基于Madyn 2000的磁悬浮轴承控制器的设计

周传月Joachim Schmied

(1.北京东方极峰科技有限公司;2.DELTA JS AG,8005 Zurich,Switzerland)

基于Madyn 2000的磁悬浮轴承控制器的设计

周传月1Joachim Schmied2

(1.北京东方极峰科技有限公司;2.DELTA JS AG,8005 Zurich,Switzerland)

电磁轴承的独特特性使其在工业上的应用快速增多。当前,对电磁轴承支承转子在效能和可预测性方面的要求达到了与传统油膜轴承和滚动轴承支承转子的同样标准。

对转子系统设计者来说,理解电磁轴承特殊的技术特性是非常重要的。电磁轴承的特性要求是由转子动力学特性和使用的工作环境两方面来定义的。基于现代力学分析软件工具,以及电子化的控制器和它们在一个DSP上的数字化成就,电磁轴承能被很好地设计出来。

本文总结了电磁轴承控制器的设计流程,同时给出了电磁轴承所支承的三个不同转子的应用。第一个是小型高速主轴转子,转速120 000r/min,第二个是小型涡轮分子泵转子,转速36000r/min,第三个是大型多级离心压缩机转子,转速600~6 300r/min。最后分别给出了它们的计算分析和试验验证结果。

电磁轴承;控制器;涡轮分子泵;大型多级离心压缩机;转子动力学;Madyn 2000软件

1 Introduction

1.1 Technical considerations in magnetic bearing design

For setting the allowable vibration limits of the rotors on magnetic bearings,it is necessary to consider the influence of small clearances,bearing capacity limits,and the limited driving torque when crossing critical speeds etc..Design specifications for the rotor damping and the location of critical speeds,such as API 617,can be used as guidelines.However,it is not sufficient to cover all aspects. Several basic questions of designing rotating machines can be referred to[1].

Where are the critical speeds?Are critical speeds within the operating speed range?Which critical speeds must be crossed during the run up of the rotor?

What is the necessary damping of the natural modes of the rotor in order to ensure the safety of the operation?How can it be achieved?

What is the necessary stiffness of the bearing?How can it be achieved?

These questions are important in the magnetic bearing design,because of the limited specific bearing capacity.At low frequencies,due to the magnetic saturation of the material,the capacity is around 0.3~1MPa,but it is reduced at higher frequencies due to the limited voltage of the power amplifiers[2,3].Bearing overloads may lead a contact of the rotor with the auxiliary bearings,and thus the friction may wear out the contact surface between the ball bearings and bushings.So the load should be considered very carefully in the design process.

A well-designed damping is extremely important to improve the robustness of the rotor.In most situations,the damping has to be provided by the bearing.Firstly,all natural modes below the maximum operating speed,which should be well-damped,must be observed and controlled. Then a controller design should be done for the magnetic bearings to provide sufficient damping forces.The key of the controller design is to give the appropriate amplitude and phase angle of the bearing transfer function.A damping characteristic is achieved for phase angles 0° < φ<90°or-180°>φ>-270°(see fig.1,3 and 6).

In certain situations,a sufficient stiffness force is also important e.g.to resist high fluid forces,which normally have very low frequencies.Moreover,the behaviour of the rotor may change with the speed or with the changes in the fluid forces.A robust controller design as presented in section 2 for the three different rotors must take all these factors into account.

1.2 Tools for the rotordynamic analyses

To analysing the behaviour of the rotor on magnetic bearings,it is necessary to use a software combined a structural analysis for rotor and a mechatronic analysis for the magnetic bearing.The detailed approach is described inreference[4-6].Arelativelysimpleandpractical approach of analysing such combined system is described in reference[7].The software features are listed in the following.

1)The structural part

-Gyroscopic effects

-rotor fluid interaction,such as labyrinth induced excitations

-dynamics of flexible parts mounted on the rotor,such as disks

-flexibility of stator parts 2)The mechatronic part

-Non-collocation of sensors and actuators

-magnetic pull(negative stiffness)of magnetic actuators

-digital controllers,taking into account the antialiasing filter,a time delay and the AD conversion

-characteristics of the hardware components of magnetic bearings(sensors and amplifiers)

-sensors as well as controllers for displacement and velocity

-coupling of bearings and/or axes by means of controllers e.g.differentcontrollers for tilting and translation rotor modes

A comprehensive tool is introduced in reference[1,8]. It also includes a controller design part,which allows to create the transfer function with the required amplitude and phase by combining standard controller components e.g. modified PID controllers,first and second order filters,all pass,notch and analogue Butterworth filters.

1.3 Typical engineering procedure

The major steps in the controller design process are asbelow.

Model the structural part of magnetic bearing through a similar method of modelling the conventional bearing.

Study the basic behaviour of the rotor,including the natural frequencies of the rotor under different speed and different bearing stiffness coefficients,and the damping ratios of each natural modes under different bearing damping coefficients.

Define the requirements and/or the properties of the electronic hardware and software which are listed in section 1.2.

Design the controller transfer function[7]by taking into account the basic behaviour of the rotor as well as the requirements of the application.

Study the actual behaviour of the combined system in a closed loop analysis.

This procedure is demonstrated in detail for three applications in the next sections.

2 Rotors,Applications Requirements And Controllers

The first step in the design procedure is to model the rotor structure and study its basic behaviour[4]The main data of the three different rotors are summarised in table 1. Table 2 shows the dimensions,the mass and stiffness diameters,the locations of the supports(triangles)and the arrangement of the nodes.Also the concentrated masses and the flexible disk of the centrifugal compressor rotor are visible.

Tab.1 Summary of the main rotor data

The lower part of table 2 shows the mode shapes at standstill and the nature frequency of free rotors.The long vertical lines indicate the locations of actuator and the shorter vertical lines indicate the locations of sensor.

2.1 Rotor 1:Small high speed rotor

The first rotor is a very small spindle realised in a research project[1].It rotates supercritically at the very high speed of 120 000 rpm=2 000 cps.

a)Basic behaviour of the rotor(table 2)

The natural frequency of the free rotor's first bending mode is at 1 714Hz.In order to cross this mode,considerable damping forces have to be provided by the bearings at an extremely high frequency.

b)The electronic hardware and software

Digital hardware is used to implement the controller. Due to the high frequency range of this small rotor,the phase losses of the electronic components are quite important(fig.1B).At 1 714 Hz they consist of the following components.

-The time delay is one period of the sampling rate,i.e. it is 96μs,which corresponds to 59°.Within this time the A/D conversion as well as the signal processing takes place.

-The zero order hold behaviour[6]of the digital controller with a sampling rate of 10 400 Hz adds another 30°.

-The amplifier i.e.the current controller has more than 45°.

Each magnetic bearing has a negative stiffness of about 53 000 N/m.The motor also has a negative stiffness in the same order of magnitude.Hence the stiffness of the bearings created by the controller should be at least around 2~3×105N/m to safely compensate these negative stiffnesses.

c)Design of the controller

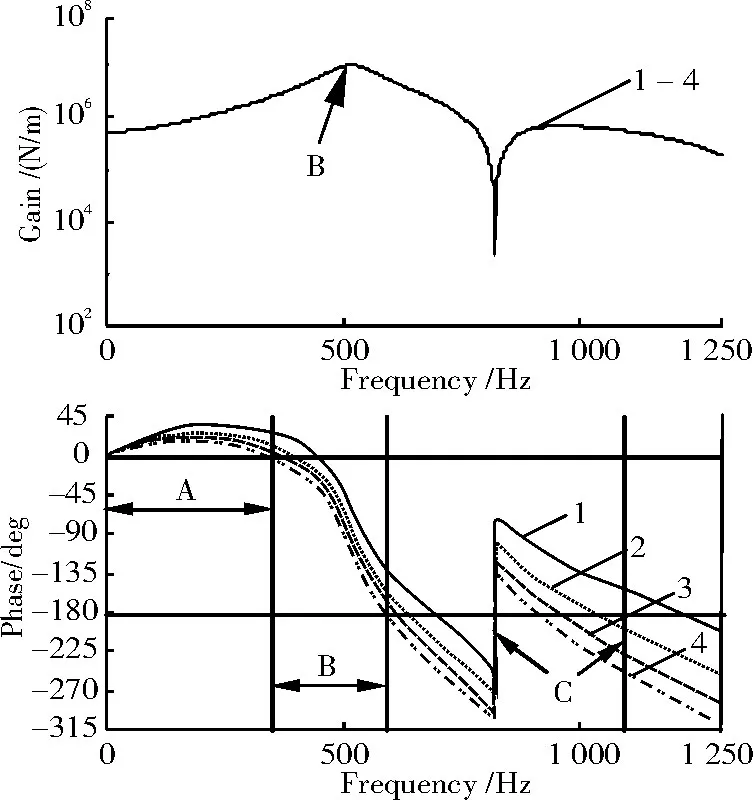

Due to the above mentioned phase losses it is impossible to damp the first bending mode with a phase angle above 0°.This could only be achieved by a phase angle below-180°.The transfer function of the bearings is shown in fig.1.Both bearings have the same function.The figure contains several curves,which demonstrate the influence of various effects.

Fig.1 Bearing transfer function of the high speed rotor

1)Controller with its analogue transfer function digitally transformed by the“first order hold”(foh[6]) method.This is programmed method in the processor.The foh method gives a good approximation to the analogue transfer function.The amplifier characteristic is also included and foh transformed as well.The curve is composed of the following elements:

-A modified PID element to damp the rigid body modes by phase lead(A).

-A second order filter at 1 100 Hz to lower the phase angle to-180°in order to damp the first bending mode at 1 714 Hz(C).

-A second order filter at 2 200 Hz approximating the amplifier.

2)The controller and amplifier in their analogue form including an analogue antialiasing filter of first order at the frequency of 5 200 Hz.This filter has almost no influence in the frequency range up to 2000 Hz.

3)The analogue form of the controller,amplifier and antialiasing filter plus the time delay of 96 μs,which lowers the phase angle significantly(curve 2).

4)Curve 3 digitally transformed by the“zero order hold”(zoh[6])method.The transfer function including the zoh behaviour gives an additional phase loss.

Curve 2 to 4,which are only plotted for the purposes of designing the controller,show the phase losses(fig.1B). The actual closed loop model is built by the digital bearing transfer function,which is transformed by first order hold (thick solid curve 1)and the zoh transformed model of the rotor with the analogue antialiasing filter switched in series.

2.2 Rotor 2:Industrial turbo molecular pump (TMP)

The second rotor is an industrial turbo molecular pump.It runs at a maximum speed of 36 000 rpm.

2.2.1 Basic behaviour of the rotor(table 2)

Because the disks with blades are large,the ratio of the polar moment of inertia to the transverse moment of inertia is quite high(table 1).Therefore the gyroscopic effect is quite extreme,as can be seen in fig.2.The forward tiltingmodefrequencyriseswiththespeedfrom0to250Hz.

Beside the rotor modes,blade modes between 600 and 800 Hz play a role,although they are not coupled with rotor modes to a high extent.However,in the testing phase they turned out,thus they had to be considered in the controller design.In the theoretical model they are assumed as rigid.

Thefirstelasticrotormodeisatafrequencyof1200Hz.

Fig.2 Natural frequencies of the modes vs.speed for the free and supported rotor

2.2.2 The electronic hardware and software

Also in this application the phase losses of the electronic components i.e.the amplifier,the antialiasing filter of second order at 4 450 Hz,the 64 μs time delay and the digital controller sampling rate at 8 900 Hz cannot be neglected.

The magnetic pull of the bearing in this case is 2.4 105N/m for the upper bearing(left in table 2)and 3.0 105N/m for the lower bearing(right in table 2)

2.2.3 Design of the controller

The transfer function of the bearings is shown in fig.3 in the same way as in fig.1.The basic design ideas are:

a)The range with positive phase is enlarged up to 330 Hz,in order to damp the widely spread tilting modes. This is done with a phase lead part of a PID element at 170 Hz.

Tab.2 Rotor models,mode shapes and natural frequencies

Mode shapes(at standstill)and natural frequencies of the free rotors(Hz)

b)In order to provide damping at the frequency of the blademodesthephasehastobedropped rapidly below-180°.This is achieved by a second order element in the denominator(phase lag element in the"base" function in the appendix),which has a frequency of 520 Hz. This has also the effect of reducing the amplitude.

c)In order to provide damping for the rotor mode at 1 200Hzinthefastphaseloss,whichwoulddropevenbelow-360°due to interrupted by a notch filter at 820 Hz.

2.3 Rotor 3:Large industrial centrifugal compressor

Fig.3 Bearing transfer function of the TMP

The third rotor is a large industrial multi-stage centrifugal compressor[8].It is driven by a 23 MWvariable speed synchronous electric motor,with a wide operating speed range from 600 rpm to 6 300 rpm.

2.3.1 Basic behaviour of the rotor(table 2)

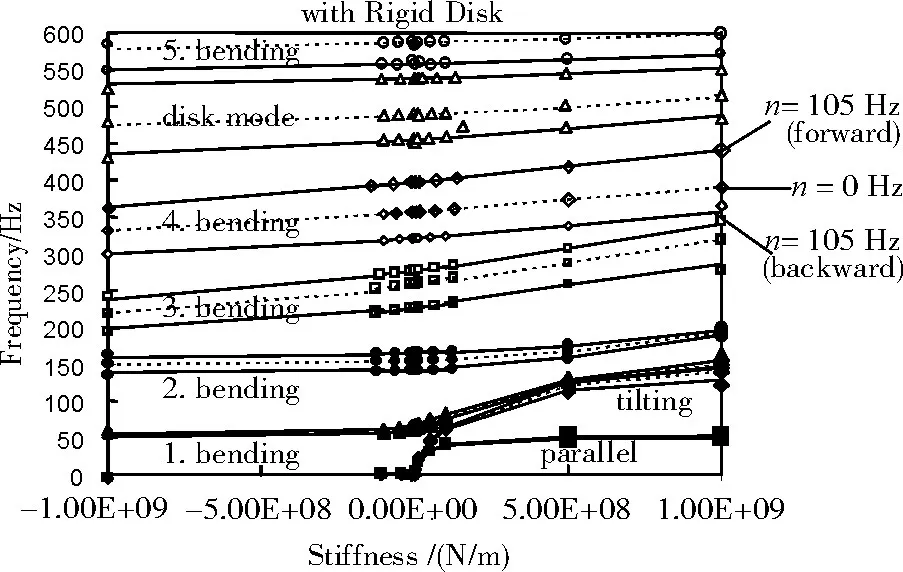

The rotor is exposed to considerable fluid forces at low frequencies.The first bending mode is at 64 Hz. Hence it is in the operating speed range and requires special attention.The frequency of the one nodal diameter vibration mode of the axial bearing disk is at 490 Hz.It had to be considered in the model for the controller design,since it strongly interacts with rotor modes.In the second and higher bending modes the flexible disk tilts more than a rigid disk would(see the mode shapes in table 2 in the appendix).It has the effect of considerably increasing the gyroscopic effect.In fig.4 and 5,the natural frequencies are presented as a function of the bearing stiffness at different speeds for a rigid and a flexible disk.The comparison of results shows that the frequency difference between forward and backward whirl as well as the frequency regions where the bearing has to provide damping increase considerably in case of the flexible disk.

Fig.4 Natural frequencies of the modes vs.bearing stiffness and speed(rigid fixed disk)

Fig.5 Natural frequencies of the modes vs.bearing stiffness and speed(flexible fixed disk)

2.3.2 The electronic hardware and software

As in the previous cases,the controller is implemented on a digital system with a sampling rate of 10 000 Hz.The phase losses due to the digitalisation and the hardware are considered,however,in this case they are not as important as in the previous cases,due to the lower frequencies.

The magnetic pull of the actuator,which has to be compensated by the controller,has a value of 1.57 107N/m.

2.3.3 Design of the controller

Figure 6 shows the magnetic bearing transfer function including the sensor,the antialiasing filter,the controller, the amplifier,the actuator and the time delay.

Fig.6 Bearing transfer function of the large industrial centrifugal compressor

Important features of the controller are:

1)To resist the high fluid forces at low frequencies the stiffness has to be above a certain limit.

2)In order to damp the rigid body modes,which are mostly affected by the destabilising labyrinth seal forces, the phase is increased by an extra filter at 18 Hz.

3) To preventsaturation ofthe amplifierthe amplitudes at high frequencies are reduced with a second order low pass filter.The phase decreases to below 0°, which generates a negative damping force for the second bending mode.However,this mode has a node slightly inside the outboard sensor.The deflections at the sensor and the actuator have reverse sign and thus the mode is slightly damped.Athigherfrequenciesthe bearing providesa dampingforcedue to the phaseangle below-180°.

The overallcontroller transfer function is an eighteenth order polynomial.It is designed by the bearing manufacturer using its own controller design software.To fully optimise the controller for this application the transfer function is synthesised with complex rather than simple poles and zeros.Digital controller hardware is essential to the implementation of this type of controller transfer function.

3 Closed Loop Behaviour

When a controller is designed,considering the basic rotor behaviour and the application requirements,the actual behaviour of the combined system should be studied. The comparison between analysis and measurements can bring up possible benefits to the model.It usually helps to complete the model and thus improves iteratively the accuracy of prediction to the behaviour of the final closed loop system.The degree of agreement between reality and prediction depends mainly on the complexity of the rotor.A fine tuning after implementation of the controller may be necessary.

In the following sections the calculation of closed loop behaviour and the experimental verification of the analysis are presented for the three rotors.

Firstly,the calculated eigenvalues composed of the natural frequency(+forward,-backward whirling)and the damping ratio of the combined rotor bearing system at standstill and nominal speed which are listed for each case. The tables(3~5)contain the eigenvalues,which can be assigned to the rotor.Besides that some eigenvalues are caused by controller poles,which interact with the rotor. This interaction can change their frequency and damping ratio.The eigenvalues caused by the controller with a damping ratio below 20%are also shown in the tables.

Secondly,examples of the calculated and measured responses to force or unbalance excitation are given.

3.1 Rotor 1:High speed rotor

The table 3 show that the rigid modes are well damped.The first forward whirling bending mode at high speed has a damping ratio of only 2.5%.It has to be improved,among others by a higher gain.The higher amplitude can only be realised with a balance compensation system as the tests showed.At this moment such a system is being optimised.A speed of 1 600 Hz has been reached.

The closed loop behaviour at standstill is confirmed by comparison ofcalculated and measured transfer functions with an excitation by the bearing.Figure 7 shows the response at the left sensor location to an excitation of 1 N at the left bearing.The resonance of the rotor's first bending at 1 709 Hz as well as the frequency of the anti resonance agree well.

The damping of the bending mode approximatelyequal to 6%is higher in the measurement.Possible reasons for this are the inner damping of the rotor and the external damping of the surrounding air.

Tab.3 Natural frequencies and damping ratios

Fig.7 Measured and calculated responses at standstill

3.2 Rotor 2:small industrial turbo molecular pump

The modes within the speed range shown in table 4 are well damped.The higher modes are stable with low damping ratios.

For this rotor the behaviour is confirmed by a comparison of a calculated and measured transfer function.

Figure 8 shows a good agreement of the responses at the left sensor located at the left bearing,which is under an excitation of 1N.

The resonances of the tilting mode as well as of theparallel mode are well visible. In addition, the measurement at 300 Hz shows the influence of the unbalance,which is not included in the load case of the calculation.In the region of 700 to 800 Hz the calculated curve deviates from the measured curve.This is probably due to elastic blade modes,which are not considered in the model.

Tab.4 Natural frequencies and damping ratios

Fig.8 Measured and calculated responses at 300 cps

3.3 Rotor 3: Large industrialcentrifugal compressor

In table 5 all damping ratios of the modes below the maximum speed are very well damped.The first bending mode,which is within the operating speed range,has a damping ratio of 20%.This complies with the specification according to API 617 for compressors,although its application to compressors supported on magnetic bearings is controversial.

Tab.5 Natural frequencies and damping ratios

Figure 9 shows the calculated and measured bearing response of the right bearing to an unbalance magnitude of G2,i.e.3 300 gmm are applied at the thrust disk and 2700 gmm at the coupling.This distribution generates a good excitation for the first bending mode.The maximum force below the maximum speed of 6 300 rpm remains below the dynamic capacity of 20 000 N peak-peak.

The agreement between measurement and calculation is good.The calculated force at higher speeds,where the compressor never runs,increases due to the controller dominated pole at 130 Hz,which has a relatively low damping.Also the measured force remains at a high level up to maximum speed for the same reason.

Fig.9 DE Bearing Response to an Unbalance G2(peakpeak amplitude)

4 Conclusions

Efficiency and predictability for handling rotors on magnetic bearings is achieved by using a modern design tool.The typical design procedure is presented.Its main steps are as below.

The study of the mechanical part i.e.modelling the rotor structure and investigate it's basic behaviour.

The study of the mechatronic part i.e.defining the requirements or determining the properties of the electronic hardware and software.

The design of the controller i.e.generating the bearing transfer function considering the gain as well as the phase. The study and interpretation of the closed loop behaviour. This procedure is iterative and needs engineering practice. Therefore the paper presents three applications.

A very small high speed spindle running at a maximum speed of 120 000 rpm,which is above the natural frequency of the free rotor's first bending mode at 1 714 Hz. Because of this high speed,the phase losses due to the electronic components and the losses due to the digitizing process are extremely important.

A small,industrialturbomolecularpump rotor running at a maximum speed of 36 000 rpm.Due to its shape this rotor has a pronounced gyroscopic effect.For this reason the frequency range between the forward and backward tilting mode is widely spread from 0 to 320 Hz. Above that,elastic blade modes in the region of 600 to 800 Hz had to be considered for the controller design.

A large industrial multi-stage centrifugal compressor with an operating speed range from 600 rpm to 6 300rpm.

This rotor is subject to high fluid forces at low frequency,has its first bending mode within the operating speed and has a flexible axial bearing disk,which strongly interacts with the rotor modes and which played an important role for the controller design.

The result of the design process is the transfer function of the bearing controller and the prediction of the closed loop behaviour.The extent of predictability depends on the complexity of the rotor and how it can be modelled accurately.The accuracy also depends on tolerances,which play an important role,especially in case of the small rotors.However,a model always helps to accelerate and improve the design,even for cases where the theoretical model is not a complete representation of the reality.In some cases,the final implementation of the controller may require a fine tuning.

For the three presented rotors,the comparison of calculation and measurement has been carried out.The result can be summarised as follows:

For the high speed spindle the measured performance of the bearing is better than predicted.The higher damping ratio of the first bending mode is probably due to damping effects,which are not part of the model.

For the turbomolecular pump,good agreement is achieved apart from elastic blade modes,which are not considered.It is rigidly modelled,since it does not seem to interact with the rotor.In this regard the model turned out to be insufficient.

For the industrial turbocompressor the theoretical prediction is very good,after the elasticity of the axial bearing disk has been taken into account.

[1]J.Schmied,F.Betschon.Engineering for Rotors Supported on Magnetic Bearings[C].Proceedings of the 6thInternational Symposium on Magnetic Bearings,Boston,1998.

[2]E.Maslen et al.Practical Limits to the Performance of Magnetic Bearings:Peak Force,Slew Rate,and Displacement Sensitivity[J]. ASME Journal of Tribology,1989. [3]Industrial Conference and Exhibition on Magnetic Bearings[M]. University of Virginia,Technomic,Lancaster,PA,1997.

[4]J.W.Lund.Stability and Damped Critical Speeds of a Flexible Rotor in Fluid-Film Bearings[J].Journal of Engineering for Industry,1974.

[5]H.D.Klement.Berechnung der Eigenfrequenz und Stabilit t von Rotoren mit MADYN.VDI Bericht Nr.1082,1993.

[6]H.D.Nelson,J.M.Vaugh.The Dynamics of Rotor-Bearing Systems Using Finite Elements[J].of Engineering for Industry,1976.

[7]K.A.Schoeneck,J.F.Hustak.Comparison of Analytical and Field Experience for a Centrifugal Compressor Using Active Magnetic Bearings[C].IMechE C104/87,1987.

[8]J.Schmied,A.B.M.Nijhuis,R.R.Shultz.Rotordynamic Design Considerations for the 23MW NAM-GLT Compressor with Magnetic Bearings[C].IMechE Fluid Machinery Symposium,The Hague,1999.

[9]G.F.Franklin,J.D.Powell,M.L.Workman.Digital Control of Dynamic Systems[M].Second Edition,Addison-Wesley Publishing Company,Inc.,New York,1994.

Design of Magnetic Bearing Controller Using Madyn 2000

Chuan-yue Zhou1Joachim Schmied2

(1.Beijing EMAX Technology Co.,Ltd;2.DELTA JS AG,8005 Zurich,Switzerland)

The industrial applications of magnetic bearing are rapidly increasing due to their unique properties.In nowadays,the efficiency and the predictability of handling rotors on magnetic bearings are required to meet the same standards level as ones of handling conventional rotors on oil or roller bearings.It is important for system designers to understand the special technical properties of magnetic bearing.The requirements of the magnetic bearing characteristic are defined by both the dynamic behaviour of the rotor and the needs of the working environment.With the modern mechanical analysis tools,together with the electronic controllers and their digital implementation on a DSP,these properties can be well designed.This paper summarises the controller design process of magnetic bearing.Three different rotors supported by magnetic bearing in different products are presented.A very small high speed spindle at 120 000r/min,a small industrial turbo molecular pump rotor rotating at 36 000r/min and a large multi-stage centrifugal compressor operating 600~6 300r/min. The results of the analyses and experimental verification are presented and discussed in this paper.

magnetic bearing,controller,spindle,turbo molecular pump,large multi-stage centrifugal compressor,rotor dynamics,Madyn 2000

TH133.3;TK05

1006-8155-(2017)04-0051-10

A

10.16492/j.fjjs.2017.04.0009

2017-04-12 北京 100022