基于弹齿轨迹的滚筒式牧草捡拾器遗漏率及工作参数优化

郁志宏,淮守成,王文明

基于弹齿轨迹的滚筒式牧草捡拾器遗漏率及工作参数优化

郁志宏1,淮守成1,王文明2

(1. 内蒙古农业大学机电工程学院,呼和浩特 010018; 2. 邢台职业技术学院机电工程系,邢台 054035)

该文基于弹齿的运动轨迹,建立了遗漏率理论模型并进行了仿真,利用MATLAB编程实现捡拾器凸轮机构的参数化设计。对凸轮轨道为正弦加速度规律运动的捡拾器进行遗漏率理论分析,并利用高速摄像系统进行试验,理论与试验的漏捡区高度线性拟合调整2为0.998 8,漏捡区面积线性拟合调整2为0.960 4。在捡拾器机器前进速度4~6 km/h,滚筒转速40~90 r/min时,应用遗漏率理论模型进行中心组合响应曲面法分析和目标优化,得到的理论工作参数最佳组合为前进速度4.0 km/h,滚筒转速54.299 r/min,此时,漏捡区高度0.796 cm,漏捡区面积6.369 cm2。在前进速度4 km/h和滚筒转速55 r/min的条件下进行不同含水率牧草的捡拾试验,遗漏率均低于国家标准要求的25%。该研究为捡拾器设计提供了理论基础,且能更好地指导实际生产。

农业机械;模型;优化;捡拾器;遗漏率;工作参数

0 引 言

捡拾压捆机是常用的牧草收获机械,作为它的主要工作部件,弹齿滚筒式捡拾器的性能好坏直接影响到捡拾压捆机的工作性能,展开捡拾器的深入研究具有一定的意义。

国内学者对弹齿滚筒式捡拾器做了很多研究工作,王国权等[1]研究设计了一种秸秆捡拾打捆机,并用ADAMS软件对捡拾器进行了仿真;王学农等[2]设计了残膜捡拾滚筒并利用SolidWorks软件对其进行了运动仿真;王锋德等[3]对4YF-1300 型大方捆打捆机的传动系统、物料捡拾和喂入系统、机械式预压缩室、压缩机构以及液压密度控制系统进行了设计和参数计算,并为验证机器作业的可靠性进行了试验;乌吉斯古楞等[4-5]应用INVENTOR软件对捡拾器进行了仿真分析;孙贵斌等[6]运用COSMOS Motion 运动仿真软件对弹齿滚筒捡拾器机构进行了运动仿真;王振华等[7]对方草捆压捆机捡拾器的工作幅宽及滚筒转速进行了设计,并对3组弹齿的捡拾器和4组弹齿的捡拾器的运动参数和遗漏率进行了对比分析;袁彩云等[8]对弹齿滚筒捡拾器的滚轮轴心在曲道内的运动轨迹进行了研究,运用UG建模并使用ADAMS对弹齿进行运动仿真分析;王文明等[9]通过ADAMS软件仿真模拟以及试验研究对多个不同轮廓的凸轮盘进行研究;肖子学等[10]利用SolidWorks软件对弹齿滚筒式捡拾器进行建模和仿真分析;丁海泉等[11]对弹齿滚筒式捡拾器的运动学特性进行了理论分析;郁志宏等[12-15]对弹齿滚筒式牧草捡拾器性能参数做了对比试验,以及三因素正交试验,并对弹齿滚筒式捡拾器弹齿进行了静力学分析。国外学者主要综合研究捡拾器整机性能[16-17]。目前未见对弹齿滚筒式捡拾器捡拾遗漏率进行过理论研究,本文基于弹齿运动轨迹,进行了遗漏率建模和仿真。

为使捡拾器设计确定结构与性能参数时,遗漏率符合国家标准[18]的要求。本文将遗漏率问题转化为漏捡区面积和高度问题进行研究,利用MATLAB编程实现捡拾器凸轮机构的参数化设计,在定参数下进行了遗漏率理论分析和高速摄像试验验证,并进行了中心组合响应曲面法分析与参数优化。

1 基于弹齿运动学的遗漏率模型建立

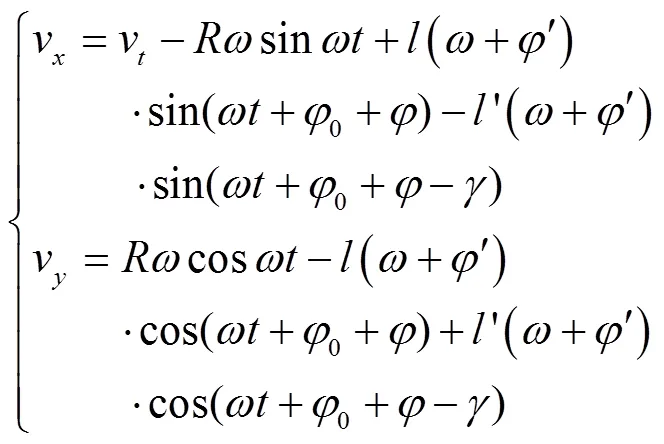

1.1弹齿运动方程

弹齿滚筒式捡拾器主要由捡拾器中间轴、滚筒盘、滚轮、凸轮盘、弹齿、管轴、护板和曲柄等组成,机构简图见图1,其实质是一个反转后的摆动从动件凸轮机构。弹齿滚筒式捡拾器的运动规律是凸轮盘不动,曲柄和弹齿连结点固定在滚筒上,滚筒在绕回转中心转动带动弹齿运动。凸轮盘的轮廓形状取决于动件曲柄的运动规律。

如图2所示建立坐标系,以凸轮机构基圆圆心为坐标原点,捡拾器前进方向为轴方向,垂直于地面的方向为轴方向,进行弹齿运动分析,凸轮机构初始摆角0方程为

式中为滚筒半径,m;为曲柄长度,m;0为凸轮基圆半径,m。

1.弹齿 2.管轴 3.曲柄 4.凸轮盘 5.滚轮 6.滚筒盘 7.中间轴 8.滚筒护板 9.侧护板 10.悬挂轴 11.支架

1.Spring-finger 2.Tube shaft 3.Crank 4.CAM disc 5.Roller 6.Cylinder plate 7.Intermediate axis 8.Cylinder guard board 9.Side guard board 10.Suspension axis 11. Stent

注:V为机器前速速度,km·h-1;为滚筒转速,r·s-1。

Note:Vis machine forword speed, km·h-1;is cylinder speed, r·s-1.

图1 弹齿滚筒式捡拾器机构简图

Fig.1 Structure diagram of spring-finger cylinder pickup collector

注:A为曲柄与弹齿连接点;B为滚子中心点;G为弹齿端部点;R为滚筒半径,m;l为曲柄长度,m;l′为弹齿长度,m;φ为凸轮机构摆角,rad;φ0为凸轮机构初始摆角,rad;γ为弹齿与曲柄夹角,rad;t为时间,s。

凸轮机构摆角是关于的摆动从动件运动规律,其方程为

式中为时间,s。

在不考虑弹齿摆动运动的情况下,弹齿运动轨迹为摆线,摆线形状取决于的大小。摆线形状方程

式中′为弹齿端部回转半径,m。

取值范围为1.2~1.5[19],此时捡拾运送物料时弹齿端部有一定的线速度但速度变化不能大,而且升举阶段弹齿端部速度相对向上;收齿时弹齿端部速度向下,即收齿时水平相对分速度为零,这样弹齿不拖挂物料。

弹齿端部点的位移、速度和加速度方程见式(4)、式(5)和式(6)。

式中为弹齿端部水平方向位移,m;为弹齿端部垂直方向位移,m;v为弹齿端部水平方向分速度,m/s;v为弹齿端部垂直方向分速度,m/s;a为弹齿端部水平加速度,m/s2;a为弹齿端部垂直方向加速度,m/s2;v为前进速度,m/s;为曲柄长度,m;为弹齿长度,m;为弹齿与曲柄夹角,rad;为摆角对时间的一阶导数;为摆角对时间的二阶导数。

弹齿端部绝对速度不得超过3 m/s[20],此时防止牧草花叶的脱落和弹齿在捡拾后带草。弹齿端部绝对速度方程为

弹齿端部回转半径方程为

1.2 遗漏率模型

弹齿滚筒式捡拾器漏捡区,如图3所示,由1、、3点构成,其中1点代表弹齿与相邻弹齿位移轨迹交点,点代表弹齿位移轨迹最低点,点代表相邻弹齿位移轨迹最低点。

弹齿运动轨迹方程为

相邻弹齿运动轨迹方程为

式中1为相邻弹齿端部垂直方向位移,m。

漏捡区面积方程为

注:1为弹齿与相邻弹齿位移轨迹交点;为弹齿位移轨迹最低点;为相邻弹齿位移轨迹最低点;为割茬高度和草条高度之和,m;为割茬高度,m。

Note:1is intersection point between spring-finger displacement trajectory and adjacent spring-finger displacement trajectory;is lowest point of spring-finger displacement trajectory;is lowest point of adjacent spring-finger displacement trajectory;is the sum of stubble height and grass height, m;is stubble height, m.

图3 弹齿滚筒式捡拾器漏捡区

Fig.3 Leakage collecting area of spring-finger cylinder pickup collector

漏捡区长度方程为

漏捡区高度H方程为

忽略草条高度不一致情况下,理论遗漏率S为

式中为漏捡区长度,m;为割茬高度和草条高度之和,m;为割茬高度,m。

2 程序“弹齿滚筒式捡拾器参数化设计系统”的实现

基于MATLAB语言设计的“弹齿滚筒式捡拾器参数化设计系统”,可实现5种常见从动件运动规律(等速运动、等加速等减速运动、三四五次方程、正弦加速度(摆线)运动和余弦加速度(简谐)运动)的凸轮机构数学模型[21-23]以及弹齿运动数学模型的设计。该系统输入凸轮机构结构参数和工作参数,运行可生成凸轮轮廓图、弹齿端部位移曲线图、弹齿端部回转半径图、弹齿端部速度图、弹齿端部加速度图以及弹齿与邻齿端部位移曲线图等,输出凸轮的最大压力角、曲率半径滚子、最大设计半径、弹齿端部回转半径、漏捡区面积、理论遗漏率、定长距离漏捡区面积、定长距离理论遗漏率和凸轮轮廓点数据文件,并输出边界条件判断结果。

以课题组研制的捡拾器试验台为例,其原型为9KJ-1.4A小方捆捡拾压捆机,试验台使用文献[4]设计的新型凸轮,升程和回程为摆线(正弦加速度)运动规律,凸轮机构结构参数如表1。

表1 凸轮机构结构参数

设置机器前进速度为4 km/h,滚筒转速为50 r/min,利用表1参数进行绘图和输出。将对应参数代入正弦加速度(摆线)运动凸轮机构数学模型获得凸轮轮廓,如图4所示。

图4 凸轮轮廓图

3 试验验证与工作参数优化

国家标准中规定捡拾器捡拾遗漏率要小于1%。捡拾器捡拾遗漏率为捡拾器在捡拾过程当中漏捡部分质量(长度小于70 mm的碎草不统计在捡拾损失饲草之内)占测定地段上的被捡牧草全部质量的百分比,方程为

式中S′为遗漏率,%;为测定长度,m;W为捡拾器漏拾牧草质量,g;P为每米草条质量,kg。

式(14)体现空间上的遗漏率,而式(15)体现质量上的遗漏率,将理论遗漏率问题转化为漏捡区面积和高度问题以便于试验验证。

3.1 试验仪器设备

捡拾器试验台见图5。高速摄像机dimaxS4、JN338型智能数字式转矩转速测量仪表、CNT800-4T0075G 和VARISPEED-616G5变频器等。

1.链传动 2.电动机 3.扭矩传感器 4.皮带传动 5.集草箱 6.带式输送器 7.滚筒捡拾器 8.后侧护板 9.草条车

3.2 试验方法

高速摄像机记录弹齿端部运动状态。摄像机与计算机通过USB数据线相连接,并应用CamWare软件控制摄像和记录。高速摄像测试系统如图6,标尺为20 mm× 20 mm和10 mm×10 mm的正方形格尺。镜头至20 mm× 20 mm标尺水平距离为1 200 mm,弹齿标定点至20 mm×20 mm标尺轴向距离为90 mm。控制软件设定每秒钟164张图像,根据摄像机最高分辨率调定分辨率为2 016×2 016。图7为弹齿端部跟踪点标定,以捡拾器回转中心轴心为坐标原点,以链轮上贴的标尺中心为标定点。记录图像上跟踪点水平像素值和垂直像素值及草条车跟踪点每秒水平像素变化值,在MATLAB中使用3次插样的方法获取拟合曲线,求出漏捡区高度且用积分求出漏捡区面积。

1.弹齿 2.侧护板 3.PCO dimax S4型高速摄像机 4.计算机

图7 跟踪点标定

3.3 试验方案

所用机型滚筒转速范围为40~90 r/min,前进速度为4~6 km/h。应用Central Composite Design(CCD)-响应面优化法[24-26]进行遗漏率研究。在Design-Expert中,按照中心组合响应曲面设计[27-31]设计试验方案,试验因素及编码水平表如表2所示。

表2 因素水平编码表

3.4 试验结果分析与工作参数优化

3.4.1 模型验证

将表2中的机器前进速度与滚筒转速和表1的机构参数输入“弹齿滚筒式捡拾器参数化设计系统”中,生成漏捡区高度和漏捡区面积,作为理论模型曲面响应数据;试验结果作为试验模型曲面响应数据,如表3所示。

表3 理论模型与试验结果曲面响应数据表

使用Origin软件将表3得到的理论漏捡区高度和试验漏捡区高度数值进行线性拟合,调整2为0.998 8,方程如图8a所示;再将表3得到的理论漏捡区面积和试验漏捡区面积数值进行线性拟合,调整2为0.960 4,方程如图8b所示。由此可知图8表面建立的遗漏率理论分析模型是较准确的。

图8 理论分析与试验数值线性拟合

3.4.2 工作参数优化

根据表3数据,各因素对理论模型漏捡区高度和漏捡区面积响应曲面如图9所示。

a. 漏捡区高度

a. Height of leakage area

b. 漏捡区面积

由图9a可知,滚筒转速与前进速度不存在交互作用,整体趋势平滑,前进速度一定时,漏捡区高度随滚筒转速的增大而减小;滚筒转速一定时,漏捡区高度随前进速度增大而增大。由图9b可知,滚筒转速与前进速度存在交互作用,在滚筒转速处于0水平时,漏捡区面积随前进速度增大而增大,波动范围为4.23~10.30 cm2,但当前进速度处于低水平时,漏捡区面积波动区间较小,波动范围为2.10~4.91 cm2。这是因为滚子主要处于凸轮机构升程阶段末期,对弹齿端部位移影响小;前进速度一定时,漏捡区面积随滚筒转速的增大而减小;滚筒转速一定时,漏捡区面积随速度增大而增大。

为了进一步得到工作参数的最佳匹配组合,以使捡拾器作业质量达到最佳,对理论模型进行边界条件的补充,如表4。

对理论模型进行多目标优化,目标函数如下:

min H

minN

1.2≤≤1.5

max≤3

4≤V≤6

40≤≤90

式中max为弹齿端部绝对速度最大值,m/s;为滚筒转速,r/min。

表4 理论模型边界条件数据表

漏捡区高度H最低和漏捡区面积N最小时的最优解为:=54.299 r/min,V=4.0 km/h。此时,漏捡区高度为0.796 cm,漏捡区面积为6.369 cm2,摆线形状为1.460,弹齿端部最大线速度3 m/s。

2017年9月15日,根据优化结果及试验的可操作性,在前进速度4 km/h和滚筒转速55 r/min的条件下进行试验,经高速摄像分析,此时漏捡区高度为0.835 cm,漏捡区面积为6.774 cm2。2017年9月21日,将含水率15%、18%、21%、25%的6 kg牧草放在2 m2的草条车上进行捡拾试验,遗漏率分别为0.2%、0.21%、0.25%、0.24%,遗漏率均低于国家标准要求的25%。

4 结 论

1)针对弹齿滚筒式捡拾器作业时遗漏率最小化问题,本文在弹齿滚筒式捡拾器运动学分析基础上,使用Matlab开发了“弹齿滚筒式捡拾器参数化设计系统”,通过输入机构参数和工作参数仿真捡拾器弹齿端部运动状态进行遗漏率理论分析,并利用高速摄像系统进行弹齿端部运动轨迹跟踪试验,验证了理论模型的正确性,理论与试验漏捡区高度线性拟合调整2为0.998 8,漏捡区面积线性拟合调整2为0.960 4。

2)前进速度为4~6 km/h,滚筒转速为40~90 r/min时,运用中心组合响应曲面法进行遗漏率理论分析得知,捡拾器前进速度一定时,遗漏率随滚筒转速的增大而减小;滚筒转速一定时,遗漏率随机器前进速度增大而增大;补充边界条件进行目标优化,得到的最佳参数组合为滚筒转速54.299 r/min,前进速度4.0 km/h,此时漏捡区高度0.796 cm,漏捡区面积6.369 cm2。在前进速度4 km/h和滚筒转速55 r/min的条件下进行不同含水率牧草的捡拾试验,遗漏率均满足国家标准要求。

[1] 王国权,余群,卜云龙,等. 秸秆捡拾打捆机设计及捡拾器的动力学仿真[J]. 农业机械学报,2001,32(5):59-61,68.

Wang Guoquan, Yu Qun, Bu Yunlong, et al. Design of pickup baler and dynamic simulation of pickup roller[J]. Transactions of the Chinese Society for Agricultural Machinery, 2001, 32(5): 59-61, 68. (in Chinese with English abstract)

[2] 王学农,陈发,张佳喜,等. 基于Solidworks残腊捡拾滚筒3D设计及运动仿真[J]. 新疆农业科技,2008,45(S2):156-158.

Wang Xuenong, Chen Fa, Zhang Jiaxi, et al. Three-dimensional design and motion simulating of tooth roller for collecting residual plastic film based on the software of Solidworks[J].Xinjiang Agricultural Sciences, 2008, 45(S2): 156-158. (in Chinese with English abstract)

[3] 王锋德,陈志,王俊友,等. 4YF-1300 型大方捆打捆机设计与试验[J]. 农业机械学报,2009,40(11):36-41.

Wang Fengde, Chen Zhi, Wang Junyou, et al. Design and experiment of 4YF-1300 large rectangular baler[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(11): 36-41. (in Chinese with English abstract)

[4] 乌吉斯古楞,刘伟峰,包那日那. 滚筒式捡拾器的运动仿真[J]. 农机化研究,2010,32(9):50-53.

Wujisiguleng, Liu Weifeng, Baonarina. Simulation of Spring-tooth Pick-up[J]. Journal of Agricultural Mechanization Research, 2010, 32(9): 50-53. (in Chinese with English abstract)

[5] 乌吉斯古楞. 弹齿滚筒式牧草捡拾器运动仿真及性能参数的试验研究[D]. 呼和浩特:内蒙古农业大学,2010.

Wujisiguleng. Simulation and Experimental Study on Performance Parameters of Spring-tooth Grass Pickup Roller[D]. Hohhot: Inner Mongolia Agricultural University, 2010. (in Chinese with English abstract)

[6] 孙贵斌,孙召瑞,吴修彬,等. 基于COSMOS Motion 的弹齿滚筒捡拾器运动仿真[J]. 农业装备与车辆工程,2010,48(8):37-39.

Sun Guibin, Sun Zhaorui, Wu Xiubin, et al. Simulation of spring-finger cylinder pickups motion based on COSMOS Motion[J]. Agricultural Equipment & Vehicle Engineering, 2010, 48(8): 37-39. (in Chinese with English abstract)

[7] 王振华,王德成,刘贵林,等. 方草捆压捆机捡拾器参数设计[J]. 农业机械学报,2010,41(增刊):107-109.

Wang Zhenhua, Wang Decheng, Liu Guilin, et al. Pickup parameters design of square baler[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(Supp.): 107-109. (in Chinese with English abstract)

[8] 袁彩云,刁培松,张道林. 弹齿滚筒捡拾器的设计与运动仿真[J]. 农机化研究,2011,33(5):73-76.

Yuan Caiyun, Diao Peisong, Zhang Daolin. Design and motion simulation of spring-finger cylinder pickups[J]. Journal of Agricultural Mechanization Research, 2011, 33(5): 73-76. (in Chinese with English abstract)

[9] 王文明,王春光. 弹齿滚筒式捡拾器参数分析与仿真[J].农机化研究,2012,43(10):82-89.

Wang Wenming, Wang Chunguang. Parameter analysis and simulation of spring-finger cylinder pickup collector[J]. Journal of Agricultural Mechanization Research, 2012, 43(10): 82-89. (in Chinese with English abstract)

[10] 肖子学. 弹齿滚筒式捡拾器的参数化设计及运动学仿真研究[D]. 呼和浩特:内蒙古农业大学,2014.

Xiao Zixue. Parametric Design and Kinematics Simulation on Spring-Finger Cylinder Pick up Collector[D]. Huhhot:Inner Mongolia Agricultural University, 2014. (in Chinese with English abstract)

[11] 丁海泉,郁志宏,刘伟峰,等. 弹齿滚筒式捡拾器运动学特性的理论分析[J]. 农机化研究,2015,37(10):76-82.

Ding Haiquan, Yu Zhihong, Liu Weifeng, et al. Theory analysis on kinematics characteristics of spring-finger cylinder pickup device[J]. Journal of Agricultural Mechanization Research, 2015, 37(10): 76-82. (in Chinese with English abstract)

[12] 郁志宏,王文明,莫日根毕力格,等. 弹齿滚筒式捡拾器捡拾性能试验[J]. 农业机械学报,2017,48(3):106-112.

Yu Zhihong, Wang Wenming, Morigenbilige, et al. Experiment on performance of spring-finger cylinder pickup collector[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(3): 106-112. (in Chinese with English abstract)

[13] 郁志宏,莫日根毕力格,王文明,等. 弹齿滚筒式牧草捡拾器性能参数对比试验研究[J]. 农机化研究,2017,39(2):122-127.

Yu Zhihong, Morigenbilige, Wang Wenming, et al. Comparison Experimental and research on the performance parameter of the spring-finger cylinder pickup collector[J]. Journal of Agricultural Mechanization Research, 2017, 39(2): 122-127. (in Chinese with English abstract)

[14] 郁志宏,达布其力吐,王文明,等. 捡拾器试验台性能参数分析与优化[J]. 农机化研究,2017,39(1):187-191,196.

Yu Zhihong, Dabuqilitu, Wang Wenming, et al. The performance parameters analysis and optimazation of pickup Experimental-device[J]. Journal of Agricultural Mechanization Research, 2017, 39(1): 187-191,196. (in Chinese with English abstract)

[15] 郁志宏,吴淑红,王文明,等. 弹齿滚筒式捡拾器弹齿的静力学分析[J]. 农机化研究,2017,39(4):27-31.

Yu Zhihong, Wu Shuhong, Wang Wenming, et al. Static analysis for spring-finger of 9KJ-1.4a forage baler pickup collector[J]. Journal of Agricultural Mechanization Research, 2017, 39(4): 27-31. (in Chinese with English abstract)

[16] Bortolini Marco, Cascini Alessandro, Gamberi Mauro. Sustainable design and life cycle assessment of an innovative multi-functional haymaking agricultural machinery[J]. Journal of Cleaner Production, 2014, 82: 23-36.

[17] Langer Thomas H, Ebbesen Morten K. Kordestani Ario. Experimental analysis of occupational whole-body vibration exposure of agricultural tractor with large square baler[J]. International Journal of Industrial Ergonomics, 2015(47): 79-83.

[18] 中华人民共和国机械行业标准.牧草捡拾器:JB/T5160-2010[S].

[19] 卡那沃依斯基. 收获机械[M]. 曹崇文,吴春江,柯保康,译. 北京:中国农业机械出版社,1983.

[20] 中国农业机械化科学研究院. 农业机械设计手册:下册[M]. 北京:中国农业科学技术出版社,2007.

[21] 李霞,刘本学,张三川. 基于MATLAB软件的凸轮轮廓曲线设计及从动件运动学仿真[J]. 中原工学院学报,2012,23(1):41-43,78.

Li Xia, Liu Benxue, Zhang Sanchuan. The design of the cam profile and the follower kinematics simulation with MATLAB[J]. Journal of Zhongyuan University of Technology, 2012, 23(1): 41-43,78. (in Chinese with English abstract)

[22] 盛凯,曾南宏. 弹齿滚筒捡拾器的机构特性及其运动数学模型[J]. 农业机械学报,1991,22(1):51-57.

Sheng Kai, Zeng Nanhong. The mechanical feature and motional math model of spring-finger cylinder pick-ups[J]. Transactions of the Chinese Society for Agricultural Machinery, 1991, 22(1): 51-57. (in Chinese with English abstract)

[23] 盛凯. 摆动从动件盘形凸轮机构CAD通用程序设计[J]. 吉林工学院学报,1986(1):121-129.

Sheng Kai. General program of CAD of plate cam mechanism with swing driven member[J]. Journal of Jilin Institute of Technology, 1986(1): 121-129. (in Chinese with English abstract)

[24] 陈魁. 试验设计与分析[M]. 北京:清华大学出版社,2005.

[25] 徐向宏,何明珠. 试验设计与Design-Expert SPSS 应用[M].北京:科学出版社责任有限公司,2016.

[26] 潘丽军,陈锦权. 试验设计与数据处理[M]. 南京:东南大学出版社,2008.

[27] 王建楠,谢焕雄,胡志超,等.甩盘滚筒式花生种子机械化包衣工艺参数优化[J]. 农业工程学报,2017,33(7):43-50.

Wang Jiannan, Xie Huanxiong, Hu Zhichao, et al. Parameter optimization on mechanical coating processing of rotary table-roller coating machine for peanut seeds[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(7): 43-50. (in Chinese with English abstract)

[28] 游兆延,胡志超,吴惠昌,等. 1MCDS-100A型铲筛式残膜回收机的设计与试验[J]. 农业工程学报,2017,33(9):10-18. You Zhaoyan, Hu Zhichao, Wu Huichang, et al. Design and experiment of 1MCDS-100A typed shovel-sieve residual film recovery machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(9): 10-18. (in Chinese with English abstract)

[29] 王雷,张华,张蕾蕾,等. 甜樱桃采后热空气处理抑制青霉病的工艺优化[J]. 农业工程学报,2017,33(6):295- 300.

Wang Lei, Zhang Hua, Zhang Leilei, et al. Process optimization of hot-air treatment on inhibition of blue mould infection for postharvest sweet cherry fruit[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(6): 295-300. (in Chinese with English abstract)

[30] 蒋恩臣,孙占峰,潘志洋,等. 超级稻摘穗收获机沉降箱性能分析与运行参数优化[J]. 农业机械学报,2016,46(1):100-105.

Jiang Enchen, Sun Zhanfeng, Pan Zhiyang, et al. Performance analysis and operational parameters optimization of deposition chamber to clean super rice in stripper combine harvester[J]. Transaction of the Chinese Society for Agricultural Machinery, 2015, 46(1): 100-105. (in Chinese with English abstract)

[31] 王永维,唐海燕,王俊,等. 蔬菜钵苗高速移栽机吊杯式栽植器参数优化[J]. 农业机械学报,2016,47(1):91-99.

Wang Yongwei, Tang Yanhai, Wang Jun, et al. Parameter optimization for dibble-type planting apparatus of vegetable pot seedling transplanter in high-speed condition[J]. Transaction of the Chinese Society for Agricultural Machinery, 2016, 47(1): 91-99. (in Chinese with English abstract)

Leakage rate and optimization of working parameters for cylinder pickup collector based on spring-finger trajectory

Yu Zhihong1, Huai Shoucheng1, Wang Wenming2

(1.,,010018; 2.054035)

The leakage rateis a very important pickup performance indexer of a grass collector machine. It is critical to determine mechanical structural and performance parameters of a grass collector so that its leakage rate is lower than national standard. The overlap area of two adjacent bullet teeth trajectory profile is called pickup leakage area. A lower leakage rate requires a smaller pickup leakage area and lower height of pickup leakage area. Leakage rate of a collector could be well represented by total pickup leakage area and height of pickup leakage area. In this study, a program named “Parametric design system of spring-finger cylinder pickup collector” was developed using MATLAB 2016b based on kinematics analysis of spring-finger cylinder pickup collector. An innovated spring-finger cylinder pickup collector was designed based on sinusoid accelerated cam mechanism at Inner Mongolia Agricultural University. In order to optimize and minimize leakage rate of this spring-finger cylinder pickup collector machine, a simulation model was established using its mechanical structural and performance parameters. This mathematical simulation model contained five kinds of follower movement law, it provided spring-finger teeth to teeth trajectory profile, spring-finger teeth speed profile and spring-finger teeth acceleration profile. These data were used to check mechanical structural parameters and boundary condition of the spring-finger cylinder pickup collector; and they were also used to calculate total pickup leakage area and height of pickup leakage area of the collector. Central composite response surface method test was taken on the new type of the pickup collector test bench developed by Inner Mongolia Agricultural University. Under conditions of forward speed of 4-6km/h and cylinder rotation speed of 40 – 90 r/min, high-speed camera system was used to track the moving trajectory of the bullet teeth end, the end displacement fitting curves ofspring fingerwere got by using three-time sample insertion method for interpolation, experimental leakage area height and leakage area were calculated. The theoretical leakage area height and leakage area were analyzed by the program. Test results are basically consistent with the theoretical results of the program. Correctness of simulation mathematical model of the program is verified.The study showed the correlation coefficient of height of pickup leakage area between theoretical model and tested result was2=0.998 8; the correlation coefficient of pickup leakage area between theoretical model and tested result was2=0.960 4. Response surface based analysis and test result showed that when forward speed was set as constant, the leakage rate decreased if the drum rotation speed was increased; and when drum speed was set as constant, the leakage rate increased if the forward speed was increased. After increasing the boundary condition of collector, the leakage rate optimization showed that the lowest leakage rate happened when moving forward speed was 4.0 km/h and a drum rotating speed was 54.299 r/min, at which point that the leakage area height was 0.796 cm, and total leakage area was 6.369 cm2. The tests were conducted for Alfalfa grass with different moisture content, when the forward speed was 4.0 km/h and drum rotation speed was 55 r/min, leakage area rate of the spring-finger cylinder pickup collector were all lower than 25% national standard.

agricultural machinery; models; optimization; pickup collector; leakage rate; working parameters

2017-08-04

2017-12-31

国家自然科学基金项目(51365035)

郁志宏,河北邢台人,教授,博士生导师,主要从事农牧业机械智能化研究。Email:yzhyqyzhyq@126.com

10.11975/j.issn.1002-6819.2018.04.005

S225.2+3

A

1002-6819(2018)-04-0037-07

郁志宏,淮守成,王文明. 基于弹齿轨迹的滚筒式牧草捡拾器遗漏率及工作参数优化[J]. 农业工程学报,2018,34(4):37-43.doi:10.11975/j.issn.1002-6819.2018.04.005 http://www.tcsae.org

Yu Zhihong, Huai Shoucheng, Wang Wenming. Leakage rate and optimization of working parameters for cylinder pickup collector based on spring-finger trajectory[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(4): 37-43. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.04.005 http://www.tcsae.org