Optimization on Ultrasonic Extraction Method of Total Flavonoids for Liriodendron chinense Sarg.×L. tulipifera L. by Response Surface Methodology (RSM)

Yi JIANG Xuqin REN Gang LI Guoqing PAN Run ZHUO

Abstract With the leaves, bark and roots of Liriodendron chinense Sarg.×L. tulipifera L. as experiment materials, the ultrasonic-assisted extraction conditions of total flavonoids were optimized by response surface Box-Behnken test design. Ultrasonic time and liquid-to-solid ratio had significant effects on the extraction amount of flavonoids from the leaves of L. chinense Sarg.×L. tulipifera L.; ultrasonic temperature and liquid-to-solid ratio had an interaction on the extraction amount of flavonoids; and the optimum ultrasonic time, temperature and liquid-to-solid ratio for the extraction of flavonoids from leaves of L. chinense Sarg.×L. tulipifera L. were 19.82 min, 28.60 ℃ and 9.48 ml/g, respectively. Ultrasonic time, temperature and liquid-to-solid ratio had significant effects on the extraction amount of flavonoids from L. chinense Sarg.×L. tulipifera L.; there was a significant interaction between any two of the factors, which had a significant effect on the extraction of flavonoids; and the optimum extraction parameters for flavonoids in the bark were the ultrasonic time of 33.66 min, the ultrasonic temperature at 32.85 ℃ and the liquid-to-solid ratio of 11.39 ml/g. Ultrasonic time and liquid-to-solid ratio had significant effects on the extraction of flavonoids from roots; there was a significant interaction between ultrasonic time and liquid-to-solid ratio and between ultrasonic temperature and liquid-to-solid ratio; and the optimum extraction parameters for flavonoids from the roots of L. chinense Sarg.×L. tulipifera L. were the ultrasonic time of 32.38 min, the ultrasonic temperature at 25.0 ℃ and the liquid-to-solid ratio of 8.00 ml/g. The results of the three models were stable. The models are feasible and have good application value.

Key words Response surface methodology; Liriodendron chinense Sarg.×L. tulipifera L.; Total flavonoids; Ultrasonic extraction

Liriodendron chinense Sarg., also called as Ezhangqiu, is a kind of angiosperm that has appeared in the Jurassic in the Mesozoic. There are only two species in the world. L. tulipifera Linn. is mainly distributed in the eastern United States and southeastern Canada. L. chinense Sarg. is distributed at 21°-32° north latitude and 103°-120° east longitude, mostly in the mountains of Jiangxi, Anhui, Sichuan, Hubei and Zhejiang. It is often mixed with deciduous broad-leaved trees and evergreen broad-leaved trees. The natural growth of L. chinense Sarg. is mainly distributed vertically at an altitude in the range of 900- 1 700 m. It is also introduced into low mountains, hills and plains with an altitude lower than 660 m[1]. In 1963, Professor Ye, a forestry breeder in China, first successfully crossed L. chinense Sarg. as the female parent with L. tulipifera L., obtaining the interspecific hybrid, L. chinense Sarg.×L. tulipifera L.[2].

As a traditional medicinal plant, L. chinense Sarg. has high medicinal value. Quanguo Zhongcaoyao Huibian (National Chinese Herbal Medicine Collection) records that the bark and roots of L. chinense Sarg. are used as a medicine, which has the effects of dispelling wind and eliminating dampness, and stopping coughing and removing phlegm, and can be used for treating cough due to wind-cold evil, rheumatism and joint pain. Flavonoids are one of the main active components in L. chinense Sarg.[3]. Flavonoids, also known as bioflavonoids, are a general term for a class of compounds based on chromone ring and benzene ring. They have broad application prospects in food, medicine and health care products. Flavonoids have antibacterial, anti-inflammatory, anti-mutation, antihypertensive, detoxification, sedative, anti-fatigue, diuretic, anti-oxidation, anti-cancer, anti-cancer, anti-lipase and other significant effects, and are important natural organic antioxidants with development prospects[4-7]. At present, there have been no reports on the research of flavonoid extraction from L. chinense Sarg. Based on previous single-factor experiments, the ultrasonic-assisted extraction conditions of total flavonoids in the leaves, bark and roots of L. chinense Sarg.×L. tulipifera L. were optimized by Box-behnken test design of the response surface methodology, aiming at providing a reasonable basis and reference for well development of the medicinal value of L. chinense Sarg.×L. tulipifera L.

Materials and Methods

Materials

L. chinense Sarg.×L. tulipifera L. was planted at the seedling base of Huaiyin Institute of Technology, 10 years old. The old leaves, bark and roots were taken separately, inactivated at 110 ℃ for 30 min and dried at 80 ℃ to constant weight. The dried samples were crushed and sieved with a 100 mesh sieve for later use.

Experimental methods

Drawing of standard curve

Rutin was accurately weighed and dissolved in 70% ethanol, obtaining a 0.214 0 g/L rutin mother liquor, which was stored in the dark. Then, 0, 1.0, 2.0, 3.0, 4.0, 5.0 and 6.0 ml of the mother liquor were accurately pipetted to a 25 ml volumetric flask, respectively. Into each volumetric flask, 70% ethanol was added to 6 ml, followed by adding 1 ml of 5% NaNO2, shaking well and standing for 6 min. Next, 1 ml of 10% Al(NO3)3 solution was added, followed by shaking well and standing for 6 min. Next, 10 ml of 4% NaOH solution was added into each volumetric flask, the solution in which was finally diluted with 70% ethanol, shaken well and stood for 15 min. The absorbance at 510 nm was determined with the corresponding reagents without rutin as a blank. A standard curve was drawn with absorbance value (A) as the ordinate and rutin concentration (C) as the abscissa.

Flavonoid extraction and determination method

A certain amount of the sample powders (1.00 g) were accurately weighed. Each was added with 70% ethanol solution according to a certain liquid-to-solid ratio, giving a mixture, which was ultrasonically extracted for flavonoids in a 180 W ultrasonic reactor for a certain time at a certain temperature and then centrifuged. Next, 1 ml of each supernatant was subjected to a color development reaction according to "Drawing of standard curve". Finally, the absorbance was measured at 510 nm to calculate the extraction amount of total flavonoids.

Response surface Box-Behnken test design

According to the results of previous single-factor experiments, ultrasonic time, ultrasonic temperature and liquid-to-solid ratio were selected as the response variables. According to the central composite design principle of Box-Behnken[8], with flavonoid extraction amount as the response value, the response surface analysis was adopted to optimize the extraction conditions of total flavonoids in different parts of L. chinense Sarg.×L. tulipifera L. The data were processed by design expert 7.0.0 software. The response surface test schemes and variable levels for different parts of L. chinense Sarg.×L. tulipifera L. are shown in Table 1 and Table 2, respectively.

Results and Analysis

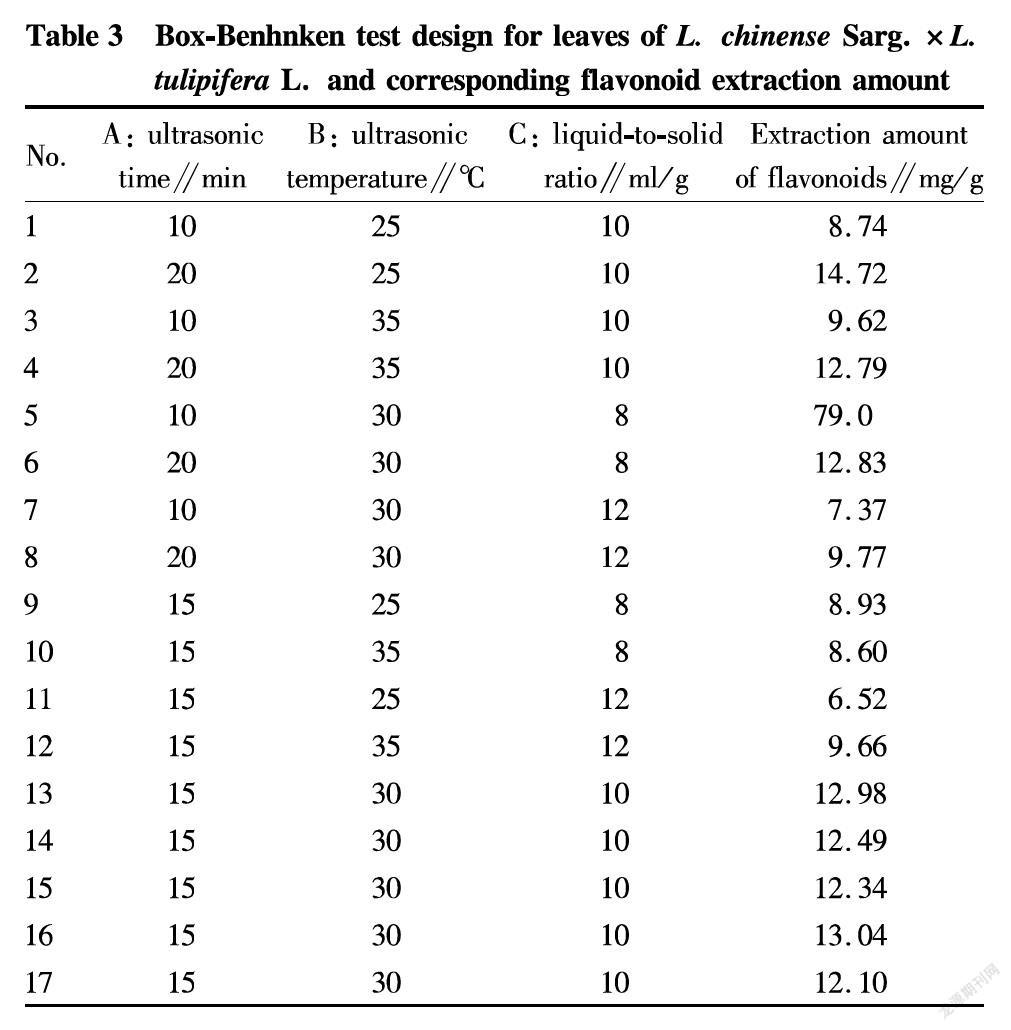

Response surface optimization of extraction conditions of total flavonoids in leaves

On the basis of the previous single factor experiments, three-factor three-level tests were used to optimize the process parameters of flavonoid extraction. The specific treatments and flavonoid extraction amounts (response values) are shown in Table 3. It can be seen from Table 3 that different ultrasonic treatments had significant effects on the amount of flavonoids extracted from the leaves of L. chinense Sarg.×L. tulipifera L., and the flavonoid content varied between 6.52 and 14.72 mg/g. The data in the table were subjected to quadratic multiple regression fitting. The regression equation of the extraction amount of flavonoids from the leaves of L. chinense Sarg.×L. tulipifera L. to the ultrasonic reaction conditions was: R1=-1 042.58+19.37 A+21.93 B+134.44 C-0.28 AB-0.63 AC+0.87 BC-0.02 A2-0.43 B2-7.70 C2.

It can be seen from Table 4 that the regression model reached a very significant level (P<0.01). The coefficient of determination of the model reached 0.962 2. Meanwhile, its lack of fit was tested to be non-significant (P=0.061 2), and the signal-to-noise ratio of the model (Adeq Precision) was 13.303. It can be seen that the model had a good degree of fitting between the simulated value and the actual value, and can explain 96.22% of the change in the response value, so the signal strength was sufficient. The effects of various factors on the extraction amount of flavonoids from the leaves of L. chinense Sarg.×L. tulipifera L. ranked as ultrasonic time (A)>liquid-to-solid ratio (C)>ultrasonic temperature (B). Ultrasonic time had a significant effect on the extraction of flavonoids, as well as liquid-to-solid ratio, while the temperature change had no significant effect on the amount of flavonoids extracted. The interaction between any two of the factors showed that there was a significant interaction between ultrasonic temperature and liquid-to-solid ratio, which had a significant effect on the extraction amount of flavonoids.

Response surface optimization of extraction conditions of total flavonoids in bark

It can be seen from Table 5 that different ultrasonic conditions had greater effects on the extraction of flavonoids in the bark, and the flavonoid content varied from 8.49 to 13.87 mg/g. The regression equation of the extraction amount of flavonoids from the bark to ultrasonic time (A), ultrasonic temperature (B) and liquid-to-solid ratio (C) was: R2=-540.29+30.79 A+23.08 B-35.33 C-0.48 AB+0.90 AC+0.82 BC-0.39 A2-0.24 B2-0.98 C2. The results of variance analysis (Table 4) showed that the model reached a very significant level (P<0.01), and the lack of fit was tested to be non-significant. The degree of fitting between the simulated value and the actual value was 98.92%, that is to say the model can well explain the response value. Meanwhile, the model had sufficient signal strength (Adeq Precision=26.294) and was highly confident. Ultrasonic time, temperature and liquid-to-solid ratio had significant effects on the flavonoids extracted from the bark of L. chinense Sarg.×L. tulipifera L., and there was a significant interaction between any two of the factors.

Response surface optimization of extraction conditions of flavonoids in roots

It can be seen from Table 5 that the ultrasonic conditions had significant effects on the amount of flavonoids extracted from the roots, and the maximum extraction amount of flavonoids was 9.21 mg/g, which was 2.6 times of the minimum extraction amount. The multiple regression of the data in the table produced the quadratic multiple regression model of the extraction rate of flavonoids to ultrasonic time, ultrasonic temperature and liquid-to-solid ratio: R3=-11.77+23.82 A-14.94 B-5.56 C-0.02 AB+0.43 AC+0.48 BC-0.44 A2+0.17 B2-1.39 C2. The analysis of variance (Table 4) showed that the regression model reached a very significant level, and its coefficient of determination was 0.973 0, indicating that the model can explain 97.30% of the change. The lack of fit was not significant, and the models signal-to-noise ratio was 23.877, indicating that the model had sufficient signal strength, and the response value can be well explained. It can be seen from Table 4 that the response of the factors to the extraction amount of flavonoids from the roots ranked as liquid-to-solid ratio (C)>ultrasonic time(A)>ultrasonic temperature (B), among which liquid-to-solid ratio (C) and ultrasonic time (A) had significant effects on the extraction of flavonoids. There was an interaction between ultrasonic time and liquid-to-solid ratio and between ultrasonic temperature and liquid-to-solid ratio, which can significantly affect the extraction of flavonoids from roots.

Model optimization and verification

The regression equation was solved by software. According to the principle of maximizing the extraction amount of flavonoids, the optimal extraction processes of flavonoids from different parts of L. chinense Sarg.×L. tulipifera L. was obtained. The optimum ultrasonic time, temperature and liquid-to-solid ratio for the extraction of flavonoids from the leaves of L. chinense Sarg.× L. tulipifera L. were 19.82 min, 28.60 ℃ and 9.48 ml/g, respectively, under which the theoretical extraction amount of flavonoids was 14.73 mg/g. The ultrasonic time, temperature and liquid-to-solid ratio were set as 20.0 min, 29.0 ℃ and 9.5 ml/g, respectively, to carry out the verification test, which gave the actual measured flavonoid extraction amount of 14.51 mg/g. The optimum extraction parameters of flavonoids in bark were the ultrasonic time of 33.66 min, the ultrasonic temperature at 32.85 ℃ and the liquid-to-solid ratio of 11.39 ml/g, and with the time of 33.5 min, temperature of 33 ℃ and liquid-to-solid ratio of 11.0 ml/g, the extraction amount of flavonoids was 13.75 mg/g, which was close to the predicted value of 13.89 mg/g. The optimal extraction process of flavonoids was the ultrasonic time of 32.38 min, the ultrasonic temperature at 25.0 ℃ and the liquid-to-solid ratio of 8.00 ml/g, which produced the predicted extraction amount of 9.21 mg/g, and the measured value was 9.04 mg/g. Therefore, the results of the three models were stable. The models are feasible and have good application value.

Conclusions

Based on the results of previous single factor experiments, the ultrasound-assisted extraction of flavonoids from different parts of L. chinense Sarg.×L. tulipifera L. was optimized by the response surface Box–Behnken design, and reasonable and reliable quadratic multivariate models were established. The results showed that ultrasonic time and liquid-to-solid ratio had significant effects on the extraction amount of flavonoids from the leaves of L. chinense Sarg.×L. tulipifera L.; ultrasonic temperature and liquid-to-solid ratio had an interaction on the extraction amount of flavonoids; and the optimum ultrasonic time, temperature and liquid-to-solid ratio for the extraction of flavonoids from leaves of L. chinense Sarg.×L. tulipifera L. were 19.82 min, 28.60 ℃ and 9.48 ml/g, respectively. Ultrasonic time, temperature and liquid-to-solid ratio had significant effects on the extraction amount of flavonoids from L. chinense Sarg.×L. tulipifera L.; there was a significant interaction between any two of the factors, which had a significant effect on the extraction of flavonoids; and the optimum extraction parameters for flavonoids in the bark were the ultrasonic time of 33.66 min, the ultrasonic temperature at 32.85 ℃ and the liquid-to-solid ratio of 11.39 ml/g. Ultrasonic time and liquid-to-solid ratio had significant effects on the extraction of flavonoids from roots; there was a significant interaction between ultrasonic time and liquid-to-solid ratio and between ultrasonic temperature and liquid-to-solid ratio; and the optimum extraction parameters for flavonoids from the roots of L. chinense Sarg.×L. tulipifera L. were the ultrasonic time of 32.38 min, the ultrasonic temperature at 25.0 ℃ and the liquid-to-solid ratio of 8.00 ml/g.

References

[1]WANG ZR. Retrospect and prospect of cross breeding of Liriodendron chinense Sarg.[J]. Journal of Nanjing Forestry University: Natural Sciences, 2003(3): 76-78. (in Chinese)

[2]DOSKOTCH RW, EL-FERALY FS. Antitumor agents. II. Tulipinolide, a new germacranolide sesquiterpene, and costunolide, Two cytotoxic substances from Liriodendron tulipifera L[J]. Journal of Pharmaceutical Sciences, 1969, 7: 877 -880.

[3]YANG DT, YANG GX, DONG W, et al. Advances in studies on chemical constituents and biological activity of Liriodendron plants[J]. Natural Product Research and Development, 2014, 26: 454-462. (in Chinese)

[4]BAI J, ZHAO SY, FAN XQ, et al. Inhibitory effects of flavonoids on P-glycoprotein in vitro and in vivo: Food/herb-drug interactions and structure–activity relationships[J]. Toxicology and Applied Pharmacology, 10.1016/j.taap.2019.02.010

[5]WANG L, SUN JS. Chemical structure and biological effects of flavonoids[J]. Journal of Agricultural University of Hebei, 2003, 26(5): 145-147.

[6]LI XG, FANG LH, DU GH. Research advances in cardiovascular protective effects of flavonoids[J]. Chinese Journal of Pharmacology and Toxicology, 2018, 4(15): 12-14. (in Chinese)

[7]BAI FM, CAI TY. Advances in research on biological activity and mechanism of flavonoids[J]. Food Science, 1999, 8(1): 112-131. (in Chinese)

[8]HE MX, LI HY, MO XQ, et al. Optimization of application parameters of soil seed bank in vegetation recovery via response surface methodology[J]. Chinese Journal of Applied Ecology, 2014, 25(8): 2311- 2316.

- 农业生物技术(英文版)的其它文章

- Analysis of the Southern China Tilapia Production and Economic Benefits of Different Breeding Patterns in 2018

- Dynamic Monitoring and Control Measures of Spodoptera frugiperda (J.E.Smmith) in Low Latitude Plateau Sugarcane Areas

- Control Effects of a New Sex Pheromone Trap and Biological Agents on Sesamia inferens Walker and Argyroploce schistaceana (Snellen)

- Comparative Study on Grain Cadmium Content and Yield in Different Rice Varieties

- Simulation Experiment of Air Temperature Variation in Multi-film Covering at Night

- Identification of Growth-promoting Bacteria from Rhizosphere of Pastures and Their Effects on Growth of Lotus corniculatus L.