An innovative design of septic tank for wastewater treatment and its performance evaluation:An applicable model for developing countries

Sajjad Haydar ,Mehwish Anis ,Gul E Hina ,*,Javed Anwar Aziz ,Mudasar Arbi

1 Institute of Environmental Engineering&Research(IEER),University of Engineering&Technology(UET),Lahore,Pakistan

2 University of Lahore,Lahore,Pakistan

1.Introduction

Currently,wastewater generated,in almost all the urban areas of Pakistan,is discharged withoutany treatment,in the nearby water bodies.It has serious implications for the water quality and intended uses of these water bodies[1].For example,in Lahore,Water and Sanitation Agency(WASA)is responsible for wastewater collection and disposal.Eight disposal stations of WASA,discharge around 4,846,666 m3·d-1(1981 cusecs)of wastewater in river Ravi on daily basis,without any treatment[2].Due to prevailing low flows in river Ravi,other than monsoon season,suf ficient dilution for the discharged wastewater is not available.This situation turns river Ravi into an open sewer.Dissolved oxygen(DO)levels are almost zero.Aquatic life is non-existent,during low flows.River water also recharges the underground water table of Lahore[3].Although,at large,it does not affect the vast groundwater aquifer below Lahore;however,shallow groundwater sources near Ravi are seriously contaminated affecting public health[3].

Establishmentofwastewatertreatmentplants involves heavy financial investment.During the last 40 years,different feasibility studies have been conducted for wastewater treatment in Lahore.However,their implementation is still awaited.In the wake of increasing deterioration in the quality of river Ravi and contamination of shallow groundwater aquifer,there is a need to explore alternate solutions.One strategy may be to provide compulsory treatment,through septic tanks,at household level.This has been incorporated into by-laws of both housing authorities in Lahore(Lahore Development Authority;Defense Housing Authority)[4].Yetits implementation is notrigorously enforced.

Another,very important issue is the non-availability of any standard design with the housing authorities or of any local design criteria for ST[5].ConventionalST is either single ordualcompartment.Two compartment ST is reported to provide better results[6].There is very less contact between the wastewater and sludge in the conventional ST.The in fluent wastewater flows,in most cases,from the upper part to outlet without any contact with sludge accumulated at the bottom of the ST.The reported BOD removal efficiency of conventional STs is nearly 55%[7].

The average BODofLahore wastewater is reported to be 245 mg·L-1[8].Taking this BOD and total estimated flow,given above,around 991-ton BOD is discharged into river Ravi,on daily basis.A significant reduction in this load may be achieved.It is possible through rigorous enforcement of by-laws on the mandatory use of ST in each house.An in-house reduction of BOD(of around 55%)would significantly reduce the load on any city level wastewater treatment plant.It may result in substantial cost savings.

Being the firststep in wastewatertreatment,ST may be turned into a more usefuldevice ifits treatmentefficiency could be further enhanced.In recent years,Anaerobic Baffled Reactor(ABR)were investigated.It uses a series of vertical baffles to force the wastewater to flow under and over them as it travels from inlet to outlet[9–19].The solids in the wastewater settle down in each compartment,forming a solid layer within which anaerobic micro-organisms develop.The solid layer gradually develops into sludge beds in the bottom of each compartment.The incoming wastewater passes through this sludge bed as it flows under the vertical baffles.The basic principle of these systems is to increase the contact between the entering wastewater and the active biomass in the accumulated sludge.The treatment efficiency of ABR is greater than 80%[20–22].The concept of baffles,used in ABR,was applied in ST.An increase in the BOD removalefficiencies of ST was observed[23,24].

This study was undertaken with the objective to further enhance the efficiency of ST.It was decided to make arrangements to increase the up flow velocity of wastewater when it passes under the baffle.This was accomplished through installation of perforated plate at the middepth of up flow chambers.The increased velocity allows fluidization(partial expansion)of the granular sludge bed present at the bottom of ST,thus improving the contact between incoming wastewater and settled sludge.The objective was to evaluate any improvement in the efficiency of ST using above stated arrangement.

2.Materials and Methods

2.1.Domestic wastewater sampling and characterization

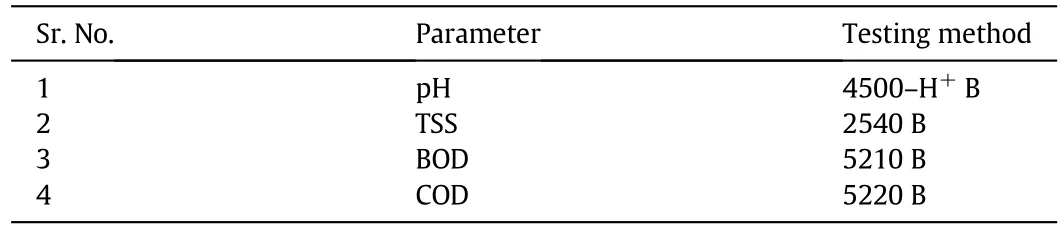

Samples of domestic wastewater were collected from sewage pumping station located in the University of Engineering and Technology(UET),Lahore.To characterize the wastewater pH,total suspended solids(TSS), five-day biochemicaloxygen demand(BOD5)and chemical oxygen demand(COD)were determined.Samples were collected daily.Thus,36 samples were collected and characterized during the course ofstudy.Testprocedures adopted foreach testare shown in Table 1[25]

Table 1 Test procedures

2.2.Experimental setup

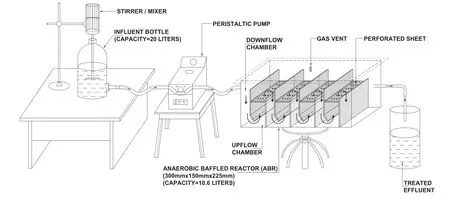

A bench scale model of ST was fabricated with super plastic acrylic sheet.It has a total volume of 10.6 L with effective volume of 8.85 L.The total length,width and depth of the ST were 300 mm,150 mm and 225 mm,respectively.The ST consisted of inlet pipe,outlet pipe,single gasvent,hanging baffles and standing baffles.Due to the standing and hanging baffles,up flow and down flow chambers were made(Fig.1).Experimental run of this model is referred as Run-1.

After Run-1,perforated plates were installed between the baffles at the mid depth(Fig.2).The purpose was to increase the up flow velocity.The experimental run of this model is referred as Run-2.

For both ST models(Figs.1 and 2),wastewater was fed through influent glass bottle with 20-liter capacity.A peristaltic pump WM-28232 was used to regulate the flow into the models.Electrical stirrer/mixer was used in the in fluent bottle in order to avoid settling in the in fluent bottle.RS Electrical Heater was used to maintain the temperature in the ST.Both models were run at a reactor temperature of 15 °C and 25 °C.For quick start up,seeding was done with sludge from an actual septic tank.

2.3.Operational plan and parameters

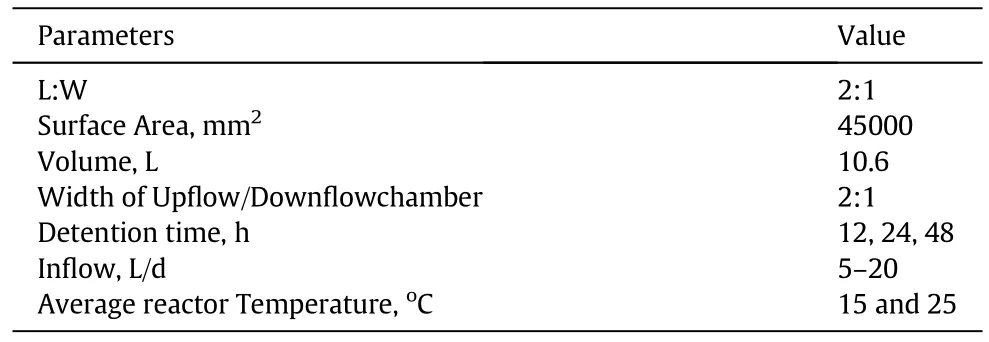

Table 2 shows the operational parameter of Run-1 and 2.Initially,the reactor was seeded with sludge.Reactor was run for 15 days as a startup time.

After startup time,Run-1 was started and continued for 48 days.During this period,treatment efficiencies were checked at 48 h,24 h and 12 h detention times.Detention time was varied by varying flow rates through peristaltic pump.Run-2 was conducted for 30 days,for the above mentioned detention times.Performance of Run-1 and 2 was measured at two reactor temperatures viz.15 °C and 25 °C.The temperature was maintained by automatic RS Electrical heater having adjustable temperature range between 15 °C–32 °C.Performance was evaluated using TSS,BOD and COD removals.pH and temperature were monitored on daily basis during the whole experimental run[26].

3.Results and Discussion

3.1.Characterization

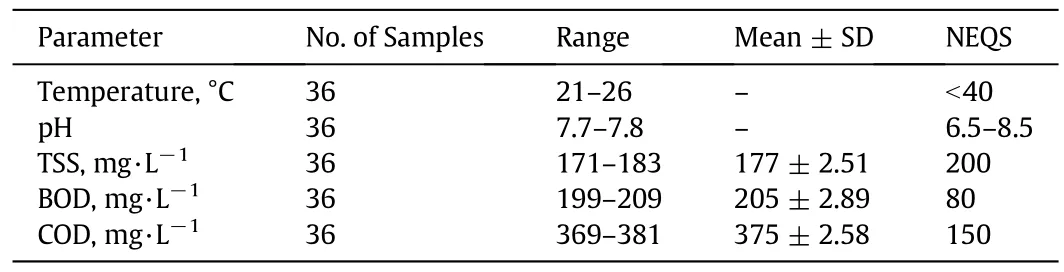

The characteristics of raw domestic wastewater collected from UET sewage pumping station are given in Table 3.It shows the parameters tested,range in which each parameter varied and mean values with standard deviation(SD).Comparison with NEQS is also made in the Table 3 It can be seen that temperature of raw wastewater varied from 21 to 26°C during November 2013 to February 2014 pH remained on slightly basic side.TSS varied from 171 to 183 mg·L-1with a mean value of 177 mg·L-1.BOD varied from 199 to 209 mg·L-1with a mean value of 205 mg·L-1.COD varied from 369 to 381 mg·L-1with a mean value of 375 mg·L-1.

3.2.Performance data of Run-1

The performance data of Run-1 is presented in Table 4,which shows BOD,COD and TSS concentrations for in fluent and effluent.Reactor pH and temperature are also shown.The last columns show the percentage removal efficiencies for BOD,COD and TSS.

For 48 h of detention time(at 15°C),the results show that mean effluent TSS concentration meets the NEQS,while BOD and COD were greater than NEQS.Mean TSS,BOD and COD removal was 54%,44%and 56%,respectively.However,at 25°C,the efficiency improved.Mean effluent concentration for TSS,BOD and COD was 71,77 and 104 mg·L-1,respectively,which are below the NEQS.Mean percentage removals for TSS,BOD and COD were 59%,62%and 72%,respectively.

For 24 h of detention time(at 15°C),TSS met the NEQS while BOD and COD were higher.Percentage removals for TSS,BOD and COD were 50%,42%and 53%,respectively.The efficiency improved at 25°C,with effluent concentration of TSS,BOD and COD having values of 80,84 and 117 mg·L-1,respectively.Thus,TSS and COD met NEQS while BOD was slightly higher.The percentage removals for TSS,BOD and COD were 54%,58%and 69%,respectively.

For 12 h of detention time(at 15°C.),TSS met the NEQS while BOD and COD were higher.Percentage removals for TSS,BOD and COD were 40%,32%and 48%,respectively.The efficiency improved at 25°C,with effluent concentration of TSS,BOD and COD having values of 94,109 and 155 mg·L-1,respectively.Thus,TSS met NEQS while BOD and COD were higher.The percentage removals for TSS,BOD and COD were 47%,47%and 59%,respectively.

Fig.1.Bench scale setup for Run-1.

Fig.2.Bench scale setup for Run-2.

Table 2 Operational parameters of the reactors

Table 3 Composition of raw domestic wastewater collected from UET sewage pumping station

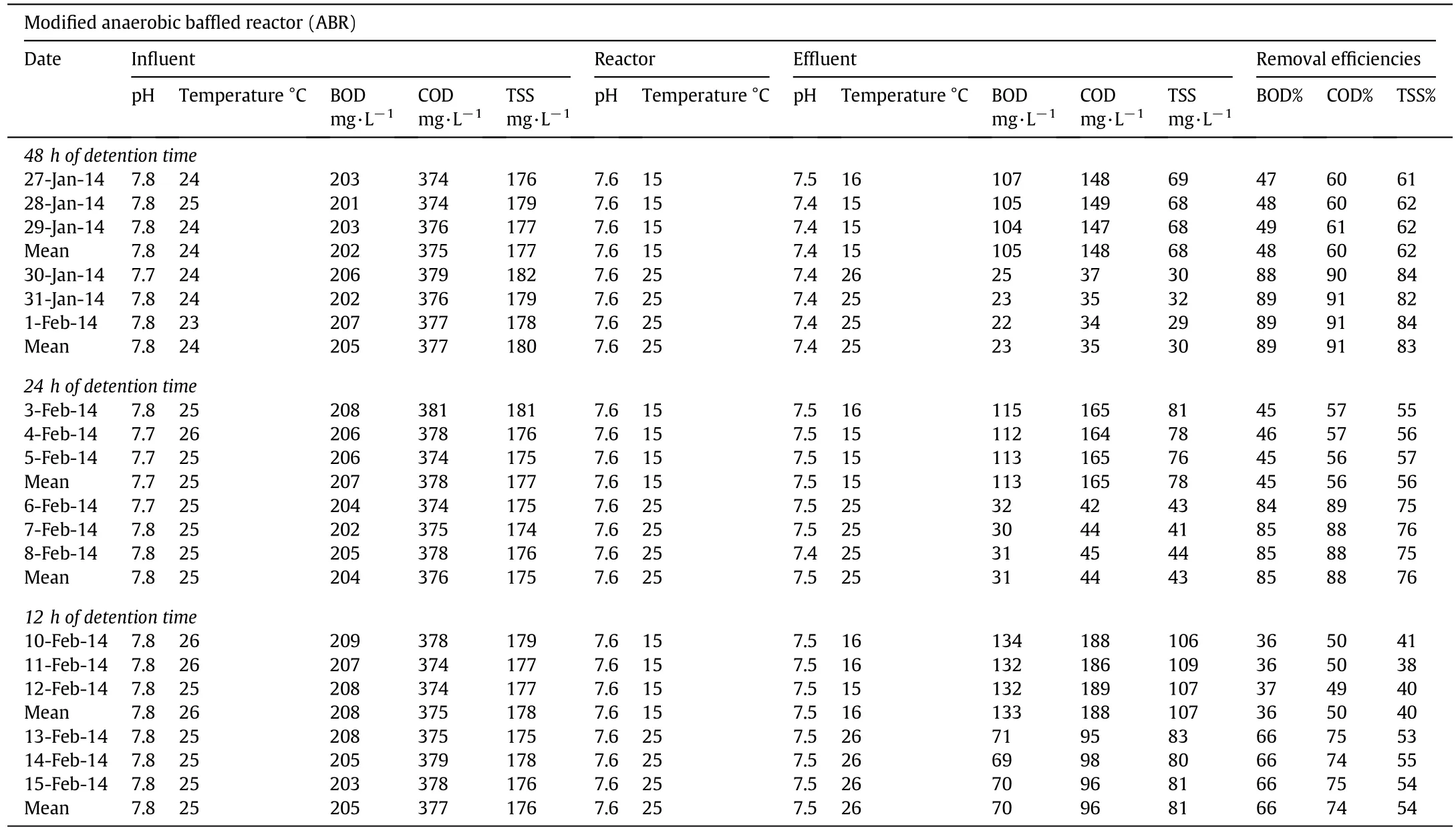

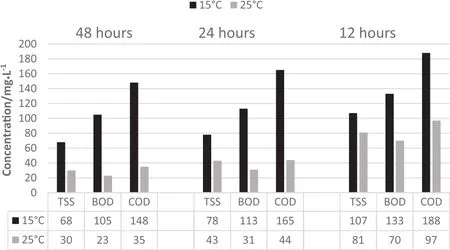

For 48 h of detention time(at 15°C),the results show that mean effluent TSS concentration meets the NEQS,while BOD and COD were higher than NEQS.Mean TSS,BOD and COD removal was 61%,48%and 60%,respectively.However,at 25°C,the efficiency improved.Mean effluent concentration for TSS,BOD and COD was 30,23 and 35 mg·L-1,respectively,which are below the NEQS.Mean percentage removals for TSS,BOD and COD were 83%,89%and 91%,respectively.

For 24 h of detention time(at 15°C.),TSS concentration met the NEQS while BOD and COD were higher.Percentage removals for TSS,BOD and COD were 56%,45%and 56%,respectively.The efficiency improved at25°C,with effluentconcentration ofTSS,BODand CODhaving values of 43,31 and 44 mg·L-1,respectively.All these values meet NEQS.The percentage removals for TSS,BOD and COD were 76%,85%and 88%,respectively.

For 12 h of detention time(at 15°C.),TSS concentration met the NEQS while BOD and COD w higher.Percentage removals for TSS,BOD and COD were 40%,36%and 50%,respectively.The efficiency improved at25°C,with effluent concentration of TSS,BOD and COD having values of81,70 and 96 mg·L-1,respectively,allmeeting NEQS.The percentage removals for TSS,BOD and COD were 54%,66%and 74%,respectively.

3.3.Performance data of Run-2

The performance data of modi fied Run-2 are presented in Table 5,which shows the BOD,COD and TSS concentrations for in fluent and effluent.Reactor pH and temperature are also shown.The last columns show the percentage removal efficiencies for BOD,COD and TSS.

3.4.Summary and discussion on results

From an analysis of performance data for Run-1(Table 4)and Run-2(Table 5),it is evident that latter gives better efficiency.In addition,efficiency is better,in both cases,at a reactor temperature of 25°C and

the treated effluentmeets the NEQS ata detention time of48 h.However,footprint is larger in case of the 48-hour detention time,and hence,more cost is involved.

Table 4 Performance data of Run-1

Table 5 Performance data of Run-2

At 24 h of detention time and 25°C,the effluent from Run-1 could not meet NEQS for BOD while Run-2 met NEQS.Footprint at this detention time is half as compared to 48 h and,hence,more cost effective while still meeting NEQS.Detention time of 12 h is not feasible in case of Run-1,however,in case of Run-2 NEQS are met.This shows that even a detention time of 12 h(at 25°C)is suf ficient in case of Run-2.This can further reduce the footprint and the associated cost of construction.

The summary of results,for Run-2,is presented in Fig.3.Here,all other data,previously given in Table 5 are filtered out.Focus in only on effluent concentration at different detention times(48,24 and 12 h)and different temperatures(15 and 25°C).It is evident that Run-2 could be a feasible solution for reactor temperature of 25°C but not for 15°C,as the effluent values for BOD and COD are higher than NEQS at this temperature.

Fig.3.Summary of effluent concentrations for Run-2.

4.Cost and Performance Comparison

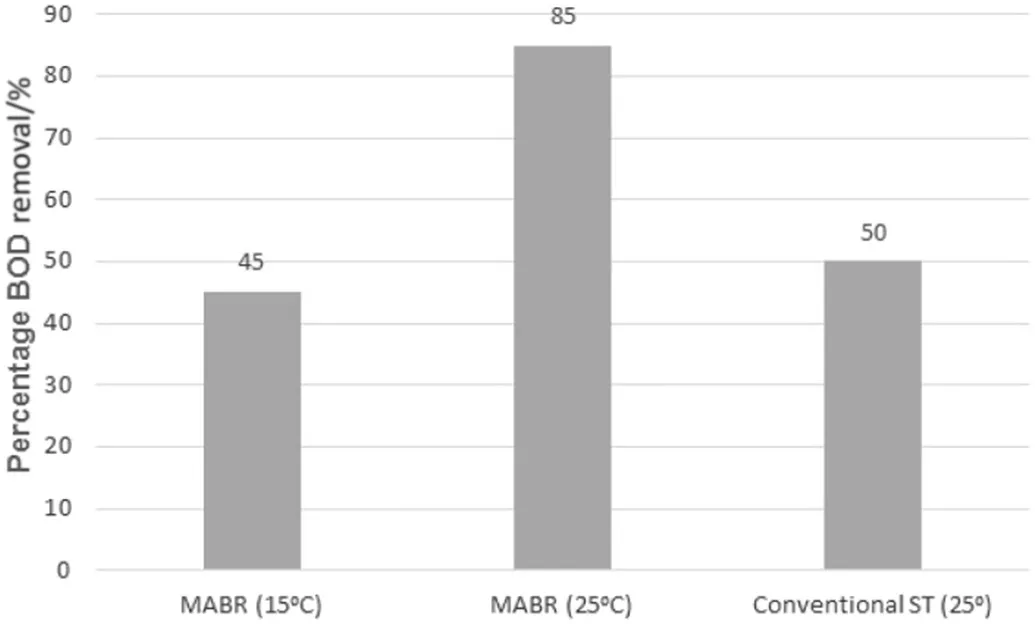

Cost and performance comparison of Run-2 proposed(MABR)through this study has been carried out with conventional two compartment ST(CABR)in this section.

The treatment efficiency of Run-2 with conventional ST[27]is shown in Fig.4.It can be clearly seen that even at a temperature of 15°C the performance of Run-2 is close to conventional ST working at 25°C.Whereas at 25°C,the Run-2 outperform the conventional ST with much higher BOD removal rates.The detention time is 24 h for all the STs.

Fig.4.Performance comparison of conventional ST with Run-2.

5.Conclusions

The following conclusions may be drawn from the study:

(1)Initialstartup ofthe reactorsystemis very important.Normalinitial startup period of Run-1 is 90 days,but if seeded from settled sludge from operating septic tank,startup period may reduce to 15 days.

(2)Run-2 is better than Run-1 in terms ofremovalefficiencies ofTSS,BOD and COD.

(3)Run-2,at detention time of 12 h and 24 h and at 25°C meets NEQS for TSS,BOD and COD.Choice may be made between the two detention times considering trade-off between costs,area required and enforced regulation by the concerned housing authority.

6.Recommendations

The following recommendations are made in light of the present study:

(1)Twenty-four hours of detention time is recommended for Run-2 setup,for maximum reduction in BOD levelwhile remaining cost effective.

(2)Housing authorities in Lahore are suggested to adopt this new design for septic tank(Run-2 setup)by inducting it in their by-laws.

(3)The recommended design criteria for Run-2 setup are as follows:

a.Detention time of 24 h

b.Up flow velocity>1 m·h-1

c.Length–width ratio 2:1

d.Width of Up flow chamber:Down flow chamber 2:1

Acknowledgements

This paper is based on a graduate research conducted in IEER,supervised by the firstauthor[28].Funding by the University ofEngineering&Technology,Lahore and support of lab staff is acknowledged.

References

[1]Q.Mehmud,Z.A.Bhatti,Low cost municipal wastewater treatmentoptions for use in Pakistan-A review,J.Sci.Vision 15(2009)71–78.

[2]H.Haider,W.Ali,Calibration and veri fication of a dissolved oxygen management model for a highly polluted river with extreme flow variations in Pakistan,Environ.Model.Assess.185(5)(2013)4231–4244.

[3]H.Haider,W.Ali,Development of dissolved oxygen model for a highly variable flow river:case study of Ravi River in Pakistan,Environ.Model.Assess.15(6)(2010)583–599.

[4]LDA,Model Building and Zoning Regulations for Development Authorities in punjab,LDA,Local Government&Community Development Department,Government of Punjab,2007.

[5]DHA(Ed.),Defence Housing Authority Construction and Development Regulations,DHA,2007.

[6]S.A.Wanasen,Upgrading Conventional Septic Tanks by Integrating in-Tank Baffles,School of Environment,Resources and Development(SERD)Asian Institute of Technology(AIT),Bangkok,Thailand,2003.

[7]K.M.Foxon,Analysis of a Pilot-Scale Anaerobic Baffled Reactor Treating Domestic Wastewater,School of Chemical Engineering,University of KwaZulu-Natal,Durban,2009.

[8]S.Hayder,H.Haider,O.Nadeem,G.Hussain,S.Zahra,Proposed model for wastewater treatment in Lahore using constructed wetlands,J.Facul.Eng.Technol.22(1)(2015)07–17.

[9]A.Bachmann,V.L.Beard,P.L.McCarty,in:Y.C.Wu,E.D.Smith(Eds.),Comparison of Fixed Film Reactors with a Modi fied Sludge Blanket Reactor,Imperial College Press 1982,pp.384–402.

[10]J.Wang,Y.Huang,X.Zhao,Performance and characteristics of an anaerobic baffled reactor,Bioresour.Technol.93(2004)205–208.

[11]M.Vossoughi,M.Shakeri,I.Alemzadeh,Performance of anaerobic baffled reactor treating synthetic wastewater in fluenced by decreasing COD/SO4 ratios,Chem.Eng.Process.Process Intensif.42(2003)811–816.

[12]H.Yu,G.K.Anderson,Performance of a combined anaerobic reactor for municipal wastewater treatment at ambient temperature,Resour.Conserv.Recycl.17(1996)259–271.

[13]M.Faisal,H.Unno,Kinetic analysis of palm oil mill wastewater treatment by a modi fied anaerobic baffled reactor,Biochem.Eng.J.9(2001)25–31.

[14]J.Bell,C.A.Buckley,Treatment of a textile dye in the anaerobic baffled reactor,Water SA 29(2003)129–134.

[15]C.Zhiqiang,W.Qinxue,G.Huabin,B.Rune,Anaerobic treatment of domestic sewage in modi fied septic tanks atlow temperature,Environ.Technol.44(2014)2123–2131.

[16]F.M.Ferraz,A.T.Bruni,B.Del,L.Vanildo,Performance of an anaerobic baffled reactor(ABR)in treatment of cassava wastewater,Braz.J.Microbiol.40(2009)48–53.

[17]K.Gopala,P.Kumar,P.Kumar,Treatment of low strength complex wastewater using an anaerobic baffled reactor(ABR),Bioresour.Technol.99(2008)8193–8200.

[18]H.Feng,L.Hu,Q.Mahmood,C.Fang,C.Qiu,D.Shen,Effects of temperature and feed strength on a carrier anaerobic baffled reactor treating dilute wastewater,Desalination 239(2009)111–121.

[19]A.Torabian,S.Abtahi,M.Amin,S.Momeni,Treatment of low-strength industrial wastewater using anaerobic baffled reactor,Iran.J.Environ.Health Sci.Eng.7(2010)229–240.

[20]A.Langenhoff,D.C.Stuckey,Treatment of dilute wastewater using an anaerobic baffled reactor:effect of low temperature,Water Res.34(2000)3867–3875.

[21]A.Van Haandel,M.Kato,P.Cavalcanti,L.Florencio,Anaerobic reactor design concepts for the treatment of domestic wastewater,Rev.Environ.Sci.Biotechnol.5(1)(2006)21–38.

[22]A.Grobicki,D.C.Stuckey,Hydrodynamic characteristics of the anaerobic baffled reactor,Water Res.26(3)(1992)371–378.

[23]C.Polprasert,Organic Waste Recycling,2nd edition John Wiley and Sons,London,1996.

[24]W.P.Barber,D.C.Stuckey,Nitrogen removal in a modi fied anaerobic baffled reactor(ABR):1,denitrification,Water Res.34(2000)2413–2422.

[25]Standard Methods,Standard Methods for the Examination of Water and Wastewater,American Public Health Association,American Water Works Association,Water Environment Federation,Washington,1998.

[26]A.H.Ghawai,J.Kris,Use of rotating biological contactors for appropriate technology wastewater treatment,Slovak J.Civ.Eng.36(12)(2009)1887–1894.

[27]S.Ed,Evaluation of septic tan and subsurface flow wetland for Jaaican public school wastewater treatment,Master Thesis,Michigan Technological University,2005.

[28]M.Arbi,Evaluation of anaerobic baffled reactor for the treatment of domestic wastewater,Masters Thesis,Institute of Environmental Engineering and Research,UET,Lahore,Pakistan,2014.

Chinese Journal of Chemical Engineering2018年4期

Chinese Journal of Chemical Engineering2018年4期

- Chinese Journal of Chemical Engineering的其它文章

- Oil field produced water treatment in internal-loop airlift reactor using electrocoagulation/ flotation technique

- From pollutant to solution of wastewater pollution:Synthesis of activated carbon from textile sludge for dye adsorption

- 17α-Ethinylestradiol removal from water by magnetic ion exchange resin☆

- Transesteri fication of sun flower oil in microchannels with circular obstructions

- The extraction of potassium from K-feldspar ore by low temperature molten salt method☆

- Decomposition behavior of CaSO4 during potassium extraction from a potash feldspar-CaSO4 binary system by calcination☆