Experimental research on blast power of fiber reinforced anti-hard target warhead

Bin Liang,Jie-qun Zhou,Gao-peng Feng,Yong-gang Lu

Institute of Systems Engineering,China Academy of Engineering Physics,China

Experimental research on blast power of fiber reinforced anti-hard target warhead

Bin Liang,Jie-qun Zhou*,Gao-peng Feng,Yong-gang Lu

Institute of Systems Engineering,China Academy of Engineering Physics,China

A R T I C L E I N F O

Article history:

Carbon fiber composite

Effect of blasting

Experimental investigation

Low collateral damage

Fiber reinforced anti-hard-target warhead is a new-type sample munition,which is only designed based on theoretical analysis and numerical simulation in laboratory.This warhead consists of carbon composite casings and high explosive,which can greatly reduce the damage to objects outside the damage range.In order to evaluate its blasting damage effect on concrete target,the three types of charges were researched by means of experiment,which are bare charge,charge with carbon composite material shell and charge with steelshell.Experimental results show that the peak overpressure of charge with carbon fiber composite shellis higher than that of charge with steelshell,but is lower than that of bare charge in the case of the same TNT equivalence.No fragments and fragment effect exist for distant target under the condition of charge with carbon fiber composite shell.However,the experimental result of the charge with steel shell is completely contrary.According to the blast effect in the concrete target,the charge with carbon composite material shell is optimal in matched impedance and detonation propagation. Also,the effective energy produced by the detonation of explosive with carbon composite material shell is the largest.

©2017 Published by Elsevier Ltd.This is an open access article under the CC BY-NC-ND license(http:// creativecommons.org/licenses/by-nc-nd/4.0/).

1.Introduction

In recent years,the low-collateral-damage munitions have been badly needed,which has good performance in reducing destruction outside the damage range,while enhancing destructive force on the target.To achieve this goal,it is necessary to design a weapon that could penetrate hard targets as deeply as a steel-shelled projectile does,while could restrain the damage of the blast within a small radius.Fiber reinforced anti-hard-target warhead is a newtype sample warhead,which is only designed based on theoreticalanalysis and numericalsimulation in laboratory.This munition consists ofcarbon composite casings and high explosive,which can greatly reduce the damage to objects outside the damage range. The blasting damage of fiber-reinforced composite warhead has already become a hot topic in development of conventional weapon and design ofdefense engineering,yet little information is available about the blasting effect on targets[1].Therefore,it is signi ficant to the development of new-concept warhead and the design of defense engineering,including the study of blastingdamage evaluation for fiber reinforced composite warhead.

The phenomena that may occur during the new-concept warhead blast in air and concrete were preliminary analyzed, including the damage of target and the ef ficiency of loaded explosives[2].The damage of target is caused by blast wave and fragments[3,4].However,the quasi-static failure ofconcrete target and the damage ef ficiency of fiber-reinforced composite warhead in the concrete structure are highly non-linear transient phenomena, which are dif ficult to be studied by using theoreticaland numerical methods.So the physical experiments play a vital role in the characterization of such problems.The results obtained from the physical experiments represent the ef ficiency of blasting damage and the failure rules of concrete target for the different charge shells.

The present work is intended to evaluate the damage characteristics of fiber reinforced anti-hard target warhead,i.e.,explosion ef ficiency in air,damage abilities of targets and damage effect of concrete targets.Explosion tests were conducted to examine the failure region ofconcrete targetsubjected to inner blast and getthe overpressure curves ofair blast.Then,the radius ofdamage and the craters of concrete targets due to bare charge,charge with composite material shell and charge with steel shell explosive are compared.

2.Blast experiment

2.1.Experimentalsamples

For enhancing the energy delivery to a target while controlling the radius of damage area as well,a sample was filled with the Composition B charge.The Composition B has been used in ammunition because it is a kind of powerful and very insensitive explosive.It is highly unlikely to explode accidentally.

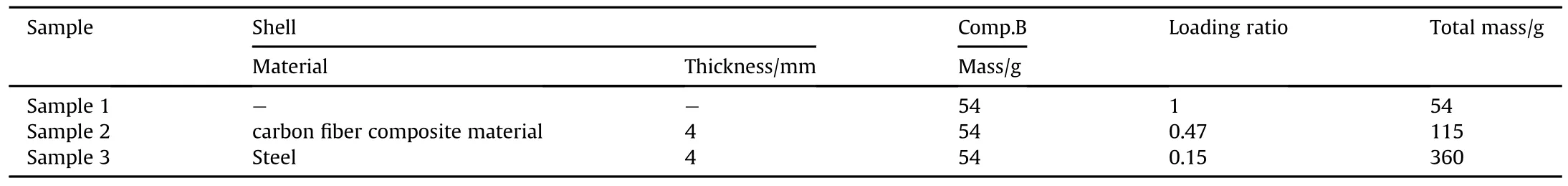

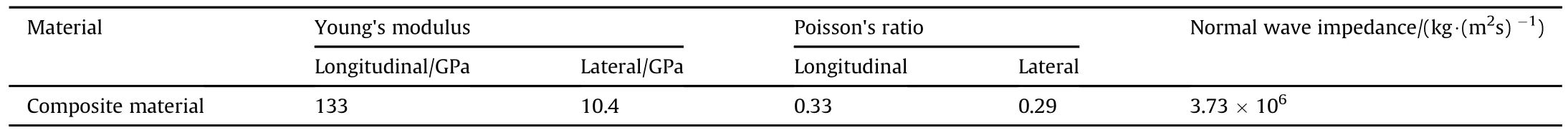

The experimental samples were designed for the comparative analysis of three types of charge,i.e.,bare charge,charge with carbon fiber composite material shell and charge with steel shell. The analysis focuses on the explosion ef ficiency in air,the damage ability of targets and the damage effect on concrete targets.The structures of charges are shown in Fig.1,and their parameters are listed in Table 1.The properties of composite material are listed in Table 2.

2.2.Test layout

2.2.1.Air explosion test layout

The air explosion test layout for overpressures of three charges is shown in Fig.2.The loaded sample is hanged over a support,and its axis is vertical to a horizontal plane.Distance between the bottom of sample and the ground is 1.5 m.Horizontal distances among overpressure sensors and loaded sample axis are 0.4 m, 0.6 m and 1.0 m,respectively.Gauges designed to measure these pressures must be robust enough to survive for the totalrecording time,typically from 100μs upwards.In order to avoid unnecessary fragment impact damage,the silicon piezoelectric sensors and charges are placed in different angles according to the estimated dispersion angles of fragments.The sensors are placed at 1.3 m, 1.1 m and 0.9 m above the ground,and the guide lines of silicon piezoelectric sensors are guarded by steeltube and sandbags.

2.2.2.Test of blasting in concrete target

The schematic diagram of an experimental setup for explosion in concrete target is given in Fig.3.The concrete specimens put on the ground are 500 mm thick and 1600 mm×1600 mm square plates,and their compressive strength is 35 MPa.A predrilled hole at target center for charges is 30 mm in diameter and 200 mm in length.A high speed camera is used to record the forming process ofblasting crater.The diameter and volume ofblasting crater could be used to evaluate the damage effect of different charges.

3.Experimental results

In the experiments,the silicon piezoelectric sensors were used to measure the shock wave over pressure caused by the explosive charge in the air.The processes of blasting damage and fracture of concrete target was recorded using high speed camera.

3.1.Air blast experimental results

A detonator is detonated atthe top ofcharge.For the bare charge and the charge with carbon fiber shell,there is no damage to the sensor,sensor bracket,concrete cylindrical target and concrete protection board afterblasting.The carbon fiber shelldebris can not be seen around the damage range.It can be inferred from the combustible carbon fiber shellmaterial and the previous round of tests[2],that the carbon fiber shellis burning after blasting.

When the air is driven by the explosive flows at high speed,the blast wave is followed by an exponential decay of pressure as a steep pressure occurs.Besides,explosions fragments could cause structuraldamage.A metalcase in contactwith explosive is usually broken into chunky fragments with the different dimensions in different directions.The measured initial velocity of fragments is 2km/s-3 km/s.The combination with the blast wave and the fragments causes the damage to target[2,3].

The target damage due to blasting of the charge with steelshell is depicted in Fig.4.From the distribution of test pieces,it can be seen that the explosion fragments produce penetration damage to steel hoop on the outer surface of the steel cylindrical concrete target and inner side of Longmen,which is 2 m far from the charge center.

A 3D numerical simulation model,which includes high explosive material,shell,air and ground,was established using AUTODYN 3D. High explosives were modeled using the Jones-Wilkins-Lee(JWL)equation of state as follows:

where p is hydrostatic pressure;v is speci fic volume;e is speci fic internalenergy;and C1,R1,C2,R2andωare materialconstants.The values of the materialconstants for many common explosives were determined from dynamic experiments and are available in AUTODYN.In the present simulation,C1,R1,C2,R2andωare assumed as 3.74×105MPa,4.15,3.75×105MPa,0.9,and 0.35, respectively[5].

Air is modeled by the ideal gas equation of state,in which the pressure is related to the energy by

whereγis constant;ρis air density;and e is the speci fic internal energy.In the simulation,the standard properties of air from AUTODYN materiallibrary are utilized,i.e.,air densityρ=1.225 kg/ m3andγ=1.4.The initial internal energy of air is assumed to be 2.068×105kJ/kg[5].

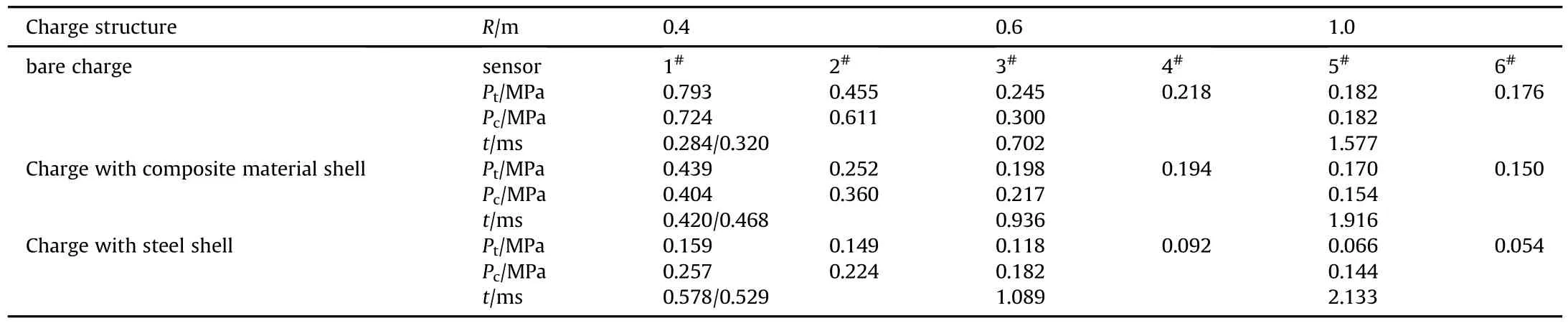

In the experiment,the waveform ofoverpressure is recorded by a testinstrument,and the measured electricalsignalis converted to the overpressure signal.The measured results of overpressure and the fitted curves of peak overpressure are shown in Table 3,Fig.5 and Fig.6,respectively.In Table 3,R is the distance from the charge center,Pt,Pcand t are the experimental value of peakoverpressure,the numerically simulated value,and the time corresponding to the peak overpressure,respectively.

Table 1 Parameters of three charges.

Table 2 Properties of composite material.

Because the test sensor layout is reasonable,the sensors and cable protection pipes were avoided to be destroyed by explosive fragments.Three air blast testing overpressure curves were successfully obtained.The sensors are numbered 1-6 according to the distance from charge axis.Since the location of the Sensor 1 is about 50 mm higher than Sensor 2(seeing Table 3),it is closer to the explosive center,which is the reason for the values measured by Sensor 1are greater than those measured by Sensor 2.

The overpressure ofexplosion shock caused by carbon fiber shell wave is about two times ofthat caused by steelshellcharge shown in Table 3,and the peak overpressure ofblastshock wave caused by the bare charge is signi ficantly higher than that caused by charge with case,the former is about two times of the latter.The peak overpressure is signi ficantly different although the height difference oftwo channels is only about 50 mm.The main reason is that the overpressure decays rapidly in the near field ofexplosion shock wave.

Fig.5 shows the test of pressure-time curves at 0.4 m from the charge center.Fig.6 represents the fitting curves of air blast overpressures(Pt)ofthree charges with the distance(R).On the basis of Table 3 and Fig.5,the propagation velocity ofexplosion shock wave in the bare charge is larger than that of shelled charges,while the propagation velocity of explosion shock wave in the carbon fiber shellis faster than that of steel shellcharge.The numericalresults agree wellwith the results in Table 3.

The experimentalresults demonstrate that the distribution and propagation of overpressure are closely related to the charge structure.The overpressure and propagation velocity ofshock wave in the bare charge are higher than those in the charge with shell. Meanwhile,the overpressure and propagation velocity of shock wave in the carbon fiber shell charge are higher than those in the steelshell.

Table 3 Experimental and numerically simulated results of air blast about different charges.

In Ref.[1],the explosion model about shell density and thickness was proposed based on the physical process of blast effect,which can be used to estimate the effect ofcharge structure on the strength of shock wave,and the in fluences of the density and thickness of charge shell on the intensity of air explosion shock wave(or energy utilization)were analyzed.Theoretical analysis proves that the shell thickness and density are the main factors affecting the energy utilization of air blast under the same loading.The ratio ofenergy using for the shelldamage and driven fragments to the totalenergy of explosive is not 0.01-0.03 in the engineering,but increases with the increase in the shellthickness ratio(ratio of shell thickness to explosive thickness)and density ratio(ratio of shell material density to explosive density),as shown in Fig.7.

The reasons for the differences are mainly two aspects:firstly,a part of energy generated by explosion of charge with shell has been used for driving shell,so that the explosion shock wave pressure of the charge with case is lower than that of the bare charge.The quality and density of the charge with carbon fiber composite material shell are relatively lower,and a part of the shell is ablated during explosion,so the driving energy of fragments is relatively smaller.As for the charge with steel shell,a large amount of explosive energy is consumed in the fragment driving,so the energy diffusing in the air decreases after blasting compared with that ofthe carbon fiber shell.Secondly,the normal wave impedance ofcarbon fiber shellis in consonance with thatof explosive or explosion product,meanwhile,the normal wave impedance of steel shell material is dissimilar to those of explosives and air.

3.2.The blasting damage to concrete target with charge

Three tests were performed to explore the driving abilities of three kinds of charge structures.High speed photographs were taken at the same frequency(50,000 frames/sec)for recording the explosion in concrete target,as shown in Fig.8.It can be seen that there exists a certain leakage and pressure relief of explosive products from the predrilled holes on a concrete target.The initial time is detonator ignition time.For the bare charge explosion,there is no explosion flame in concrete gun mouth.However,there exist explosion flames for both the carbon fiber charge and steelshelled charge.The explosion flame of steelshelled charge is more obvious and lasting longer,which is caused by the circular constraint ofthe charge.

For the bare charge,the diameter ofexplosion hole is larger than the diameter of cylinder explosive,and the explosive products are not bound by the circum restraint,that is why the explosion gas leakage along the axis of charge is later.In the condition of shelled charges,there is a circular restriction,therefore,the explosion products leak from the initiation point along the axis to the charge explosion hole,which leads to different levelexplosion flames.The strength ofcarbon fiber shellis weaker than that of the steelshell, and the explosive products leaked along the axialdirection are less than that ofthe steel-shelled charge,therefore the explosion flame is weaker and shorter.

In this paper,the de finition ofcharge energy distribution ratio is that the ratio of axial and radial energy distributions after explosion.Through the analysis of high speed photographs(seeing Fig.8),it can be found that the charge energy distribution ratio isdifferent,and the distributed energy of carbon fiber shelled charge is larger than that of the steelshelled charge and less than that of the bare charge since the axialconstraint are different.

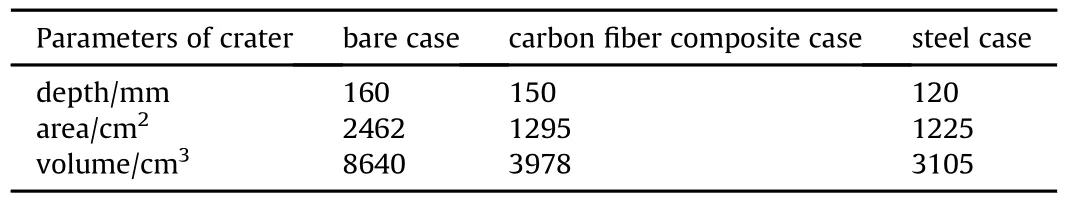

Three blasting craters in the concrete target induced by explosion are shown in Fig.9.The speci fic sizes of blasting craters are listed in Table 4.There are some differences in blasting craters among the three kinds ofcharge.For the bare charge explosion,the ratio of bottom radius to mouth radius(Ra)is the smallest,i.e.,the funneltaper is the smallest.The blasting funneltaper is the largest for steel shelled charge,and is in the middle for the carbon fiber shell counterpart.Moreover,the blasting crater depth(H),the funnel area(S),pit crater volume(V)all have the same rules.

It can be seen from Table 4 that the blasting crater sizes and shapes caused by the three kinds ofcharges are different.From the principle ofshock wave propagation in multilayer media[6],it can be known that the surface wave impedance of carbon fiber composite shelled charge is more closer to those of the explosives(or explosive products)and concrete than the steelshelled material,so that the wave impedance of carbon fiber composite shelled charge is more matching with explosive,and the initial overpressure caused by the explosion of carbon fiber shelled charge is higher than that of the steel shelled one.

It is a matter of controlling the energy and putting it to better use.Carbon fiber composite is lightweight,and the weight of carbon fiber composite case will account for only 10 to 20 percent of totalweight of munitions.

From the explosion energy distribution,the strength of the carbon fiber shell material is lower than that of the steel shell material,the consumption of shell fracture energy in explosion is relatively low,at the same time,the explosion product leakage of carbon fiber shell is relative less than the counterpart of the steel shell,so that the effective explosion energy to target damage of carbon fiber shell is higher than that of the steel shell.The axial constraint ofthree charges are different,so that the utilization rate of carbon fiber shelled charge is higher than that of steel shelled charge and lower than that of bare charge.

4.Conclusions and discussion

In the present work,the effect of carbon fiber sheet reinforcement on the damage performance of concrete target was investigated.The local damage degree of concrete plates subjected to inner explosion was estimated by using experimentalmethod.The following conclusions can be concluded from the aboveexperimentalresults.

Table 4 Blasting craters sizes of concrete.

Under the condition of the same quantity of explosives,the overpressure and the propagation velocity of shock wave in the carbon fiber composite shelled charge are higher than those in the steel shell,and are lower than those in the bare charge.The explosion fragments of carbon fiber composite shelled charge could not produce damage to target.The steel shelled charge has killing effect on distant target.

In the case of the explosion damage effect of charge blasting in concrete target,the carbon fiber shelled charge is better than the steel shelled charge in the impedance matching,and is more conducive to the propagation ofblast shock wave.In the case of the same quantity of explosives,the effective energy(impulse),the radial and circular energy ratio of the carbon fiber shell charge to the concrete target is higher than that of the steelcharge.It can be concluded that the damage ef ficiency of the carbon fiber shelled charge is higher than that of the steelshelled charge and less than that of the bare charge.

The carbon fiber shell charge in the air explosion will not produce a lot of lethal damage elements(such as fragments),which can be used for the urban environment.In view of the carbon fiber reinforced armor-piercing warhead having the characteristics above,the anti-hard-target projectile with head made of high strength steel or body using the composite shell has excellent damage effect on concrete target,which is superior to the traditionalsteel shell.Furthermore,the explosive damage effect willbe further improved when the loading ratio of warhead is increased greatly.Therefore,the application of fiber reinforced warhead technology with high filling ratio is defective to facing the challenges from forti fications fortress concrete targets,which signi ficantly enhances the damage effect of blasting on target.

The designed new monition with carbon fiber composite case and enhanced-blast explosive increases the impulse delivered to the intended target and that eliminates collateral damage causedby shellfragments.The experimentalresults welldemonstrate that, even though the new munition produces a more powerfulblast,the range of its damage footprint is smaller than that of conventional warheads.

Acknowledgements

This research is partially sponsored by the Chinese-NSF Foundation(11672278)and Chinese-NDTF(B1520132012).The authors would like to thank Prof.X.W.Chen at China Academy of Engineering Physics for valuable joint discussion on explosive engineering.The authors are also grateful to reviewers for discerning comments on this paper.

[1]Goldsmith Werner.Review Non-ideal projectile impact on targets.Int JImpact Eng 1999;22:95.395.

[2]Liang B,Chen ZF,Lu YG.Numerical simulation and experimental investigation of blast effect of explosive charge covered with different materials shell.J PL Univ Sci Technol Sci Ed 2007;8(5):429-34.

[3]Liang B,Chen ZF,Lu YG.Investigation of blast effect of explosive charge with different shell material.Chin J Explos&Propellants 2008;31(1):6-11.

[4]Ohkubo K,Beppu M,Ohno T,Satoh K.Experimental study on the effectiveness of fiber sheet reinforcement on the explosive-resistant performance of concrete plates.Int J Impact Eng 2008;35:1702-8.

[5]Shi Yanchao,Hao Hong,Li Zhong-Xian.Numerical simulation of blast wave interaction with structure columns.Shock Waves 2007;17:113-33.

[6]Lili Wang.Foundation of stress waves.Beijing:Nationaldefense Industry press; 2005.p.35-60.

12 January 2017

*Corresponding author.

E-mail address:zhoujiequn1414@126.com(J.-q.Zhou).

Peer review under responsibility of China Ordnance Society

http://dx.doi.org/10.1016/j.dt.2017.04.002

2214-9147/©2017 Published by Elsevier Ltd.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Received in revised form 27 March 2017

Accepted 17 April 2017

Available online 19 April 2017

- Defence Technology的其它文章

- Impact-disrupted gunshot residue:A sub-micron analysis using a novel collection protocol

- Ignition and combustion of pyrotechnics at low pressures and at temperature extremes

- A comparative study of combustible cartridge case materials

- Enhanced propellant performance via environmentally friendly curable surface coating

- An approach for optimization of the wallthickness(weight)of a thickwalled cylinder under axially non-uniform internal service pressure distribution

- Trajectory optimization of a de flectable nose missile