Gas-liquid flow splitting in T-junction with inclined lateral arm *

Le-le Yang(杨乐乐), Shuo Liu(刘硕),Hua Li(李华) ,Jian Zhang(张健) ,Ying-xiang Wu(吴应湘), Jing-yu Xu(许晶禹)

Gas-liquid flow splitting in T-junction with inclined lateral arm*

Le-le Yang(杨乐乐), Shuo Liu(刘硕),Hua Li(李华) ,Jian Zhang(张健) ,Ying-xiang Wu(吴应湘), Jing-yu Xu(许晶禹)

This paper studies thegas-liquid flow splitting in T-junction with inclined lateral arm. The separation mechanism of the T-junction is related to the pressure distribution in the T-junction. It is shown that the separation efficiency strongly depends on the inclination angle, when the angle ranges from 0oto 30o, while not so strongly for angles in the range from 30oto 90o. Increasing the number of connecting tubes is helpful for the gas-liquid separation, and under the present test conditions, with four connecting tubes, a good separation performance can be achieved. Accordingly, a multi-tube Y-junction separator with four connecting tubes is designed for the experimental investigation. A good agreement between the simulated and measured data shows that there is an optimal split ratio to achieve the best performance for the multi-tube Y-junction separator.

Gas-liquid separation, T-junction, numerical simulation, split ratio

The tee junctions are widely used in petroleum and chemical industry. When a gas-liquid two-phase flow is introduced into the tee junctions, one almost inevitably sees the phase mal-distribution, with seri- ous consequences on the behavior of the downstream equipment. However, the tee junctions can serve as a partial phase separator when this natural phase mal- distribution is enhanced. As a partial phase separator, the tee junctions have an obvious advantage in the size. However, for a simple tee junction, it is difficult to prevent the liquid emerging from the lateral arm. Based on an extensive literature review, Saieed et al.[1]suggested to explore a combination of more than one tee junctions for the phase separation.

A large number of variables influence the phase separation at the tee junctions, and the separation mechanism remains an issue to be studied[2]. The methods for studying the flow splitting in the T-junc- tion can be basically divided into three categories. For the first category, experimental laws are used to obtain empirical correlations by fitting experimental data[3, 4]. For the second category. phenomenological models are established[5, 6]. The methods of these two catego- ries are only applicable under particular operating conditions and with special tee junction geometries. Therefore, we have to consider the third category: using numerical simulations.

In the present study, the gas-liquid flow splitting in the T-junction with inclined lateral arm is numeri- cally simulated to investigate the detailed phase mal- distribution phenomena, focusing on the effects of the inclination angles and the number of connecting tubes on the phase split. Based on the numerical simulation results, a compact multi-tube Y-junction separator with four connecting tubes is designed to achieve a good gas-liquid separation performance. To verify the numerical model, the experimental results obtained by this separation system are compared with numerical simulation results.

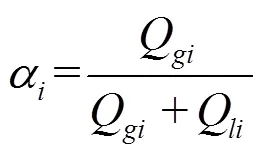

The inlet, the straight arm, and the lateral arm gas volume fraction are calculated by

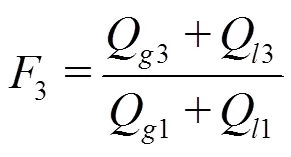

The split ratio is defined as the ratio of the mixture flow rate at the lateral arm to that at the inlet as follows

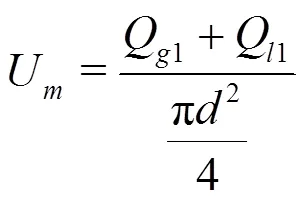

The superficial velocity of the mixture at the inlet is calculated according to the standard definition

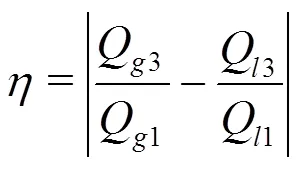

In order to evaluate the phase separation perfor- mance of the T-junction separator, the separation effi- ciency proposed by Yang et al.[8]is employed as

Numerical results show that the pressure at the inlet is higher than that at the lateral arm but lower than that at the straight arm, because of the decelera- tion of the fluid while flowing through the T-junction. Due to the Bernoulli effect, there is a reversible pres- sure rise at the straight arm and the lateral arm. Various vortices are produced at the place where the fluid just enters the lateral arm, to cause a large pres- sure drop with turbulence and energy losses. Thus, the irreversible pressure drop at the lateral arm is larger than the reversible pressure rise. Meanwhile it is exactly the opposite at the straight arm. Thus we will have a pressure drop at the lateral arm and a pressure recovery at the straight arm, to provide centripetal forces for the fluids to turn into the lateral arm. In the gas phase, the inertial force is larger than the centri- petal force, which makes the gas phase preferentially flow into the lateral arm. Conversely, it is harder for the liquid phase to change direction and exit through the lateral arm than the gas phase.

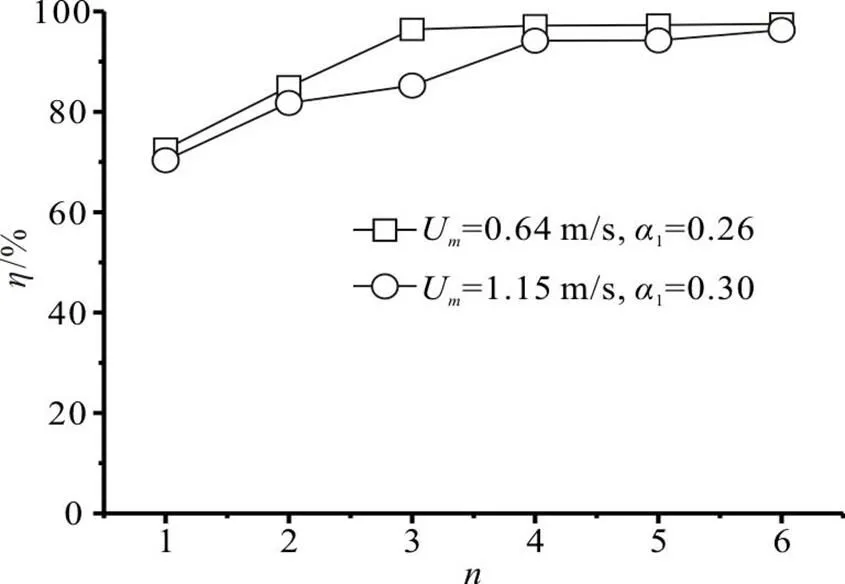

Fig.2Effect of the number of connecting tubes on the phase split

Fig.3Schematic diagram of the flow loop

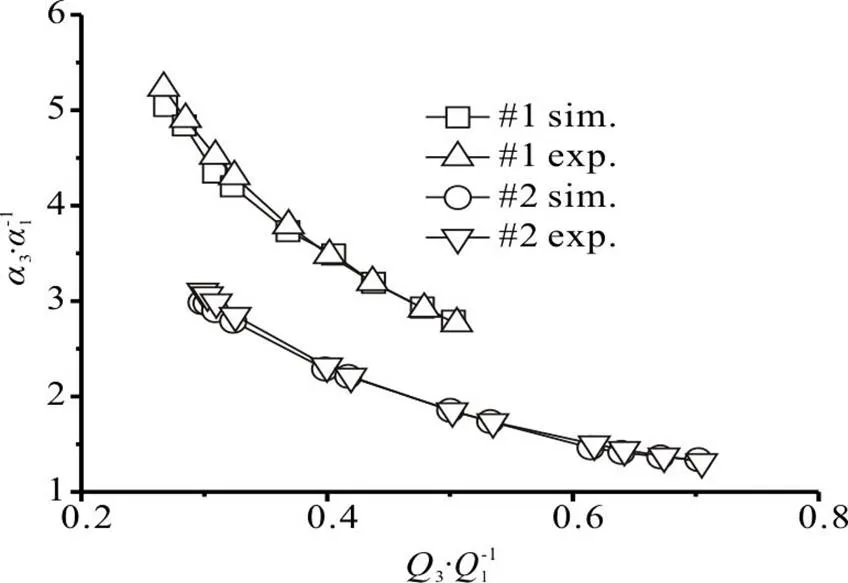

Fig.4Comparison between numerical and experimental results

Fig.5Effect of split ratio on separation efficiency

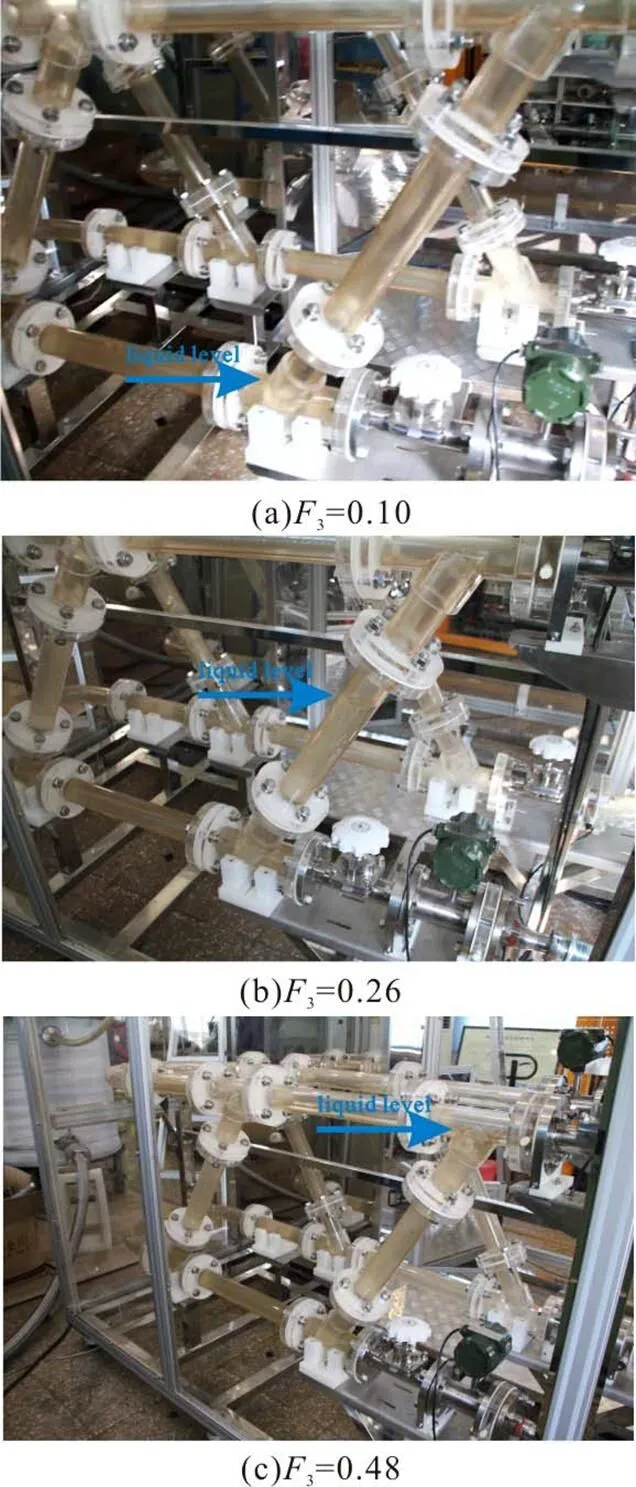

Fig.6(ColorOnline) Gas-liquid flow splitting in multitube Y- junction separa- tor for different split ratios

Figure 5 shows the effect of the split ratio on the separation efficiency for three groups of numerical results. As can be observed, the separation efficiency firstly increases and then decreases with the increase of the split ratio. Namely, there is an optimal split ratio for the best performance of the multi-tube Y- junction separator. Figure 6 indicates the splitting of the gas-liquid flow in the multi-tube Y-junction sepa- rator for different split ratios. When the split ratio is fairly small, the liquid level is very low, with an amount of the gas flowing through the straight arm. As the split ratio increases, more gas flows into the first lateral arm. And due to the hydraulic jump, the liquid level rises in the lateral arm. Then the liquid will be carried into the gathering tube with the rising gas stream through the first lateral arm and drains into the subsequent lateral arm. However, the liquid level will provide a barrier preventing the gas at the gathering tube from flowing back into the straight arm. In this case, the complete separation is almost achi- eved. If the split ratio increases further, the gas stream will carry more liquid into the lateral arm. At the same time, the residence time of the liquid at the gathering tube will decrease, which makes it more difficult for the liquid to fall into the straight arm. This process will lead an amount of the liquid to exit with the gas stream from the lateral arm and an amount of the pure water to emerge from the straight arm.

[1] Saieed A., Sam B., Pao W. et al. A Review of T-junction geometrical effect on two-phase separation[J]., 2016, 11(24): 14233-14238.

[2] Baker G., Clark W. W., Azzopardi B. J. et al. Controlling the phase separation of gas–liquid flows at horizontal T-junctions [J]., 2010, 53(8): 1908-1915.

[3] Zheng N., Zhao L., Hwang Y. et al. Experimental study on two-phase separation performance of impacting T-junction [J]., 2016, 83: 172-182.

[4] Yang L., Xu J. An experimental study on gas and liquid separation at Y-junction tubes by pressure control [J]., 2017, 52(8): 1496-1503.

[5] Margaris D. P. T-junction separation modelling in gas- liquid two-phase flow [J]., 2007, 46(2): 150-158.

[6] Sun D. C., Zhang Y., Qiu S. Z. et al. Models development of liquid drops entrainment at a T-junction with a large vertical up branch [J]., 2017, 110: 555-561.

[7] Desamala A. B., Vijayan V., Dasari A. et al. Prediction of oil-water flow patterns, radial distribution of volume fraction, pressure and velocity during separated flows in horizontal pipe[J].,2016, 28(4):658-668.

[8] Yang L., Azzopardi B. J., Belghazi A. et al. Phase sepa- ration of liquid-liquid two-phase flow at a T-junction[J]., 2006, 52(1): 141-149.

(June 21, 2017,Accepted November 13, 2017)

©China Ship Scientific Research Center 2018

*Project supported by the National Natural Science Foun- dation of China (Grant No. 51779243), the Strategic Priority Research Program of the Chinese Academy of Sciences (Grant No: XDb22030101).

Le-le Yang (1992-), Male, Ph. D. Candidate,

E-mail: yanglele@imech.ac.cn

Hua Li,

E-mail: lihua@imech.ac.cn

- 水动力学研究与进展 B辑的其它文章

- Spectral/hp elementmethods:Recent developments,applications, and perspectives *

- Modeling of single film bubble and numerical study of the plateau structure in foam system *

- Influence of upstream disturbance on the draft-tube flow of Francis turbine under part-load conditions *

- Numerical study of the wave-induced slamming force on the elastic plate based on MPS-FEM coupled method *

- 3-D Lagrangian-based investigations of the time-dependent cloud cavitating flows around a Clark-Y hydrofoil with special emphasis on shedding process analysis *

- The experimental study of hydrodynamic characteristics of the overland flow on a slope with three-dimensional Geomat *