Study on the effect of wheat bran dietary fiber on the rheological properties of dough

Ning Liu,Sen Ma*,Li Li,Xiaoxi Wang*

College of Food Science and Technology,Henan University of Technology,Zhengzhou 450001,China

Keywords:

Wheat bran dietary fiber

Wheat dough

Rheological properties

Viscoelasticity

ABSTRACT

The aim of the study was to determine the influence of wheat bran dietary fiber on wheat flour dough rheological properties.In this paper,wheat bran dietary fiber(WBDF)with different levels(0,3%,6%,9%,12%)were added to wheat flour and the characterization of dough rheological properties was conducted by rapid visco-analyzer,farinograph, as well as rotational rheometer.The results from pasting properties showed a gradual reduction in peak viscosity,trough viscosity,final viscosity and setback with increasing WBDF content.At high WBDF concentration,the significant increase of water absorption,formation time as well as weakening degree implied the harder formation of gluten network structure and the competition for water between gluten and WBDF particles. Such conclusion was in line with the findings from dynamic rheology tests,in which the doughs containing WBDF were more sensitive to strain regardless of their rigid and stiff texture.This study revealed vulnerable dough structure induced by WBDF,as well as the strengthened elastic property,elaborating the harmful effects of WBDF on the rheological properties of doughs.

1.Introduction

Wheat bran is the main by-product of wheat processing and contains a variety of active substances.The content of dietary fiber in wheat bran is the highest and it is a good source of dietary fiber.In recent decades,the physical and chemical properties of dietary fiber such as solubility,viscosity,water holding and fermentability have been well illustrated.As human's seventh largest nutrients,dietary fiber is believed to be beneficial to human health in many ways including maintaining gastrointestinal function,lowering postprandial glycemic index,and lowering the risk of cardiovascular disease,metastatic disease,and colon cancer[1,2].Klurfeld[3]confirmed that wheat bran dietary fiber has the effect of reducing diverticulosis and gallstone formation and preventing colon cancer.Studies have shown that the intake of dietary fiber in worldwide is lower than recommended[4–6],and traditional flour products are a good carrier of dietary fiber undoubtedly.More and more scholars are devoted to the study of the quality of dietary fiber products and it was found that fiber incorporation could reduce the elasticity of steamed bread[7].Bleis et al.[8]studied the effect of wheat bran with different grain size on the texture and rheological properties of bread and found that the addition of wheat bran enhanced the mechanical properties of bread. Despite these advantages, consumers still find it hard to accept the texture and taste of dietary fiber.

The formation of dough is an important step in the processing of flour products.The proper formation of continuous network of wheat gluten imparts doughs with both viscosity and elasticity.It has been acknowledged that dough quality was directly governed by the gluten network structure.Some scholars[9–14]studied the effect of dietary fiber on dough properties and found that the effects of dietary fiber on gluten network structure was both improved and deteriorated,which may relate to differences in the type,structure,size,and amount of dietary fiber added.Zhang et al.[15,16]studied the effect of three grain sizes of bran on the farinograph characteristics,and found that fine bran significantly increased the water absorption of the dough, decreased the formation time, and made the dough more elastic. Peressini et al. [17] believed soluble dietary fiber could increase the elasticity and strength of the dough.

Many studies have suggested the adverse effects of wheat bran dietary fiber should be responsible for the quality deterioration of wheat flour products.Herein,the wheat bran dietary fiber was extracted and blended with flour to study the changes in dough rheological properties,as well as provide theoretical reference for the comprehensive utilization of wheat bran.

2.Materials and methods

2.1.Materials

Plain flour was purchased from Zhengzhou Jinyuan noodles industry Co.(Henan,China).Wheat bran was purchased from Guangdong baiyan grain and oil industry Co.(Guangdong,China).

2.2.Extraction of wheat bran dietary fiber

The wheat bran dietary fiber was prepared according to Han et al.[18].The wheat bran was pulverized to 420 μm.The powdered wheat bran was mixed with distilled water(1:10,W/V)and crushed by colloidal grinding for 25 min.The mixture was then washed under running water and dried in a drying oven.Afterwards,the dried wheat bran mixed with distilled water(1:10,W/V)was heated at 95°C for 30 min,followed by adjustment to pH 5.6 with HCl,and then added high temperature resistant α-amylase(1.5%,W/W)reaction for 30 min,and iodine solution was used to inspect whether the reaction completely.After the temperature down to 50 °C,pH of the mixture was adjusted to 9.0 with NaOH,and added alkaline protease(3%,W/W)reaction for 2 h.The mixture was filtered until the filtrate was clarified and rinsed the residue twice with 95%alcohol and acetone respectively,and then the filter cake was dried in oven for 24 h at 60°C.Finally,the extraction was crushed to 150 μm.

2.3.Rheological properties determination

2.3.1.Determination of pasting properties

Pasting properties of samples were determined by a rapid viscoanalyzer(Newport Scientific,Australia)according to American Association of Cereal Chemists(AACC)Method 76-21.Five characteristic parameters were measured from the RVA curve: Peak viscosity, Trough viscosity,Breakdown,Final viscosity,Setback.

2.3.2.Measurement of farinograph characteristics

According to the approved American Association of Cereal Chemists(AACC) Method 54-21, the rheological properties of the dough during mixing affected by different amounts were studied on a farinograph(Brabender,Germany).The parameters determined were:water absorption(percent),formation time(minutes),stability time(minutes),and weakening degree(FU).

2.3.3.Determination of dynamic rheological properties

Dynamic rheological properties were determined according to Sandeep et al.[19]and Stathopoulos et al.[20]with some modification.To measure the effect of different WBDF levels on the dynamic rheological properties of dough,the test was performed using a rotational rheometer(RheoStress 6000, Thermo Fisher Haake, Germany) with a 20 mm diameter steel plate gapped by 2 mm.The dough was placed between the plates of the rheometer and a thin layer of silicon oil was applied to the exposed surface of the dough to prevent drying during testing.A strain sweep test was performed at a constant temperature of 25°C with a strain range of 0.01%–0.1%and a constant frequency of 1 Hz to identify the linear viscoelastic region.Frequency sweep tests were performed from 0.1 to 10 Hz at 25°C.The storage modulus(G′),loss modulus(G″)and tan δ(G″/G′)were recorded.Finally,a creep sweep was performed with conditions:temperature 25°C,strain 0.1%,frequency 1 Hz.All tests were run in triplicate.

2.4.Statistical analysis

The parameter results of various indicators obtained in the experiment were represented by Origin 8.5. The result was statistically analyzed using SPSS software (SPSS Inc., Chicago, USA). Analysis of variance(ANOVA)was used to determine significant differences between the results and Duncan's test was used to compare the means with a significance level of 0.05.

3.Results and discussion

3.1.Paste properties

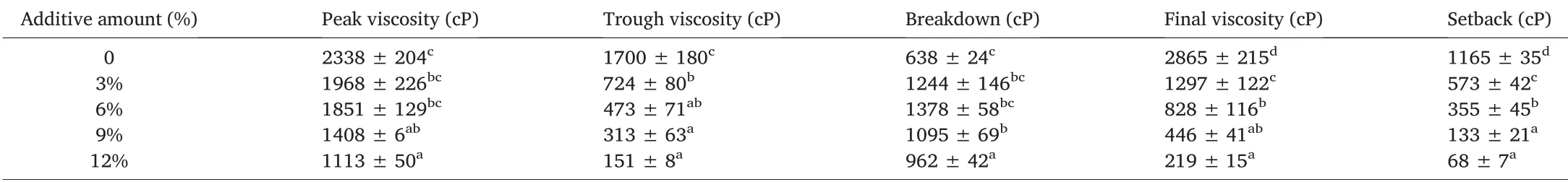

Paste properties of fiber fortified doughs are shown in Table 1.The peak viscosity,trough viscosity,final viscosity and setback were negatively correlated with wheat bran dietary fiber concentration.With the increment of wheat bran dietary fiber, the breakdown value first increased and then decreased.The peak viscosity is a parameter related to the capacity of starch to absorb water and swelling of the starch granules during heating[21],which indicates the maximum swelling of the starch granules.Upon WBDF addition,the peak viscosity dramatically decreased which may be results of the competition for water between WBDF and starch granules. Final viscosity depends on the starch content, amylose, amylopectin, as well as amylose/amylopectin ratio[22]. With increasing wheat bran dietary fiber contents, the relative content of starch in the sample decreases, so the final viscosity decreases.High water retention of dietary fiber allows the redistribution of water molecules in doughs,which makes it less available for retrogradation[23],and inhibits the aging of starch to a certain extent,as a result,the setback value gradually decreased.

3.2.Farinograph characteristics

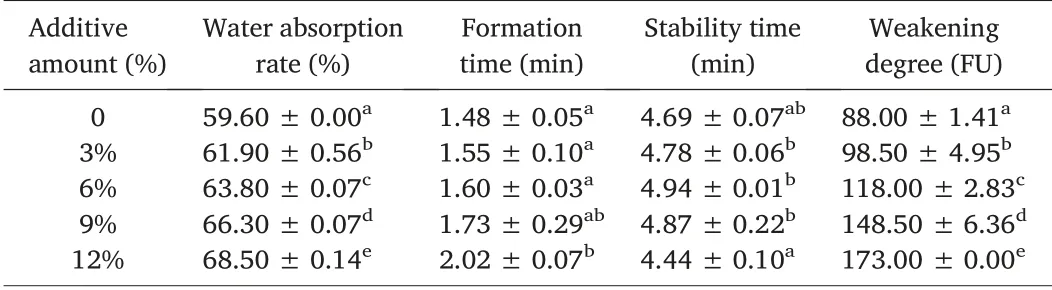

As shown in Table 2,with the increment of wheat bran dietary fiber levels,the water absorption of the dough gradually increased,which is consistent with the results from özboy et al.[24]and Sudha et al.[25].The water absorption rate of the dough after adding the WBDF may be due to the fact that the dietary fiber contains a large number of hydroxyl groups and it can be combined with water by hydrogen bond.Therefore,the dietary fiber has a stronger water absorption than the main components of wheat flour, i.e. starch and protein, and led to a significant increase in water absorption rate[26].Farinograph characteristics showed an increase of dough formation time and weakening degree at high WBDF level.The rise of dough formation time may be related to the impairment of gluten network structure induced by WBDF that required longer time for doughs to reach their optimal state.The increase of the weakening degree further certified damage of gluten network structure induced by WBDF[27].The stability time increased in the level of wheat bran dietary fiber from 0 to 9%and then decreased when the level reached to 12%.It is possible that the existence of WBDF hindered the hydration and extension of peptides which resulted in difficulties in the proper formation of gluten matrix during mixing[28].

3.3.Dynamic rheological properties

3.3.1.Strain sweep

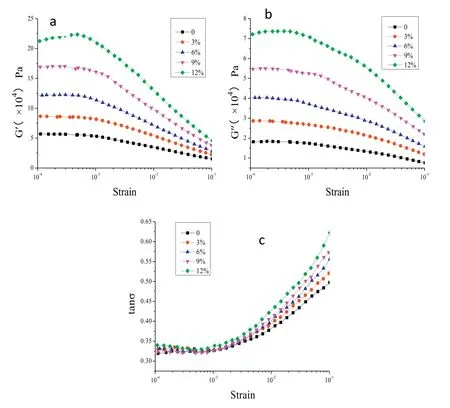

Rheology is the study of the horizontal flow and vertical deformation of matter,which is closely related to the structure of sample.Dynamic rheology is to obtain the rheological properties of viscoelastic materials by analyzing them with rheometer[29].As shown in Fig.1,for wheat bran dietary fiber enriched doughs,both storage modulus(G′)and loss modulus(G″)were higher than control group. Dynamic moduli (storage modulus, G′and loss modulus,G″)have been reported to be affected by the flour protein content and protein quality[30]as well as water content of the dough.G′refers to the energy that can be recovered after a sinusoidal deformation during a vibration period,which represents the elastic nature of the sample.G″refers to the energy consumed after the sinusoidal deformation of a vibration period,which represents the viscous nature of the sample.In this test,G′was higher than G″,implying the elastic nature of dough system.The increase of G′and G″with increase wheat bran dietary fiber concentration suggested a more elastic property of doughs.However,the shrinkage of the linear viscoelastic region demonstrated an unstable dough system upon WBDF incorporation[31].

3.3.2.Frequency sweep

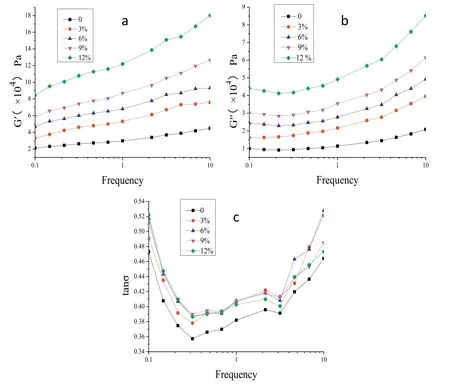

The frequency sweep results of dough with WBDF were presented in Fig.2.The results showed that storage modulus(G′)and loss modulus(G″)in different doughs increased with frequency increase.Meanwhile,G′and G″increased in the dough when the level of WBDF increased.The increase of viscoelastic moduli may be attributed either to the reduction of lubrication by water due to the competition for water between gluten and fiber[32,33],or to the fibers acting as a filler in a viscoelastic matrix[34].Thetan δ (G″/G′) initially decreased in the low range of frequency with 0.1–0.5 Hz,however,with frequency increasing,tan δ increased,which indicated the growing solid-like dough structure. Generally, the gluten network was not well formed because of the addition of wheat bran dietary fiber,which has been proved in many studies[35–37].

Table 1 The pasting properties of flour containing different amounts of WBDF.

Table 2 The farinographical properties of flour containing different amounts of WBDF.

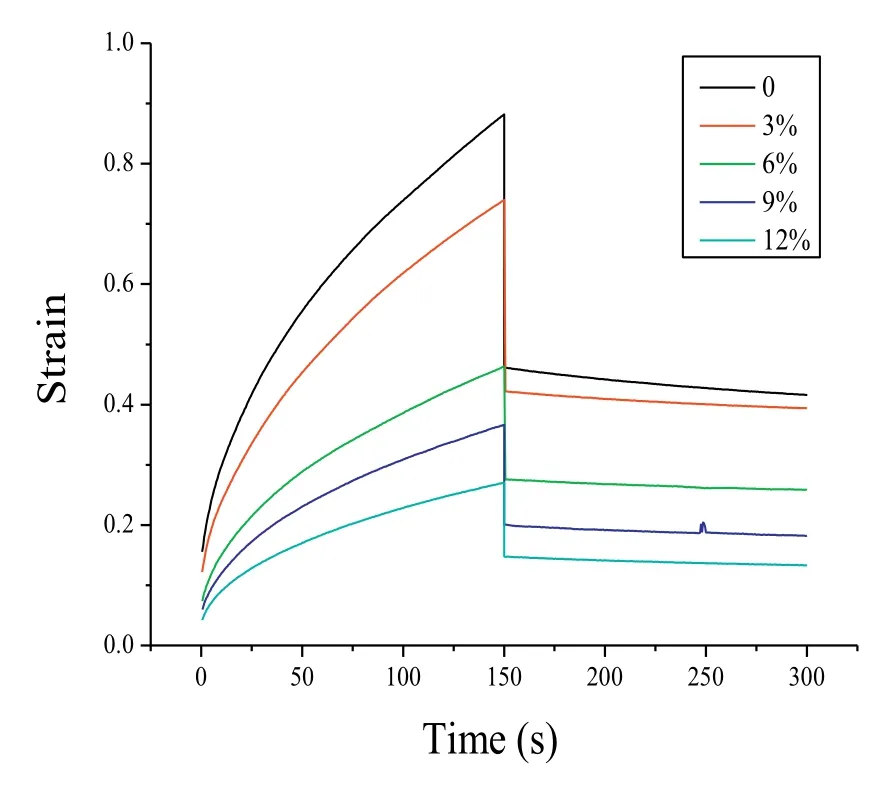

3.3.3.Creep sweep

Creep-recovery curves of the dough with or without WBDF exhibited a typical viscoelastic behaviour combining both viscous fluid and elastic components[38,39].The strain of dough system changed continuously with time.The maximum strain showed that the control group presented less resistance to deformation than fiber enriched dough.The results obtained showed the same trend observed in the strain sweep.This indicated that dough with wheat bran dietary fiber showed higher mechanical strength than the control sample[40].Doughs rich in WBDF were much stiffer than control sample may because the high water-binding of wheat bran dietary fiber lead to limited hydration of starch and protein in dough system(see Fig.3).

Fig.1.Effect of WBDF on strain sweep of dough.(a)storage modulus(G′);(b)loss modulus(G′′);(C)tan δ(G″/G′).

Fig.2.Effect of WBDF on frequency sweep of dough.(a)storage modulus(G′);(b)loss modulus(G′′);(C)tan δ(G″/G′).

4.Conclusions

Fig.3.Effect of WBDF on strain of dough.

The influence of wheat bran dietary fiber on dough rheological properties was assessed.It seems that the addition of WBDF adversely influence the proper formation of doughs,regardless of its addition level(0–12%).During mixing procedure,there were difficulties for fiber fortified doughs to quickly reached to the optimum states as observed by the longer formation time,shorter stability time,as well as remarkable higher weakening degree.Similar findings could also be visible in the strain sweep,frequency sweep and creep recovery test.Generally,the existence of WBDF led to significant increase in the elastic nature of doughs,meanwhile,the doughs are more brittle upon strain.This may be a result of water redistribution in gluten as well as the physical damage to gluten matrix induced by WBDF.Our work confirms the adverse effects of WBDF on gluten network formation which may lead to the reduction in gluten viscoelasticity and quality deterioration of fiber enriched flour products.However,the specific mechanism of destruction is still not clear and further research is needed.

Declaration of Competing Interest

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Acknowledgment

This work was supported by Henan Province Colleges and Universities Young Backbone Teacher Plan(No.2016GGJS-070),the Fundamental Research Funds for the Henan Provincial Colleges and Universities in Henan University of Technology(No.2018RCJH08),and National Natural Science Foundation of China(No.31571873).

Grain & Oil Science and Technology2019年1期

Grain & Oil Science and Technology2019年1期

- Grain & Oil Science and Technology的其它文章

- Antidepressant activity and HPTLC fingerprinting of stearic acid in different days of wheat seedlings

- Consolidated bioprocess of corn stover to polysaccharide using Chaetomium globosum CGMCC 6882

- Isolation and characterization of biosurfactant producing bacteria from groundnut oil cake dumping site for the control of foodborne pathogens

- Synergism of essential oils with lipid based nanocarriers:emerging trends in preservation of grains and related food products