Simulation Experiment of Air Temperature Variation in Multi-film Covering at Night

Chuankun ZHANG Yunhua NIU Zigao JIAO Chongqi WANG Min WEI Kun XU Ning YANG

Abstract In order to provide theoretical basis and data support for improving the production mode of covering, this study investigated the nighttime air temperature formed by multiple layers of films with tunnel sheds and small tunnel sheds as trial subjects. The experiment was carried out in four tunnel sheds with 0 or 2 small tunnel sheds covered by 0, 1, 2 and 3 layers of films, respectively in Jinan, Shandong Province in winter of 2018. The nighttime air temperatures of tunnel sheds and small tunnel sheds formed by 1, 2, 3 and 4 layers of plastic film were measured and analyzed to simulate the temperature environment of early-spring season. The results showed that there were little differences between the nighttime air temperatures inside the tunnel sheds which was installed 0-3-layer small tunnel sheds inside, and there were uncertainty in the values of the air temperatures inside and outside the tunnel sheds; and the nighttime temperature conditions were constantly improved with the number of plastic film layers increasing under the conditions of this study. The analysis indicated that the mechanism of raising the temperature surrounded by plastic film was not only due to its own thermal parameter (thermal conductivity). MATLAB fitting analysis results showed that the increment of nighttime temperature in multi-film coverings became smaller with the number of film layers increasing. In this study, the number of layers in multi-film covering should not exceed 5 layers.

Key words Multi-film covering; Tunnel shed; Small tunnel shed; Nighttime air temperature; Simulation; Thermal parameter

Multi-film covering cultivation can bring forward the planting date of crops in winter and spring and the time to market consequently, so it improves economic benefits and is promoted and applied in a large area in production[1]. The number of film layers varies with the planting time of crops. Generally, 1-6 layers of films are often used in production[2-6]. Due to the saying that "one layer of film increases the night temperature by 2 ℃" in production practice, some producers continue to increase the number of layers of the covering, which can even reach 7 or 8 layers in some places. Therefore, to study the relationship between the number of covering layers and its thermal insulation effect and to determine the optimal number of covering layers are of important guiding significance for multi-film cultivation.

As a heat accumulator in multi-film covering cultivation, soil absorbs solar radiation energy during the day through temperature rising, and then releases heat into air[7]at night to form temperature environment, to prevent the crops from being damaged by low temperature outside. Under the greenhouse effect[8], the temperature inside the multi-film covered sheds during the day is high, which is easy to meet the needs of crops. The outside temperature is very low at night, the heat released quickly from the soil to the outside, and the temperature in the shed is usually very low, which poses a threat to crop growth. Therefore, understanding the changing law of nighttime temperature in sheds is of great significance in multi-film covering cultivation. However, most studies have focused on the promotion and application of cultivation modes, while few quantitative studies have been conducted on the nighttime temperature environments formed by different layers of film coverings.

Considering that the transplanting time of crops covered by different layers of films differs in winter and spring, it is difficult to carry out research on the temperature environments formed by different layers of film coverings after planting. In this study, multi-point monitoring and data analysis were carried out on the nighttime temperature in idle tunnel sheds covered by different layers of films in the winter of 2018, aiming at providing data support for improving the multi-film covering cultivation technology.

Materials and Methods

Test facilities

The test tunnel sheds were located in the test base of Institute of Vegetables and Flowers, Shandong Academy of Agricultural Sciences, Jinan City (36°67′N, 116°98′E). The tunnel sheds had a length of 20 m, a width of 4.5 m and a height of 2.6 m, a total of four, which were designated A, B, C and D respectively (Fig. 1). No small tunnel shed was set in tunnel shed A; in tunnel shed B, there were 2 rows of small sheds covered by one layer of film, which were 1.0 m wide with a bracket height of 0.6 m; tunnel shed C was provided with 2 rows of tunnel sheds covered by 2 layers of films, which were 1.0 m wide and had the bracket heights of 0.6 and 0.8 m, respectively; and tunnel shed D was provided with 2 rows of tunnel sheds covered by 3 layers of film, which were 1.0 m wide and had the bracket heights of 0.6, 0.8 and 1.0 m, respectively. The tunnel sheds and each layer of small tunnel shed were covered with EVA multi-functional dripping film.

Test design and methods

Temperature sensors were installed in the four tunnel sheds at 10 m from east to west, 2.2 m from the south side, and 1.3 m from the ground. The measured temperatures were recorded as T2-1, T2-2, T2-3 and T2-4, respectively. In each small tunnel shed, a temperature sensor was set at about 0.5 m from the north side and 0.3 m from the ground, and the measured temperatures were recorded as T3, T4 and T5, respectively. A temperature sensor was installed outside the tunnel sheds at 1.3 m from the ground and 0.5 m from the north side of the tunnel sheds to measure the temperature outside the sheds, which was recorded as T1. The structures of the tunnel sheds and small tunnel sheds and the distribution of the temperature sensors are shown in Fig. 1. The films of the tunnel sheds were always covered, and each layer of the film of the small tunnel sheds was uncovered according to the solar radiation during the day and covered at night.

The temperature of each measuring point was measured using a JTNT-C multi-channel temperature heat flow meter. The technical parameters of the temperature sensors were as follows: temperature range -20-85 ℃, accuracy ± 0.5 ℃, normal temperature up to ± 0.2 ℃, and resolution 0.1 ℃. The test was carried out from November 10, 2018 to December 10, 2018, and the data were recorded at night everyday (i.e., from 18:00 pm to 6 am of the following day), with an interval of 5 min, 12 data every hour, which were averaged as the temperature at that time. In this experiment, the temperature data of each measurement point inside and outside the tunnel sheds on November 29, 2018, November 30, 2018 and December 1, 2018 during the test period were selected for analysis.

Data analysis

The MATLAB software was used to fit the change of temperature at each measuring point over time under different layers of film coverings. The original functions of the fitting functions were solved, and were then subjected to integration, and the relationship between the integral value and the number of film layers was fitted.

Results and Analysis

Effects of setting small tunnel sheds on the nighttime temperature in tunnel sheds

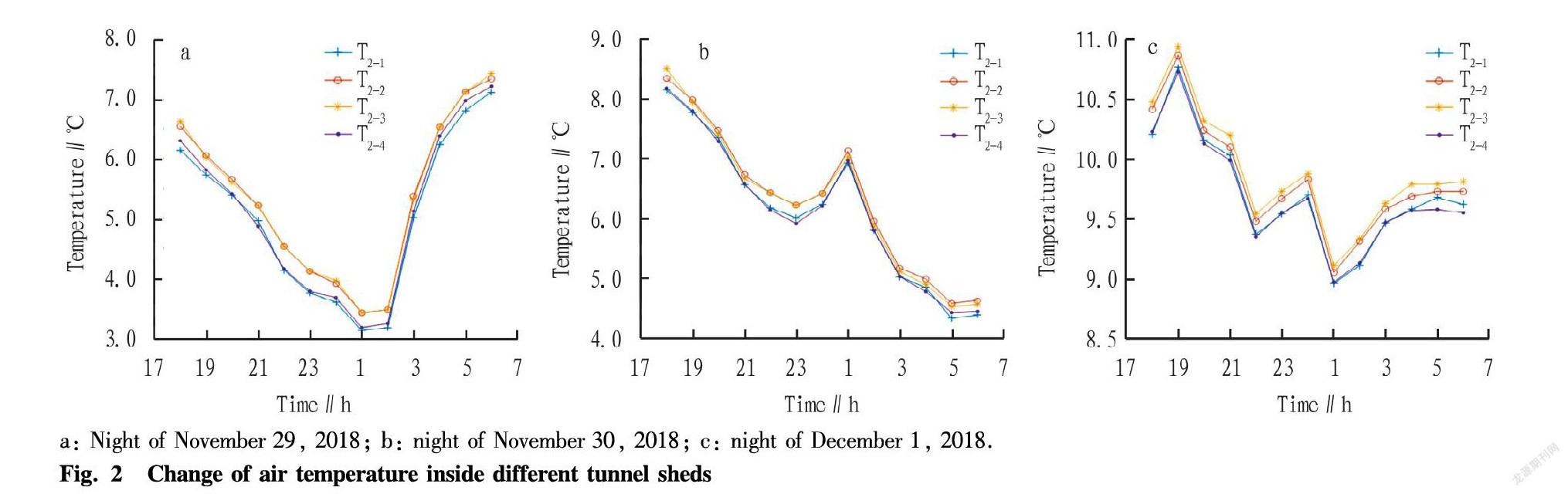

On November 29, 2018, November 30, 2018 and December 1, 2018, the change of the temperature in the four tunnel sheds at night (i.e., T2-1, T2-2, T2-3 and T2-4) with time is shown in Fig. 2. It can be seen that the trends of T2-1, T2-2, T2-3 and T2-4 were basically the same. The temperature in the tunnel sheds set with small tunnel sheds covered by 1 or 2 layers of films was slightly higher than that of the tunnel sheds set with no mall tunnel shed or the small tunnel sheds covered by 3 layers of films, but the differences were small (Fig. 2), indicating that the small tunnel sheds in the tunnel sheds had no obvious influence on the temperature inside the tunnel sheds. Therefore, the mean value of T2-1, T2-2, T2-3 and T2-4 was calculated to serve as the air temperature inside the tunnel sheds.

However, comparing the temperatures of the three days, there were big differences in temperature change. This is mainly because the outside temperature played a decisive role in the temperature in the tunnel sheds, and the large atmospheric temperature differences between any two of the three days caused the differences in the nighttime temperature in the tunnel sheds.

Change of temperature outside the tunnel sheds and at the measuring points covered by different layers of films over time

On November 29, 2018, November 30, 2018 and December 1, 2018, the changes of T1, T2, T3, T4 and T5 over time are shown in Fig. 3. It can be seen that the temperature change trends of various measuring points in the tunnel sheds were basically consistent with the change trend of the outside air temperature T1. The more the number of the covering layers, the higher the temperature, and the performance was T2<T3<T4<T5. It indicated that within the range of this experiment, the more the number of the covering layers, the better the insulation effect.

The difference between T2 and T1 was irregular. On November 29, 2018, T2 and T1 were larger than one another at different time at night; on the night of November 30, 2018, the order was basically T2<T1; and on the night of December 1, 2018, the order was basically T2>T1. It has been verified that plastic film can improve the internal temperature of facilities after production practice. However, under the premise that the thermal conductivity of the plastic film was fixed[9-10], there was uncertainty in the temperature difference between the inside and outside of the tunnel sheds at different dates in this experiment. It shows that the mechanism of nighttime temperature increase inside plastic film-covered tunnel sheds is not only based on the thermal parameters (thermal conductivity) of the plastic film itself, but also other mechanisms of action, which needs further discussion.

Fitting analysis of temperature outside the tunnel sheds and at the measuring points covered by different layers of films

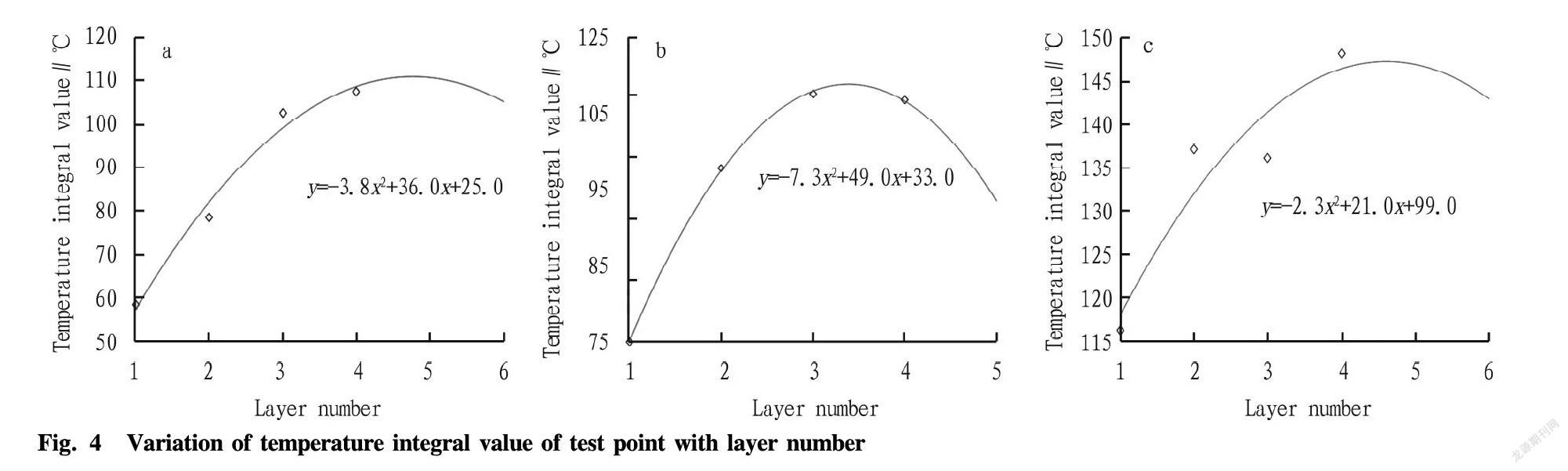

The changes of T1, T2, T3, T4 and T5 on the nights of November 29, 2018, November 30, 2018 and December 1, 2018 over time were fit with MATLAB, and the integral values of the fitting functions are shown in Table 1. It can be seen that as the number of the covering layers increased, the integral values of the fitting functions of T2, T3, T4 and T5 increased continuously overall. T4 and T5 on the night of November 30, 2018, and T3 and T4 on the night of December 1, 2018, showed differences between the integral value and the measured value, which might be due to the difference in accuracy of the fitting function.

Further, the integral value was fitted with the change of the number of layers, and the results are shown in Fig. 4. As the number of layers increased, the increment in the integral value of the temperature function of the measuring points covered by different layers of films decreased continuously, and the integral value increased at first with the increase of the number of the covering layers within a certain range, but started to decrease when the number of layers exceeded a certain value. The decrease in the value indicates that for the nighttime thermal insulation effect of multi-layer film, the number of the covering layers is not the more the better, and when the number of layers is too large, it not only fails to achieve a better heat preservation effect, but also increases the cost. The fitting equations in Fig. 4 were subjected to derivation, respectively, giving the x values of 4.74, 3.36 and 4.57, respectively, which indicate that the internal temperature of the film coverings would no longer increase when the number of layers exceeds 4.74, 3.36 and 4.57, respectively, that is, the number of the coverings layers should not exceed 5 layers.

Discussion

The air heat in tunnel sheds at night comes from the heat accumulated in the soil in the tunnel sheds during the day[11]. In theory, the air temperature in the tunnel sheds should be higher than the temperature outside the sheds, but from the results of this study, there is uncertainty in the temperature inside and outside the tunnel sheds. This might be because when the soil heat in the tunnel sheds is lost to the outside, it fist makes the air temperature near the ground in the tunnel sheds rise, and then the air near the ground in the tunnel sheds performs heat exchange with the air near ground outside the tunnel sheds through the side face of the tunnel sheds, making the air temperature near the ground outside the tunnel sheds increase; and limited by the height of the tunnel sheds, the air near the ground in the tunnel sheds is much less pressured by the air at the top of the tunnel sheds than the air near the ground outside the tunnel sheds by the low-layer atmospheric pressure, and the air outside the tunnel sheds rises and forms natural convection, giving rise to turbulent flow outside the tunnel sheds[7], which affects the temperature of the surrounding air outside the tunnel sheds. Therefore, the uncertainty of the temperature of the air inside and outside the tunnel sheds might be caused by the different levels of air turbulence outside the tunnel sheds in different weathers. The relationship between the temperatures inside and outside the tunnel sheds needs further study. Under the present experimental conditions, after the integral values of the nighttime temperature fitting functions exceeded 4.74, 3.36 and 4.57, respectively, the internal temperature within the multi-film coverings would no longer increase. Comprehensively, it is considered that the number of the covering layers should not exceed 5 layers.

Conclusions

(1) Plastic film can increase the internal temperature of facilities at night, but the mechanism of its thermal insulation need to be further studied.

(2) As the number of covering layers increases, the increase amplitude in nighttime temperature of multi-film coverings gradually decreases.

(3) Under the conditions of this study, the number of layers for multi-film covering cultivation is preferably not more than 5 layers.

References

[1]HUANG SC. Several problems of plastic film-covered vegetables in early spring[J]. Liaoning Agricultural Sciences, 1965(6): 18-23. (in Chinese)

[2]ZHANG SQ, ZHANG TS, FENG ZM, et al. High-efficient planting patterns of multilayer plastic mulching spring potato in Hebei Province double cropping cultivated region[J]. Chinese Potato Journal, 2015, 29(4): 213-216. (in Chinese)

[3]SONG LY, YIN RS, WANG PQ, et al. High-efficiency multi-film covering greenhouse cultivation techniques for Yangjiaocui in Qingxian County, Hebei Province[J]. Greenhouse Horticulture, 2014(6): 64-66. (in Chinese)

[4]DU ZX. High-yield and high-efficiency multi-film covering cultivation techniques for potato in Tengzhou City[J]. Jilin Vegetable, 2012(10): 25. (in Chinese)

[5]GUO ZY. Five-film and six-film cultivation technique of early-maturing melon in greenhouse[J]. Xibei Yuanyi, 2018(1): 22-24. (in Chinese)

[6]GAO XD, PAN XQ, WU YR, et al. Technical regulation for early maturity cultivation of watermelon in greenhouse[N/OL]. Hebei Science and Technology Daily, 2017-03-11 (004). (in Chinese)

[7]CUI XM. Agrometeorology[M]. Beijing: Higher Education Press, 2006: 49-50, 40. (in Chinese)

[8]LI SJ, GUO SR. Facility horticulture[M]. Beijing: China Agriculture Press, 2011: 140, 142-144. (in Chinese)

[9]WANG BX. Engineering heat and mass transfer[M]. Beijing: Science Press, 2015: 6-8. (in Chinese)

[10]LIU CZ, LI GB. Thermal engineering foundation[M]. Beijing: China Machine Press, 2015: 128-130. (in Chinese)

[11]ZANG YH, BAI Q, FENG MQ, et al. Measurement and analysis of earth wall and surface solar radiation in solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(11): 164-172. (in Chinese)

- 农业生物技术(英文版)的其它文章

- Analysis of the Southern China Tilapia Production and Economic Benefits of Different Breeding Patterns in 2018

- Dynamic Monitoring and Control Measures of Spodoptera frugiperda (J.E.Smmith) in Low Latitude Plateau Sugarcane Areas

- Control Effects of a New Sex Pheromone Trap and Biological Agents on Sesamia inferens Walker and Argyroploce schistaceana (Snellen)

- Comparative Study on Grain Cadmium Content and Yield in Different Rice Varieties

- Identification of Growth-promoting Bacteria from Rhizosphere of Pastures and Their Effects on Growth of Lotus corniculatus L.

- Evaluation of Ecological Environment Quality of Typical Forest Parks