the initial volume ratio of acetonitrile to water is 51:49, the gradient elution can achieve the best separation effect with stable baseline and less interference, which is more suitable for the detection of this project.

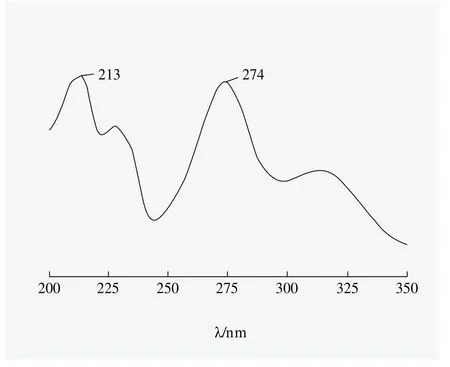

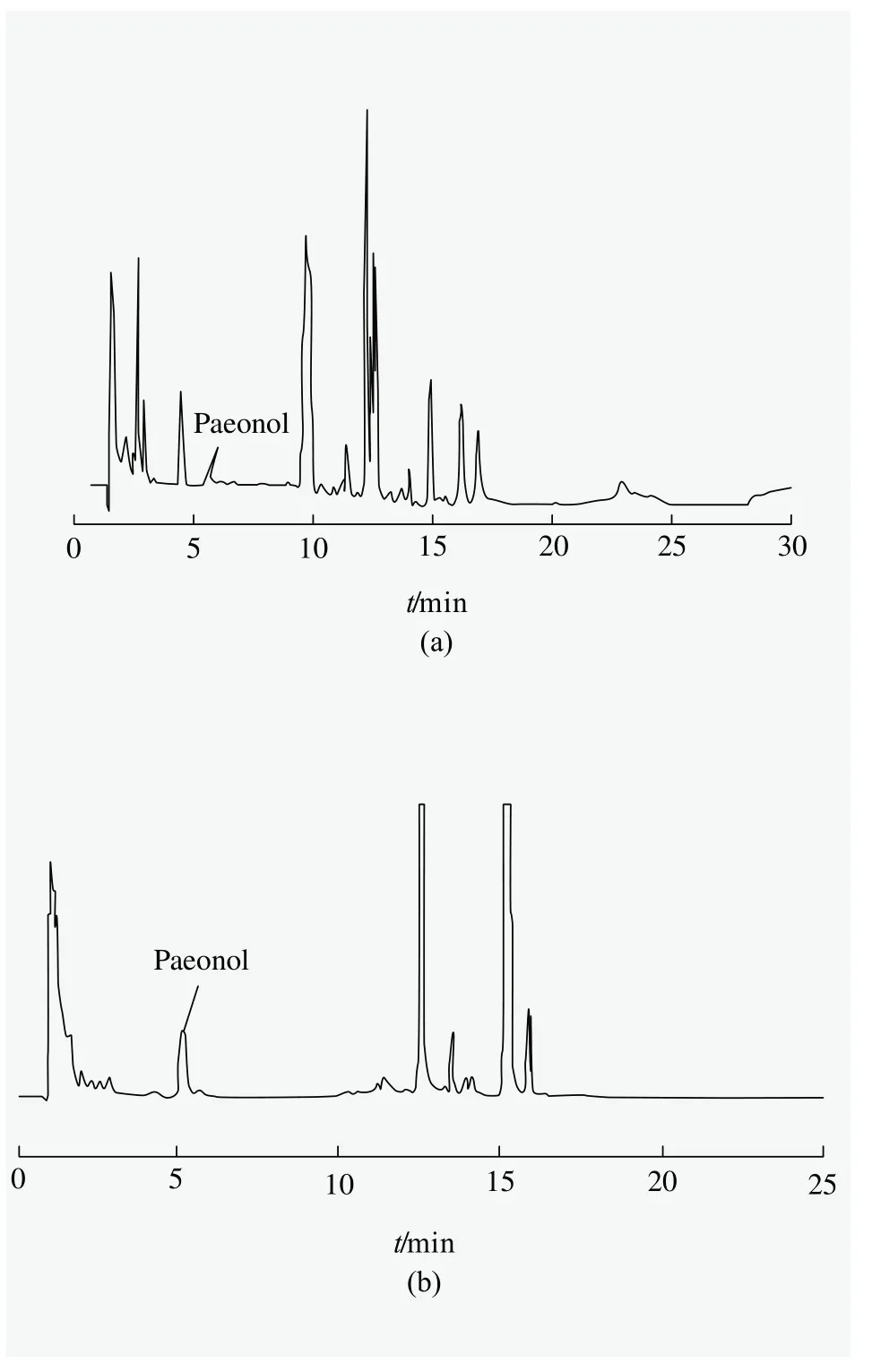

Selection of detection wavelength

The maximum absorption wavelength of paeonol (Figure 1) is 213 nm, followed by 274 nm.Because the detergent contains a large amount of surfactants and other components, the ultraviolet absorption wavelength is mostly within the range of 200~240 nm, with the chromatogram absorption peaking at 213 nm predominantly.The separation effect is bad, with large interference (Figure 2a).It is suggested to choose 274 nm as the detection wavelength (Figure 2b), which makes the target chromatographic peak better separated from other chromatographic peaks.The interference peak is less, which improves the detection accuracy of paeonol in the sample.Therefore, 274 nm is selected as the detection wavelength.

Figure 1.The spectrum of the sample

Figure 2. Chromatograms of samples

Linear relationship

Under the above-mentioned chromatographic conditions, after the baseline of the instrument stabilized, use the concentration-peak area external standard method for quantitative analysis, and prepare the mass concentration of 0.1, 0.5, 1.0, 5.0, 10 and 20 μg / mL standard solution for injection analysis.In terms of the experimental results, the linear regression equation isy=1.969 29×10-6x+0 (r2=0.999 191), whereyis the mass concentration of paeonol (μg / mL), andxis the paeonol peak area,ris the correlation coefficient, and the value ofris larger than 0.999, indicating that paeonol has a good linear relationship in the mass concentration of 0.1~20 μg / mL.The viscosity of the detergent sample is high, so it needs to be diluted and volume-contained for injection detection.Based on 10-fold dilution, the minimum quantitative detection limit of the sample is 1.0 mg / kg.

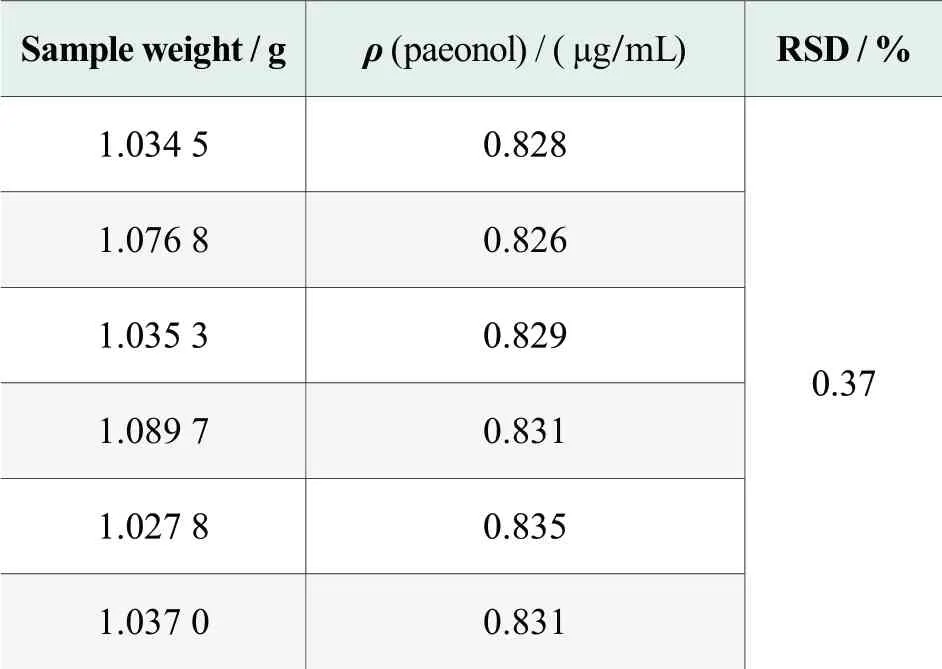

Repeatability test

Accurately weigh 1.000 0 g (without paeonol) hand sanitizer sample in a 50 mL volumetric flask, and then add 2 mL of paeonol standard solution (the paeonol concentration is 20 μg / mL).Dilute to the mark with the mixed mobile phase.Prepare 6 sample solutions according to this method and test 6 times.The experimental results are shown in Table 2.It can be seen from Table 2 that the RSD is 0.37%, which means the method has low error and has good repeatability.

Table 2.Repeatability test

Precision experiment

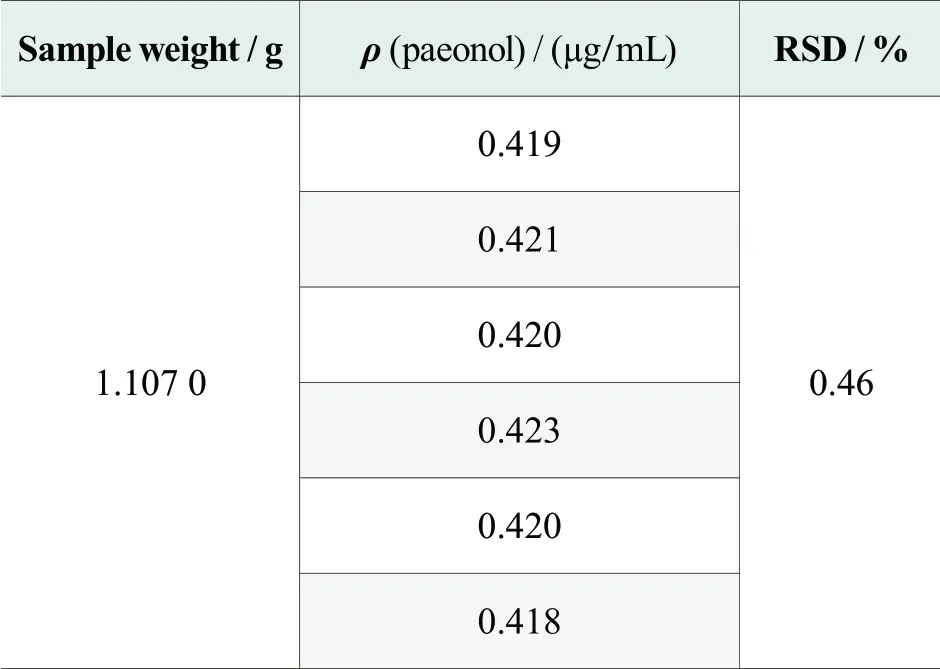

Accurately weigh 1.000 0 g (without paeonol) hand sanitizer sample in a 50 mL volumetric flask, and then add 1 mL of paeonol standard solution (the paeonol concentration is 20 μg / mL).Dilute to the mark with the mixed mobile phase.Test this sample solution 6 times.The experimental results are shown in Table 3.It can be seen from Table 3 that the RSD is 0.46%, indicating that the method has fewer errors and the better precision.

Table 3.Precision test

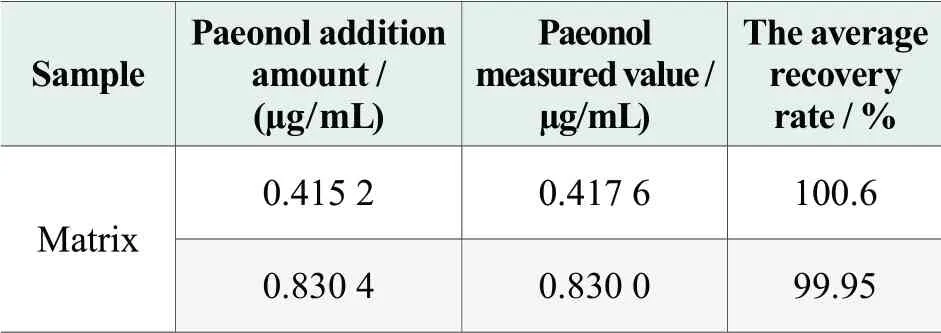

Recovery experiment

Accurately weigh 1.000 0 g matrix sample (without paeonol) in a 50 mL volumetric flask, add 1 mL or 2 mL of a paeonol standard solution with mass concentration of 20 μg / mL, dilute and ultrasonically shake the mobile phase, and then set the volume to the scale.The experimental results are shown in Table 4.According to Table 4, the recovery rate was 99% to 101%, which meet the analysis requirements.

Table 4.Recovery test (n=6)

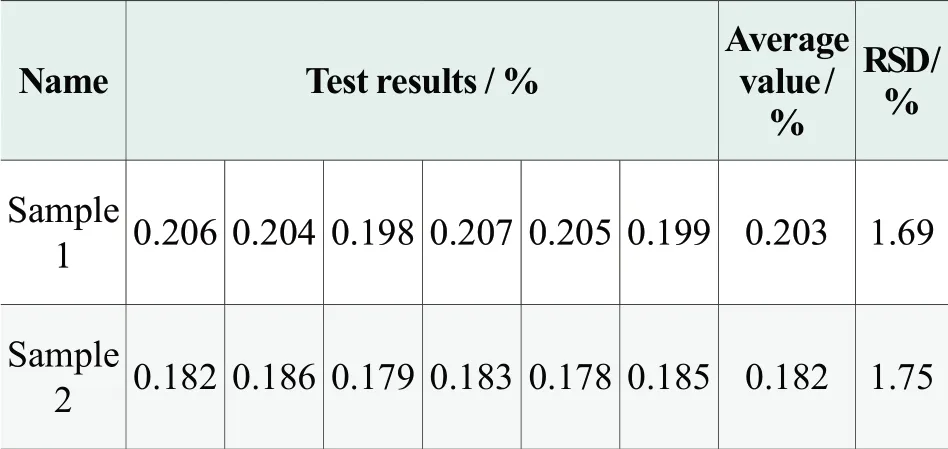

Commercially available sample test

Accurately weigh 1.000 0 g of the commercially available sample in a 50 mL volumetric flask, dilute with the mixed mobile phase, ultrasonically shake, and dilute to the scale for use.Determine the paeonol content in the sample.The experimental results can be found in Table 5.

Table 5.Test results of paeonol in the samples

In terms of the experimental results in Table 5, the RSD of the six results of the two groups of commercially available samples were 1.69% and 1.75% respectively, indicating that the method has fewer errors and better parallelism.

Conclusion

Using high performance liquid chromatography to determine paeonol in detergent.It can be seen from the experimental results that the standard solution is linearly correlated at 0.1~20 μg / mL, and the minimum quantitative detection limit is 1.0 mg / kg, and the recovery rate is 99% to 101%.

China Detergent & Cosmetics2019年3期

China Detergent & Cosmetics2019年3期

- China Detergent & Cosmetics的其它文章

- Experimental Design of Cosmetics Human Efficacy Evaluation

- Application Research of Bamboo Vinegar in Daily Chemicals

- Fluorinated Surfactants and Fluorinated Polymer Materials (III): Personal Opinion on the Problems of PFOS

- A New Method to Improve the Product Stability and Performance of Soap-based Cleanser at Two Different Temperatures

- Safety and Risk Management of Cosmetic Products

- Innovation Reshapes the Future of Detergent Industry in China