Analysis of the current density characteristics in through-mask electrochemical micromachining(TMEMM)for fabrication of micro-hole arrays on invar alloy film

D-som JIN,Kwng-ho CHUN,Eun-sng LEE

aSchool of Mechanical Engineering,Inha University,Incheon 22212,Republic of Korea

bDepartment of Mechanical Engineering,Inha University,Incheon 22212,Republic of Korea

Analysis of the current density characteristics in through-mask electrochemical micromachining(TMEMM)for fabrication of micro-hole arrays on invar alloy film

Da-som JINa,Kwang-ho CHUNa,Eun-sang LEEb,*

aSchool of Mechanical Engineering,Inha University,Incheon 22212,Republic of Korea

bDepartment of Mechanical Engineering,Inha University,Incheon 22212,Republic of Korea

Available online 21 December 2016

*Corresponding author.

E-mail address:leees@inha.ac.kr(E.-s.LEE).

Peer review under responsibility of Editorial Committee of CJA.

Production and hosting by Elsevier

http://dx.doi.org/10.1016/j.cja.2016.10.021

1000-9361©2017 Production and hosting by Elsevier Ltd.on behalf of Chinese Society of Aeronautics and Astronautics.

This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Invar alloy consisting of 64%iron and 36%nickel has been widely used for the production of shadow masks for organic light emitting diodes(OLEDs)because of its low thermal expansion coefficients(1.86 × 10-6cm/°C).To fabricate micro-hole arrays on 30 μm invar alloy film,through-mask electrochemical micromachining(TMEMM)was developed and combined with a portion of the photolithography etching process.For precise hole shapes,patterned photoresist(PR)film was applied as an insulating mask.To investigate the relationship between the current density and the material removal rate,the principle of the electrochemical machining was studied with a focus on the equation.The finite element method(FEM)was used to verify the influence of each parameter on the current density on the invar alloy film surface.The parameters considered were the thickness of the PR mask,inter-electrode gap(IEG),and electrolyte concentration.Design of experiments(DOE)was used to figure out the contribution of each parameter.A simulation was conducted with varying parameters to figure out their relationships with the current density.Optimization was conducted to select the suitable conditions.An experiment was carried out to verify the simulation results.It was possible to fabricate micro-hole arrays on invar alloy film using TMEMM,which is a promising method that can be applied to fabrications of OLEDs shadow masks.

©2017 Production and hosting by Elsevier Ltd.on behalf of Chinese Society of Aeronautics and Astronautics.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Electrochemical;

Invar alloy film;

Micromachining;

OLED shadow mask;

Photoresist film mask(PR film mask);

Through-mask

electrochemical micro

machining(TMEMM)

1.Introduction

A shadow mask is a particular metal film that is used in smart phone displays and televisions.It is used to deposit organic compounds to realize the R-G-B colors in organic light emitting diodes(OLEDs).It is mainly made of invar alloy,which has a low thermal expansion coefficients,high strength at extremely low temperature,impact toughness,and excellent machinability properties.Machined holes require high accuracy for high resolution.The mask has micro-scale hole patterns that have a taper-shaped cross-section.Chemical etching and laser machining are widely used for manufacturing shadow masks.Chemical etching is used to compensate for the drawbacks of general mechanical processing and widely used for strength in micro fabrication.However,it can cause oxidation and discoloration of material surface and decrease processing uniformity.Despite the use of double-side etching,it is difficult to realize a tapered shape because of the isotropic characteristic of etching.Laser machining also has a disadvantage in realizing tapered shapes,and it generates burrs and thermal stress on a workpiece.Due to these problems,these methods usually need a secondary process.This study suggests electrochemical micromachining(EMM)as an alternative method to fabricate shadow masks.1–4

EMM is controlled by the current in an electrolytic and has the advantages of good surface quality,no stress,high efficiency,and no tool wear.It can be applied in aerospace,medical science,and the display industry.This process makes it possible to remove materials selectively by electrochemical reaction at the anode workpiece.Metal is dissolved at the anode,and oxygen bubbles are produced.Many studies have been conducted to apply EMM to invar alloy.In pulsed electrochemical machining(PECM),a pulsed voltage leads to better surface roughness than a DC voltage.In addition,the fabrication of micro-holes using a micro-electrode needs sophisticated control of the machining gap and the pulse on/off time to get the machinability.5,6

Micro-hole arrays can be machined with through-mask EMM(TMEMM).This process can also be applied for the fabrication of micro-dimple arrays on cylindrical inner surfaces.The current density distribution was analyzed for different values of inter-electrode spacing to determine the interelectrode gap(IEG)for experiments.7A modified microscale pattern transfer can be applied without photolithography of substrates to fabricate micro-dimple arrays on a workpiece.8Many papers focused on reducing the ratio of the etched profile diameter to the micro-pattern diameter.By analyzing the current density on a workpiece’s surface,it is possible to minimize the taper angle with different thicknesses of dry-film using the finite element method(FEM).9,10Previous papers usually focused on the fabrication of micro-dimple arrays for surface texturing using EMM.

In this study,the TMEMM of a 30 μm invar alloy film was investigated.A patterned photoresist(PR)mask was covered on the invar alloy film as an insulator.A simulation was performed to predict the current density on the workpiece surface.The current density is critically related to the electrochemical machinability and analyzing it allows us to predict the influence of each parameter and select appropriate machining conditions for experiments.The FEM was used for this process,and we analyzed the results of variables such as the thickness of the PR mask,the IEG,and the electrolyte concentration.The distribution of current density is related to the uniformity of machined holes,so it can also be used to predict the uniformity of a shape on a wide-area workpiece.After the simulation,the optimization was conducted through design of experiments(DOE)to predict the suitable machining conditions.Based on the simulation,micro-hole arrays were fabricated on the 30 μm invar alloy film.

2.Principle of TMEMM

When a potential difference is applied between two electrodes,the anode material dissolves electrochemically according to Faraday’s law.With this electrolysis reaction,hydrogen gas is generated at the cathode,and hydroxides are generated at the anode.EMM is done to remove the material selectively to fabricate micro-hole arrays with the electrolysis reaction at the anodic workpiece in an electrolyte with adequate machining conditions.When the material dissolves,the electric charges separate around the material surface.The surface of the material has a negative electric charge,and the electrolyte that is in contact with the surface has a positive electric charge,so an electric double layer is formed.

This layer forms a potential difference,and the ionization of the material is determined according to the electric potential.Therefore,it is important to set suitable machining conditions such as electrolyte concentration,IEG,and voltage which influence the double layer.11,12During the electrochemical reaction,a diffusion layer is also formed around the workpiece material.High current density makes the material dissolve faster than the extraction of metal ions.The thicker the diffusion layer is,the slower the migration speed of the ions is,which slows down the dissolving.Therefore,an appropriate current density on the material is needed,which can be done by controlling the potential between the two electrodes.13

Fig.1(a)shows a schematic of the TMEMM process.Firstly,the PR film mask with a pattern is fabricated on the workpiece based on the photolithography process.An STS cathodic meshed tool and the anodic workpiece are fixed in a specially designed one-piece jig,and the gap is controlled using a gap gauge.The advantages of this process compared to machining with a microelectrode are as follows14:

·Improved precision

·Simple process

·Low costs

·Less-sophisticated machining conditions such as IEG.

This method ensures that desired micro-shapes are machined with high efficiency,and it also does not need a sophisticated method such as gap control or complex preparation of a micro-sized cathode.Fig.1(b)shows the fabrication process of a patterned mask on the invar alloy film.

3.Current density distribution in TMEMM:theoretical model and definitions

During TMEMM,material removal is related to the current density distribution on the workpiece surface.To predict the electrochemical machinability during TMEMM,the current density distribution on an invar alloy film surface was simulated and analyzed with varying machining conditions.

The IEG(G)and the thickness of the patterned PR dry-film mask(H)were varied to simulate the current density and its distribution.The following assumptions were made15,16:

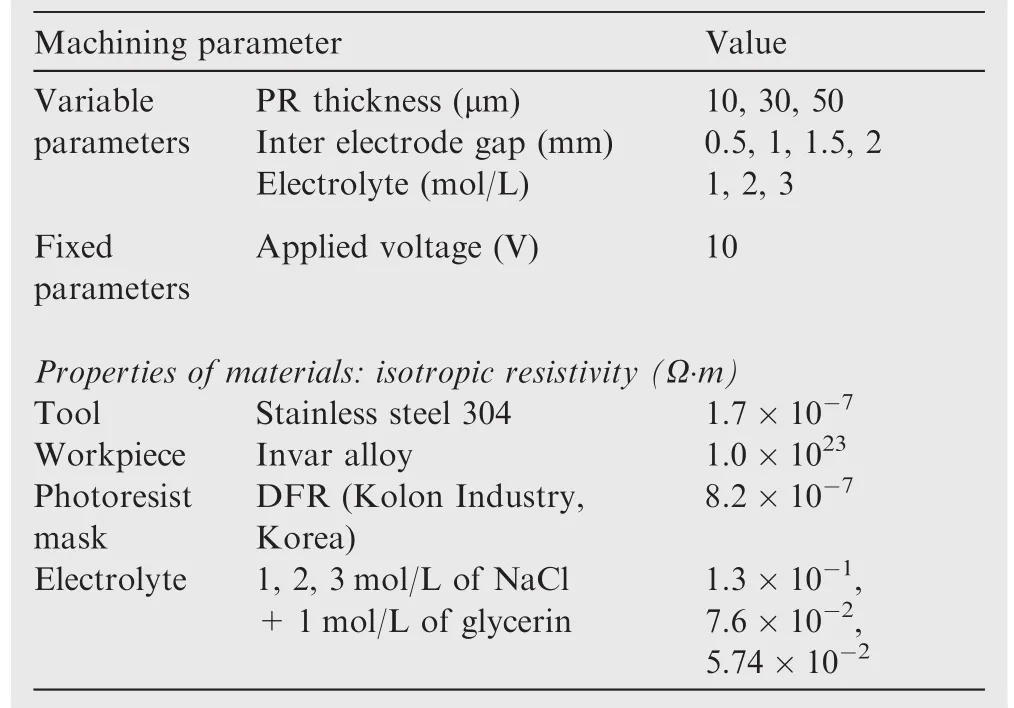

Table 1 Machining parameters and properties for analysis.

(1)The current density distribution at the anode surface follows the Ohmic effects.

(2)The conductivity of the electrolyte(κ)is constant.

(3)The temperature of the electrolyte(T)is constant.

(4)The electrolyte concentration gradient is negligible.

(5)The electrical parameters are constant.

The definition of the electric potential distribution for calculating the current density distribution obeys Laplace’s equation for the potential across the two electrodes in the IEG domain Ω(ΔV).The definition is shown in Fig.2.The current and potential depend on the Ohm’s law without concentration gradient as

where κ is the electrolyte conductivity,inis the normal current density,and φ is the electric potential.17The metal removal rate depends on the applied current density and can be calculated with the following equation:

whereVgis the mass of dissolved metal,η is the current efficiency(assumed to be constant at 100%),Fis the Faraday constant,and ω is the electrochemical equivalent(g).Eq.(2)can be derived as follows:

whereAis the atomic weight(g),ν is the valance,andtis the time that the Faraday current is applied.

According to the theory of electrochemical machining,the rate of anode erosion can be derived as follows18:

whereEis the electric field intensity,which can be extracted from FEM simulation.From these equations,it can be concluded that the current density is a critical parameter for predicting the material removal process during machining.19,20

The boundary conditions are as follows:

In the boundary conditions,all the surfaces which are in contact with the electrolyte in the electrolytic cell are expressed with the letter Γ.

FEM analysis was done using ANSYS.Modeling was done with the following scales: lengthL=90 μm, widthW=60 μm,pitches between squared holes=180 μm and 210 μm in each direction,thickness of the PR maskH=10,30,and 50 μm,IEGG=0.5,1,1.5,and 2 mm,and electrolyte concentration=1,2,and 3 mol/L(using isotropic resistivity)respectively with 1 mol/L of glycerin.Details of machining parameters and properties for analysis are listed in Table 1.

By applying DOE,it was confirmed the contribution of each factor to the current density in ANSYS workbench 16.1.Fig.3 shows the results.The IEG has the largest effect,and the isotropic resistivity is relatively insignificant.Therefore,these were used as a reference to select machining conditions for the experimental study.

4.Results and discussion of FEM simulation

4.1.Effect of variable thickness of PR mask on current density

The current density distribution with varying thickness of the PR mask is shown in Fig.4.Because of the big differences between the values of current density,a doubleY-axis is used.The thickness of the PR mask means the aspect ratio,H/W(orL).The mask aspect ratio has a great influence on the current density distribution in the TMEMM process.

The thinner the PR mask is,which means the aspect ratio is low,the more non-uniform the current density distribution is observed.As shown in Fig.4,compared with the current densities in the 30 μm and 50 μm PR masks,the current density in the 10 μm PR mask is uneven and the lowest current density is on the center of the trench.

During the machining process,the current density vector is formed at the machining area.The direction of the vector is perpendicular to the surface.As the thickness of the mask is getting thinner,a more overlapped vector occurs due to the concentration of the normal vector,and this concentration phenomenon leads to an increase of current density.When considering aY-Zcross-section,a thicker PR mask has a wider flat section,and thereby the concentration of the vector and the overlap are reduced so that it has a relatively uniform current density.

In addition to the exposed areas,corrosion also occurs on unexposed areas that are close to the exposed areas.This phenomenon is stronger when the mask is thinner.This may explain the results shown in Fig.4(a)for the 10 μm PR mask.

Non-uniform current density results in the development of localization,which means a large aspect ratio of the mask makes the overcut of holes decrease during the machining process.This occurs because uneven current density on the workpiece surface requires more machining time to fabricate holes.This can be explained with the isotropic characteristics of electrochemical machining.At the beginning of machining,dissolution of materials occurs along only theZdirection of the workpiece,and the dissolution rate is uniform because of the uniform current density distribution on the surface.This leads to a smaller overcut length.However,with the increase of machining time,material dissolution on the side of the micro-hole along theXandYdirections occurs as well.The unexposed areas near the boundary of the hole pattern are also dissolved,which results in overcutting.

Fig.4(b)shows the uniformity of the machined holes in a wide range.There is no significant difference between all the holes because the electric field from the electrodes is fully supplied,which is very important in terms of uniformity of the processing in wide-area machining.

The current density decreases with increases in the mask thickness,which means that the aspect ratio of the mask influences the current density value.The current density is proportional to the volume of material removal,so more time is needed for the same size of holes with a thicker mask(50 μm)than that with a thinner mask(10 μm).However,the mask thickness and the current density are not proportional in the 30 μm mask.The current density value is extremely large,which means there is an optimum aspect ratio between the size of the area to be dissolved(LandW)and the thickness of the mask.This can be explained with Fig.5,which shows the current vectors during the machining.

Fig.5(b)shows the vectors for 30 μm mask thickness,and the vectors around the workpiece are active and distribute all over the surface compared to the other conditions.To verify the relationship between the PR mask thickness and the current density value,an additional simulation was conducted for each thickness(Fig.10(a)).The results show that a thicker PR mask leads to a lower current density value,but not for the 30 μm PR mask.This means that there is an optimal aspect ratio between the insulation thickness and the machined hole size.The aspect ratio has an effect on the current density value of the workpiece surface.A thicker mask has a more even current density distribution but also a lower current density value,so both conditions need to be considered to select an appropriate mask thickness.

4.2.Effect of variable IEG on current density

Fig.6(a)shows the current density distribution of a machined area with a variable IEG,a 30 μm PR mask,and an electrolyte concentration of 3 mol/L NaCl with 1 mol/L of glycerin.The results show that the current density distribution becomes more even with an increase of the IEG,but the change is insignificant.Fig.6(b)shows the uniformity of the current density over three holes.It confirms that the current density value becomes more uniform with an increase of the IEG.Fig.7 shows the vector of the current density distribution at each IEG.As the IEG increases,the current density spreads more evenly throughout the workpiece surface,which leads to the uniform current density seen in Fig.6.

On the other hand,the current density value decreases with an increase of the IEG.As the IEG increases,the range of the electric field becomes wider,and thus the concentration of the electric field vector drops at the electrode surface.Therefore,in the narrow gap,the current density vector is densely concentrated and this leads to an increase in the material removal rate(MRR)in the experiments.Therefore,to select an appropriate IEG,both the uniformity and the current density need to be taken into account at the same time.The current density value is related to the material removal rate,and the current density distribution in a wide area is associated with the uniformity of the machined holes.

The electric field around an electrode spreads out more if the IEG is too big.If the IEG is too small,hydroxide and hydrogen bubbles are generated during the machining process,and they interfere as they remain in the IEG.If the IEG is too large,the machinability is decreased because the influence of the electric field becomes insignificant.Since the IEG is an important factor in this process,it is necessary to set a proper IEG by referring to the current density simulation.

4.3.Effect of variable electrolyte concentration on current density

To analyze the changes of electrical properties with each of electrolyte concentration,the isotropic resistivity of electrolyte was selected as a variable.It can be obtained by taking the inverse of the measured electrical conductivity(F-74BW,HORIBA,Japan)at each concentration.Electrical conductivity refers to the extent to which a substance or solution carries an electric charge,which is affected by the IEG,cross-sectional area,charge size,and the temperature and concentration of the ions.The electrical conductivity is significantly related to the current density and the current density distribution.Identifying the relationship between the electrolyte concentration and the current is useful for conducting the experiment.

The isotropic resistivity of each condition was0.139(1 mol/L NaCl with 1 mol/L of glycerin),0.076(2 mol/L NaCl with 1 mol/L of glycerin),and 0.057(3 mol/L NaCl with 1 mol/L of glycerin)Ω·m.The thickness of the PR mask and the IEG were fixed as 30 μm and 2 mm,respectively.The results are shown in Fig.8.The concentration does not significantly affect the current density distribution,but the current density increases with the electrolyte concentration.This means that the action of the electric field increases with the increase of electrolyte concentration(and the decrease of isotropic resistivity),although the difference is very small.Fig.9 shows the form of the vector of current density around the workpiece.There are no big differences between each concentration because the current density value of concentration has just a small difference from each other.

4.4.Summary of simulation

An increase of machining time makes more overcut by permeating electrolyte between the PR mask and the workpiece in the EMM because of the isotropic characteristic.Therefore,it is important to set adequate conditions to achieve accuracy as well as high machinability per unit time.

From the analysis of current density in variable parameters,it is possible to figure out the influences of the machining conditions on the current density.Fig.10 shows the relationship between each factor and the current density.Fig.10(a)shows the result of PR thickness.In this graph,the data of PR30 is too high,so the graph is drawn with doubleY-axis.Fig.10(b)is the result of IEG,and Fig.10(c)is the result of electrolyte concentration.Each factor shows a clear trend with the current density.These findings provide fundamental knowledge for the experimental study of fabrication of micro-hole arrays on invar alloy film using TMEMM.

Table 2 Candidate conditions for the optimized maximum current density.

Additionally,by enlarging one of the holes shown in the current density vector in theX-Yplane to figure out the detailed shape,it can be seen that a vector is formed rounded along the four lines of the pattern and converges at the corners.Thus,this current density vector is displayed as an elliptical shape.The flow of the current occurs along with the current density vector,and metal is also being dissolved along with this flow of the current.Therefore,the machined hole is predicted to have an elliptical shape influenced by the flow of the current density vector.

4.5.Optimization of machining conditions for current density

To obtain appropriate experimental conditions,optimization was applied with DOE,which shows the number of cases that satisfy the respective ranges.Optimization was performed for the results that satisfied the assigned output variables(Table 2).Condition 1 showed a maximum current density of 0.25536 mA/μm2for a PR mask thickness of 44.942 μm,IEG of 1.26 mm,and isotropic resistivity of 0.0538 Ω·m.Condition 2 had a maximum current density of 0.2229 mA/μm2for a PR mask thickness of 45.098 μm,IEG of 0.895 mm,and isotropic resistivity of 0.060 Ω·m.Lastly,condition 3 showed a maximum current density of 0.2331 mA/μm2for a PR mask thickness of 45.176 μm,IEG of 0.703 mm,and isotropic resistivity of 0.0520 Ω·m.

To select the optimum conditions among the above conditions,another simulation was conducted to confirm the current density distribution for each condition.The results are shown in Fig.11(a).Conditions 1 and 2 have uniform current density distributions in the machined area,whereas condition 3 has a non-uniform current density distribution,but it is insignificant.Fig.11(b)shows the current density distribution for three holes and it is clear that conditions 1 and 2 have better results than condition 3.Conditions 1 and 2 have almost the same tendencies in the current density distribution,but condition 1 has a higher value than that of condition 2.The vectors of current density are shown in Fig.12.It can be seen that conditions 2 and 3 have instability in specific machined areas.Therefore,based on Figs.11 and 12,condition 1 was selected as the optimum conditions.

5.Experimental verification

5.1.Experimental system

An experiment was done to fabricate micro-hole arrays on invar alloy film with a 30 μm thickness.The experimental system is schematically shown in Fig.13.It consists of an electrolyte agitation system,electrodes,a micro pulse generator,a PC-controller,an oscilloscope,and electrolyte conductivity measuring equipment(HORIBA,F-74BW).Pulsed power controlled by the pulse generator is provided from a power supply(hybrid precision,Korea)with a 30 A maximum output current and a 100 V maximum output voltage,and the pulse attains a 1 μm resolution.

The TMEMM was adapted and based on the machining conditions from the optimization results,which were a 45 μm negative PR mask(Kolon,Korea),a 3 mol/L NaCl aqueous solution with 1 mol/L of glycerin and isotropic resistivity of 0.0574 Ω·m,and an IEG of 1.5 mm.Although the optimization results show an IEG of 1.26 mm,it was increased due to other factors such as the flow of the electrolyte and the hydroxide and hydrogen bubbles.The other parameters were a current of 1.2 A,and an electrolyte agitation speed of 200 r/min.A wide-area stainless-steel mesh electrode was used as the cathode tool.

5.2.Experimental results

The results are shown in Fig.14.Experiments were carried out with different pulse conditions.Fig.14(a)shows the results in pulse on/off times of 1 μs and 3 μs.The micro-hole array was machined with a width of 88 μm and height of 104 μm.Fig.14(b)shows the results in pulse on/off times of 9 μs and 27 μs.The micro-hole array was machined with a width of 112 μm and height of 132 μm.All the machined holes have a shape of ellipse as predicted from the simulation.

As the pulse cycle increases,the size of machined holes and the taper angle increase as well with the same machined time.Pulse cycle is related to the machining rate.If the pulse cycle is too short,processes will not be completed and conditions are unstable,but it can enhance the precision of the machined shape.On the other hand,if the pulse cycle is too long,the machined shape will not be precise,but it can improve the machining rate.

These results show that TMEMM with a patterned PR mask is a promising method for the production of microhole arrays.

6.Conclusions

TMEMM was applied to fabricate a micro-hole array on invar alloy film with a 30 μm thickness.To study the current density,a simulation was carried out using the FEM with varying PR mask thickness,IEG,and electrolyte concentration.Several conclusions can be drawn from the simulation results.

(1)The current density distribution became more even with increasing PR mask thickness.However,the current density was not proportional to the thickness.At a 30 μm thickness,the current density increased rapidly.Except for this case,the current density decreased with increasing thickness of the PR mask.

(2)The current density distribution became more even with an increase of the IEG,but the change was insignificant.

(3)The concentration did not significantly affect the current density distribution,but the current density increased with increasing the electrolyte concentration.

(4)The conditions were optimized to obtain the best machining conditions using DOE and condition 1 was selected as the optimum set of conditions.It showed a maximum current density of 0.26 mA/μm2for a PR mask thickness of 44.942 μm,IEG of 1.26 mm,and isotropic resistivity of 5.38× 10-2Ω·m.

(5)An experiment was conducted with optimization results.Micro-hole arrays were machined with a width of 88 μm and height of 104 μm in pulse on/off times of 1 μs and 3 μs and a width of 112 μm and height of 132 μm in pulse on/off times of 9 μs and 27 μs.

Acknowledgements

This work was supported by the National Research Foundation of Korea(NRF)grant funded by the Korean government(MSIP)(No.2015R1A2A1A15054116).

1.Huang ZH,Qi GJ,Zeng XT,Su WM.A method for undercut formation of integrated shadow mask used in passive matrix displays.Thin Solid Films2006;503(1–2):246–9.

2.Chung IY,Kang KH,Kim JD,Sohn IB,Noh YC,Lee JM.Femtosecond pulsed laser ablation of OLED shadow mask invar alloy.J Korean Soc Precis Eng2007;24(12):50–6.

3.Kim C.Production of shadow-mask-improved technology.J Mater Process Technol2002;127(3):409–18.

4.Tian P,Bulovic V,Burrows P,Gu G,Forrest S,Zhou T.Precise,scalable shadow mask patterning of vacuum-deposited organic light emitting devices.J Vac Sci Technol A1999;17(5):2975–81.

5.Kim S,Choi S,Choi W,Yang B,Lee E.Pulse electrochemical machining on Invar alloy:optical microscopic/SEM and noncontact 3D measurement study of surface analyses.Appl Surf Sci2014;314:822–31.

6.Kim W,Baek S,Lee E,Tak Y.A study of pulse EMM for Invar alloy.Proceedings of the KSPE autumn conference.2004.p.70–3.

7.Qu NS,Chen XL,Li HS,Zeng YB.Electrochemical micromachining of micro-dimple arrays on cylindrical inner surfaces using a dry-film photoresist.Chin J Aeronaut2014;27(4):1030–6.

8.Qu NS,Zhang XF,Chen XL,Li HS,Zhu D.Modif i ed microscale pattern transfer without photolithography of substrates.J Mater Process Technol2015;218:71–9.

9.Chen XL,Qu NS,Li HS,Xu ZY.Pulsed electrochemical micromachining for generating micro-dimple arrays on a cylindrical surface with a flexible mask.Appl Surf Sci2015;343:141–7.

10.Qu NS,Chen XL,Li HS,Zhu D.Fabrication of PDMS micro through-holes for electrochemical micromachining.Int J Adv Manuf Technol2014;72(1–4):487–94.

11.Landolt D,Chauvy P,Zinger O.Electrochemical micromachining,polishing and surface structuring of metals:fundamental aspects and new developments.Electrochim Acta2003;48(20):3185–201.

12.Tang L,Li B,Yang S,Duan Q,Kang B.The effect of electrolyte current density on the electrochemical machining S-03 material.Int J Adv Manuf Technol2014;71(9–12):1825–33.

13.Lee E,Baek S,Cho C.A study of the characteristics for electrochemical micromachining with ultrashort voltage pulses.Int J Adv Manuf Technol2007;31(7–8):762–9.

14.Das AK,Saha P.Machining of circular micro holes by electrochemical micro-machining process.Adv Manuf2013;1(4):314–9.

15.Nouraei S,Roy S.Electrochemical process for micropattern transfer without photolithography:a modeling analysis.J Electrochem Soc2008;155(2),D97-103.

16.Chen X,Qu N,Fang X,Zhu D.Reduction of undercutting in electrochemical micro-machining of micro-dimple arrays by utilizing oxygen produced at the anode.Surf Coat Technol2015;277:44–51.

17.Kwon G,Sun H,Sohn H.Wall profile developments in throughmask electrochemical micromachining of Invar alloy films.J Electrochem Soc1995;142(9):3016–20.

18.Wang G,Li H,Qu N,Zhu D.Investigation of the hole-formation process during double-sided through-mask electrochemical machining.J Mater Process Technol2016.Available from:http://dx.doi.org/10.1016/j.jmatprotec.2016.01.010.

19.Zhang J,Zhu D,Xu Z,Zhang K,Liu J,Qu N,et al.Improvement of trailing edge accuracy in blisk electrochemical machining by optimizing the electric field with an extended cathode.J Mater Process Technol2016;231:301–11.

20.Zhu D,Qu N,Li H,Zeng Y,Li D,Qian S.Electrochemical micromachining of microstructures of micro hole and dimple array.CIRP Ann-Manuf Technol2009;58(1):177–80.

7 June 2016;revised 6 July 2016;accepted 19 July 2016

CHINESE JOURNAL OF AERONAUTICS2017年3期

CHINESE JOURNAL OF AERONAUTICS2017年3期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Review on signal-by-wire and power-by-wire actuation for more electric aircraft

- Real-time solution of nonlinear potential flow equations for lifting rotors

- Suggestion for aircraft flying qualities requirements of a short-range air combat mission

- A high-order model of rotating stall in axial compressors with inlet distortion

- Experimental and numerical study of tip injection in a subsonic axial flow compressor

- Dynamic behavior of aero-engine rotor with fusing design suffering blade of f