Consolidated bioprocess of corn stover to polysaccharide using Chaetomium globosum CGMCC 6882

Lin Peng,To Ning,Weno Lu,Peizhng Chen,Hifeng Li,Ynjie Yi,Zicho Wng,*,Yunsen Hu,*

a National Engineering Laboratory for Cereal Fermentation Technology,Jiangnan University,Wuxi 214122,China

b College of Biological Engineering,Henan University of Technology,Zhengzhou 450001,China

Keywords:

Corn stover

Chaetomium globosum CGMCC 6882

Polysaccharide

ABSTRACT

Polysaccharide produced from medicinal endophytic fungus not only has applications in foods,but also exhibits multiple biological activities.In this work,an endophytic fungus Chaetomium globosum CGMCC 6882 could use corn stover to produce a polysaccharide(GCP-SC)by consolidated bioprocess and the titer of GCP-SC reached 3.2 g/L.The transcriptional levels of genes related to cellulose degradation(cbh,cdh,glu and egl)in C.globosum CGMCC 6882 were 4.38,3.85,3.13,and 2.17 folds compared to the control group when corn stover was used as the sole carbon source.Moreover,GCP-SC showed a time-and dose-dependent manner of inhibitory effect on A549 cells and the inhibitory rate reached 93.3%.This work provides meaningful data on agricultural residues utilization and facilitation of future relative resource conversion studies.

1.Introduction

Polysaccharide,which widely exists in plants,microorganism,algae,and animals,is a kind of natural macromolecular polymer with biological activities[1].Polysaccharide produced from medicinal endophytic fungus not only has applications in foods, such as viscoelasticity, emulsibility,suspensibility,and thickening,but also exhibits multiple biological activities, including antioxidant, anticancer, immune-regulation, antitumor,and neuroprotection properties[2,3].Therefore,investigations on the biological activities and production property of polysaccharide from medicinal endophytic fungus have great application values.

With the exhaustion of global oil resources and emission of greenhouse gas,the abundant,green,clean,renewable,cost-effective,and environmental friendly features of lignocelluloses make it a promising alternative to fossil resources [4,5].Many high value-added feed additives, biofuels and chemicals have been produced from lignocelluloses,including signal cell protein,viscose rayon,cellulose nitrate,cellulose acetate,nano-fibrillated cellulose,short chain fatty acids and bio-ethanol[5–7].Agricultural residues are common type lignocellulosic materials and generated in large quantities worldwide,approximately 700 million tons agricultural residues were produced in China every year and accounted for 20%–30%of the world total yield[8].However,agricultural residues are usually left unused,discarded optionally or burnt directly due to the lack of an effective application,thus wasting resources and polluting environment[4,9].

Chaetomium.globosum is widely distributed in natural world and considered the third common fungus after Penicillium and Aspergillus[10].Until now,the endoglucanase,exoglucanase,cellobiose dehydrogenase,xylanase and other cellulases involved in cellulose and hemicellulose degradation were discovered and isolated from C. globosum [11–13]. Meanwhile,Chefetz et al.[14]reported that C.thermophilium could secrete ligninolytic enzymes to degrade lignin.These results suggested that Chaetomium fungi are a promising candidate for bioconversion of lignocelluloses to high value-added chemicals.

In present study, the ability of an endophytic fungus C. globosum CGMCC 6882 using corn stover for polysaccharide production was investigated by cellulose congo red medium plate and batch fermentation,respectively. At the same time, the cellulase genes (cbh, cdh, glu and egl) in C.globosum CGMCC 6882 were studied by RT-PCR,and the effect of polysaccharide(GCP-SC) produced from corn stover by C.globosum CGMCC 6882 on the viability of human lung carcinoma A549 cells was assayed by MTT method.

2.Materials and methods

2.1.Microorganism and batch fermentation

2.1.1.Microorganism and chemicals

C.globosum CGMCC 6882 was isolated from G.pentaphyllum herb.The chemicals were analytical grade,and bought from Sinopharm Chemical Reagent Co.,Ltd.(China).Cellulose congo red medium was bought from Qingdao Hope Bio-Technology Co.,Ltd.(China)and contained NaNO31.0 g/L,Na2HPO41.2 g/L,KH2PO40.9 g/L,MgSO40.5 g/L,KCl 0.5 g/L,yeast extract 0.5 g/L,casein hydrolysate 0.5 g/L,congo red 0.2 g/L,cellulose powder 5.0 g/L,agar 15.0 g/L,pH=7.0±0.1.Corn stover was collected from the suburb of Zhengzhou,cut into small pieces and dried in an oven at 80°C to constant weight,after which,the dried corn stover was shattered by a muller and filtered through a 60 mesh screen.

2.1.2.Seed medium

For preparing the seed medium,spores of C.globosum CGMCC 6882 on the PDA plates were scratched with a disposable spreader,then diluted to 1×107spores/mL with distilled water and inoculated at a rate of 1%(V/V).

2.1.3.Batch fermentation

Fermentation medium used for C.globosum CGMCC 6882 contained corn stover 40 g/L,(NH4)2SO41.0 g/L,KH2PO41.5 g/L,K2HPO42.0 g/L,NaCl 0.5 g/L, CaCl20.5 g/L, MgSO41.0 g/L, FeSO40.01 g/L, MnSO40.01 g/L,ZnSO40.01 g/L,CoCl20.01 g/L,peptone 1.0 g/L.Fermentation temperature was 28°C, cultivation time was 7 d,pH was maintained at 7.0±0.02 with 2 mol/L NaOH and 2 mol/L HCl,7 L fermenter(LiFlus GM BioTRON,Korea)containing 4 L medium,aeration rate was 1.0 vvm and stirring was 150 r/min,respectively.All experiments were conducted in triplicate assays.

2.2.Biomass and GCP-SC yield determination

At an interval time of 24 h,20 mL culture broth was taken during the fermentation process and filtered through a Whatman No.1 filter.The filter liquor was centrifuged at 20,000×g for 30 min and GCP-SC concentration in the supernatant was detected using phenol-sulfuric acid method at 490 nm.Resulting mycelium was washed twice with deionized water and dried in an oven at 80 °C to constant weight. The dry weight of C. globosum CGMCC 6882 biomass was calculated by weighing the dry mycelium.

2.3.Real-time reverse transcription PCR analysis

Approximately 0.5 mL C.globosum CGMCC 6882 spore suspension was incubated in 500 mL flask containing 50 mL fermentation medium(corn stover and glucose as carbon sources,respectively),then cultured at 28°C and 180 r/min for 3 d.The mycelium was freeze dried,grinded and extracted by TRIzol(Sangon,Shanghai,China),and Total RNA was treated with RNase-free DNase(Sangon,Shanghai,China).First Strand cDNA Synthesis Kit(Sangon,Shanghai,China)was used for first-stand cDNA synthesis. The actin gene was used as the internal control and RT-PCR was conducted in triplicate for each sample.A total of 30 cycles were done for PCR amplification,94°C 4 min, 94°C 30 s,60°C 30 s,72°C 1 min and 72°C 7 min.PCR product was analyzed using 2.0%(W/V)agarose gel electrophoresis and then stained with ethidium bromide.The band intensity was analyzed using Bio-Imaging System with the Quantity One 1-D analysis software(Bio-Rad,CA,USA).According to successfully sequenced genome information of C.globosum CBS 148.51,the primers and relevant sequences used in this work are listed in Table 1.

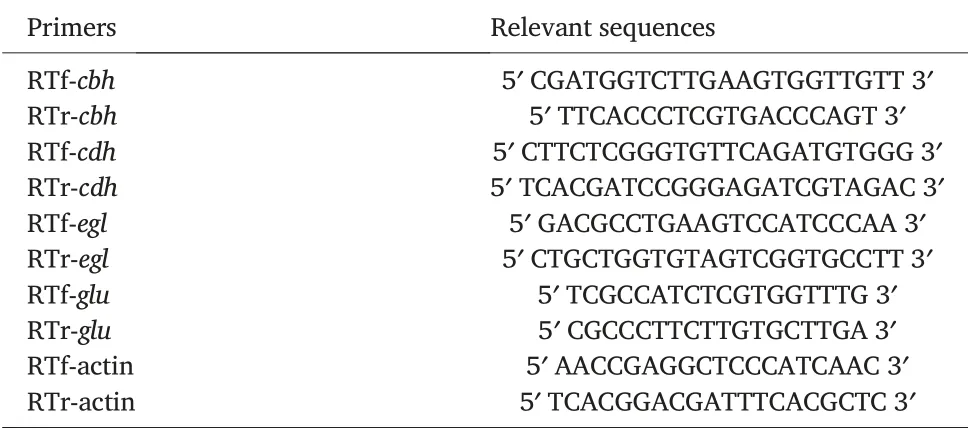

Table 1 Primers and relevant sequences used in this work.

2.4.Extraction and isolation of polysaccharide produced from corn stover

The extraction and isolation of GCP-SC were conducted according to the methods reported in our previous work[15,16].

2.5.Effects of GCP-SC on the viability of human lung carcinoma A549 cells

Effects of GCP-SC on cell viability were determined by indirectly measuring the ability of lung cancer A549 cells transforming MTT to a purple formazan dye [17]. Human lung carcinoma A549 cells were obtained from American Type Culture Collection and cultured in H-DMEM medium with 10%inactivated FBS at 37°C in a saturated 5%CO2.Briefly,A549 cells were placed in 96-well plates with a density of 5 × 104cells/mL and cultured at 37°C with 5%humidified CO2for cells to attach.After an incubation time of 24 h,the A549 cells were treated with various concentrations of GCP-SC(50,100,and 200 μg/mL)and incubated at 37°C with a humidified 5% CO2for interval hours (12, 24, and 36 h). Under the same conditions,the distilled water was used as control.After the treatment of GCP-SC,10 μL MTT(5 mg/mL)was added to each well and incubated for another 4 h at 37°C.Then,the medium was aspirated and 200 μL DMSO was added to each well for dissolving purple formazan dye.The chrominance ratio was measured at absorbance of 490 nm by a 96 well microplate reader(Tecan,GENios ELIASA Co.,Austria).The inhibitory rate of GCP-SC on A549 cells were calculated using the following equation:Inhibitory rate(%)=(1-AExp/ACon)×100%.Where AExpis the absorbance of the sample and AConis the absorbance of control.

3.Results and discussion

3.1.Properties of C.globosum CGMCC 6882 using lignocelluloses

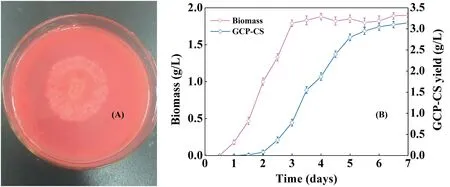

Complex and rigid structure of lignocelluloses limit their utilization by microbial degradation,and numerous pretreatment strategies are used to break drown the resistant structures and improve the convenience of lignocelluloses,such as dilute acid,alkaline,steam explosion,microwave,inorganic salts and enzymatic hydrolysis [18,19].However,pretreatment is energy dissipation and easy to pollute the environment,which may also release inhibitory compounds and complicate the downstream fermentation processes[20].Consolidated bioprocessing could integrate the enzyme production,saccharification and chemicals synthesis by one microorganism,and then facilitating the biological process [21]. As shown in Fig. 1A,C. globosum CGMCC 6882 could grow on cellulose congo red medium plate and form a diameter of 3.5 cm white fungus circle after cultured at 28 °C for 4 d, indicating the lignocelluloses utilization ability of C. globosum CGMCC 6882. Moreover, Fig. 1B revealed that C. globosum CGMCC 6882 could utilize corn stover to produce a polysaccharide(GCPSC),the cell growth time was 2.5 days,dry cell weight was approximately 1.9 g/L and GCP-SC titer reached 3.2 g/L.

3.2.Real-time reverse transcription PCR analysis

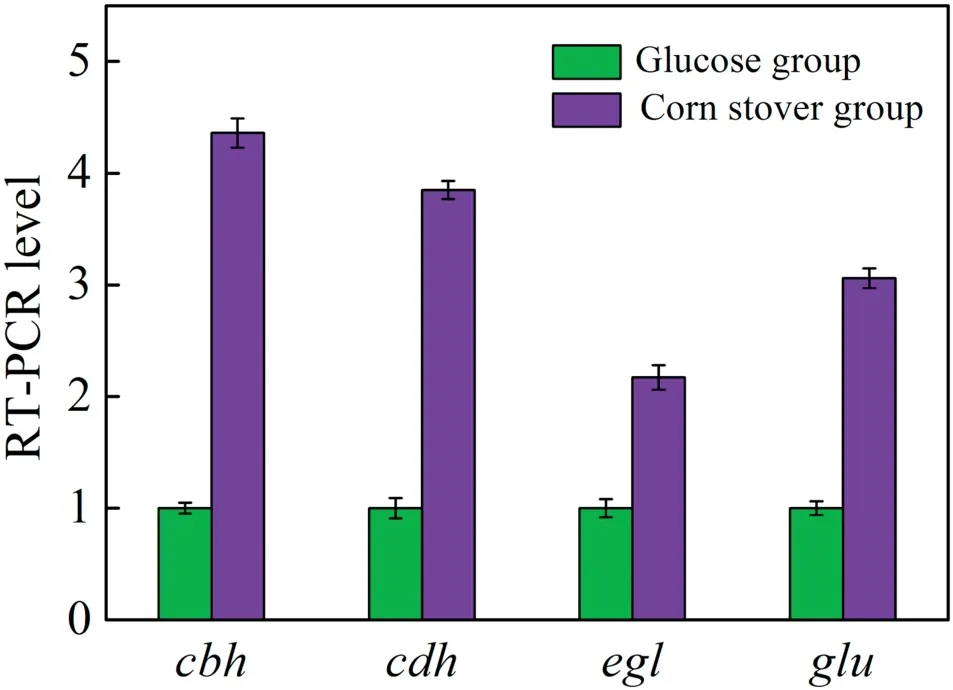

Utilization of lignocelluloses by a microorganism needed many hydrolytic enzymes,endoglucanase(egl)clipped cellulose internally and generated short chain cellulose, cellobiohydrolase (cbh) degraded cellulose chains from the ends and produced cellobiose,β-glucosidase(glu)hydrolyzed cellobiose to glucose,cellobiose dehydrogenase(cdh)and glucoside hydrolase promoted the enzymatic glycation of cellulose[22,23].However,glucoside hydrolase related to more genes and was not studied in this work[24].As can be seen from the RT-PCR results in Fig.2,the RT levels of egl,cbh,glu and cdh were all higher than 1.0 and the order was cbh(4.38)>cdh(3.85)>glu(3.13)>egl(2.17).This result suggested that cellulase genes in C.globosum CGMCC 6882 were activated when corn stover was used as the sole carbon source,and C.globosum CGMCC 6882 could be a promising cellulose utilization microorganism if adaptive evolution method and advanced metabolic engineering toolboxes are used in future[25,26].

Fig.1.Profiles of C.globosum CGMCC 6882 growth on cellulose congo red medium plate.(A)Batch fermentation with corn stover as carbon source.(B)The symbols represent biomass(○)and GCP-SC(◇).

Fig.2.Relative transcription PCR level of cellulase genes in C.globosum CGMCC 6882.

3.3.GCP-SC characteristics and anticancer activity

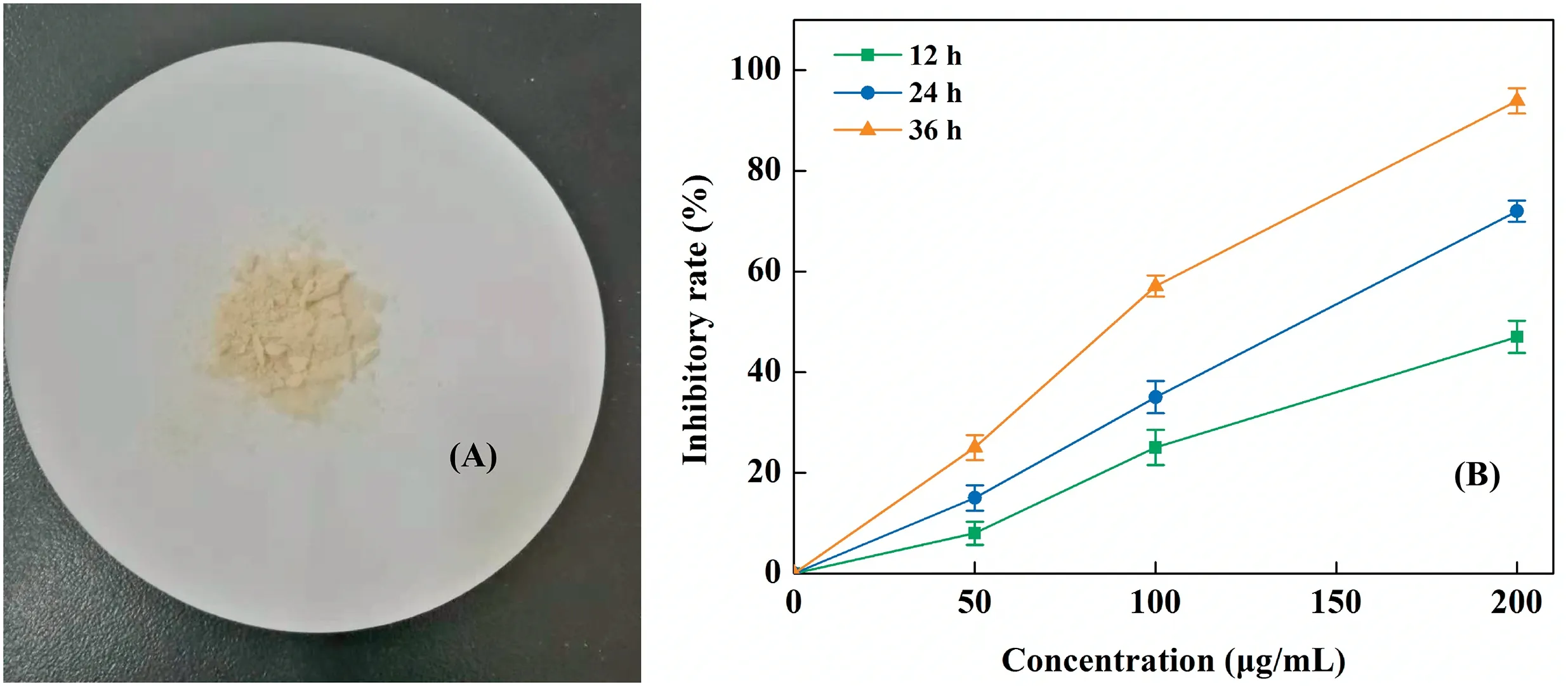

After the culture broth was concentrated,impurities removed,alcohol precipitated and freeze dried, a polysaccharide (GCP-SC) was obtained(Fig.3A).Fig.3B showed that the viability of human lung A549 cells was inhibited by GCP-SC,and which was in a time-and dose-dependent manner. When the GCP-SC concentration was 50 μg/mL, and the reaction time were 12,24,and 36 h,the inhibitory rates of GCP-SC on A549 cells were 3.2%,7.5%,and 12.1%,respectively.With the increase of GCP-SC concentration and reaction time,the inhibitory rate of GCP-SC on A549 cells increased,which reached 93.3%at a GCP-SC concentration of 200 μg/mL with an action time of 36 h.These results suggested that GCP-SC had an excellent inhibitory effect on lung cancer A549 cells and were in agreement with other researchers.For instance,Wu et al.[27]reported that a polysaccharide(PGL)extracted from Glehnia littoralis displayed an inhibitory activity for the migration of A549 cells.Xie et al.[28]found that the polysaccharide(CPP)from Cyclocarya paliurus leaves had a strong inhibition effect on the growth of human gastric cancer Hela cells.The polysaccharide fractions of PRM3 and PRM1 purified from Rhynchosia minima root exhibited strong in vitro anticancer activities against lung cancer A549 cells and liver cancer HepG2 cells in a dose-dependent manner[16].

4.Conclusions

Due to the lack of an effective application,plenty of agricultural residues have been left unused or burnt directly,and this caused the wasting of resources and environmental pollution. An endophytic fungus C.globosum CGMCC 6882 could use corn stover to produce polysaccharide(GCP-SC),the transcriptional levels of genes related to cellulose degradation in C. globosum CGMCC 6882 were activated when corn stover was used as the sole carbon source without adaptive evolution or metabolic engineering manipulation.Meanwhile,GCP-SC displayed a time-and dosedependent manner on lung cancer A549 cells inhibition.

Declaration of Competing Interest

All the authors confidently declare that there is no conflict of interest,and paper is approved by all authors for publication.

Fig.3.Polysaccharide GCP-SC(A)and its effects on the viability of human lung carcinoma A549 cells(B).

Acknowledgements

This work is supported by the Natural Science Foundation of Youth Support Plan of Henan University of Technology(2017QNJH10),High Level Research Fund for Qualified People of Henan University of Technology(2017BS011),and the Natural Science Foundation of Henan Province Education Department(19A180015).

Grain & Oil Science and Technology2019年1期

Grain & Oil Science and Technology2019年1期

- Grain & Oil Science and Technology的其它文章

- Study on the effect of wheat bran dietary fiber on the rheological properties of dough

- Antidepressant activity and HPTLC fingerprinting of stearic acid in different days of wheat seedlings

- Isolation and characterization of biosurfactant producing bacteria from groundnut oil cake dumping site for the control of foodborne pathogens

- Synergism of essential oils with lipid based nanocarriers:emerging trends in preservation of grains and related food products