Drying Characteristics of Intermittent Microwave Coupled with Air Drying of Chinese Radish (Raphanus sativus L.) Slices

PENG Yu, ZHAO Dandan, LI Mo, WEN Xin, NI Yuanying,*

(1. National Engineering and Technology Research Centre for Fruits and Vegetable Processing, College of Food Science and Nutritional Engineering, China Agricultural University, Beijing 100083, China; 2. College of Bioscience and Bioengineering, Hebei University of Science and Technology, Shijiazhuang 050018, China)

Drying Characteristics of Intermittent Microwave Coupled with Air Drying of Chinese Radish (Raphanus sativus L.) Slices

PENG Yu1, ZHAO Dandan2, LI Mo1, WEN Xin1, NI Yuanying1,*

(1. National Engineering and Technology Research Centre for Fruits and Vegetable Processing, College of Food Science and Nutritional Engineering, China Agricultural University, Beijing 100083, China; 2. College of Bioscience and Bioengineering, Hebei University of Science and Technology, Shijiazhuang 050018, China)

The effectiveness of various microwave-convective drying treatments (pulse ratio and air) on the drying characteristics and quality of white radish slices was studied. The moisture ratio, drying rate, effective diffusivity (Deff), and activation energy (Ea) were assessed, and the internal temperature of samples during the drying process and fi nal product color were measured. The Deffincreased gradually and then rapidly as moisture content decreased. The Eaof samples increased slightly and then increased rapidly as the moisture content decreased. A logistic model could describe the relationship between Eaand moisture content well. The Eaof samples without air was the highest. Among all the drying treatments, the samples dried with a high pulse ratio (on/off, 5 s/20 s) at a low hot air temperature (30 ℃) exhibited the lowest temperature and the lowest difference between the maximum and minimum temperature of samples and had the most desirable color.

intermittent microwave drying; air drying; activation energy; effective diffusivity; color

PENG Yu, ZHAO Dandan, LI Mo, et al. Drying characteristics of intermittent microwave coupled with air drying of Chinese radish (Raphanus sativus L.) slices[J]. 食品科学, 2017, 38(17): 85-93. DOI:10.7506/spkx1002-6630-201717015. http://www.spkx.net.cn

PENG Yu, ZHAO Dandan, LI Mo, et al. Drying characteristics of intermittent microwave coupled with air drying of Chinese radish (Raphanus sativus L.) slices[J]. Food Science, 2017, 38(17): 85-93. (in English with Chinese abstract) DOI:10.7506/ spkx1002-6630-201717015. http://www.spkx.net.cn

Chinese white radish (Raphanus sativus L.) belongs to the family Brassicaceae, informally known as the mustard family, with an edible, pungent root[1]. It is an important vegetable crop worldwide, especially in China, Japan,Korea, and Southeast Asia due to its wide adaptation, high yield, highly nutritional and medicinal value because of its inhibition effect on hyperlipidemia, coronary heart diseases and cancer[2]. Its roots can be processed into a wide range of fresh, dried, salted, pickled, and fermented products[3].

Drying is a common method used in the processing of the white radish. The traditional preservation of products through drying were based on sun and solar drying techniques, which are affected by daily weather conditions, have a relatively long drying cycle, and for which poor quality, contamination, and energy consumption are of problems[4]. In industrial processing of radish, convective hotair drying is widely used for drying bioproducts, but involves low energy effi ciency, high operating costs, and long drying time due to a low heat and mass transfer rate, causing quality losses regarding nutritional value, color, flavor, shrinkage, and texture[5-7]. Another common method used in food product drying is microwave drying, which has been increasingly used. Due to the internal heat generation pattern, microwave drying improves the dried products quality, increases the dehydration rate and has a relatively high energy effi ciency compared to conventional hot-air drying[8]. It is usually used in the dehydration of food products that have high moisture content[9], and is especially used in the falling-rate drying period due to it being economically advantageous[10]. However, if it is not properly applied, the disadvantages such as high cost[11]and poor quality product (e.g. charred edge, over-oxidation) would hinder the application of microwave drying on a large scale[12-13].

Many studies have aimed to make the application of the microwave in the drying process more effi cient. One way is to apply intermittent or pulsed microwave instead of continuous microwave, which can avoid uneven heating and improve product quality as well as energy utilization by allowing redistribution of temperature and moisture profiles within the product during off times due to thermal diffusion[14]. During the intermittent microwave drying process, the tempering period allows time for the internal moisture to diffuse to equalize moisture and temperature gradients during the resting period when no heat is supplied or a reduced level of heat is provided. Intermittent microwave drying has been successfully used for food products such as grain kernel[15], potato pieces[16], and carrot[9,17]. Another method is to combine the microwave with other drying techniques such as convective hot-air, vacuum, and freeze drying[18-19]. It has been reported that microwave-aided convective hot-air drying was used in the drying process of food products high in moisture content such as cherry tomato[20], okra[21], banana[22], sage leaves[23], potato[24], carrot[25], apple[26], mushroom[26-28], garlic[29], cranberries[30-31]and pumpkin[5], improving the quality of the dried products and the energy utilization.

In our previous study[17], intermittent microwave coupled with hot-air (60 ℃) drying was used in the drying of carrot slices. The shortest drying time, which had relatively low energy consumption, provided the best quality of fi nal product with best color appearance, highest rehydration rate, and α- and β-carotene contents as compared with other four drying methods (hot-air drying, continuous microwave drying, microwave after hot-air drying, and hot-air after microwave drying). To study further the effect of intermittent microwave-coupled air drying on the drying characteristics, the white radish was selected for this study due to its tissue uniformity and high moisture. The aim is to determin the effect of different intermittent pulse ratios and the air conditions, i.e. with or without air, and high or low temperature, on drying characteristics, including drying r ate, effective diffusivity, activation energy, internal product temperature, and color of the dried product.

1 Materials and Methods

1.1 Plant materials

Fresh white radish (Raphanus sativus L.) was purchased in a local supermarket. All of the test radishes were free of disease, had a similar shape and approximate size (length (350 ± 10) mm, diameter (80 ± 5) mm), and were stored at 4 ℃ and a relative humidity (RH) of 95%. The initial moisture content of the radishes was (17.23 ± 0.01) g H2O/g dry mass. A sharp cylindrical mould was used to cut the radishes into circular slices with a diameter of 68 mm and thickness of 10 mm prior to drying.

1.2 Drying apparatus

Fig. 1 The diagram of the intermittent microwave drying equipment

Fig. 1 shows the intermittent microwave drying apparatus which consists of a laboratory microwave oven with cavity dimension of 350 mm × 350 mm × 240 mm (NJL07-3, Nanjing Jiequan Electric Instrument Co., Nanjing, China) with an output of 700 W at 2 450 MHz, a control unit to adjust microwave pulse ratio (PR), and an air-heating unit to regulate the temperature of air, as well as an autom atic weighing system. The air can be controlled to be on or off, and the speed of airflow was (5.0 ± 0.2) m/s, which was measured by anemoscope (GM8903, Biaozhi Electric Instrument Co., Shenzhen, China) at the air intake of the microwave oven. The PR was calculated using the following equation[14].

1.3 Methods

1.3.1 Drying procedure

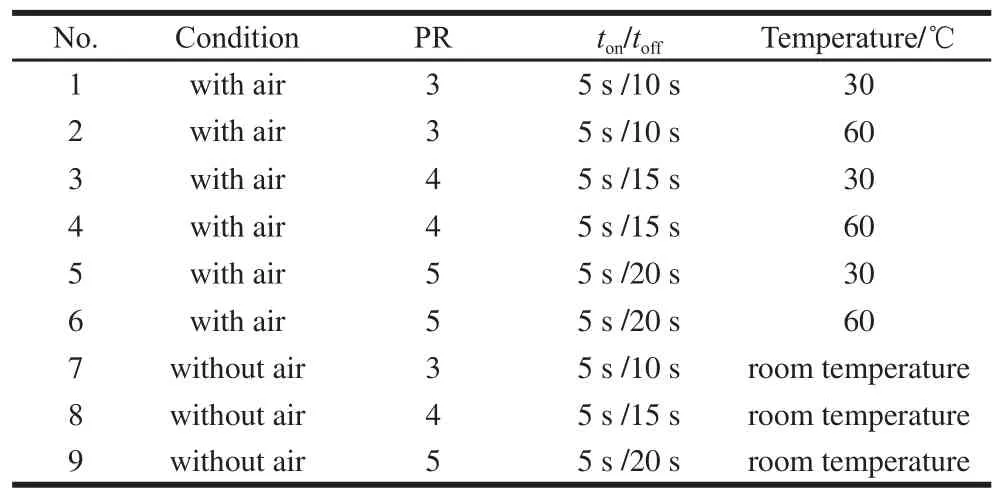

Fresh radish slices, weighing 300 g each, were weighed and spread evenly on a plastic tray and dried by nine different methods as follows (Table 1).

Table 1 Experiment parameter of nine metheods

Meanwhile, the apparatus was set to record the sample weight every 0.1 second. The data was sampled at every five-minute interval from the record for the data processing step. The drying process was stopped when the moisture content reached 0.1 (db). Each experiment was done in triplicate.

1.3.2 Drying rate, effective diffusivity (Deff) and activation energy (Ea) measure

During the drying process, moisture ratio (MR), drying rate, effective diffusivity (Deff, the reciprocal of the required time for a certain amount of water going through the unit evaporation area of material), and activation energy (Ea, the energy needed to evaporate moisture per gram of product) were determined as follows:

where M0is initial moisture content/%; Mtis the moisture content at time of measurement t/%; Meis equilibrium moisture content/%. For microwave drying, it can be assumed that Me= 0.

where Mt(%db) and Mt+dt(%db) are the moisture content at measuring time t and t+dt, respectively.

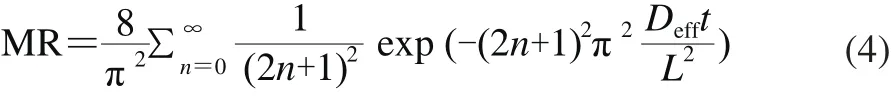

The Deffwas estimated by Fick’s diffusion model. Equation (4) is applicable for flaky product[18]. According to our previous findings when calculating the Deffof carrot slices[17]and Chinese jujube[19]dried by microwave drying, the variation trend of Deffin both shrinkage and nonshrinkage was similar to each other, and the Deffof samples was calculated considering that the shrinkage was lower than that calculated without considering shrinkage for the same drying process. In this study, the Deffwas calculated assuming no shrinkage.

where L is the thickness of the sample/m. To avoid the large truncation error of Eq. (4)[20], a trail-and-error method was used in this study by setting n = 109. The principle is: the calculated MR is derived from the right side of Eq. (4) by assuming a Deff, and if the relative percentage error between the calculated MR and the experimental MR is small enough, e.g., less than 0.003%, the assumed Deffis the real Deff, otherwise, an adjusted Deff(which is enlarged or diminished) is used to calculate another calculated MR until the relative percentage error is small enough.

The Eaof samples for microwave drying was calculated with an Arrhenius-type equation expressed as equation (5) as follows[21]:

where D0is the Arrhenius factor/(m2/s); Eais the activation energy for moisture diffusion/(J/mol or W/g); miis the mass of samples at the ithsampling time/g; P is the microwave power/W.

The dependence between moisture content, M, and activation energy Ea, were described by logistic function as equation (6) as follows:

1.3.3 Temperature measurement measure

A fluorescence fiber-optic temperature sensor (FOTS-DINA-2050, Beijing, China), with a probe diameter of 2 mm, was used to measure the internal temperature of the white radish slices. Before drying, the probe was inserted into the side of the sample at the midpoint of the thickness and the diameter.

1.3.4 Color measure

As the surface of dried samples are rough, the color is difficult to measure, and the difference in moisture content between the fresh and dried samples leads to a large difference in the value of brightness (L*) resulting in no reference value of total color difference (ΔE*). To avoid the influ ence of moisture on the color measurement, the dried samples were rehydrated to reach the same moisture content as that of the fresh samples. Then, the rehydrated samples were smashed into slurry for uniformity. A Hunter Lab-scan colorimeter (MS/S-4500L, Hunter Associates Laboratory Inc., Reston, VA, USA) was used to determine the color value according to [22]. The total color difference (ΔE*) was determined by using the following equation:

where L*, a*, and b* are the current coordinates and L0*, a0*, and b0* are the initial coordinates.

1.4 Statistical analysis

The experimental results were expressed as ±s. Statistical analysis was performed using the software SAS 8.0 and OriginPro 8.0. Tukey’s mul tiple range test was used to evaluate the signifi cant difference between the means at a 95% signifi cance level.

2 Results and Analyses

2.1 Drying kinetics

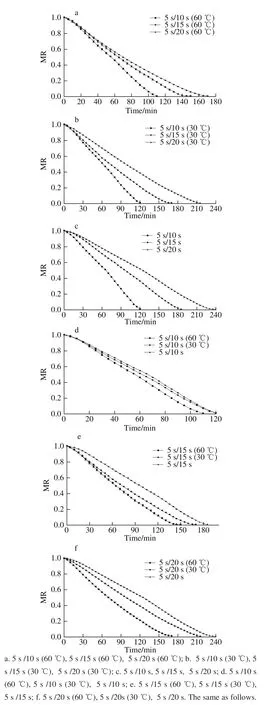

The drying time required to reach final moisture content was in the range of 110-240 min depending on the PR and drying air temperature (Fig. 2). Under the same air conditions, the drying time of samples signifi cantly increased as the PR decreased (Fig. 2a, b, c). With the same heating PR, samples dried by intermittent microwave drying with air need less time to reach fi nal moisture content than those dried by intermittent microwave drying without air, and the higher temperature, the less the drying time (Fig. 2d, e, f). In addition, as the PR increased, the effect of air conditions on the drying time increased because of the increase of off time, during which the air condition is the leading factor of moisture loss. This observation was similar to the result of previous research[6].

Fig. 2 Variation of moisture ratio (MR) with drying time of white radish slice during intermittent microwave drying coupled with or without air

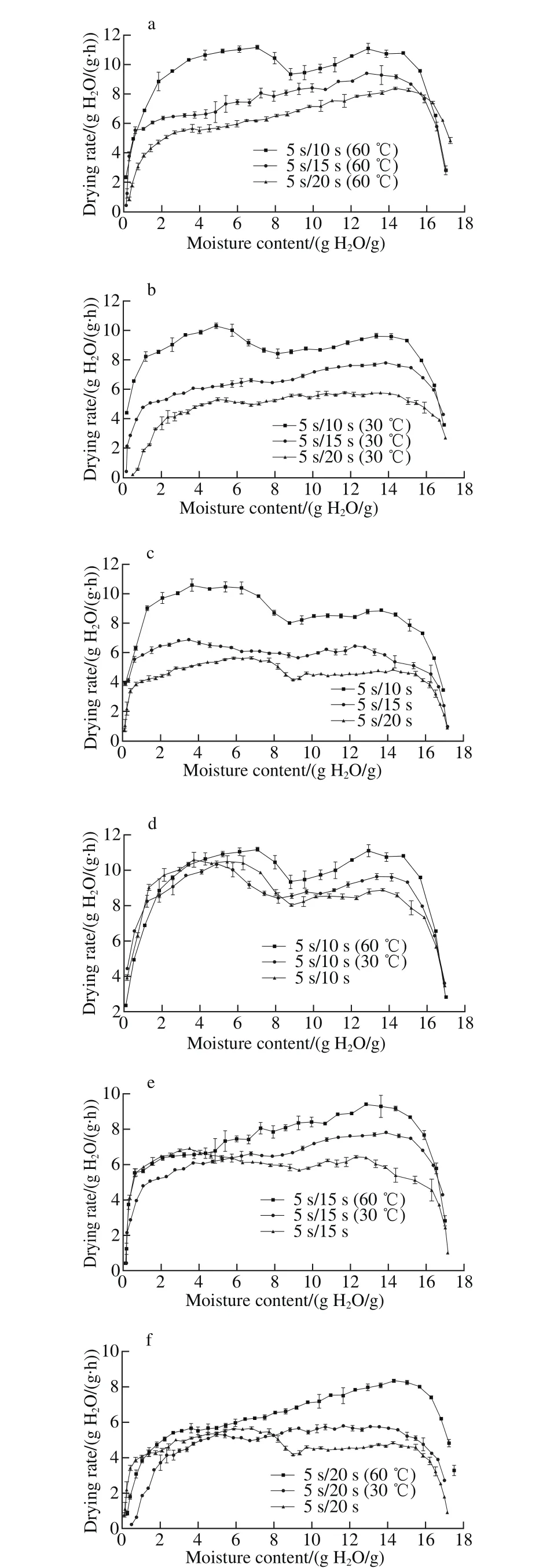

Fig. 3 Variation of drying rate with moisture content of the radish slice during intermittent microwave drying coupled with or without air

The drying rate was calculated at different times and plotted against moisture content as shown in Fig. 3. It was seen that under the same air conditions, decreasing PR increased the drying rate. For the samples dried under low PR (ton/toff, 5 s/10 s), with air or without air, as well as the samples dried by intermittent microwave without air (Fig. 3c, d), the drying rate increased at fi rst (a warm-up period), and then decreased at the end (a falli ng-rate period) after reaching a high-speed drying period. The second drying period can be divided into two stages: a constant drying period (above 8.0 g H2O/g) and a high-speed drying period (1.0-8.0 g H2O/g). This may be that, at low PR, the condition of the air has little effect of the drying characteristics of the samples, and at the beginning, the surface of the samples contained enough moisture, and moisture inside could transferred to the surface in time. The moisture transfer rate inside was equal to its evaporation rate on the surface, resulting in a constant drying rate. With the decreasing moisture content and the high internal pressure owing to the internal heating mechanism, forming a porous structure, the moisture directly evaporated in situ, leading to a high-speed drying rate. When samples reached a certain moisture content, the movement of water was mostly in a symplastic transport way and the dehydration rate was low.

For the samples dried under the condition of 5 s/15 s (60 ℃), 5 s/20 s (60 ℃), and 5 s/15 s (30 ℃), the drying rate showed a warm-up period followed by a falling-rate period, which agreed with the report that the intermittent microwave with air drying of carrot slices[17]and strawberry[32]. The air increased the evaporation of moisture at the surface, and the moisture inside transferred slowly, while the product surface dried out quickly, leading to the generation of a barrier layer preventing free movement of moisture, resulting in a fast decrease in drying rate. As the moisture content decreased, the difference in the partial pressure of water between the outside and the inside made the moisture inside transfer quickly, leading to a relative slowdown in the drying rate.

The samples dried under the condition of 5 s/20 s (30 ℃) showed a constant and high speed drying period. This was because during the early drying periods, moisture content was greater in white radish, and the movement of water was mostly by transmembrane transport and the cell wall pathway, leading to a high drying rate[17]. Besides, the relatively lowtemperature air and long microwave off time attributed to the balance of moisture and temperature distribution, resulting in a long constant drying period.

2.2 Effective diffusivity (Deff)

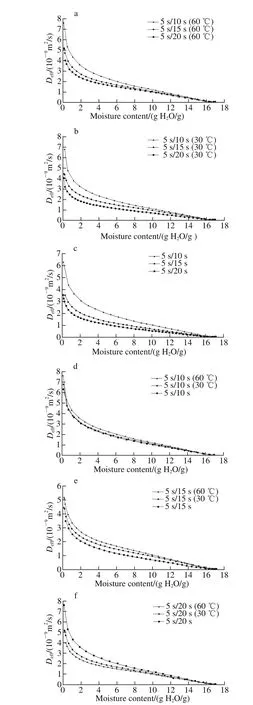

Fig. 4 Variation of effective diffusivity with moisture content of white radish slice during intermittent microwave drying coupled with or without air

It can be seen from Fig. 4 that the Deffincreased as the moisture content decreased during the nine different drying processes and showed a rapid increase when the moisture content was below approximately 1.0 (db); this phenomenon had been reported by others[33-35]. This was because the reciprocal of Deffindicates the required time for a certain amount of water going through the unit evaporation area of material.

Microwave drying is based on the dielectric loss, where water absorbs most of the energy released by the electromagnetic fi eld. The high moisture content and internal heat generation of samples caused a high internal vapour pressure, which made the pore structure remain open and the microstructure of the product to be partly ruined. In addition, a great decrease in the moisture content at the end of the drying period also caused a capillary contraction and an increase in surface tension, resulting in an increase in the specific surface area of the unit evaporation zone and thus rapid increase in the Deff.

2.3 Internal temperature

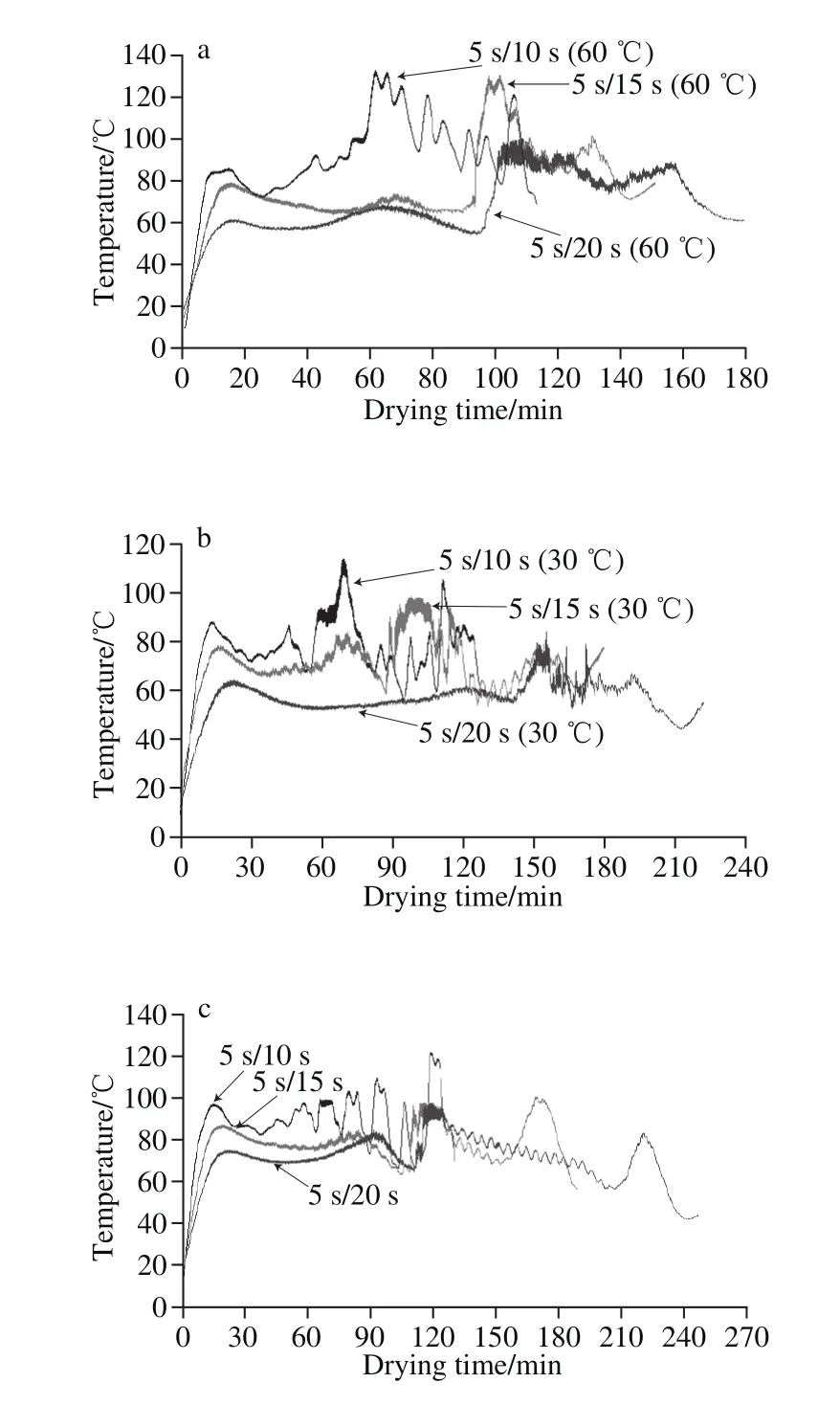

Fig. 5 Variation of internal temperature of white radish slice with drying time during intermittent microwave drying coupled with or without air

Fig. 5 presents the internal temperature profiles of samples during the nine drying processes. The temperature increased at first, then reached a plateau, followed an increase period, and decreased at the end. This pattern is attributed to that at the beginning, the samples started to absorb microwaves, leading to an increase of temperature. With the evaporation of moisture content on the surface of the samples, forming moisture and temperature gradients, the heat absorbed from the microwaves was equal to the heat conduction and evaporation, resulting in a constant temperature period. With the decrease of moisture content and the formation of pore structure, the moisture largely evaporated locally inside, leading to a high vapour pressure, which made the temperature increase. When samples reach a certain moisture content, all the free water had been removed, and the heat absorbed from the microwaves decreased, which made the temperature decrease.

Under the same air conditions, the lower the PR, the higher the internal temperature (Fig. 5a, b, c). For the samples dried at low PR (ton/toff, 5 s/10 s), the air conditions had little effect on the internal temperature (Fig. 5d). It can be seen from Fig. 5e, for the samples dried at medium PR (ton/toff, 5 s/15 s), the temperature of samples dried with low temperature air (30 ℃) and without air were lower than those dried with high temperature air (60 ℃). For samples dried at high PR (ton/toff, 5 s/20 s) with low temperature (30 ℃), the temperature and the difference of the maximum and minimum temperature of samples was the lowest, and the highest was the samples dried without air (Fig. 5f). This showed that long off time and low air temperature had contributed to the balance of temperature distribution.

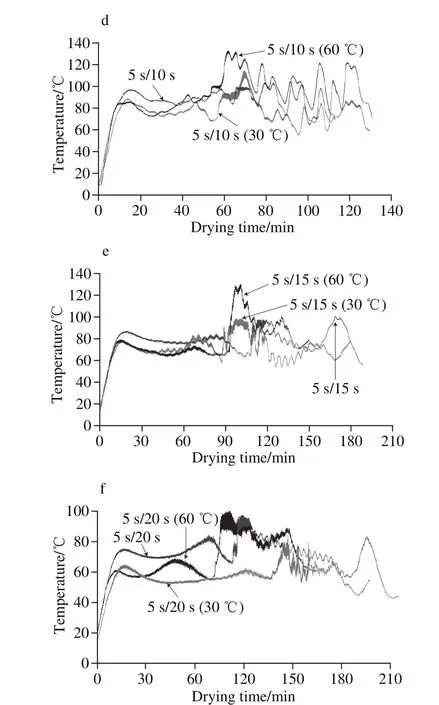

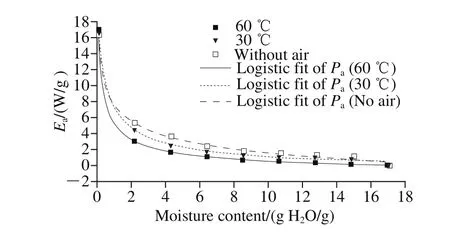

2.4 Activation energy (Ea)

The relationship of ac tivation energy and moisture content of samples during the nine drying process was obtained from the slopes of straight lines given by the natural logarithm diffusivity, ln (Deff,i), vs. reciprocal of microwave output power (1/P) at various levels of mass, mi, in Eq. (5). The coefficients of determination, R2, of all regression equations ranged from 0.944 59 to 0.999 9, and the standard deviation, σ, ranged from 0.002 73 to 0.036 99, suggesting a good linearity between ln (Deff,i) and 1/P, which meant that an Arrhenius-type equation, Eq. (5), can well describe the relationships between effective diffusivity and activation energy.

Besides, logistic function dependence between moisture content, M, and activation energy Ea, could be employed to describe the data in Fig. 6 as follows:

For samples dried with 60 ℃ air:

(R2= 0.996 37, 0.1 ≤ M ≤ 16.77)

A logistic model could describe the relationships between activation energy and moisture content fairly well, which was in agreement with a previous study[33-36].

Activation energy can express how easily or difficult the moisture transfers outward from the inside of products under a certain air condition. The Eaof samples dried without air was the highest, and the second highest was the samplesdried with low temperature air (30 ℃) under the same moisture content, showing that air had contributed to the evaporation of moisture content. Besides, the Eaof samples increased slightly and then increased rapidly as the moisture content decreased (Fig. 6). Similar results were obtained for daily flower buds and chilli flesh by Ding Shenghua[33], Zhao Dandan[35]and Zhao Dandan[17]et al. It was ascribed to the fact that a majority of free wa ter transport has been implicated in loss of moisture initially, which was relatively easy to remove from the porous materials, thus a low and almost a constant power density was needed. However, as the moisture content decreased, the bound water star ted to pose an important influence on diminishing of moisture, and the less the bound water content in the material remained, the higher the Eais needed[37].

Fig. 6 Variation of activation energy with moisture content of white radish of samples during intermittent microwave drying with or without air

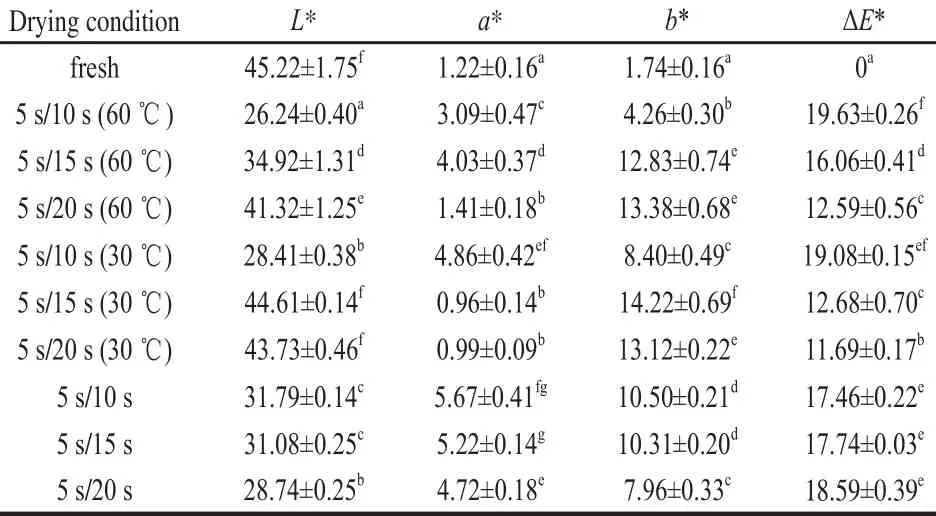

2.5 Color

Table 2 Color of white radish slice dried by nine different drying methods in required time to reach target moisture content (0.1 g H2O/g)

Color is one of the most important attributes of dried food products since it influences consumer acceptability is related to fi avour and aroma, and dried foods are susceptible to color deterioration[38-40]. The color parameters of dried products are given in Table 2. All the samples after drying had lower values of L*, and higher values of a* and b* than fresh samples. The decrease in values of L* and increase in values of a* were caused by browning reactions[36]. It can be seen that the samples dried by intermittent microwave drying without air had the worst color appearance, whereas the color of samples dried in high PR with air were close to that of fresh samples. Browning reaction is effected by drying temperature, drying time and the uniformity of temperature, samples dried under the condition of 5 s/20 s (30 ℃) had the most desirable color among the samples dried by nine different methods, with the lowest ΔE* and the values of L*, a* and b* close to those of the fresh one, owing to the relatively short drying time as well as the low and uniform temperature of drying.

3 Conclusions

Different drying treatments each had a different effect on the drying rate period, and only the samples dried with a high pulse ratio (ton/toff, 5 s/20 s) at low temperature (30 ℃) exhibited a constant drying rate period. The moisture content of 1.0 (db) corresponded to the moisture content of the inflexion point where the high dehydration rate was transformed into a low dehydration rate in the microwave or in the microwave drying process.

The Deffincreased gradually and then rapidly as moisture content decreased in all drying processes.

The Eaof samples dried increased slightly and then increased rapidly as the moisture content decreased and a logistic model could describe the relationships between Eaand moisture content well. The Eaof samples without air was the highest, followed by the samples dried with low temperature air (30 ℃), then those dried with high temperature (60 ℃) under the same moisture content.

The long power off drying period and low temperature had contributed to the quality of the fi nal dried product. As for samples dried with a high pulse ratio (ton/toff, 5 s/20 s) at low temperature (30 ℃), the internal temperature and the difference of the maximum and minimum internal temperature of samples was the lowest and the color was the most desirable among all the drying treatments.

[1] LAËRTIUS D. The Co lumbia Electronic EncyclopediaTM[M]. New York: The Columbia University Press, 2013: 1.

[2] CURTIS I S. The noble radish: past, present and future[J]. Trends in Plant Science, 2003, 8: 305-307. DOI:10.1016/s1360-1385(03)00127-4.

[3] JUN H L, HUI J K. Vacuum drying kinetics of Asian white radish (Raphanus sativus L.) slices[J]. LWT-Food Science and Technology, 2009, 42(1): 180-186. DOI:10.1016/j.lwt.2008.05.017.

[4] LENART A. Osmo-c onvective drying of fruits and vegetables: technology and application[J]. Drying Technology, 1996, 14(2): 391-413. DOI:10.1080/07373939608917104.

[5] ALIBAS I. Microwave, air and combined microwave-air-drying parameters of pumpkin slice[J]. Food Science and Technology, 2007, 40(8): 1445-1451. DOI:10.1016/j.lwt.2006.09.002.

[6] ARIKAN M F, AYHAN Z, SOYSAL Y, et al. Drying characteristics and quality parameters of microwave dried grated carrots[J]. Food and Bioprocess Technology, 2012, 5(8): 3217-3229. DOI:10.1007/s11947-011-0682-8.

[7] FENG H, YIN Y, TANG J. Microwave drying of food and agricultural materials: basics and heat and mass transfer modeling[J]. Food Engineering Reviews, 2012, 4(2): 89-106. DOI:10.1007/s12393-012-9048-x.

[8] SOYSAL Y, AYHANB Z, ESTÜRK O, et al. Interm ittent microwaveconvective drying of red pepper: drying kinetics, physical (colour and texture) and sensory quality[J]. Biosystems Engineering, 2009, 103(4): 455-463. DOI:10.1016/j.biosystemseng.2009.05.010.

[9] MEHMET F A, ZEHRA A, YURTSEVER S, et al. Drying characteristecs and quality parameters of microwave-dried grated carrots[J]. Food an d Bioprocess Technology, 2012, 5: 3217-3229. DOI:10.1007/s11947-011-0682-8.

[10] MEDENI M. Microwave/air and microwave fi nish drying of banana[J]. Journal of Food Engineering, 2000, 44: 71-78. DOI:10.1016/s0260-8774(99)00167-3.

[11] NIJHUIS H H, TORRINGA H M, MURESAN S, et al. Approaches to improving the quality of dried fruit and vegetables[J]. Trends in Food Science & Technology, 1998, 9(1): 13-20.

[12] DROUZAS A E, SARAVACOS G D. Microwave/vacuum drying of model fruit gels[J]. Journal of Food Engineering, 1999, 39: 117-122.

[13] YONGSAWATDIGUL J, GUNASEKARAN S. Microwave-vacuum drying of cranberries: Part II. quality evaluation[J]. Journal of Food Processing and Preservation, 1996, 20: 145-156. DOI:10.1111/j.1745-4549.1996.tb00851.x.

[14] GUNASEKARAN S. Pulsed microwave-vacuum drying of food materials[J]. Drying Technology, 1999, 17(3): 395-412. DOI:10.1080/07373939908917542.

[15] ZHANG D, MUJ UMDAR A S. Deformation and stress analysis of porous capillary bodies during intermittent volumetric thermal drying[J]. Drying Technology:An International Journal, 1992, 10(2): 421-423. DOI:10.1080/07373939208916444.

[16] SANGA E, MUJUMDAR A S, RAGHAVAN G S V. Experim ental and numerical analysis of intermittent microwave-convection drying[C]//RAMLI E W. Proceedings of asia-australia drying conference. Malaysia: Institution of Chemical Engineers Publication, 2001: 203-215.

[17] ZHAO Dandan, AN Keji ng, DING Shenghua, et al. Two-stage intermittent microwave coupled with hot-air drying of carrot slices: drying kinetics and physical quality[J]. Food and Bioprocess Technology, 2014, 7(8): 2308-2318. DOI:10.1007/s11947-014-1274-1.

[18] DOYMAZ I. Thin-la yer drying of spinach leaves in a convective dryer[J]. Journal of Food Process Engineering, 2009, 32(1): 112-125. DOI:10.1111/j.1745-4530.2007.00205.x.

[19] WANG Yuxin, TAO Hongyan, AN Kejing, et al. Effect of carbonic maceration on infrared drying kinetics and raisin qualities of Red Globe (Vitis vinifera L.): a new pre-treatment technology before drying[J]. Innovative Food Science and Emerging Technologies, 2014, 26: 462-468. DOI:10.1016/j.ifset.2014.09.001.

[20] LI Hui, ZHAO Cuiping, GUO Yunhan, et al. Mass transfer evaluation of ultrasonic osmotic dehydration of cherry tomatoes in sucrose and salt solutions[J]. International Journal of Food Science and Technology, 2012, 47: 954-960. DOI:10.1111/j.1365-2621.2011.02927.x.

[21] DADALI G, APAR D K, OZBEK B. Estimation of effective moisture diffusivity of okra for microwave drying[J]. Drying Technology, 2007, 25(9): 1445-1450. DOI:10.1080/07373930701536767.

[22] ROMANO G, BARANYAI L, GOTTSCHALK K, et al. An approach for monitoring the moisture content changes of drying banana slices with laser light backscattering imaging[J]. Food and Bioprocess Technology, 2008, 1(4): 410-414. DOI:10.1007/s11947-008-0113-7.

[23] ESTÜRK O. Interm ittent and continuous microwave-convective airdrying characteristics of Sage (Salvia offi cinalis) leaves[J]. Food and Bioprocess Technology, 2012, 5(5): 1664-1673. DOI:10.1007/s11947-010-0462-x.

[24] WANG Jun, XIONG Yongsen, YU Yong. Microwav e drying characteristics of potato and the effect of different microwave powers on the dried quality of potato[J]. European Food Research and Technology, 2004, 219(5): 500-506. DOI:10.1007/s00217-004-0979-1.

[25] PRABHANJAN D G, RAMASWAMY H S, RAGHAVAN G S V. Microwav e assisted convective air drying of thin layer carrots[J]. Journal of Food Engineering, 1995, 25(2): 283-293. DOI:10.1016/0260-8774(94)00031-4.

[26] FUNEBO T, OHLSSON T. Microwav e-assisted air dehydration of apple and mushroom[J]. Journal of Food Engineering, 1998, 38(3): 353-367. DOI:10.1016/s0260-8774(98)00131-9.

[27] KHRAISHEH M A M, MCMINN W A M, MAGEE T R A. A multip le regression approach to the combined microwave and air drying process[J]. Journal of Food Engineering, 2000, 43(4): 243-250. DOI:10.1016/s0260-8774(99)00158-2.

[28] TORRINGA E, ESVELD E, SCHEEWE I, et al. Osmotic dehydration as a pre-treatment before combined microwave-hot-air drying of mushrooms[J]. Journal of Food Engineering, 2001, 49(2/3): 185-191. DOI:10.1016/s0260-8774(00)00212-0.

[29] SHARMA G P, PRASAD S. Drying of garlic (Allium sativum) cloves by microwave–hot air combination[J]. Journal of Food Engineering, 2001, 50(2): 99-105. DOI:10.1016/s0260-8774(00)00200-4.

[30] BEAUDRY C, RAGHAVAN G S V, RENNIE T J. Microwave fi nish drying of osmotically dehydrated cranberries[J]. Drying Technology, 2003, 21(9): 1797-1810. DOI:10.1081/drt-120025509.

[31] SUNJKA P S, RENNIE T J, BEAUDRY C, et al. Microwav econvective and microwave-vacuum drying of cranberries: a comparative study[J]. Drying Technology, 2004, 22(5): 1217-1231. DOI:10.1081/drt-120038588.

[32] CHANGRUE V. Hybrid (osmotic, microwave-vacuum) drying of strawberries and carrots[D]. Quebec: Macdonald Campus of McGill University, 2006: 1.

[33] DING Shenghua, YOU Jia, AN Kejing, et al. Effectiv e diffusivities and energy consumption of daylily in microwave drying[J]. International Journal of Food Science and Technology, 2012, 47(12): 2648-2654. DOI:10.1111/j.1365-2621.2012.03147.x.

[34] WANG Zhengfu, FANG Sheuzhegn, HU Xiaosong. Effectiv e diffusivities and energy consumption of whole fruit Chinese jujube (Zizyphus jujube Miller) in microwave drying[J]. Drying Technology: An International Journal, 2009, 27(10): 1097-1104. DOI:10.1080/07373930903221200.

[35] ZHAO Dandan, ZHAO Cuiping, TAO Hongyan, et al. The effe ct of osmosis pre-treatment on hot-air drying and microwave drying characteristics of chilli (Capsicum annuum L.) fi esh[J]. International Journal of Food Science and Technology, 2013, 48: 1589-1595. DOI:10.1111/ijfs.12128.

[36] LIU Lijun, WANG Yuxin, ZHAO Dandan, et al. Effect of carbonic maceration pre-treatment on drying kinetics of chilli (Capsicum annuum L.) fi esh and quality of dried product[J]. Food and Bioprocess Technology, 2014, 7(9): 2516-2527. DOI:10.1007/s11947-014-1253-6.

[37] AVERSA M, CURCIO S, CALABRÒ V, et al. Experime ntal evaluation of quality parameters during drying of carrot samples[J]. Food and Bioprocess Technology, 2012, 5(1): 118-129. DOI:10.1007/s11947-009-0280-1.

[38] MAGDALENA Z, MAREK M. Color characteristics of carrots: effect of drying and rehydration[J]. International Journal of Food Properties, 2012, 15(2): 450-466. DOI:10.1080/10942912.2010.489209.

[39] SETH S, AGRAWAL Y C, GHOSH P K, et al. Effect of moisture content on the quality of soybean oil and meal extracted by isopropyl alcohol and hexane[J]. Food and Bioprocess Technology, 2010, 3(1): 121-127. DOI:10.1007/s11947-008-0058-x.

[40] KOCA N, BURDURLU H S, KARADENIZ F. Kinetics of colour changes in dehydrated carrots[J]. Journal of Food Engineering, 2007, 78(2): 449-455. DOI:10.1016/j.jfoodeng.2005.10.014.

白萝卜间歇微波热风耦合干燥过程干燥特性分析

彭 郁1,赵丹丹2,李 茉1,温 馨1,倪元颖1,*

(1.中国农业大学食品科学与营养工程学院,国家果蔬加工工程技术研究中心,北京 100083;2. 河北科技大学生物科学与工程学院,河北 石家庄 050018)

对比不同的间歇微波功率与热风耦合干燥及间歇微波干燥对白萝卜干燥特性(水分比、有效扩散系数和活化能)、中心与表面温度和颜色的影响。结果表明,有效扩散系数随水分含量的下降先缓慢上升后快速上升,活化能随水分含量的降低先缓慢升高后快速升高,Logistic模型能很好地反映活化能和水分之间的关系,并且单独进行间歇微波干燥的样品的活化能较高。干燥条件设定为间歇比5 s/20 s,热风温度30 ℃的样品其在干燥过程中物料中心温度最低,中心温度与物料表面温度相差最少,且干燥产品颜色最好。

间歇微波干燥;热风干燥;活化能;有效扩散系数;颜色

TS255.3

A

1002-6630(2017)17-0085-09引文格式:

2016-07-12

公益性行业(农业)科研专项(201503142)

彭郁(1992—),女,硕士,研究方向为果蔬加工。E-mail:py_ivy@163.com

10.7506/spkx1002-6630-201717015

*通信作者:倪元颖(1960—),女,教授,硕士,研究方向为果蔬加工。E-mail:niyuany@163.com