Review of Infrared signature suppression systems using optical blocking method

Nidhi Baranwal , Shripad P. Mahulikar

Department of Aerospace Engineering, Indian Institute of Technology Bombay, Mumbai, 400076, India

Keywords:IR signature suppression Optical blocking Performance penalty IR signature level Engine back-pressure

A B S T R A C T With rapid advancements in Infra-Red (IR) detection techniques, the range from where the IR-guided missiles are able to lock the target aircraft has increased. To avoid the detection and tracking by modern IR-guided missiles,the aircraft and helicopters also demand progress in its stealth techniques.Hence,study of Infra-Red Signature Suppression(IRSS)systems in aircraft and helicopters has become vital even in design stage.Optical blocking(masking)is one of the effective IRSS techniques used to block the Line-Of-Sight(LOS)of the hot engine parts of the exhaust geometry.This paper reviews the various patents on IR signature suppression systems based on the optical blocking method or a combination of IRSS techniques. The performance penalties generated due to installation of various IRSS methods in aircraft and helicopters are also discussed.

1. Introduction

Survivability of modern fighter aircraft into hostile territory is maximized by reducing detectability, minimizing susceptibility to being hit if detected and minimizing vulnerability to being shot down after being hit by the enemy. Aircraft's susceptibility can be reduced by i) suppressing aircraft signatures; ii) destroying the enemy's air defense system;iii)employing on-board and off-board threat warning systems; and iv) electronic counter-measures [1].But sometimes these electronic counter-measures and on-board threat warning systems could make a stealth aircraft an easy target.Hence,reducing aircraft signatures(e.g.,Radar,IR,acoustic)is the most important technique of enhancing survivability of aircraft/helicopters in hostile environment. Aircraft signatures are broadly classified into two categories: a) Active Signature; b) Passive Signature. Active signatures (e.g., Radar) use the reflected signal to get the information about the target aircraft; whereas,passive signatures (e.g., IR) are emitted by the target itself [37]. IR waves scattered from target surfaces are utilized by the IR laserguided weapons, which is an active device. A dual-band metamaterial perfect absorber with an MIM (Metal-insulator-metal)structure can be used to reduce the target's IR signatures used by IR laser-guided missiles [23]. Between 1967 and 1993, many aircraft/helicopters were destroyed by the IR-guided or heat seeking missiles.The IR-guided missiles passively acquire and intercept aircraft by detecting their IR (heat) signature, and generally home to the high temperature areas of the target aircraft for detection and tracking purposes.In case of passive detection,target is unaware of being detected [19]; therefore, the passive signatures are considered as more lethal than active signatures.

The aircraft is surrounded by the atmosphere and the atmosphere plays a dual role in target detection, first as a medium of propagation and second as a background source against which target is often contrasts [38]. The propagation of IR radiation through atmosphere largely depends upon local meteorological conditions. Interaction of electromagnetic radiation with the atmospheric constituent results in two major phenomenon: i)extinction, i.e., attenuation of IR radiation by absorption and scattering;ii)emission,either by thermal radiation of the atmospheric constituents or by diffuse reflection [7]. The attenuation of IR radiation passing through the atmosphere is greatly dependent on the wavelength of radiation, temperature, concentration and distribution of radiation participating gases. The atmospheric gases like CO2,H2O(vapor),O3,CO etc.are responsible for the absorption and scattering of the IR radiation[17].Though atmosphere is a good absorber of IR radiation,the atmospheric windows,the 1.9-2.9 μm,3-5 μm and 8-12 μm bands have good IR transparency; hence,these bands are used for detection [16]. Outside atmospheric windows, the attenuation of IR radiation is high, because of the absorption and scattering by the H2O (vap.) and CO2[6]. The IR band is divided into three different regions:(i)SWIR(1-3 μm),(ii)MWIR(3-5 μm)and(iii)LWIR(8-14 μm).These bands are used for different purposes, e.g., the 1.9-2.9 μm band is used for the detection of very hot sources or for solar reflections. The 3-5 μm band is used for the high temperature surface detection(hot spots of an aircraft).Whereas,the 8-12 μm band is used for the detection of the part having comparatively lower temperature, e.g., rearfuselage skin [37]. The LWIR detector can detect the aircraft from all aspect; whereas, MWIR detector can only detect the aircraft from rear aspect.In addition,the 8-12 μm band can also be used for surveillance of the sky.

IR detection technology has become very advanced in last few decades. The advancements in IR detector technologies have increased the ability of the IR-guided missiles to lock the target aircraft from longer distances[46].The HgCdTe(Mercury Cadmium Telluride) and Quantum Well Infrared Photodetectors (QWIPs) are most widely used technologies for the IR detection purposes.They offer high sensitivity with wavelength flexibility in MWIR and LWIR spectral bands [41]. The cryogenically cooled InSb and HgCdTe(Mercury Cadmium Telluride) arrays are most suitable for MWIR spectral band[8].Various emerging technologies are quantum dot infrared photo-detectors (QDIPs), type-II strained layer superlattice, and QDIPs with type-II band alignment [22]. Such advancements in IR detector systems have increased the importance of IR signature suppression systems in modern stealth aircraft.Therefore, the IR signature suppression (IRSS) techniques are vital for survivability enhancement of a target aircraft in hostile environment.

1.1. Survey of IR signature suppression techniques

A growing importance of aircraft survivability requires in-depth research in the field of IR signature suppression techniques. Aircraft's gas turbine engine parts (tailpipe, turbine exit disc, nozzle etc.) are crucial sources of IR emission from the rear aspect, especially in the 1.9-2.9 μm and 3-5 μm bands. The rear fuselage skin radiates predominantly in the 8-12 μm band. The prime objective of an IRSS system is to reduce the Infra-Red Signature Level (IRSL)below the threshold level, while maintaining the engine performance [39]. In addition to various aerospace vehicles, the IRSS technology is also vital in marine vehicles. Schleijpen [42] has discussed the various techniques of IR signature suppression and lock-on range reduction of ships. The techniques of IR signature suppression are based on following:

(i) Optical blocking (masking) of hot engine parts; reducing the visibility of tailpipe and engine hot parts is one of the most important methods of suppressing IR signature from the rear aspect. This includes the modification in nozzle geometry,jet-pipe geometry and incorporation of some optical block.The Optical Block Suppressor(OBS)discussed by Sully et al. [49] provides full blockage of the view of hot engine parts. Rectangular shaped nozzle became popular in stealth aircraft (e.g., F-117A, B-2, F/A-22 etc.), because they increase the ratio of perimeter to cross-sectional area. Using a 2-D nozzle in aircraft restricts the visibility of engine hot parts from the rear aspect.Placing the engine over the wings in B-2 bomber restricted the visibility of engine hot parts to a large extent from the ground based IR seeker.

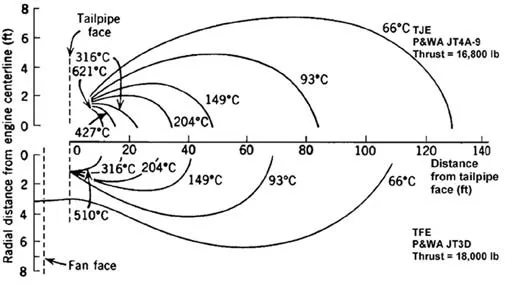

(ii) Peak temperature reduction of exhaust gases;several IRSS systems work on cooling the hot engine parts and exhaust plume,which are dominant sources of IR signature from the rear aspect.Hudson[20]presented the exhaust temperature contours of Turbo-Jet Engine(TJE)and TFE,and plume size of TJE found to be more than the TFE (shown in Fig. 1). Temperature of exhaust gases are generally reduced by enhancing the mixing process with the surrounding air[18,31,34].This is achieved by altering the exhaust geometry and by incorporating some device.Sully et al.[49]discussed the concept of Film Cooled Tailpipe(FCT),which uses ejector action to entrain secondary air for cooling of the tailpipe and plume. After incorporating FCT, the side-on signature reduced to approximately 30%of the baseline and rear view signature reduced to approximately 40%of the baseline[49].Dix et al. [14] performed a series of experiments using spectro-radiometer to investigate the potential reduction in IRSL from a TJE through the use of non-axisymmetric notched nozzle. They compared the IRSL of simple nozzle with 25°, 35°, 45°and 60°notched nozzles. A significant reduction in IRSL near 4.3 μm was observed with the 60°notched nozzle, and 33% of the hottest part of the exhaust plume was reduced[14].The ejector type IR suppressors(e.g.,lobed mixer-ejector) were used to increase the mixing process outside the nozzle. Zhang et al. [52] performed experiments on lobed forced mixers from IR signature suppression consideration. They calculated total radiation intensity; a significant reduction in IR signature was achieved through lobed nozzle. Knowles & Saddington [24] have studied various nozzle geometry modifications to increase mixing relative to that from a circular nozzle. They also found that lobed nozzles are efficient at promoting rapid mixing(200%increase, compared with a circular nozzle, half of this being due to increased perimeter).Shan and Zhang[43]performed experiment on multi-lobed forced mixers, which enhances the mixing of core flow and by-pass flow in the exhaust system of a turbo-fan engine. They concluded that, (i)lobed forced mixture increases the mixing efficiency by 65% relative to the confluent mixer, (ii) as By-Pass Ratio (BPR) increases, the mixing efficiency increases; and at BPR=1, the plume IR radiation is suppressed by 40%.High By-Pass Ratio(BPR)engines resulted in lower plume length and that leads to lower plume IR signature.Decher[12]concluded that the increase in nozzle aspect ratio decreases the emitted radiation of those parts of the spectrum where the optical thickness (i.e., product of optical absorption coefficient and emitting gas slab thickness) is small.

Fig.1. Exhaust plume temperature distribution of TJE and TFE [20].

(iii) Modification in aircraft skin temperature ; matching of aircraft IR radiance with the background IR radiance is important to reduce the contrast (positive or negative) between target and the background.This is achieved by electric heating of skin [15], heating and cooling of skin using thermo-electric module [40], and reducing temperature of visible exhaust pipe or hot parts using ambient air [32].

(iv) Surface property modification; IR contrast can also be reduced by optimizing the emissivity of aircraft skin [13,28]and reducing reflectivity of reflecting aircraft surfaces(when earthshine/sunshine reflections are important) [27]. Emissivity can be optimized by physical and chemical treatment of the radiation surfaces.Mahulikar et al.[28] observed that the IR signature is more sensitive to emissivity in the 8-12 μm band, as compared to the 3-5 μm band. This method of IR signature suppression does not impose any major performance penalties.

Most of the IR suppressors have some type of penalties associated with their incorporation. The major performance penalties generated with incorporation of IRSS system are engine backpressure, additional weight, increased drag, higher cost and complexity [26]. This paper reviews the various optical blocking methods of IR signature suppression (mainly of aircraft and helicopters from rear aspect) and the penalties associated with them.Advancements and developments in IRSS techniques in helicopters have already been discussed by Zhang et al. [53] and Paszko [35].Cooling of exhaust gases is a major technique employed to reduce the IR emissions of a helicopter in flight [35]. The airframe, stagnation region of the aircraft nose and the leading edges of the wings are prime sources of IR signature from the front and side aspect.Plume emission is visible from much wider view angles than tailpipe or other engine hot parts.But they emit only in a few discrete bands (4.15-4.20 μm band in non-afterburning mode) of the IR spectrum[25].From the front aspect(head on),the higher tracking rate(as aircraft and missile are moving in opposite directions)leads to increase in lethal range than from the rear aspect. As, in such situation,the pilot does not get adequate time to react;hence, the aircraft is more susceptible from the front aspect. In spite, the reasons of focus of optical blocking method from rear aspect are following: 1) the emissivity of the engine tailpipe and the turbine exit disc (if visible) are considered as 0.9 i.e., behaves like a blackbody[45].Therefore,for a fighter aircraft,the positive contrast in IR radiation is more in the 1.9-2.9 μm and 3-5 μm from the rear aspect; 2) the temperature of stagnation region of the aircraft and wing leading edges are relatively lower than the temperature of engine hot parts.Hence,only IR detector operating in the 8-12 μm band can be used for locking aircraft from the frontal aspect;3)the paper focuses on IR signature suppressors based on optical blocking method, which is mainly employed to provide blocking of engine hot parts, and they are mostly visible from the rear aspect. Therefore, focus of optical blocking method used for IR signature suppression shifts towards rear aspect.

2. IR signature suppression techniques using optical blocking

Optical blocking(masking)method is used to block the Line-Of-Sight(LOS)of the hot engine parts of the exhaust geometry.Visible areas of engine exhaust geometry and plume are major sources of IR signature of an aircraft having gas turbine engine. Blocking the visibility of aircraft engine hot surfaces partially/completely will reduce the solid angle subtended by the hot parts on the detector,which prevents the aircraft engine hot parts from IR detection.Optical blocking can be considered as a more effective way of reducing IR signature, as compared to cooling techniques. As cooling of exhaust gases increases their density and hence, engine back pressure penalty increases. The penalty generated with incorporation of optical blocking method depends on its design.The optical block should be designed in such a way that it should not increase the engine back-pressure.This is achieved by reducing the visibility of engine hot parts to a narrow range of view angle with minimum flow restrictions.As flow restrictions increases the engine back-pressure, which results in engine power loss, for a given engine operating point. The engine exhaust geometry modifications, e.g., alteration in nozzle geometry (nozzle exit area reduction)and fitment of new assembly(use of block element)are some of the techniques used for optical blocking of the engine hot parts.If a new assembly is used for optical blocking purposes then either it should not get heated up or its visibility must be restricted to a very narrow range of view angle;else,it will partly reduce the effectiveness of optical blocking.

Sometimes, the optical blocking is accomplished by a bend in the duct, to stop direct LOS to engine components. Some IR suppressors redirect the exhaust gases into the main rotor to block the direct view to the engine axis, but it has drawbacks in terms of thrust, effective weight of the suppressor and unpredictable rotor and airframe heating. Hence, the IR suppressors are objectionable under non-combat conditions, as it causes penalties in aircraft performance. Most of the IR suppressors generate some kind of penalties, which objects its use during non-combat conditions.Hence,some known suppressors have the facility of removal of the IRSS system, when aircraft is operating in non combat conditions.Various IR suppressors have been designed and patented till now.Some IR signature suppression methods,which employ the optical blocking technique, are discussed below:

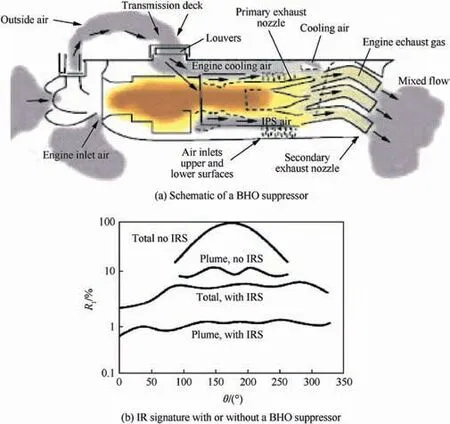

2.1. Black Hole Ocarina(BHO)IRSS system designed by Barlow and Petach [4]

Fig. 2. Black Hole Ocarina (BHO) IRSS system [4].

This suppressor was first introduced in Hughes helicopter for providing protection against heat-seeking missiles.This suppressor uses a combination of black hole(blocks the visibility of engine hot parts) and ocarina systems (provides the multiple outlets). As shown in Fig. 2 (a), this system works on the principal of blocking the engine hot parts and uses multiple exhaust technique to dissipate the plume.The black hole system consists of finned nozzle with internal bends to prevent the direct view of engine hot parts,while presenting a metal at 200°F.The ocarina system of multiple exhausts dissipates the exhaust plume and reduces its IR signature.The finned nozzle is cooled by rotor downwash in hover and by the turbulent air flow in forward flight. Fig. 2(b) shows the plot of relative infrared intensity (RI) versus view angle (θ). The incorporation of BHO system on YAH-64 helicopter resulted in 30%and 40%reduction in IRSL from the hot engine parts and from the plume,respectively.

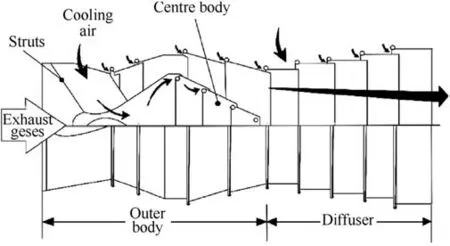

2.2. Center body tailpipe (CBT) IRSS system designed by Thompson et al. [50]

This IRSS system consists of a film cooled outer duct(as shown in Fig. 3), which is surrounded by a film cooled center body and followed by a film cooled diffuser. Being a discrete emitter, the exhaust plume is the least contributor towards the total IR radiation from the rear.The engine hot parts and other solid surfaces emit at all wavelengths at all temperatures. Therefore, a center body was proposed,which blocks the direct visibility of exhaust duct,and all visible metal surfaces are convectively cooled.Thompson et al.[50]designed this IR suppressor for the Bell-205 helicopter and it was found that CBT reduced 70% IRSL from the side aspect in the 3-5 μm band and 80% from 30°off-tail.

2.3. IR suppressor designed by Chew et al. [10]

This IRSS system consists of unique arrangement of multiple baffles that are connected together as a single baffle module. The baffle arrangement breaks down the exhaust flow into separate flow streams and permits mixing of hot and cool gas flows while eliminating the line-of-sight of the hot turbine parts. This suppressor provides a feature to easily remove the baffle modules when IR suppression is not required.

2.4. IR suppressor designed by Siefker et al. [44]

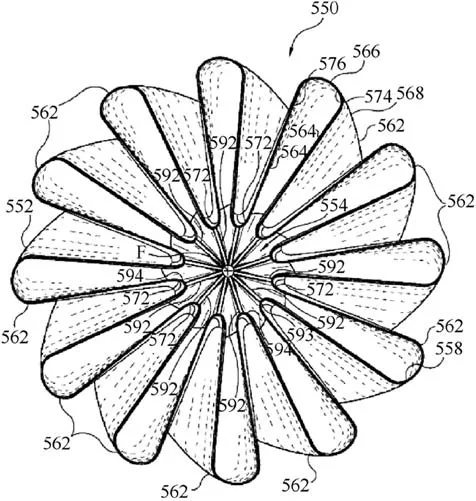

This IRSS system consists of exhaust mixer coupled to the engine along an outlet, which provides optical blocking by reducing the visibility of hot parts. As shown in Fig. 4, the mixer consists of several curved or twisting pattern of lobes (relative to a reference axis) projecting radially away from the axis, which results in lineof-sight blockage of the hot parts of the exhaust portion of the engine.This multi-lobed mixture may additionally include a curved pattern relative to the reference axis to enhance the line-of-sight blockage. This suppressor also works by enhancing the mixing of exhaust gases with cooler air and reduces the noise level generated by the gas turbine engine.

Fig. 3. Schematic of center body tailpipe used in Bell-205 helicopter [50].

Fig. 4. Elevational view of exhaust mixer designed by Siefker et al. [44].

2.5. IR suppressor designed by Wollenweber [51]

This IRSS system requires mounting a core engine to a vehicle,coupling a fuselage radially outward and around the core engine,and coupling an exhaust nozzle to the core engine to channel exhaust gases discharged from the core engine.The IR suppressor is placed in flow communication with the engine exhaust nozzle for channeling exhaust gases to facilitate suppressing exhaust IR signature. This IRSS system consists of an access door and a flow channel that is coupled to the access door, such that the flow channel is movable with the access door from a closed position to an open position.This IRSS system facilitates in reducing exhaust IR signature.

2.6. IR suppressor designed by Steyer et al. [48]

The suppressor is mounted downstream from the aircraft engine outlet,which helps in reducing the IR radiation emitted by the engine. It consists of an elongated duct having a hollow interior extending towards an axial centerline for transporting exhaust gas emitted by the vehicle,and a baffle positioned inside the duct.The baffles are used to obstruct the downstream end line-of-sight observation of the engine hot components. The method also includes application of emissivity coating to at least one of the duct and the baffle.

2.7. IR suppressor designed by Mahulikar et al. [29]

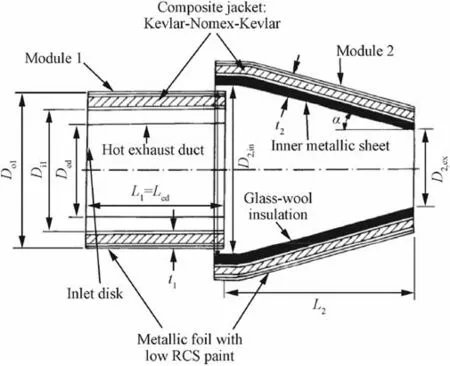

This IRSS system conceals the source of IR signature, and camouflages the exposed surfaces with the background radiation. The IRSS system completely blocks the visibility of the exhaust duct's outer surfaces and visibility of inner surfaces are restricted to a narrow range of view angle. This IRSS system is developed in two Modules (shown in Fig. 5); Module 1 is located over the engine exhaust duct using stiffeners, and module 2 is located over the Module 1. The inner surface of the Module 2 has a thin metallic layer followed by glass-wool insulation. This glass wool insulation is covered by the same composite Kevlar-Nomex-Kevlar as in Module 1. This system reduces the solid angle subtended by the inlet disk surface and the inner surface of the hot exhaust duct,and also the range of the viewing aspect angle over which they are visible. The weight penalty is reduced by using lightweight composite and glass wool; both have low thermal conductivity, which reduces their thicknesses.

Fig.5. IRSS system designed by Mahulikar et al.[29]for the helicopter engine exhaust duct.

2.8. IR suppressor designed by Chapkovich et al. [9]

This IRSS system consists of a double walled exhaust duct and double walled septum. Double walled structure provides path for the secondary cooling air flow, where cooling air passes through the spiral septum slots to cool the surfaces and mixes with the exhaust gases downstream to cool the exhaust plume. A spiral septum is in the shape of helix extended up to the exhaust duct and rotating 360°that fully masks the line of sight to the heated exhaust components. This spiral septum arrangement minimizes the exhaust flow restrictions and hence,power loss associated with the engine is reduced.

2.9. IR suppressor designed by Sokhey and Kornegay [47]

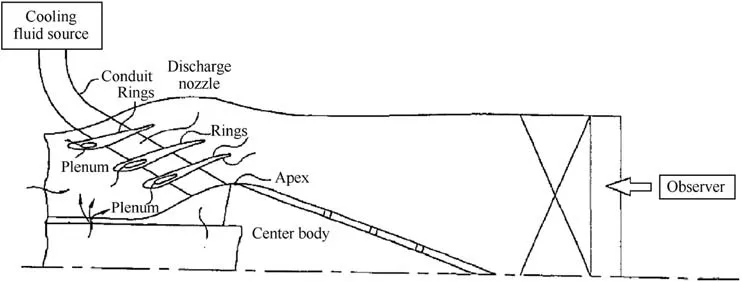

This IRSS system consists of a center body inside the discharge nozzle and a conduit enclosing the center body as shown in Fig.6.

The center body is symmetrical about the reference axis and consists of cooling slots,which emits fluid like ambient air or air from the compressor.The rings depicted in Fig.6 are disposed upstream of the apex that helps the center body in blocking the view of turbine from the outside observer. These rings are in airfoil crosssectional shaped, symmetrical about the axis and include cooling plenums to receive cooling fluid from the cooling passageway.

2.10. Nozzle exit area reduction [3]

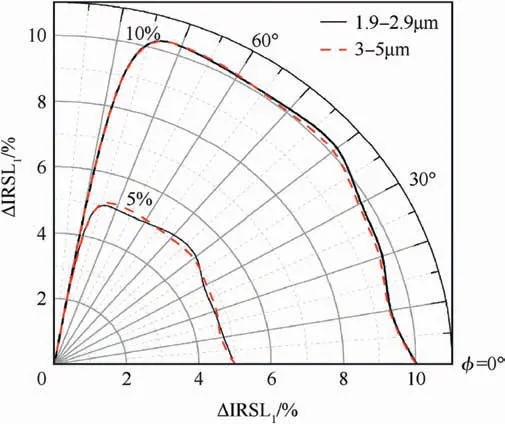

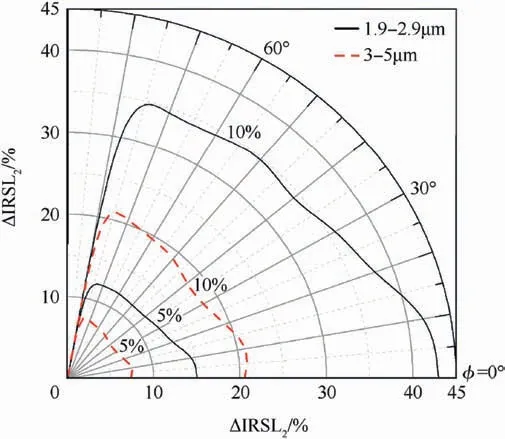

Reduction in nozzle exit area results in a decrease in visible planer area,which leads to decrease in solid angle subtended by the hot engine parts. A reduction in the nozzle's exit area reduces the visibility of the jet-pipe's and converging nozzle's inner surfaces from the rear side.The solid angles subtended by separate parts of the exhaust geometry are calculated using a parallel ray projection method [30], from different viewing angles (0°≤φ ≤90°). The ωsubtended by visible projected planer area (Apl) of the engine hot parts on the plane normal to the LOS(Line of Sight)is calculated as ω=Apl/LOS2[33]. The study is performed by considering two different cases:i)constant turbine exit temperature(TET)(Case 1);ii)constant design point thrust(Case 2).For a fixed TET(Case 1),the percentage decrease in IRSL relative to IRSLdp(ΔIRSL1%),due to the reduced solid angle subtended by the hot engine parts, is almost same as the percentage reduction in Anerelative to Ane,dp(ΔAne,red%)(Fig. 7). When the engine thrust level is maintained at the design point value(Case 2),a reduction in the choked Anerelative to Ane,dp,results in a higher TIT (Turbine Inlet Temperature).

3. IR signature suppression penalties

IR suppressors are meant to effectively reduce IR signature from different view angles, but with low performance penalties [26], as incorporation of IR-suppressors increases the power required to overcome IR signature suppression penalties. For constant engine power, the mission power decreases, as the power required to overcome IR signature suppression penalties increases [3]. Presence of center body (e.g., Center body tailpipe) results in disturbance to the exhaust flow,in addition to the weight penalty.Active cooling of the center body should be avoided, as active version takes power from the main engine for its operation, which will further reduce the power available for the mission.As discussed in the previous section, the black hole system of BHO IRSS system consists of finned nozzle with internal bends to prevent the direct view of engine hot parts. Sharp bend in nozzles leads to mission power loss, for a given engine operating point [29]. To keep the mission power constant, engine power must be increased with incorporation of IR suppressor, which leads to increase in temperatures of the tailpipe,exhaust plume and all engine heated surfaces,and results in increase in IRSL. Hence, the optical block should be designed in such a way that it should not increase the engine backpressure. As, penalties associated with IRSS systems can partly reduce the effectiveness of optical blocking. Major performance penalties associated with installation of IR suppressors are following:

Fig. 6. Side sectional view of the IRSS system designed by Sokhey and Kornegay [47].

Fig. 7. Polar plot for percentage decrease in IRSL for 5% and 10% reductions in Ane relative to Ane,dp, in 1.9-2.9 μm and 3-5 μm bands for constant TET [3].

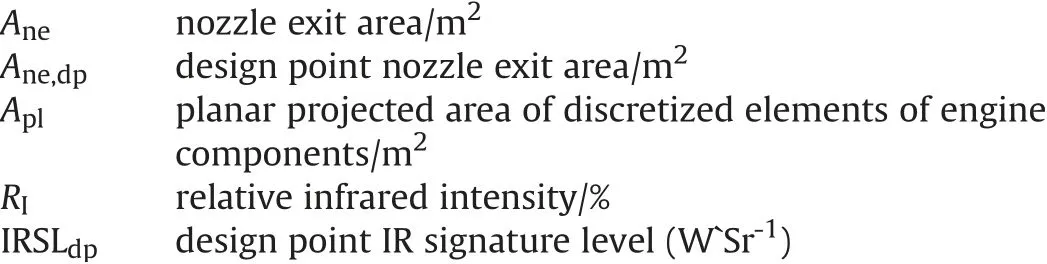

3.1. Additional weight of IR suppressors

Additional weight of IR suppressors results in much greater stresses on the rotor blade and shift in engine operating point.So,in order to bring it back to its design point, more thrust is needed to support the additional weight of the suppressor. A center plug in the exhaust duct,which is used for blocking the line-of-sight to the hot engine parts from the rear aspect,increases the engine weight.Several stealth paints like ferrite-based coating, MX-410 on some aircraft made it too heavy to fly [21]. Long mixing and diffuse sections are required to enhance the mixing of exhaust gases with the cold ambient air.A long diffuser,used for IR suppression would be too bulky for helicopter applications [36]. Many passive IR suppressors based on optical blocking and mixing of exhaust gases with ambient air,add to the weight and results in available engine power loss (Table 1). To compensate the loss of power, engine operating point shifts to a higher temperature and reduces the effectiveness of the IR suppressor. The IR suppressor designed by Mahulikar et al. [29] reduces weight penalty by using lightweight composite and glass wool; both have low thermal conductivity,which reduces their thicknesses.

3.2. Increase in engine back-pressure

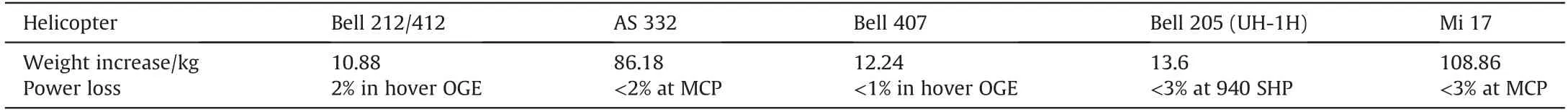

Engine back-pressure is the pressure downstream to the flow,due to which pressure gradient is reduced and it is often caused by the obstruction in flow. The presence of center body, baffle arrangement, diversion of the exhaust flow or any obstruction in the flow increases the engine back-pressure. The IR suppressors having cooling air pump actions results in back-pressure penalty[5]. Increase in back-pressure penalty is the major drawback of various IR suppressors,e.g.,CBT.Presence of center body in the CBT and cooling of exhaust gases in flow path (results in increase in their density);both results in increase in engine back-pressure[29].From Table 1,the effect of this increased engine back-pressure due to CBT IRSS system in Bell-205 (UH-1H) helicopter is about 3%power loss, for the engine operating point corresponding to 940 SHP. Incorporation of 2-D nozzles also increases the engine backpressure significantly, which decreases the available mission power for a given engine operating point.Baranwal and Mahulikar[3]have performed the quantitative study of the effect of engine backpressure penalty on IRSL due to choked nozzle exit area reduction.The effect of engine back-pressure penalty on IR lock-on range has also been studied [2]. In Fig. 8, ΔIRSL2% represents the percentage increase in IRSL relative to the design point IRSL(IRSLdp)at constant thrust. A significant increase in IRSL due to the nozzle exit area reduction is seen for both of the bands (i.e., 1.9-2.9 μm and 3-5 μm) when thrust was maintained at the design point value(Fig.8).This is due to the shift in engine operating point to higher temperature to maintain the same design point thrust. The increased temperature based IR radiance (due to shift in engine operating temperature)from the tail-pipe dominates the decreased IR radiance due to reduction in the visible area of the hot engine parts [3].

3.3. increase in cost and complexity

Fig. 8. Polar plot for percentage increase in IRSL for 5% and 10% reductions in Ane relative to Ane,dp, in 1.9-2.9 μm and 3-5 μm bands for constant thrust [3].

Table 1Increase in weight and engine power loss due to IR suppressor installation on various helicopter [11].

Installation of IR suppressor increases cost and system complexity,which reduces its reliability.Fitment of various types of jet mixing systems,presence of optical block,cooling pump,altered nozzle geometry etc. increases the overall complexity of the exhaust duct. Sometimes they require changes in the exhaust system geometry also. But, this increase in cost of stealth aircraft or helicopter can be justified by the increase in its survivability in hostile environments.

3.4. Influence on other signatures

Mixing of free stream with exhaust gases at high-speed,obstruction in the flow result in broad-band jet noise; consequently, aural signature increases. Noise suppression can be achieved by increasing the surface area of the jet stream.Screech liners in afterburner and sandwich composite skins with pyramidal structures pointing inward are being used to absorb engine noise[21].

4. Conclusions

Incorporating an IR suppressor in a combat aircraft is the first step towards increasing its survivability. Many IR suppressors use optical blocking method to avoid the detection of aircraft's engine hot parts from IR detectors. This paper focuses on IR signature suppressors based on optical blocking method, which is mainly employed to provide blocking the view of engine hot parts.Optical blocking can be considered as a more effective way of reducing IR signature,as compared to cooling techniques.As cooling of exhaust gases increases their density and hence, engine back pressure penalty increases. The penalties generated with incorporation of optical blocking method depend on its design. The optical block should be designed in such a way that it should not result in increase in engine back-pressure. From the study, it can be said that the penalties generated due to the incorporation of IR signature suppression techniques can adversely affect the target aircraft performance in various ways.Hence,the penalties generated in the form of increased engine back-pressure, weight, cost, complexity and other signatures(like Radar and acoustic)should be minimum after implementation of IR suppressor. The visibility of engine hot parts should be in a narrow range of view angle with lower flow restrictions; because flow restrictions increases engine backpressure that results in engine power loss, for a given operating point.Keeping in view the capabilities of recent IR-guided missiles,the incorporation of IRSS system should generate minimal penalties. The best optical blocking method should not involve following:a)increase in engine back-pressure;b)active cooling of engine hot parts or heated part of the optical block, as active version takes power from the main engine for its operation,which decreases the available mission power. In addition to this, heated part of the optical block should not be visible and weight of the optical block should be minimal.

Acknowledgements

The authors thank the Indian Institute of Technology Bombay's Post-Doctoral Research Program, vide appointment no. AO/Admn-1/33/2018 dated 10.Aug'2018 for providing funding.

Nomenclature

Greek Scripts Δ difference operator/-ΔIRSL1 /% percentage decrease in IRSL relative to IRSLdp at constant turbine exit temperature ΔIRSL2 /% percentage increase in IRSL relative to IRSLdp at constant thrust φ viewing aspect angle (φ=0° for direct rear view along engine axis)/°ω solid angle/Sr Abbreviations BHO Black Hole Ocarina BPR By-Pass Ratio CBT Center Body Tailpipe FCT Film Cooled Tailpipe IR Infra-Red IRSL Infra-Red Signature Level IRSS Infra-Red Signature Suppression IRST Infra-Red Search and Tracking LOS Line-Of-Sight LWIR Long Wave Infra-Red MCP Maximum Continuous Power MIM Metal Insulator Metal MWIR Mid Wave Infra-Red OBS Optical Block Suppressor OGE Out-of-Ground Effect QDIP Quantum Dot Infrared Photo-detector RCS Radar Cross Section SHP Shaft Horse Power SWIR Short Wave Infra-Red TET Turbine Exit Temperature TFE Turbo-Fan Engine TJE Turbo-Jet Engine

- Defence Technology的其它文章

- Body armour - New materials, new systems Ian G. Crouch*

- Special materials in pyrotechnics VII: Pyrotechnics used in thermal batteries☆

- Real-time calculation of fragment velocity for cylindrical warheads

- Heavy metal free primers: Polymorphism of gadolinium and titanium in the context of GSR glass phase Felice Nunziata

- Mitigation of EDFA transient effects in variable duty cycle pulsed signals

- Ballistic impact properties of woven bamboo- woven E-glassunsaturated polyester hybrid composites