Influence of Mercerization on Cotton Fiber Varieties from Different Regions

WANG Hua( ), MUGAANIRE Tendo Innocent

1State Key Laboratory of Textile Science&Technology,Ministry of Education,Donghua University,China2State Key Laboratory of Textile Science&Technology,College of Textiles,Department of Textile Engineering and Technology,Donghua University,Shanghai201620,China

Abstract:The influence of mercerization on cotton varieties from Africa,Xinjiang and Australia was studied.The micro-morphology,mechanical property and crystalline structure were analyzed before and after mercerization.Mercerization made the surface of fibers smoother which resulted in improved luster of fiberes with better results observed in Australia,Xinjiang and Africa cotton varieties respectively.Although fiber strenth increased due to orientation of intra fiber cellulose chains,there was a general in the crystallinity index amongst the three varieties of cotton after mercerization.Reduced crystallinity is a function of improved processability and thus Australian cotton is more processable than cotton from Africa and Xinjiang.

Key words:reversals;mercerization;crystallinity;micro-morphology

Introduction

Mercerization is a major chemical treatment process applied to cotton fibers in various subsequent to other processes. It consists of impregnating the material with a concentrated solution of sodium hydroxide. Multiple objectives of mercerization such as adding luster to fibres, improving dyeing characteristics, and increasing strength have been demonstrated in several works[1]. Morphologically, the surface of a single cotton fibre is composed of continuous reversals. The length of the reversal zones is around several micrometers and the frequency of reversal along the fiber ranges from 2 to 27 cm-1, depending on different varieties[2].

Studies have noted that the reversals act as weak points, leading to increased fiber breakage at such points. However the strength observed between reversals can reach as 25% which is higher than that at a reversal[3]. On the contrary, some works have reported that the reversal is the strongest point along the fiber[4]. From scanning electron microscope (SEM )images taken on the broken fiber ends, Dweltz and Sparrow found out that the fibers broke adjacent to a reversal zone and not at a reversal point[5].

The properties of cotton fibers, such as strength and appearance are closely related to their structures[6]. It has been discovered with electron and X-ray diffraction (XRD) that cotton fiber is basically a polymorphic crystalline cellulose. The crystalline morphology can be divided into four types: cellulose I[7], II[8], III[9]and IV[10]. Natural cotton is termed as cellulose I. After industrial mercerization, cotton changes to cellulose II, while the treatment of cotton with liquid ammonia or primary alkyl amines results in cellulose III. The existence of amorphous domain in cotton fibers has been proven by diffuse scattering among XRD, which has been related to the randomness associated within the Fringe-Micelle model or as imperfect chain alignment in islands[11]. The tensile strength of cotton fibers is greatly influenced by the degree of orientation between chain molecules and the fibre axis. In general, the more highly molecules are oriented, the fibers are of higher strength[12].

Besides the United States of America being the largest supplier of cotton to China, 50% of total cotton into China is imported from the Cotton-4 (C-4) countries (Benin, Burkina Faso, Chad, and Mali), and 60% of exports to India and Uzbekistan. According to the Chinese cotton classing system imported cotton and cotton planted in China are all classified as 7 different grades. It is mainly based on the length of fibers without accounting for other properties of cotton. Although it belongs to the same grade, cotton produced in different areas exhibit remarkable differences. The objective of this study is to investigate property distinctions of cotton fibers from China, Africa and Australia. They all belong to the grade 3 (high-medium) in quality according to the Chinese cotton classing system and are widely applied in production of yarn counts 13 tex and coarser. In this paper, the micro-morphologies, crystalline structures, and mechanical properties of these three cotton varieties before and after mercerization were studied in details. The information from this study will provide guidance to the industry in material selection and yarn product properties prediction.

1 Experimental

1.1 Materials

Three samples harvested from Xinjiang, China (labelled as Xinjiang-CN), Africa (labelled as KATI-AF) and Australia (labelled as BG-AU) which were classified as the grade 3 (high-medium length) according to the Chinese cotton classing system, were used as obtained.

1.2 Pre-treatment

Since there were impurities on the surface of raw cotton fibers, such as seed-coat fragments, aborted seeds and leaves, the samples were rinsed before mercerization. For each sample, 6 g of cotton fibers was immersed in 300 mL NaOH solution (1.5 g/L) and boiled for 1.5 h. And 5 ml of Na2SO3solution (1.5 g/L), Na2SiO3solution (1.5 g/L) and Na3PO4solution (1 g/L), were dropped into the system during stirring.

After that, the fibers were taken out and rinsed with tap water for 5 times at 80 ℃, and then rinsed with large amount of deionized water. Then the samples were dried in oven at 100 ℃ for 1.5 h.

1.3 Mercerization

After pre-treatment, the samples were immersed in 300 mL NaOH solution (180 g/L) at 20 ℃ for 10 min, and then rinsed with water. In the end, the samples were rinsed with deionized water and dried in oven at 100 ℃ for 1.5 h.

1.4 Characterization

1.4.1Singlefibermechanicalproperties

The single fiber strength and breaking elongation were tested with XQ-2 fiber strength meter at(20±2)℃ and relative humidity of (65±3)%. The machine head speed was set to 5 cm/min. The data are the average results from 50 specimens.

1.4.2SEM

The micro-morphology of cotton fibers was characterized with a scanning electron microscopy (JSM-5600LV,JEOL, USA.

1.4.3XRDmethod

XRD measurements were performed on a D/Max-2550PC system from Rigaku atvoltage of 40 kV and current of 44 mA with copper radiation of 0.154 nm. The samples were all grounded into powder for crystalline testing. As for the fiber orientation study, the fibers were aligned and fixed on the sample holder for testing.

2 Results and Discussion

2.1 Fiber morphology

Figure 1 shows the SEM images of the Xinjiang samples, before (Figs. 1(a) and 1(b)) and after NaOH mercerization (Figs. 1(c) and 1(d)). It can be seen from the images that before NaOH treatment, the cotton fibers had twisted-band shape, with the average width of 16 μm and the length of the reversal zones is around 95 μm. From Fig. 1(b), which is of higher magnification, it can be observed that in the middle of the reversal there are some tiny wrinkles, while the edge of fiber bands is quite smooth. After NaOH treatment, the reversals disappeared, and the shape changed to almost-round column with the widest diameter around 14 μm. In Fig. 1(d), it can be seen that the surfaces of fibers turned smoother with some wrinkles remaining.

(a)

(b)

(c)

(d)

Fig. 1 SEM micrographs of cotton fibers sample from Xinjiang-CN before ((a) and (b)) and after ((c) and (d)) treatment with NaOH

Figures 2-3 show the micro-morphologies under SEM of sample KATI-AF, and BG-AU before and after NaOH treatment, respectively. Comparing to Xinjiang-CN fibers, the KATI-AF fibers before treatment are wider of around 19 μm in width, with relatively shorter reversal zone of around 81 μm (Fig. 2(a)). After treatment the fiber turned into column shape with smaller diameter of around 13 μm. The fibers have a loose reversal structure, and the remained wrinkle after treatment can be clearly observed on the whole surface of fiber.

(a)

(b)

(c)

(d)

Fig. 2 SEM micrographs of sample KATI-AF before ((a) and (b)) and after ((c) and (d)) treatment with NaOH

The BG-AU fiber exhibited the longest reversal zone among the three samples with length of 136 μm. The average width of the band shaped fiber is about 18.3 μm (Fig. 3(a)). In the zoomed image (Fig. 3(b)), besides the wrinkles in the middle of band, after treatment, the diameter of the column shaped fiber is about 11.8 μm, which is the thinnest among all fibers, with almost no reversal can be detected along the fiber. The surface is very smooth with few wrinkles in the middle of fiber (Figs. 3(c) and 3(d)).

(a)

(b)

(c)

(d)

Fig. 3 SEM micrographs of sample BG-AU before (a and b) and after (c and d) treatment with NaOH

From the images of all the three samples, the mercerization greatly improves the micro-morphology of cotton fibers. Through mercerization, the reversed fibers became straight and smooth. This explains the reason that cotton fibers become lustrous after mercerization. Among all the three mercerized samples, the fibers of sample KATI-AF exhibit the worst morphology because some wrinkles still existed on the surface.

2.2 XRD analysis

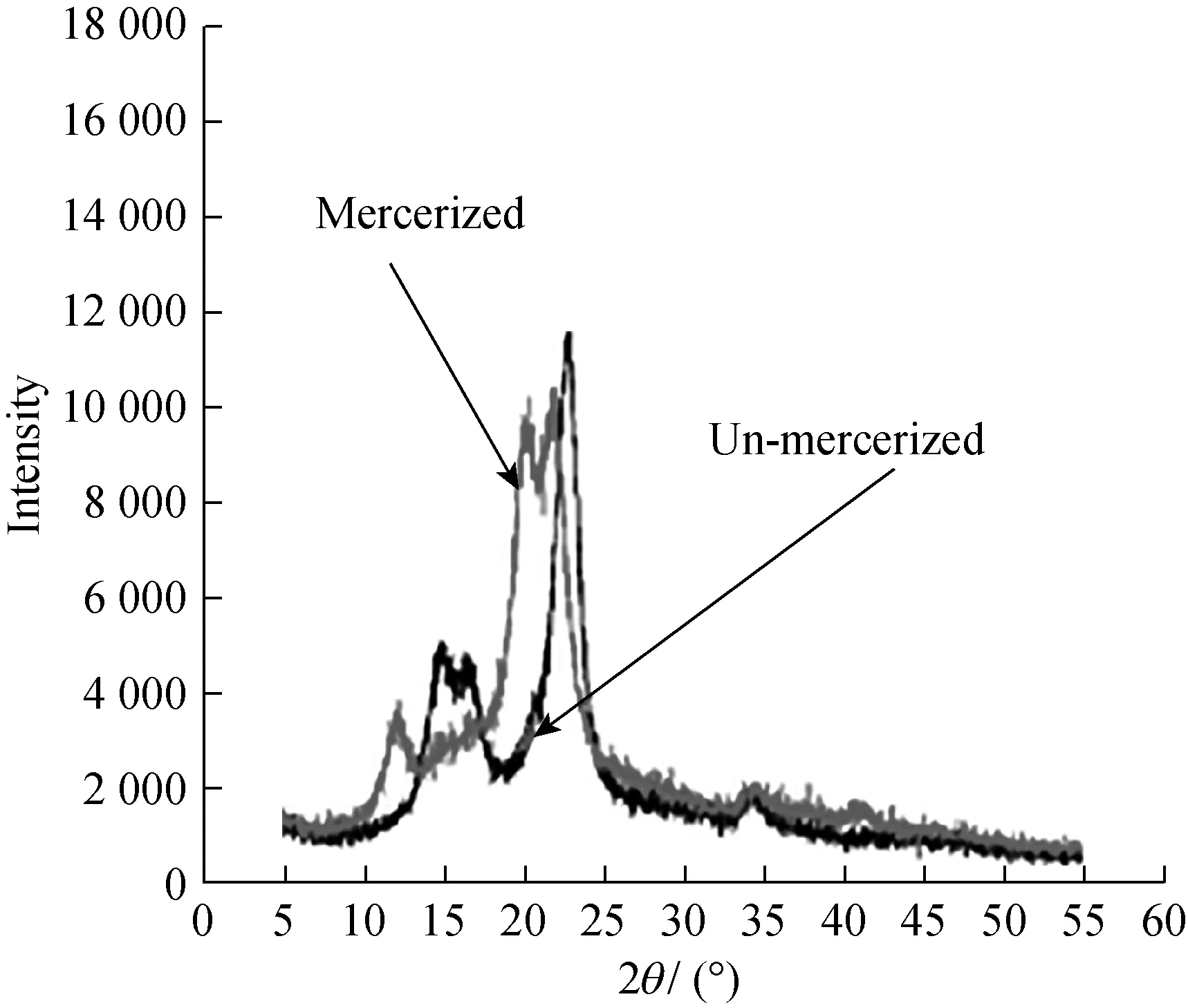

The XRD patterns of the sample fibers are shown in Fig. 4, and the peaks positions and the interplanar spacings of the three varieties samples before and after mercerization are shown in Table 1. In the three XRD plots, the characteristic peaks of cellulose I can be clearly seen in curves of the three samples before mercerization. In the curves of mercerized samples, the new peaks appearance indicates the conversion of cellulose I to cellulose II, while the conversion only happened to part of the samples, with peaks belonging to cellulose I still existed in low intensity.

Table 1 Diffracting angles and interplanar spacing for the three cotton samples under investigation

(a) Xinjiang-CN

(b) KATL-AF

(c) BG-AU

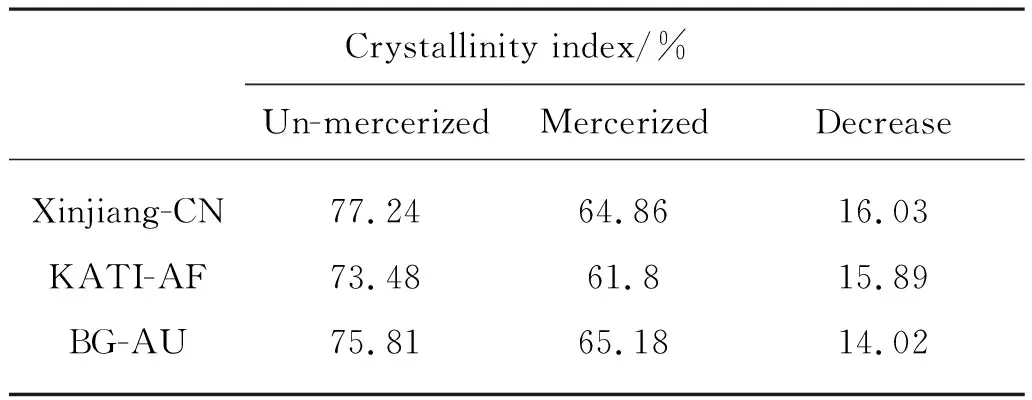

It has been reported that mercerization reduces the crystallinity of cotton by 7%-11%[11], which results into improvement in reagent uptake, and fiber luster[13]. The three samples all exhibited decrease in crystallinity after mercerization, while the decreases are 16.03%, 15.89%, and 14.02% (Table 2), respectively, which are higher than the range that has been reported elsewhere.

Table2Summary of crystallinity index for un-mercerized and mercerized cotton samples

Crystallinity index/%Un-mercerizedMercerizedDecreaseXinjiang-CN77.2464.8616.03KATI-AF73.4861.815.89BG-AU75.8165.1814.02

The degree of crystallite orientation of sample cotton fibers was also studied with XRD, by measuring the percentage of cellulose polymer chains that are parallel to the axis of fiber. The results are shown in Table 3, indicate that mercerization greatly increased the orientation degree of the polymer chains in cotton fibers, due to a decrease in crystallinity[14-15].

Table 3 Crystallite orientation of the three samples

3.3 Mechanical properties

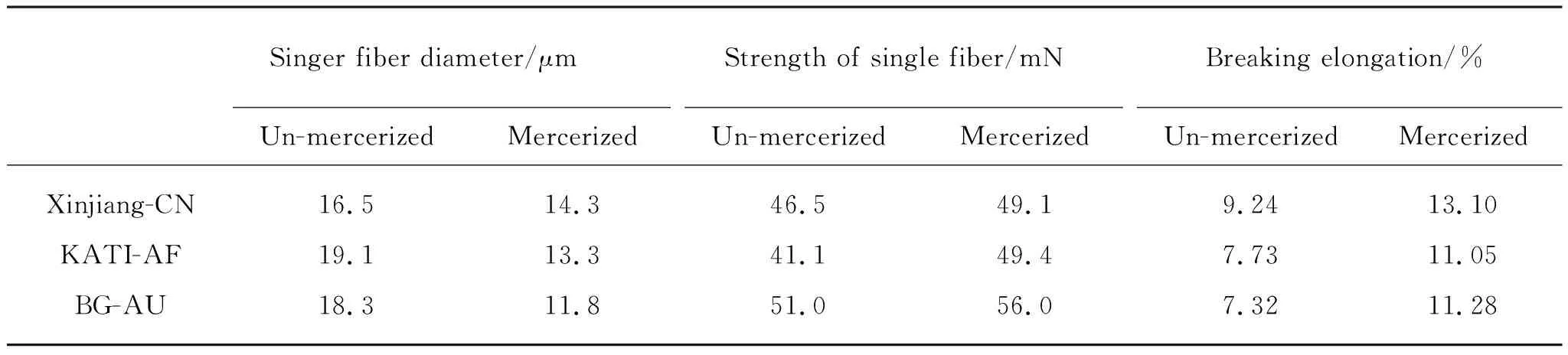

The physical properties of cotton fibers, such as length, fineness, strength and maturity have great influence to the yarns and the final textile products. Here the physical properties of the single fiber of samples, including strength, breaking elongation were investigated before and after mercerization, and the data are shown in Table 4. Also, the average diameters of fibers, measured in SEM images were listed in Table 4.

Table4Diameter, strength and breaking elongation data of single fiber of the three samples, before and after mercerization

Singer fiber diameter/μmStrength of single fiber/mNBreaking elongation/%Un-mercerizedMercerizedUn-mercerizedMercerizedUn-mercerizedMercerizedXinjiang-CN16.514.346.549.19.2413.10KATI-AF19.113.341.149.47.7311.05BG-AU18.311.851.056.07.3211.28

The strength of sample fibers was determined by breaking a single fiber held between two jaws with the distance of 10 mm. It is a property of great importance in industry, since it contributes to yarn tenacity and textiles durability[16-17]. The breaking elongation data was obtained by directly measuring the elongation at the breaking point, which should be considered when yarn manufacturers assemble bale laydowns for yarn quality control[18]. Table 4 shows that as for fiber strength, sample BG-AU exhibits the highest value, both before and after mercerization. This indicates that the textile produced from BG-AU is of relative high strength and durability in daily use. While in the breaking elongation test, Sample Xinjiang-Cn exhibit the highest value, the values of the other two samples are very close, which means that the textile from Xinjiang-Cn may be of higher resistance to deformation.

After mercerization, all sample fibers exhibited enhanced mechanical properties. This can be attributed to the increased cellulose chain orientation accompanied by the decrease of crystallinity[19]; or the disappearance of reversals along cotton fibers since reversals are week points when fibers were broken[20].

4 Conclusions

In this paper, three main kinds of cotton were selected and compared. Focus was mainly taken on the micro-morphology, the crystallite structure of cellulose chains, and the mechanical properties of cotton fibres. These fiber properties changed after mercerization with NaOH solution. SEM micrographs indicated that mercerization inflated fibers with the reversals mostly uncoiled while the degree of change varied among cottons from different region. This explained the reason that NaOH treatment improved the luster of cotton fibers. The study with XRD proved that mercerization changed the crystalline structure of cellulose chains inside cotton fibers. Mercerization also changed the physical properties of fibers with strength and breaking elongation both enhanced, which improved the processability of cotton in mills. It is suggested that increased crystalline orientation and removal of reversals all contribute to the improvement in physical properties of fibers. in this regard, Australian cotton had better properties compared to Xinjiang and African varieties.

Journal of Donghua University(English Edition)2018年5期

Journal of Donghua University(English Edition)2018年5期

- Journal of Donghua University(English Edition)的其它文章

- Characterization of Oxygen Plasma Modified Polyimide Fibers Interfacial Adhesion Performance by Single Fiber Fragmentation Test

- Reliability Modeling of Phased Mission System with Phase Backup by Stochastic Petri Net

- Software Defect Prediction Method Based on Rule Knowledge Extraction Model

- Research on Software Structure Analysis Technology and Reliability Evaluation Method of Warship Equipment

- Measuring Quality of Economic Growth Incorporating Environment and Social Welfare:a Total Productivity Approach with an Application on China

- Improved Weight Function for Nonlocal Means Image Denoising