病死猪辅热快速好氧发酵工艺参数优化与装备研制

谭鹤群,聂 杰,万 鹏,付 豪,李鑫安

病死猪辅热快速好氧发酵工艺参数优化与装备研制

谭鹤群,聂 杰,万 鹏,付 豪,李鑫安

(1. 华中农业大学工学院,武汉 430070;2. 农业农村部长江中下游农业装备重点实验室,武汉 430070)

将病死猪、辅料拌合后加入发酵菌种,在50~70 ℃条件下进行辅热快速好氧发酵处理,可在短时间内将病死猪转化为干颗粒物料。为了优化发酵工艺参数,提高发酵处理质量,该文采用辅热快速好氧发酵试验装置,以猪死胎为原料、麸皮为辅料,选取通风量和温度为试验因素,以产物的总游离氨基酸(free amino acid,FAA)质量分数、含水率、粒度分布和pH值作为试验指标,开展了病死猪辅热快速好氧发酵处理试验。发酵温度选取50、60和70 ℃ 3个水平,通风量选取8、9和10 L/(L·min) 3个水平。结果表明,发酵温度60 ℃、通风量10 L/(L·min)时处理效果最佳。在此基础上,设计并试制了一台处理能力为150 kg/批的病死猪辅热快速好氧发酵处理设备,并进行了初步试验。设定通风量为10 L/(L·min),发酵温度为60 ℃,发酵3 d后物料中的FAA质量分数为20.74 g/kg,含水率为14%左右,pH值为5.4,88.89%能通过4.75 mm编织筛,未检出大肠杆菌,平均每处理1 kg病死猪的能耗为2.37 kW∙h。试验结果表明,试制的装备能在3 d内将冰冻状态的病死猪无害化处理转变为干颗粒物料,处理产物能满足后续有机肥生产的要求。

发酵;装备;通风;病死猪;辅热快速好氧发酵;游离氨基酸;无害化处理

0 引 言

生猪养殖过程中因死胎、疾病、自然灾害等原因,会产生大量病死猪,据统计,2017年中国生猪出栏6.89亿头,在养殖过程中,生猪死亡率为5%~10%[1]。这些病死猪如不进行及时处理或处理不当,会对人和动物造成危害,对环境造成污染,对资源造成浪费。近年来,国内媒体报道过多起由于病死猪处理不当而引起的食品安全和严重环境污染事件[2-4]。目前,生产实际中的病死猪处理方式主要有填埋、焚烧、化制、堆肥等4种方法。填埋法可能会产生大量恶臭气体并导致土壤和地下水受到病原体和尸体分解产物的污染,给人类食品和动物饲料带来卫生风险[5-6];焚烧法所需的焚烧炉由于造价和能耗较高,往往需要将死亡动物进行集中处理,在运输的过程中可能造成动物疾病的传播和扩散[7],不完全燃烧所释放的二恶英和呋喃是致癌物,会对人类的生殖、发育和免疫系统产生负面影响[8]。化制法和堆肥法的处理周期往往长达数月,而且处理过程中会产生大量恶臭气体[9-12],难以满足猪场大量病死猪及时、无害化处理的要求。

辅热快速好氧发酵是将畜禽死体和适当的辅料、菌种置于设有转子的容器中进行好氧生物降解。处理过程中,往容器内通入热空气,一方面提供好氧发酵所需的氧气,另一方面提供维持发酵温度所需的热量。容器内的转子则不断对混合物料进行搅拌,一方面使菌种和病死猪原料、辅料接触更为充分,提高发酵速度,另一方面通过转子上的刀片切碎病死猪原料,使混合物料在生物降解、水分降低的同时,逐渐变成颗粒状产品。畜禽死体经高温发酵处理后体内病原体会被消灭[13-14],部分蛋白质会被降解成氨基酸。处理后的产品如果作为植物肥料,其中的氨基酸可以直接被植物吸收[15-18],提高作物产量[19-21],还可以改善土壤环境,提高土壤中酶的活性[20-22]。因此,可考虑将病死猪辅热快速好氧发酵产物制成氨基酸肥料。

目前,病死猪辅热快速好氧发酵处理还处于探索阶段,处理工艺对处理效果的影响未见相关报道。本文首先以猪死胎为原料,麸皮为辅料,研究发酵温度和通风量对处理效果的影响。在此基础上,设计并试制了一台批次处理量为150 kg的病死猪辅热快速好氧发酵处理设备,并对样机开展了处理试验。

1 材料与方法

1.1 试验材料

猪死胎:来自于湖北省天门市某养猪场。运回实验室后在−4 ℃条件下冷冻备用。麸皮:购自武汉市洪山区某饲料店。菌种:购自中国台湾某公司。

1.2 试验设备

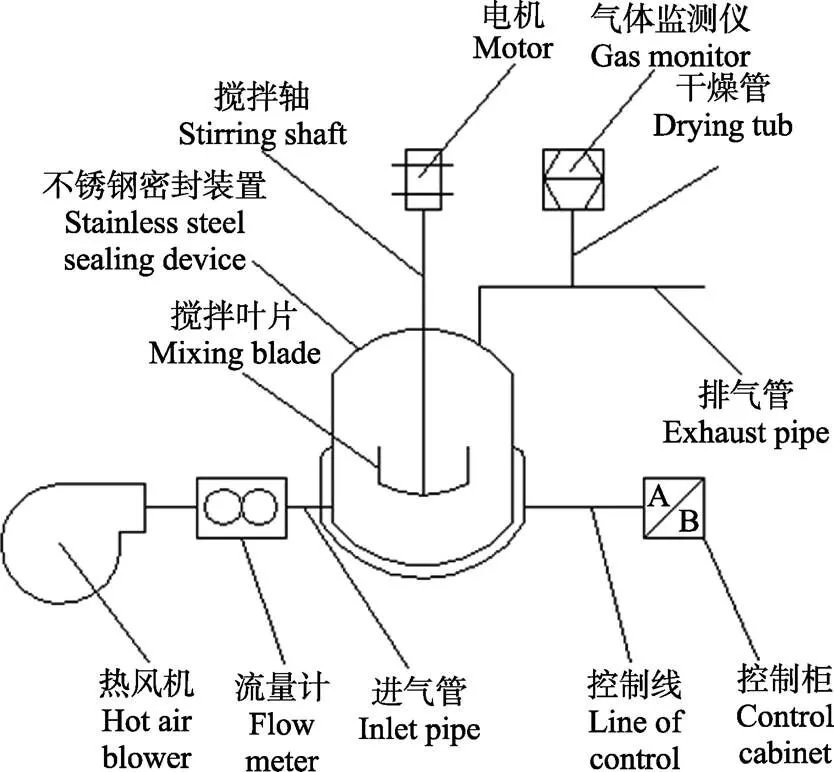

试验在如图1所示的病死猪辅热快速好氧发酵装置中进行。该装置容积为10 L,采用夹层水浴加热,热风机(潍坊汇众机电设备有限公司,加热功率3 kW,风机功率120 W,风量范围0~300 L/min)用来调节流量以及出风的温度,流量计(江苏沪仪自动化仪表有限公司,测量范围1.6~16 m3/h,精确度1.5%)用于对通入的风量进行监测。水浴温度、热风机流量及热风温度、搅拌轴转速等均通过控制箱设置和调节。

图1 病死猪辅热快速好氧发酵试验装置

1.3 试验方法

试验于2018年8−10月在华中农业大学工科基地进行。以单位发酵装置容积每分钟通风量(简称通风量)、发酵过程中装置内维持温度(简称温度)作为试验因素。每个因素设置选取3个水平进行试验。

每次试验选取一头猪死胎(质量1.5~2.2 kg),用电锯将冷冻的死猪分割成约5 cm左右的块状,然后放入绞肉机绞碎,称量绞碎后的猪体,按猪体质量:麸皮质量1.5∶1(干基比,按猪含水率75%,麸皮含水率9%折算成湿基比约为5.5∶1)称取适量麸皮,拌合后按菌种质量:猪体质量为1∶25(干基比,按猪含水率75%,菌种含水率10%折算成湿基比约为1∶100)加入菌种。猪体初始含水率为75%,麸皮初始含水率为9%,混合后的物料含水率为65%,pH值为6.5,游离氨基酸(free amino acid,FAA)质量分数为6.0 g/kg。最后将混合后的物料投入图1所示发酵装置中开始辅热快速好氧发酵处理(物料容积约占装置容器的1/3),在处理过程中持续搅拌与通风。

温度试验:设定通风量为8 L/(L∙min),分别进行温度50、60和70 ℃[23-27]的处理试验。为了使发酵过程中发酵物料水分含量保持在维持微生物活动的适宜范围,试验中,每发酵24 h,加水将含水率重新调至65%。

通风量试验:以温度试验中的最佳温度作为通风量试验温度,分别进行通风量为8、9和10 L/(L∙min)的处理试验。

1.4 采样与检测

1)采样

每次试验发酵3 d(加入菌种时开始计时),通风量试验在发酵结束时取样,温度试验每隔24 h取样。取出的样品一部分用于检测含水率和pH值,一部分风干后用于游离氨基酸检测。每次试验完成后将全部发酵物料风干,测定其粒度分布。

2)测定方法

含水率:按GB/T 8576—2010(复合肥料中游离水含量的测定—真空烘箱法)的方法测定。

pH值:按NY525—2012(有机肥料)的方法测定。

粒度分布:采用从上到下孔径依次为4.75、3.35、2.36、1.70、1.18 mm盲筛的编织筛组。每次称取风干后的样品100 g,放入最上层筛,用振动筛分器(8411型电动振动筛,功率120 W)筛分15 min。筛分完毕,分别称量各层筛上物并将结果绘制成粒度特征曲线。

FAA质量分数:按NY/T 1975-2010 (水溶肥料—游离氨基酸质量分数的测定)的方法测定。

2 结果与分析

2.1 温度对发酵效果的影响

如表1所示,3种温度条件下,发酵物料中的FAA质量分数都呈现出先升高后降低的趋势,均在第2天达到最大值。温度为60和70 ℃时,第3天的FAA质量分数相比第2天变化很小。而温度为50 ℃时,第3天的FAA质量分数比第2天大幅度下降。从含水率变化情况看,以初始含水率65%计算,每发酵1 d,50 ℃时下降8个百分点~11个百分点,60 ℃时下降24个百分点~27个百分点,而70 ℃时下降40个百分点~50个百分点。经1 d发酵,70 ℃条件下发酵物料含水率仅有16%~18%,从其FAA质量分数仅比发酵前提高3%左右来看,可以认为,发酵温度为70 ℃易造成发酵物料水分流失过快,不利于微生物对病死猪的降解。

表1 不同温度与发酵时间的发酵物料中的游离氨基酸(FAA)质量分数、含水率和pH值

注:通风量为8 L∙ L–1∙min–1。每发酵24 h,加水将含水率重新调至65%。

Note: The ventilation rate is 8 L∙ L–1∙min–1. Water content maintained at 65% by adding water every 24 h.

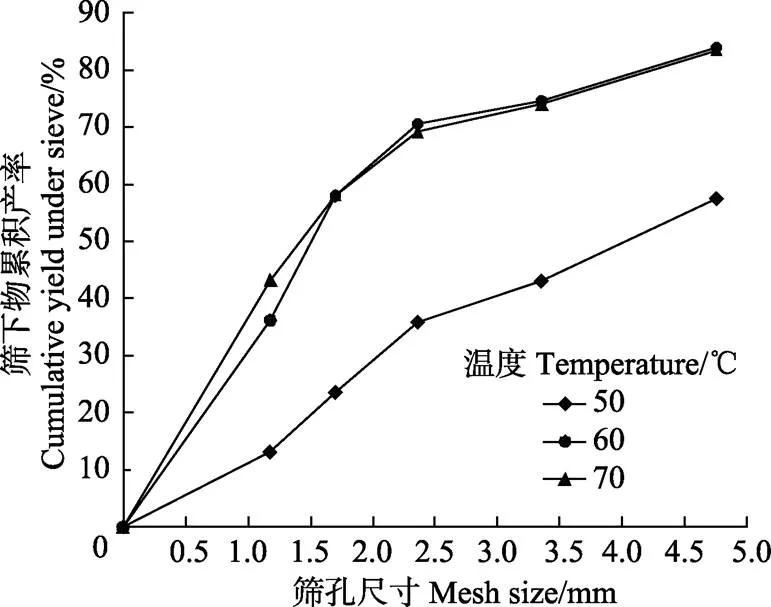

温度为50和60 ℃,处理3 d后发酵物料中的FAA质量分数分别为18.51、16.62 g/kg,比发酵前分别提高了12.51和10.62 g/kg 。但从粒度分布来看(见图2),50 ℃时4.75 mm编织筛的物料通过率仅有57.40%,而60、70 ℃时可分别达到83.95%和83.44%,这一方面是因为高温促进了病死猪特别是皮和骨头的降解,另一方面是因为水分越低,在搅拌作用下物料越松散。

注:通风量为8 L∙L–1∙min–1。

本试验中,发酵3 d后物料pH值均低于发酵前的pH值,与徐滔明和赵旭等的研究结果一致[28-30]。

综合分析,50 ℃时,虽FAA质量分数最高,但每1 d含水率仅下降8个百分点~11个百分点,且发酵物料中存在大块未降解的猪肉块和皮毛,导致其4.75 mm编织筛通过率低;70 ℃时,发酵物料粒度分布与60 ℃情形相似,但由于含水率下降过快,发酵3 d后FAA质量分数仅比发酵前提高3.42 g/kg,死猪降解程度低。因此,发酵温度以60 ℃左右为宜。

2.2 通风量对处理效果的影响

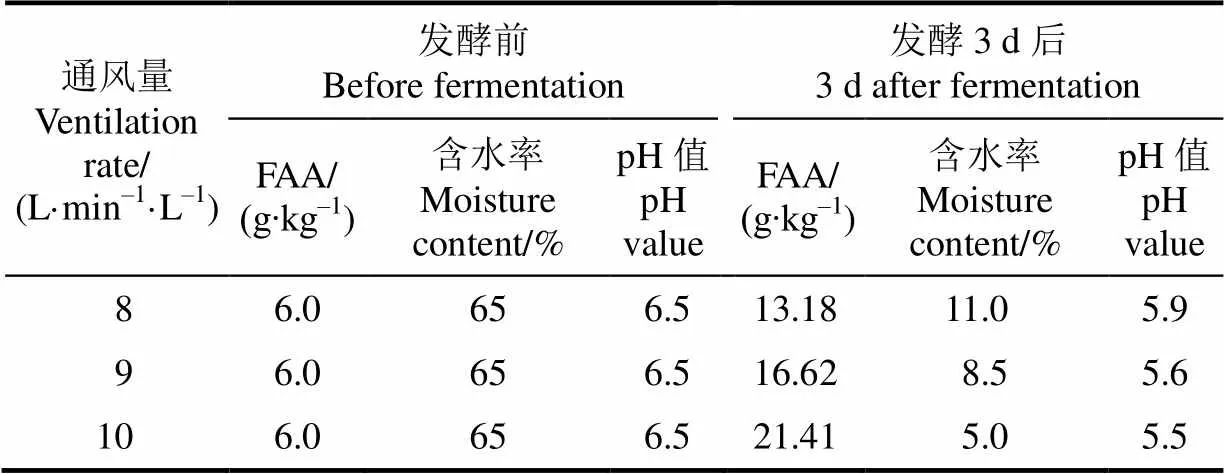

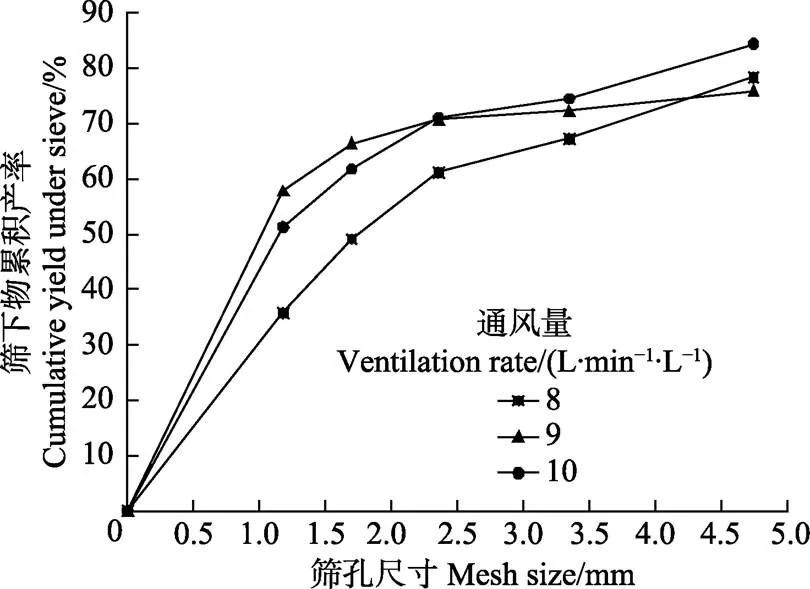

如表2所示,3种通风量水平下,发酵产物的含水率均在12%以下,pH值均在5.5以上,满足农业行业标准《有机肥料》(NY525-2012)的要求。通风量为8、9和10 L/(L∙min)时,产物中FAA质量分数分别为13.18、16.62和21.41 g/kg,比发酵前分别提高121.1%、178.9%和259.4%;含水率依次为11.0%、8.5%和5.0%,pH值依次为5.9、5.6和5.5,表现为通风量越大,发酵物料含水率越低,FAA质量分数越高,pH值越低。

表2 通风量对FAA质量分数、含水率和pH值的影响

注:温度为60 ℃。

Note: The temperature is 60 ℃.

发酵温度同为60 ℃时,通风量与产物中FAA质量分数呈现正相关,这是由两方面原因造成的:1)热风通风量增大时,发酵温度提高速度更快,同时也能为好氧微生物活动提供更充足的氧气,从而使微生物对病死猪的降解程度更高;2)胡天觉等的研究表明[31],低含水率会抑制噬温好氧微生物的活动。好氧发酵后期,好氧微生物的代谢会消耗蛋白降解产生的FAA,因此,通风量增大,发酵物料中水分流失快,会抑制微生物对FAA的降解。

本试验中,发酵后物料的pH值均低于发酵前混合物料的pH值,与温度试验结果一致。

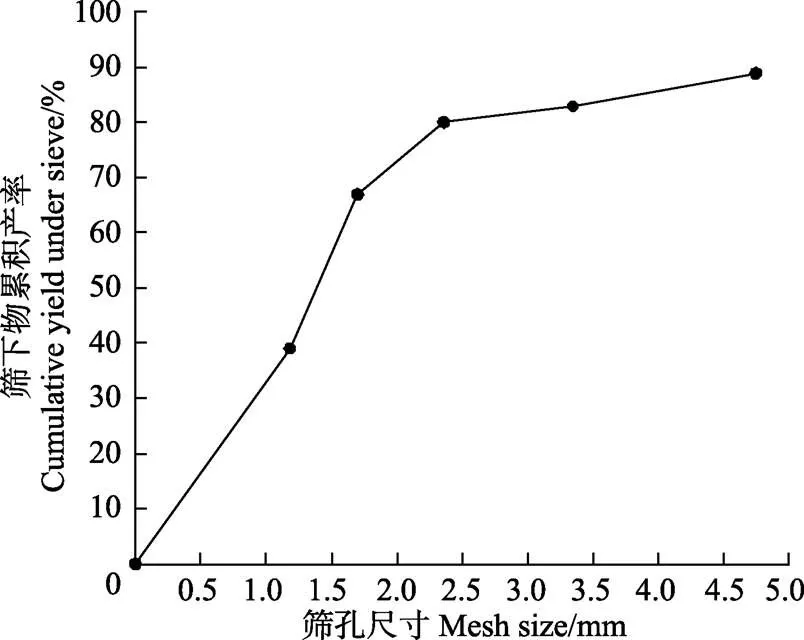

3种通风量水平下,4.75 mm编织筛通过率均达到70%以上,其中通风量为10 L/(L∙min)时最高,可达84.40%(见图3)。图3还显示,通风量越大,细颗粒比例越高,这与通风量加大后,含水率降低,发酵产物由于搅拌而破碎有关。

综合分析,当发酵温度为60 ℃时,通风量10 L/(L∙min)的发酵效果优于8和9 L/(L∙min)的发酵效果。

注:温度为60 ℃。

3 病死猪辅热快速好氧发酵处理装备研制

3.1 处理装备的设计

按发酵温度60 ℃时和通风量10 L/(L∙min)的要求,选择空气加热组件和风机型号,在此基础上设计了如图4所示的病死猪辅热快速好氧发酵处理装备。

该装备主要由进气组件、搅拌组件、加热组件、机架组件和舱盖组件组成。进气组件包括加热风机、送气管、空气分流罐、进气管,搅拌组件包括减速电机、搅拌轴、处理槽、动刀、定刀,加热组件包括工业电热毯、保温层,机架组件包括机架、脚支撑、盖板,舱盖组件主要包括舱盖和出气口。加热组件中的工业电热毯粘连在处理槽外壁上,保温层附在工业电热毯上。该装置每批次能处理150 kg病死猪,批次处理时间缩短至2~3 d;处理产物呈干颗粒状,便于后续有机肥生产。图5是样机的实物图片,其主要技术参数如表3。

图4 病死猪辅热快速好氧发酵处理装置结构简图

图5 病死猪辅热快速好氧发酵处理装置实物图

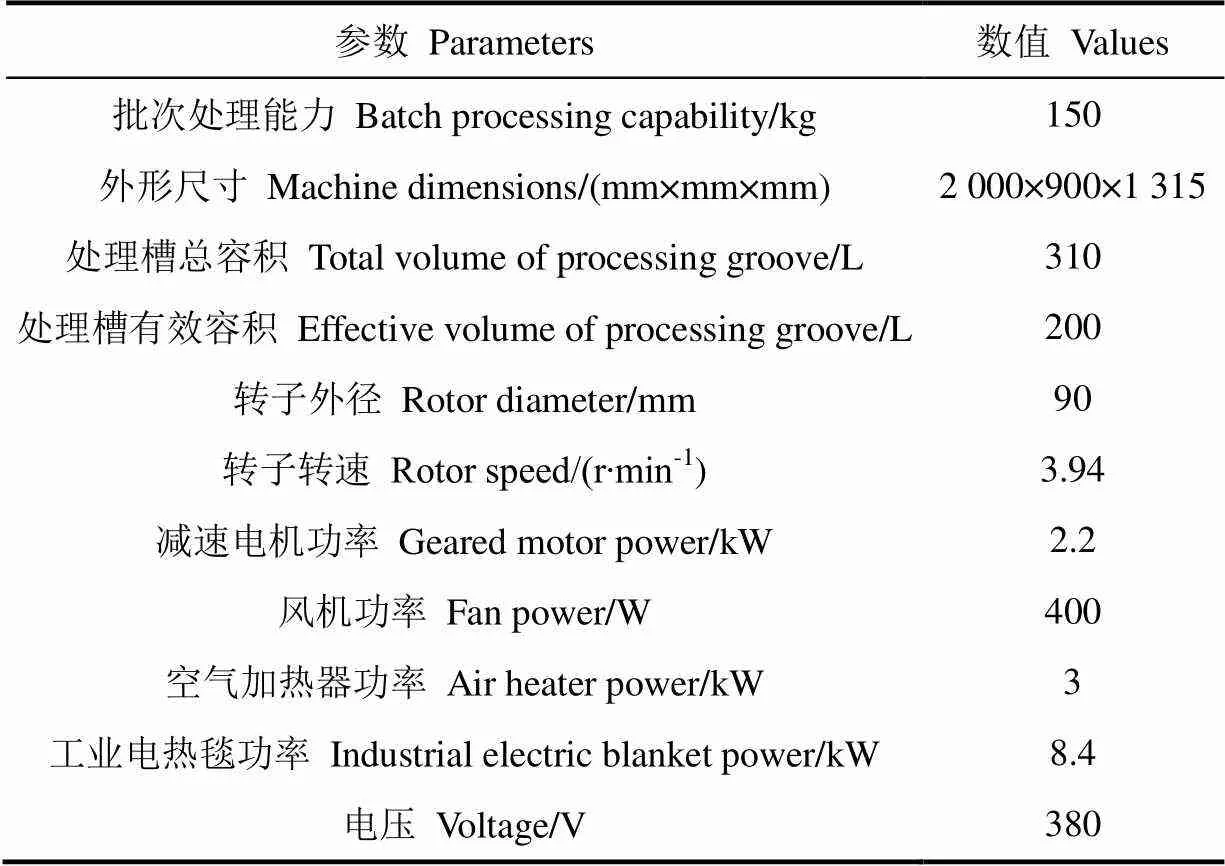

表3 病死猪辅热快速好氧发酵处理装置主要技术参数

3.2 装备试验与结果分析

3.2.1 试验方法

2018年12月,在华中农业大学“生猪健康养殖与协同创新中心”进行病死猪辅热快速好氧发酵装置的处理试验。试验以华中农业大学进行生物试验后产生的病死猪为原料,并采用1.1节所述麸皮和菌种。

试验时,先打开热风机和主电机,设定温度为60 ℃,通风量为10 L/(L∙min),将冷冻后待处理的死猪约150 kg投入处理槽内,并开始计时。约60 min后,按死猪质量:麸皮质量为1.5∶1(干基比)加入麸皮,按菌种质量:猪体质量为1∶25(干基比)加入菌种。在设备运转期间,搅拌轴按正转15 min—停转2 min—反转3 min—停转40 min的顺序,以1 h为周期循环运行。试验进行3 d,试验结束后取样,用于检测产物FAA质量分数、含水率、pH值、粒度分布和大肠杆菌,大肠杆菌检测参照GB 4789.3-2016(食品安全国家标准,食品微生物学检验-大肠菌群计数),其他检测方法同1.4节。

3.3.2 试验结果

如图6所示,经过3 d发酵后,死猪基本被降解,降解后的产物呈黄褐色细颗粒状,无明显骨头和毛皮。

a.发酵前a. Before fermentationb.发酵后b. After fermentation

处理3 d后,物料含水率为14%左右, pH值为5.4;FAA质量分数为20.74 g/kg。土壤中游离氨基酸质量分数一般仅为1~2 mg/kg[32],因此,病死猪经处理后若作为有机肥使用,能提高土壤游离氨基酸质量分数。如表4所示,发酵后物料中游离氨基酸主要为丙氨酸、谷氨酸、亮氨酸、脯氨酸、缬氨酸、组氨酸、甘氨酸、赖氨酸和丝氨酸,其中包含了一些土壤中较为缺乏的游离氨基酸,如脯氨酸、缬氨酸和组氨酸[33]。丙氨酸、谷氨酸和亮氨酸是产物中质量分数最高的3种游离氨基酸,共占产物FAA质量分数的43.3%。

如图7所示,发酵产物4.75 mm编织筛通过率为88.89%,1.7 mm编织筛通过率为66.96%,1.18 mm编织筛通过率为39.00%。

表4 发酵后物料中17种游离氨基酸质量分数

图7 发酵后物料粒度分布

如图8所示,发酵物料中未检出大肠杆菌。从启动设备总电源开始计算耗电量,至3 d发酵完成时,处理1 kg死猪的全程平均能耗为2.37 kW∙h。

图8 发酵后物料大肠杆菌检测(平板计数法,未检出)

4 结 论

通过实验室工艺参数试验和样机试验,得出如下结论:

1)实验室条件下,对经切碎的病死猪进行辅热快速好氧发酵,发酵温度为60 ℃,通风量为10 L/(L∙min)时,3 d内能将病死猪处理成干颗粒状物料,处理后物料中游离氨基酸FAA质量分数为21.41 g/kg,含水率为5%,pH值为5.5,84.4%能通过4.75 mm编织筛。

2)本文研制的辅热快速好氧发酵装置能直接处理冰冻状态的病死猪,3 d内能将冰冻状态的病死猪处理转化成干颗粒状物料,每批次处理病死猪量为150 kg。设定发酵温度为60 ℃,通风量为10 L/(L∙min)时,处理产物中未检出大肠杆菌,FAA质量分数为20.74 g/kg,含水率为14%左右,pH值为5.4。处理1 kg死猪的能耗为2.37 kW∙h,处理后物料88.89%能通过4.75 mm编织筛,能满足后续有机肥生产的要求。

[1] 习佳林,董红敏,朱志平,等. 死畜禽堆肥化处理研究进展[J]. 中国农业科技导报,2010,12(2):76-80. Xi Jialing, Dong Hongmin, Zhu Zhiping, et al. Research progress on composting treatment of dead livestock[J]. Journal of Agricultural Science and Technology, 2010, 12(2): 76-80. (in Chinese with English abstract)

[2] Wu L, Xu G, Wang X. Identifying critical factors influencing the disposal of dead pigs by farmers in China[J]. Environmental Science and Pollution Research, 2016, 23(1): 661-672.

[3] Wu L, Xu G, Li Q, et al. Investigation of the disposal of dead pigs by pig farmers in mainland China by simulation experiment[J]. Environmental Science and Pollution Research, 2016, 24(2): 1469-1483.

[4] Hu Y, Feng Y, Huang C, et al. Occurrence, source, and human infection potential of cryptosporidium and enterocytozoon bieneusi in drinking source water in Shanghai, China, during a pig carcass disposal incident[J]. Environmental Science & Technology, 2014, 48(24): 14219-14227.

[5] 杜耀,方圆,沈东升,等. 填埋场中硫化氢恶臭污染防治技术研究进展[J]. 农业工程学报,2015,31(增刊1):269-275. Du Yao, Fang Yuan, Shen Dongsheng, et al. Review on pollution control technologies of hydrogen sulfide odor in landfill[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(Supp.1): 269-275. (in Chinese with English abstract)

[6] Gwyther C L, Williams A P, Golyshin P N, et al. The environmental and biosecurity characteristics of livestock carcass disposal methods: A review[J]. Waste Manag, 2011, 31(4): 767-778.

[7] Pollard S J T, Hickman G A W, Irving P, et al. Exposure assessment of carcass disposal options in the event of a notifiable exotic animal disease: Application to avian influenza virus[J]. Environmental Science & Technology, 2008, 42(9): 3145-3154.

[8] Rier S E. Environmental immune disruption: A comorbidity factor for reproduction?[J]. Fertility & Sterility, 2008, 89(2): e103-e108.

[9] 郭东坡,陶秀萍,尚斌,等. 死猪堆肥处理的通风率选择探讨[J]. 农业工程学报,2013,29(5):187-193. Guo Dongpo, Tao Xiuping, Shang Bin, et al. Selection of ventilation rates on dead pig composting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(5): 187-193. (in Chinese with English abstract)

[10] 吴银宝,汪植三,廖新俤,等. 猪粪堆肥臭气产生与调控的研究[J]. 农业工程学报,2001,17(5):82-87. Wu Yinbao, Wang Zhisan, Liao Xindi, et al. Study on the odor production and control of swine manure composting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2001, 17(5): 82-87. (in Chinese with English abstract)

[11] Weiping X, Tim R, Douglas I G, et al. A biosecure composting system for disposal of cattle carcasses and manure following infectious disease outbreak[J]. Journal of Environment Quality, 2009, 38(2): 437-450.

[12] Reuter T, Xu W, Alexander T W, et al. Biocontained carcass composting for control of infectious disease outbreak in livestock[J]. Journal of Visualized Experiments, 2010(39): 1-3.

[13] Williams A P, Edwards-Jones G, Jones D L. In-vessel bioreduction provides an effective storage and pre-treatment method for livestock carcasses prior to final disposal[J]. Bioresour Technol, 2009, 99(17): 4032-4040.

[14] Gwyther C L, Jones D L, Golyshin P N, et al. Bioreduction of sheep carcasses effectively contains and reduces pathogen levels under operational and simulated breakdown conditions[J]. Environmental Science & Technology, 2013, 47(10): 5267-5275.

[15] Jones D L, Healey J R, Willett V B, et al. Dissolved organic nitrogen uptake by plants: An important N uptake pathway?[J]. Soil Biology & Biochemistry, 2005, 37(3): 413-423.

[16] Treseder K K, Czimczik C I, Trumbore S E, et al. Uptake of an amino acid by ectomycorrhizal fungi in a boreal forest[J]. Soil Biology & Biochemistry, 2008, 40(7): 1964-1966.

[17] Kielland K. Amino acid absorption by arctic plants: Implications for plant nutrition and nitrogen cycling[J]. Ecology, 1994, 75(8): 2373-2383.

[18] NäSholm T, Kielland K, Ganeteg U. Uptake of organic nitrogen by plants[J]. New Phytologist, 2009, 182(1): 31-48.

[19] 穆军,呼世斌,王永科. 猪蹄甲制备氨基酸螯合微肥及其对小白菜生长的影响[J]. 农业工程学报,2008,24(7):185-187. Mu Jun, Hu Shibin, Wang Yongke. Preparing fertilizers of amino acid chelate micro element from pig hoof nail and its effect on growth of pakchoi[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(7): 185-187. (in Chinese with English abstract)

[20] 吕娜娜,沈宗专,王东升,等. 施用氨基酸有机肥对黄瓜产量及土壤生物学性状的影响[J]. 南京农业大学学报,2018,41(3):456-464. Lü Nana, Shen Zongzhuan, Wang Dongsheng, et al. Effects of amino acid organic fertilizer on cucumber yield and soil biological characters[J]. Journal of Nanjing Agricultural University, 2018, 41(3): 456-464. (in Chinese with English abstract)

[21] 张树生,杨兴明,黄启为,等. 施用氨基酸肥料对连作条件下黄瓜的生物效应及土壤生物性状的影响[J]. 土壤学报,2007, 44(4):689-694. Zhang Shusheng, Yang Xingming, Huang Qiwei, et al. Effect of application of amino acid fertilizer on biological properties of cucumber plants and soil microorganisms under continuous mono-cropping[J]. Acta Pedologica Sinica, 2007, 44(4): 689-694. (in Chinese with English abstract)

[22] 陈杰. 鱼蛋白降解氨基酸肥对土壤理化性质、酶活性以及微生物群落的影响[D]. 上海:上海师范大学,2015. Chen Jie. The Effects of Amino Acids Hydrolyzed from Fish Wastes on Soil Physicochemical Properties, Enzyme Activities and Microbial Community[J]. Shanghai: Shanghai Normal University, 2015. (in Chinese with English abstract)

[23] McKinley V L, Vestal J R. Physical and chemical correlates of microbial activity and biomass in composting municipal sewage sludge[J]. Applied & Environmental Microbiology, 1985, 50(6): 1395-403.

[24] Beffa T, Blanc M, Marilley L, et al. Taxonomic and metabolic microbial diversity during composting[M]. The Science of Composting. Netherlands: Springer, 1996.

[25] Brigante M, Zanini G, Avena M. On the dissolution kinetics of humic acid particles: Effects of pH, temperature and Ca2+concentration[J]. Colloids and Surfaces A (Physicochemical and Engineering Aspects), 2007, 294(1/2/3): 64-70.

[26] 杜少甫,韦光辉,柳东阳,等. 不同温度对病死猪生物降解效果的影响[J]. 安徽农业科学,2015,43(35):170-171,173. Du Shaofu, Wei Guanghui, Liu Dongyang, et al. The biodegradation effects of dead pigs at different temperatures[J]. Journal of Anhui Agricultural Sciences, 2015, 43(35): 170-171, 173. (in Chinese with English abstract)

[27] 曹云,黄红英,吴华山,等. 畜禽粪便超高温堆肥产物理化性质及其对小白菜生长的影响[J]. 农业工程学报,2018,34(12):251-257. Cao Yun, Huang Hongying, Wu Huashan, et al. Physico-chemical properties of hyperthermophilic composting from livestock manures and its effects of Chinese cabbage[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(12): 251-257. (in Chinese with English abstract)

[28] 徐滔明,罗志威,易子霆,等. 复合微生物菌剂在猪粪有机肥堆肥中的应用[J]. 湖南农业科学,2016(2):41-43. Xu Taoming, Luo Zhiwei, Yi Ziting, et al. Application of composite microbial agent in pig manure organic fertilizerE[J]. Hunan Agricultural Sciences, 2016(2): 41-43. (in Chinese with English abstract)

[29] 赵旭,王改兰,陈春玉,等. 谷糠和堆肥作为微生物菌剂载体的研究[J]. 安徽农业科学,2015,43(14):179-180,223. Zhao Xu, Wang Gailan, Chen Chunyu, et al. Study of bran and compost as a carrier for microbial Inoculants [J]. Journal of Anhui Agricultural Sciences, 2015, 43(14): 179-180, 223. (in Chinese with English abstract)

[30] 焦洪超,张洪芳,栾炳志,等. 不同通风量对猪粪好氧堆肥效果的影响[J]. 农业工程学报,2008,24(12):173-177.Jiao Hongchao, Zhang Hongfang, Luan Bingzhi, et al. Effects of ventilation on aerobic composting of swine feces[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(12): 173-177. (in Chinese with English abstract)

[31] 胡天觉,曾光明,黄国和,等. 仓式好氧堆肥中影响有机物发酵降解的主要因素[J]. 湖南大学学报:自然科学版,2004(5):31-35. Hu Tianjue, Zeng Guangming, Huang Guohe, et al. Factors Influencing the organic solid waste biodegradation in aerobic vessel compost system[J]. Journal of Hunan University: Natural Science, 2004(5): 31-35. (in Chinese with English abstract)

[32] 宋奇超,曹凤秋,巩元勇,等. 高等植物氨基酸吸收与转运及生物学功能的研究进展[J]. 植物营养与肥料学报,2012,18(6):1507-1517. Song Qichao, Cao Fengqiu, Gong Yuanyong, et al. Current research progresses of amino acids uptake, transport and their biological roles in higher plants[J]. Plant Nutrition and Fertilizer Science, 2012, 18(6): 1507-1517. (in Chinese with English abstract)

[33] Yu Z, Zhang Q, Kraus T E C, et al. Contribution of amino compounds to dissolved organic nitrogen in forest soils[J]. Biogeochemistry, 2002, 61(2): 173-198.

Process parameter optimization and equipment development of thermophilic aerobic fermentation of dead pigs

Tan Hequn, Nie Jie, Wan Peng, Fu Hao, Li Xinan

(1.430070,; 2.430070,)

Carcass of dead pigs can be converted into dry granular materials rapidly by aerobic fermentation at 50 to 70 ℃ after adding fermentation strains into the mixture of pig carcass and auxiliary materials such as wheat bran. In order to optimize the fermentation process parameters and improve the quality of fermentation, a laboratory rapid aerobic fermentation system together with heating device was adoptedin this study to process the stillbirth pigs. In the experiments, ventilation rate and fermentation temperature were selected as experimental factors and the mass fraction of total free amino acid (FAA), moisture content, particle size distribution and pH value of the products were selected as experimental indexes. The fermentation temperature was set at 50, 60 and 70 ℃ and the ventilation rate was set at 8, 9 and 10 L/(L∙min). One pig stillbirth (1.5-2.2 kg) was selected in each experiment. The frozen pig carcass were divided into blocks of about 5 cm with a chainsaw, and then ground in a meat mincer. The carcass pieces were weighed and mixed with appropriate amount of bran to achieve a weight ratio of the bran to the carcass of 1:1.5 (dry-based ratio under bran moisture content of 9% and carcass moisture content of 75%, equivalent to a wet base ratio of about 1:5.5). After mixing, fermentation strains were added to attain strain weight: pig weight of 1:25 (dry-based ratio, or 1:100 for wet-based ratio assuming the strain moisture content of 10% and carcass moisture content 75%). The moisture content of mixed materials was about 65%, the pH value was about 6.55, and the mass fraction of FAA was 6.0 g/kg. In the controlled experiments with different fermentation temperatures, the ventilation rate was 8 L/(L·min). In order to keep the moisture content of fermentation materials within the appropriate range to maintain microbial activities during the fermentation process, the moisture content was adjusted to 65% by adding water after every 24 hours of fermentation. The results showed that the moisture content of fermented materials decreased by 8-11, 24-27 and 40-50 percentage at 50, 60 and 70 ℃, respectively. The mass fractions of FAA in fermented materials after 3 days of fermentation were 18.51, 16.62 and 9.42 g/kg, and the passing rates of 4.75 mm braided sieve were 57.40%, 83.95% and 83.44% respectively. In the control experiments with different ventilation rates, the fermentation temperatures were 60 ℃. The results showed that when the ventilation rate was 8, 9 and 10 L/(L·min), the moisture contents of the fermentation materials after fermentation for 3 days were 11%, 8.5% and 5%, the mass fraction of FAA was 13.18, 16.62, and 21.41 g/kg, respectively. The 4.75 mm woven sieve passing rate was more than 70%, which could reach 84.4% when the ventilation rate was 10 L/(L·min). Comprehensive analysis showed that the treatment effect was best when the fermentation temperature was 60 ℃ and the ventilation rate was 10 L/(L·min). Based on the above results of processing technology, a thermophilic aerobic fermentation equipment with a processing capacity of 150 kg per batch for dead pigs was designed and developed. This equipment was tested under a ventilation rate of 10 L/(L·min) and the fermentation temperature of 60 ℃. After 3 days of fermentation, the FAA mass fraction in the products was 20.74 g/kg with the moisture content of about 14% and the pH value of 5.4. Moreover, 88.89% of the products could pass the braided sieve of 4.75 mm diameter andwere not detected in the products. The energy consumption of the equipment was 2.37 kW∙h per kg of dead pigs. The experimental results showed that the equipment could transform the dead pigs in the frozen state into dry particle materials in 3 days, and the treated products could meet the requirements of subsequent organic fertilizer production.

fermentation; equipment; ventilation; dead pig; thermophilic aerobic fermentation; free amino acid; harmless treatment

2019-02-26

2019-03-31

中央高校自主基本科研业务费专项资金(2662015PY151,2662017JC042)

谭鹤群,副教授,博士,主要从事农产品加工机械与畜牧机械研究。Email:thq@mail.hzau.edu.cn

10.11975/j.issn.1002-6819.2019.08.031

S216

A

1002-6819(2019)-08-0262-07

谭鹤群,聂 杰,万 鹏,付 豪,李鑫安. 病死猪辅热快速好氧发酵工艺参数优化与装备研制[J]. 农业工程学报,2019,35(8):262-268. doi:10.11975/j.issn.1002-6819.2019.08.031 http://www.tcsae.org

Tan Hequn, Nie Jie, Wan Peng, Fu Hao, Li Xinan. Process parameter optimization and equipment development of thermophilic aerobic fermentation of dead pigs[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(8): 262-268. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.08.031 http://www.tcsae.org