Numerical simulation and optimized design of cased telescoped ammunition interior ballistic

Ji-gng Wng,Yong-gng Yu,Ling-ling Zhou,Rui Ye

aSchool of Energy and Power Engineering,Nanjing University of Science and Technology,Nanjing,210094,China

bChongqing Wangjiang Industry Co.,Ltd,Chongqing,400071,China

1.Introduction

Cased telescoped ammunition(CTA)is a kind of charge structure with a projectile embedded in the cartridge case.Compared with concepts using conventional ammunition,the length of CTA is small and the appearance of CTA is simple[1,2].Because of its unique structure,the feeding mechanism is simple and the feeding distance is much shorter.Thus,ammunition storage space can be effectively used.Compared with the conventional ammunition of the same caliber,the overall performance of CTA is more superior.

Due tothe superior performance of CTA,manycountries,such as USA[3-5],England and France[6,7],have launched a study of CTA technology and obtained many achievements in this field.For example,the 45M911 45 mm CTA gun is developed by France.The 40 mm cased telescoped weapon system(CTWS)is developed by a joint Anglo-French project.These results fully illustrate the feasibility of the CTA weapon system used for equipment.

The sketch of a typical CTA structure is shown in Fig.1.It can be seen that there is a big difference in the structure between CTA and conventional ammunition.Thus the interior ballistic process is different from the conventional ammunition.In the process of CTA interior ballistic,the fast burning propellant in the auxiliary chamber at the bottom of the projectile is ignited by the primer after the primer is struck.The propellant gases,generated by the fast burning propellant,drive the projectile to move forward along the control tube.Then the projectile is propelled into the barrel with a certain velocity.At this time,due to the special structure of CTA,the main charge around the center igniting primer and controlling tube is ignited and a large volume of gas is generated to propel the projectile along the barrel until the projectile exists the muzzle.

In order to achieve successful shooting,there is a need for a reasonable design of CTA interior ballistics because of the particularity of CTA interior ballistics.The interior ballistic design,usually based on the interior performance requirements and design indices,is to determine the structure elements and loading parameters of the gun system.If a conventional engineering design method is used,the CTA interior ballistic scheme maybe feasible,but it can't be ensured that the scheme is optimal.In recent years,the intelligent optimization algorithm has been applied to variable fields.Among it,the genetic algorithm is most widely used.In this paper,we will apply a genetic algorithm to produce an optimal design by taking a 35 mm CTA interior ballistic model as an example.

2.Interior ballistic model of CTA

The object of CTA interior ballistic design is the interior ballistic process.Thus interior ballistic equations are used for the design[8].In this paper,we take a 35 mm CTA as the research object and establish a CTA zero-dimensional interior ballistic model with combining the characteristics of interior ballistic process[9-11].

The interior ballistic process can be divided into two stages based its characteristics,which are first ignition stage and second ignition stage.The first ignition stage mainly involves the combustion of fast burning propellant and the interior ballistic equations are as follows

Among that,ψbis the burned percentage of fast burning propellant,χband λbare shape characteristic quantity of fast burning propellant,Zbis the burned relative thickness

Among that u1b,nb,and e1bis the burning rate coefficient,burning rate-pressure exponent and arc thickness of the fast burning propellant respectively

Among that,m is the mass of projectile,v is the velocity of the projectile,S is the maximum cross-section area of the projectile,p is the pressure in the chamber.

Among that,lbis the travel of the projectile in the controlling tube.

Among that,φbis the secondary power coefficient of the first ignition stage,m is the mass of the projectile,lψbis equivalent length of the free volume of the first stage,fb,αb,ρpb,ωband Δbis the gunpowder force,covolume,density,charge quantity and charge density of fast burning propellant respectively,θb= γ-1 and γis specific heat ratio,V0band l0bis the chamber volume and equivalent length of the fast burning propellant respectively.

The interior ballistic equations of the second ignition stage are as follows

where,ψand Z is the burned percentage and burned relative thickness of main charge propellant respectively,χandλis the shape characteristic quantity of the main charge propellant,u1,n,e1is the burning rate coefficient,burning rate-pressure exponent and arc thickness of the main charge propellant respectively,l is the travel of the projectile in the barrel,p is the average pressure behind the projectile,Fr is the engraving resistance,φ is the secondary power coefficient of the second stage,lψis equivalent length of the free volume of the second stage,V0and l0is the chamber volume and equivalent length of main charge propellant,respectively,f,ω,Δ,α and ρpis the gunpowder force,main charge quantity,charge density,covolume and density of the main charge.

Fig.2 shows the flow chart of the simulation process.As the figure shows,at the beginning of the simulation,the initial value of the interior ballistic parameters is calculated according to the loading parameters.After that,loop calculation of the interior ballistic parameters is conducted with the first stage equations until the projectile exists the control tube.After the projectile enter into the gun tube,loop calculation is conducted with the second stage equations until the projectile exists the gun tube.Finally,the calculation results are outputted,including the velocity and pressure.

3.Optimization

3.1.Genetic algorithm

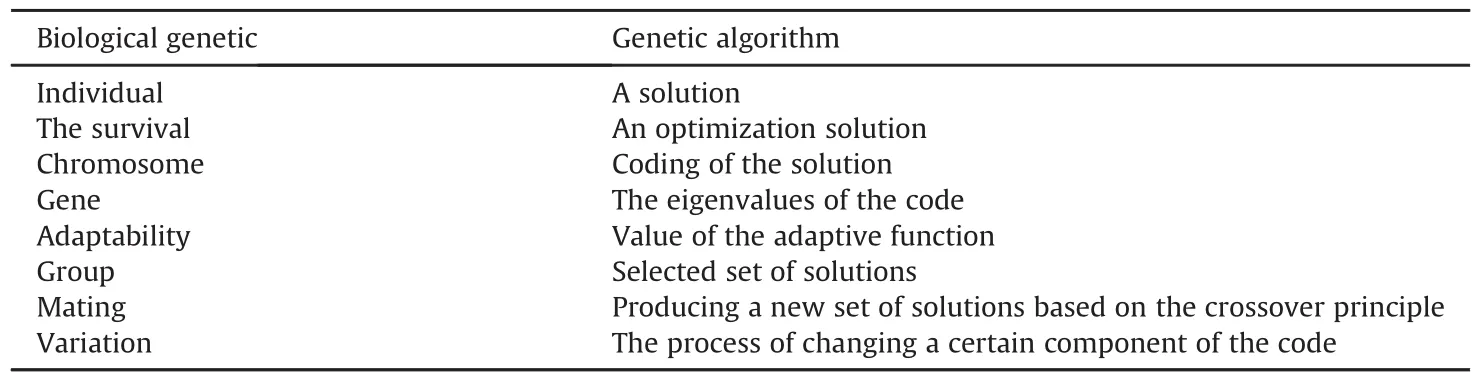

The main idea of the genetic algorithm is the law in the natural field,which is the survival of the fittest[12-14].This algorithm is to establish objective function and constraint conditions for solving the problem.The genetic algorithm will encode the scheme parameters and then continue the selection,crossover and mutation of the population of candidate solutions.Byconstantly updating the population,the solution to the problem is gradually evolved to an optimum.Table 1 shows the relationship between biological genetic concepts and genetic algorithm concepts.

The main components of the genetic algorithm include the group,the coding method,the selection strategy and the genetic operation.

(1)In the genetic algorithm,the group is composed of a certain number of individuals,and each individual corresponds to a solution.The individuals in original group are randomly generated,and the size of the group is a linear multiple of the length of the code.

(2)Coding is the basic work of the genetic algorithm,which determines relationship between the solutions and the genetic codes.

(3)The selection strategy in the genetic algorithm is choosing the most adaptable individuals in the group,which are evaluated by the adaptive function.

(4)The most important part of the genetic algorithm is the genetic operation,including mating and variation operation.

Fig.3 shows the flow chart of the optimization process.The genetic algorithm firstly needs to encode the optimal problem and construct the fitness function.Then the evolution usually starts from a population of randomly generated individuals,and is an iterative process,with the population in each iteration called a generation.In each generation,the fitness of every individual in the population is evaluated.The individuals are stochastically selected from the current population based on the fitness.Those more fit individuals are recombined and mutated to form a new generation.The fitness of the new generation is closer to the optimal solution than that of the initial population by comparative selection and code update.The solutions of the population will approach to the optimal solution by iterations of the algorithm.The solution of the last generation can be regarded as the optimal solution to the problem.

3.2.Determination of optimal variables

In the process of interior ballistic design,there is some in fluence of the gun structure and charge conditions on the interior ballistic characteristics.Thus,more variables are involved in the CTAoptimal design,such as the length of barrel,propellant chamber volume,charge quantity and charge shape of the propellant.The variables selected should be mutual independent and have most direct and biggest in fluence on the scheme.The propellant chamber volume and charge quantity have considerable in fluence on the peak pressure of the gun and muzzle velocity of the projectile.So we will select those two parameters as design variables and conduct an optimal design.

Table 1The relationship between biological genetic concepts and genetic algorithm concepts.

3.3.Constraint conditions

In the process of interior ballistic design,the constraint conditions are determined based on the material of the gun,ammunition charge condition and related prior art.The usually used constraint conditions in the interior ballistic design are peak pressure,chamber volume and charge density.The peak pressure is an important index in the interior ballistic design.To determine the peak pressure should not only consider the interior ballistic performance but also consider the factors of gun barrel material strength.The size of the chamber volume will affect the performance of artillery.If the size of chamber volume is too large,it will occupy larger space and apply adverse effects on other features of the weapon system.The charge density is in fluenced by the charge shape and density of the propellant,and should be chosen according to the current state of art.

As mentioned above,the boundary conditions of the design variables were chamber volume V0∈[0.33,0.41]dm3and main charge densityΔ∈[0.75,0.95]kg/dm3.The upper limit of the peak pressure is set to be 322 MPa as a constraint.

3.4.Objective function

There are many constraints used to satisfy the schemes,but not of all are optimal.Thus we need an objective function to evaluate the quality of the scheme.The main goal of the interior ballistic optimal design is to obtain a larger muzzle velocity of projectile with pressure as small as possible.Thus we select the muzzle velocity of projectile as the optimized objective function.

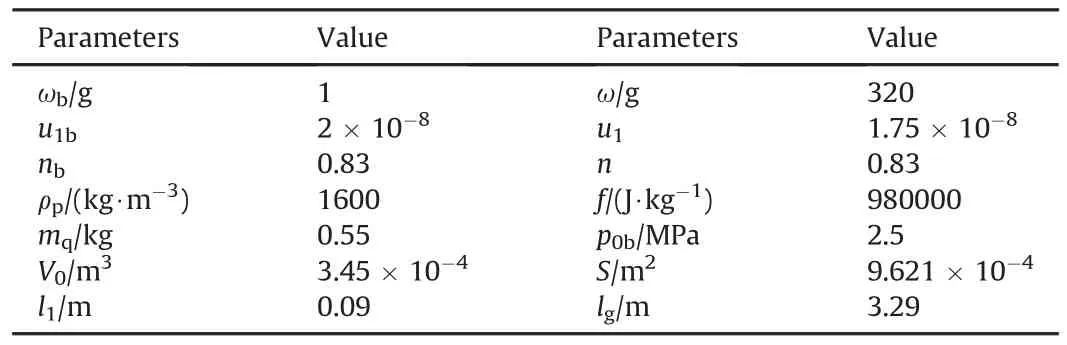

Table 2Charge parameters of CTA.

4.Result and analysis

4.1.Numerical simulation of 35 mm CTA interior ballistic

Numerical simulation is conducted based on an initial scheme of 35 mm CTA firing experiment and then an optimal design is carried out.The charge parameters of the CTA experiment is shown in Table 2.

The comparison between numerical results and experiment data is shown in Table 3.The maximum relative error of projectilemuzzle velocity and peak pressure is 0.68%and 0.56%,respectively.The calculated results are in good agreement with the experimental results,which validates the model.

Table 4Genetic algorithm parameters.

4.2.Results of optimal design

The parameters of the genetic algorithm adopted in the calculation were shown in Table 4.

The convergence process of genetic algorithm of generations is shown in Fig.4.It can be seen that the design variables of chamber volume V0and charge densityΔ,constraint condition of peak pressure pmand objective function of vgoscillate largely in the early stage of the iterations.However,the oscillation decreases gradually as the genetic algorithm continues.Due to the mutation of some individuals during the generation in the convergence process,the design variables of chamber volume V0and charge densityΔ,constraint condition of peak pressure pmand objective function of vgmutate occasionally in the convergence process.However,it doesn't affect the convergence of optimization results.Thus,the optimal design of obtaining largest muzzle velocity of CTA projectile is V0=0.3869 dm3,Δ=0.8728 g/cm3and the optimized initial velocity of CTA is vg=1182 m/s.

Table 5Optimization results.

Four independent optimal calculations were carried out and the optimal results of each optimization were shown in Table 5.As can be seen in Table 5,the optimal results of chamber volume V0,charge densityΔand peak pressure were in the constraint range.The optimal results meet the actual situation and the design requirements and were better than that of the initial scheme.Comparingof the fouroptimal results,it can be seen that the results of each calculation are not the same.The deference between the optimal results is due to the existence of some certain randomness of the genetic algorithm in iterations.At first,the individuals of the initial population were randomly generated.Then,the individuals,which were chose to recombined,were selected randomly.The location of the coding recombination is also stochastic.In addition,whether the individual is to mutate and the location of coding mutation is also random.Though a difference of each optimization exists,the difference is small and the results are basically the same.At the same time,the difference in the peak pressure and projectile muzzle velocity of each optimization is very small.The optimization results are constantly approaching to the optimal results,which imply that using a genetic algorithm to optimize the interior ballistic design is feasible.

4.3.Comparison of optimized scheme with the experimental scheme

The numerical results of the interior ballistic characteristics of the last optimized scheme in Table 4 were compared with that of the initial scheme,which were shown in Fig.5 and Fig.6.

From Fig.5,it can be seen that pressure change of the pressure curve of the optimized scheme is small at the early stage of the interior ballistic process.This is because of a smaller charge density than that of the initial scheme.However,the charge quantity of the optimized scheme is much larger.At the late stage of the interior ballistic process,as the space behind the bottom of projectile increases,the in fluence due to the bigger chamber volume gradually decreases.The pressure of the optimized scheme would exceed that of the original scheme.Thus the pressure change of the optimized scheme is relatively gentler.

From Fig.6,in the process of projectile motion,the projectile velocity increases slower,because the pressure behind the bottom of projectile is relatively small.At the late stage,the pressure behind the bottom of projectile is relatively large,the acceleration rate is larger.Comparing the two schemes,the total impulse obtained in the whole interior ballistic process of the optimized scheme is larger at almost the same peak pressure.The muzzle velocity of the projectile increases by 14 m/s.The new scheme obtained by the genetic algorithm is more optimal than the original one.It's feasible to optimize the CTA interior ballistic design using a genetic algorithm.

5.Conclusions

A two stage ignition model of CTA interior ballistics was established using the classical interior ballistic theory.A numerical simulation was carried out based on the experimental condition and the calculated results are in good agreement with the experimental data.

An optimal design of CTA interior ballistics was established using a genetic algorithm.The best optimal scheme is obtained by setting the peak pressure,setting the present range of chamber volume V0and charge densityΔ.

Four different optimized results were obtained by four independent optimal calculations.The difference between each scheme is small and the calculated performance parameters are similar.The optimal results constantly approach the best optimal solution.

[1]Kelly WJ,Marscher WD.Cased telescoped ammunition smart seal development.AD A406070.2002.

[2]Hao Zhang,Xin Lu,Yong-gang Yu,Yanhuang Zhou.Design for the seal system and charge of a CTA Gun.Acta Armamentarii 2006;27(4):630-3.

[3]Woodley CR.Development of a one-dimensional internal ballistic model of a cased telescoped ammunition gun.In:15th international symposium on ballistics;1995.

[4]Huston MG,Stavenjord KH,Sankhla C.DOD cased telescoped ammunition and gun technology program.ADA370886.1999.

[5]Farrand TG.Initial evaluation of the CTA international 40mm cased telescoped weapon system.USA Aberdeen:US Army Research Laboratory;2000.

[6]Wareen JB.DOD CTA and gun technology program.USA:Evaluation Report of Department of Defense;1989.

[7]Boisson D,Sadat H,Rigollet F.Computation of boundary layers and calculation of parietal heat flux during a shot in gun barrel:comparison with the experiment for 45mm CTA gun.In:15th international symposium on ballistics;1995.

[8]Zhiming Jin.Interior ballistics of guns.Beijing:Beijing Institute of Technology Press,pp.9~79;2004.

[9]Xin Lu,Yanhuang Zhou,Yonggang Yu.Experimental study and numerical simulation of propellant ignition and combustion for cased telescoped ammunition in chamber.J Appl Mech 2010;77(5):051402-1-051402-5.

[10]Xin Lu,Hao Zhang,Yanhuang Zhou,Yong-gang YU.Numerical analysis on interior ballistics of cased telescoped ammunition.J Nanjing Univ Sci Technol 2008;32(6):690-4.

[11]Hao Zhang,Yanhuang Zhou.A 0-Dimensional interior ballistic mode and calculation of cased telescoped ammunition gun.J Ballist 2005;17(2):80-3.96.

[12]Goldberg DE.Genetic algorithm in search,optimization and machine learning.Massachusetts:Addison-Wesley Publishing Company;1989.

[13]Gambardella LM,Mastrolilli M,Rizzoli AE.An optimization methodology for intermodal terminal management.J Intell Manuf 2001;12(5):521-34.

[14]Wenxun Xing,Jinxing Xie.Modern optimization methods.Beijing:Tsinghua University Press;2005.p.113-47.

- Defence Technology的其它文章

- Evaluating location specific strain rates,temperatures,and accumulated strains in friction welds through microstructure modeling

- Crystal lattice free volume in a study of initiation reactivity of nitramines:Impact sensitivity

- The effects of compressibility and strength on penetration of long rod and jet

- A DFT study on TNGU isomers and aluminized cis-TNGU composites

- The kinetic of mass loss of grades A and B of melted TNT by isothermal and non-isothermal gravimetric methods

- Crystal lattice free volume in a study of initiation reactivity of nitramines:Friction sensitivity