A comparative study of combustible cartridge case materials

Wei-to Yng,Jin-xing Yng,Yu-cheng Zhng,Sn-jiu Ying

aXi'an Modern Chemistry Research Institute,Xi'an,710065,PR China

bSchool of Chemical Engineering,Nanjing University of Science and Technology,Nanjing,210094,PR China

A comparative study of combustible cartridge case materials

Wei-tao Yanga,*,Jian-xing Yanga,Yu-cheng Zhanga,San-jiu Yingb

aXi'an Modern Chemistry Research Institute,Xi'an,710065,PR China

bSchool of Chemical Engineering,Nanjing University of Science and Technology,Nanjing,210094,PR China

A R T I C L E I N F O

Article history:

Foamed combustible material

Closed vessel test

Co-combustion behavior

Dynamic vivacity

Foamed combustible materialbased on polymer bonded RDX was fabricated using CO2as foaming agent. The inner structures of felted and foamed combustible materials were presented by SEM.The two materials presented different formulations and inner porous structures.The combustion behaviors of felted and foamed materials were investigated by closed vessel test.Simultaneously,the co-combustion behavior of combustible cartridge case with 7-perf consolidated propellants was also investigated.The results of closed vessel test is applicable to gun system which is made of the foamed combustible material as component.

©2017 The Authors.Published by Elsevier Ltd.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

1.Introduction

In the past,the porous combustible materials for combustible cartridge case or caseless ammunitions were fabricated by various methods,such as felt-moulding,winding or impregnation of resin in the felted combustible components,in which nitrocellulose were used as energetic ingredient[1-5].The materials can burn out in a shortened time due to a giant internal surface area,leaving no burning residue.The material is easily ignited and mis fires due to the in flammable property of nitrocellulose component when it leaves in hot gun chamber.Hence,the foamed combustible materials based on polymer bonded RDX,which present better heat resistance,were fabricated[6,7].The foamed combustible materials have the advantages of adjustable energy content,high burn rate, improved heat resistance and low vulnerability[7-12].

In the weapon systems,the presence of combustible material complicates the interior ballistic performance,in that the combustible materialdiffers in its combustion characteristics from the propellant.Its burning characteristics have signi ficant effect on the interior ballistic cycle.Early attempts at investigating the combustion of the porous combustible materials in closed vessel were not entirely successfulsince the discrepancies of combustion behavior were noted in measured and predicted pressures in the gun chamber[8].In fact,the dependence of combustion behavior on porous structure,sample size and loading density on combustion behavior were also noticed when a porous material was burned in a closed bomb.In addition,the material may be ignited by varied ignition pressures for different applications.Consequently,the energy output will not follow the desired way.

In this paper,a comparison of the foamed material with the felted combustible material was investigated.What's more,the effects of two kinds of cartridge case on consolidated propellants were tested by closed bomb test.The results of this study will be primarily used for the further development of combustible cartridge case.The findings may also be applicable to other applications in which the foamed combustible materials are used.

2.Experiment

The combustion properties of combustible materials in 109 ml closed vessel were tested,and the data sampling interval was 0.001 ms.Sample size was 10×10×6 mm.The output of closed vessel test data acquisition system was fed to a computer,and the pressure histories were recorded.Nitrocellulose with nitrogen content of 12.0%was used as ignition powder,of which the force constantand co-volume ofignition powder are 883 J/g and 1.0 cm3/ g,respectively.

The mass of ignition powder was calculated according to Eq.(1)

where V0is the volume of closed vessel;migis the mass ofignition powder;Δis the loading density;ρis the density of sample;pigis the ignition pressure;figis the force constant ofignition powder;α is the co-volume of ignition powder.

The mass of tested sample,m,is calculated according to Eq.(2)

3.Results and discussion

3.1.Inner structures

The two types of combustible materials,i.e.felted combustible cartridge case material and foamed combustible material were observed by SEM.Felted combustible cartridge case material was felted and moulded from a mixture of nitrocellulose fibers,cellulose fibers and binder.The nitrocellulose content is 62%,and the density of the material is 1.0 g/cm3.The foamed combustible components were blended,kneaded,moulded and dried by traditional method.The dried materials were placed in a high pressure vessel,and CO2 in the vessel was pumped to 15 MPa.After the sample was exposed in SC-CO2 at 50°C for 10 h,the pressure was quenched rapidly to atmospheric pressure.The details of foaming equipment was described in Ref.[6].RDX content of the formulation is 70%in weight,and the density of the foamed sample is 1.34 g/cm3.The density of sample before foaming is 1.61 g/cm3. Hence,the relative densities ofsample before and after foaming are 0.83,or the expansion ratio is 1.2.

Different inner structures were obtained using two different methods.The inner structures were observed by scanning electron microscope(SEM).Fig.1 and Fig.2 show the inner structures ofthe felted and foamed materials.As shown in the Fig.1,the felted case is composed of fibers which were piled up and bonded.The average diameter of fibers was about 20μm.In Fig.2,the cross section of foamed sample presents a micro foamed structure,which is composed of RDX particles and micro pores with diameter<10μm.

3.2.Combustion characteristics of felted and micro foamed combustible materials

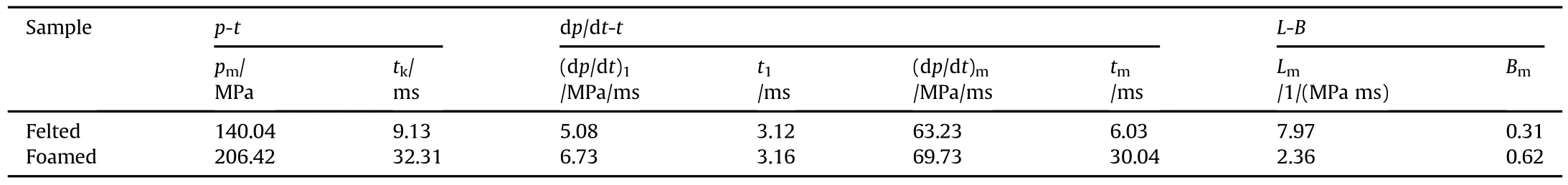

The burning behaviors of combustible materials are in fluenced by the formulations as wellas the inner structure.A comparison of pressure histories,dp/dtcurves and L-B curves offelted and foamed samples are shown in Fig.3,Fig.4 and Fig.5,respectively.The initial temperature of tested samples was 25°C.Table 1 presents the maximum pressure(pm),burning time(tk),peaks ofd p/d t-t curves, maximum dynamic vivacity and corresponding value of B.

Obvious differences in combustion behavior were observed from the pro files of pressure histories and d p/d t-t curves in Figs.3 and 4.The maximum pressure offoamed propellant is higher than that of the felted one under the same loading,thus indicating that the foamed material contains more energy.Simultaneously,the felted sample got ignited due to its in flammability before the ignition powder burned out.Hence,the pressure increased smoothly from atmospheric pressure to pm.Since the foamed materialwas hard to ignite,the pressure history of foamed sample contained an initial pressure rise of ignition powder combustion and the pressure rise of tested sample.The pressure increased slowly atthe initialburning period and started to rise rapidly when t was about 25 ms.Compared with felted sample,d p/d t value of foamed sample increased to peak 2 after d p/d t value dropped to zero.

Fig.5 shows L-B curves of felted and foamed combustible materials.As shown in Fig.5,the vivacity of felted sample is higher than that of foamed sample.Since the felted sample was easy to ignite and the flame penetrated in the felted sample in ignition,the burning area was giant at initial period.Therefore,the maximum vivacity of felted sample was obtained at lower relative pressure (B=0.31).Since the foamed sample was hard to get ignited and penetrated,its initial combustion area was small,and the maximum vivacity was obtained during later combustion (B=0.62).The signi ficant difference of dynamic vivacity between the felted and foamed materials in the closed vessel tests indicates that the two case types have different burning mechanisms.

3.3.Co-combustion behavior

The double-base oblate spherical propellants were foamed using CO2as the blowing agent by a batch foaming process.The consolidated propellants were molded using energetic adhesive.To achieve the high burning progressivity ofconsolidated propellants, a propellant geometry with 7-perforation structure was used(see Fig.6).More detail about consolidated propellants is shown in Ref.[13].

As can be seen from Fig.7,the curve shape of consolidated propellant is similar to that of7-perforation propellant with lower dynamic vivacity value.The dynamic vivacity of consolidated propellant starts to fall slowly for B=0.5,and L-B curve is flat before B=0.5.

Table 1 Characteristic points of p-t curves,d p/d t-t curves and L-B curves.

Figs.8 and 9 show L-B curves of felted and foamed combustible materials with consolidated propellants,respectively.The mass ratio of cartridge case and 7-perf propellant is 1:1,and the loading density is 0.2 g/cm3.As shown in Fig.8,the maximum dynamic vivacity offelted case+7-perfpropellant is higher than that of the foamed one+7-perf propellant.The maximum vivacity in Fig.8 was obtained at lower relative pressure(B=0.21).Since the foamed sample was hard to get ignited and penetrated,the initial combustion area was small and the maximum vivacity was obtained during later combustion(B=0.45).Figs.8 and 9 indicate that the co-combustion of foamed case and 7-perf propellant shows better combustion progressivity and smaller initial burning area.

4.Conclusions

The new type of combustible material presents a signi ficant difference in inner structure and burning characteristics in comparison with the traditional felted case material.The new combustible material has good combustible behavior,including heat resistance(long ignition delay time),burning progressivity and consistency under differentconditions ofloading.This material has great potential for application in combustible cartridge case, modular charge in the near future.

[1]Shedge MT,Patel CH,Tadkod SK,et al.Polyvinyl acetate resin as a binder effecting mechanicaland combustion properties of combustible cartridge case formulations.Def Sci J 2008;58(3):390-7.

[2]K.Johnson,S.Levine,M.Nusbaum,et al.Duplex combustible cartridge case[P]. U.S.Patent:3,823,668;1974.7-16.

[3]K.O.Jacobsen,E.Troen.Combustible cartridge casings and method for making same[P].U.S.Patent:3,977,325;1976.8-31.

[4]W.S.Baker.Method of making combustible cartridge cases[P].U.S.Patent: 3,282,146;1966.11-1.

[5]F.J.Zimmerman.The development ofsmallcaliber combustible cartridge case ammunition[A],In:ICRPG/AIAA 3rd Solid Propulsion Conference;1968.

[6]Yang W,Li Y,Ying S.An investigation of the preparation and performance of microcellular combustible material.Central Eur J Energ Mater 2014;11(2): 257-69.

[7]Yang W,Ying S.Burning characteristics ofmicrocellular combustible ordnance materials.Propellants,Explos Pyrotech 2016;41(1):136-41.

[8]Yang W,Li Y,Ying S.Burning characteristics of microcellular combustible objects fabricated by a con fined foaming process.Propellants,Explos Pyrotech 2015;40(1):27-32.

[9]Yang W,Li Y,Ying S.Burning characteristics of microcellular combustible objects.Def Technol 2014;10(2):106-10.

[10]Yang W,Li Y,Ying S.Fabrication of graded porous and skin-core structure RDX-based propellants via supercritical CO2 concentration pro file.J Energ Mater 2015;33(2):91-101.

[11]Yang W,Ying S.Microcellular foaming of CA/RDX composites in a batch supercritical CO2 process.Chin J Explos propellants 2016;39(2):22-6.

[12]Robbins FW,Colburn JW,Zoltani CK.Combustible cartridge cases:current status and future prospects[R].Aberdeen:ARMY BALLISTIC RESEARCH LAB ABERDEEN PROVING GROUND MD;1992.

[13]Li Y,Yang W,Ying S.Burning characteristics of consolidated gun propellants. Propellants,Explos Pyrotech 2015;40(1):33-8.

9 January 2017

*Corresponding author.

E-mail address:njyangweitao@163.com(W.-t.Yang).

Peer review under responsibility of China Ordnance Society.

http://dx.doi.org/10.1016/j.dt.2017.02.003

2214-9147/©2017 The Authors.Published by Elsevier Ltd.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Received in revised form 4 February 2017

Accepted 27 February 2017

Available online 28 February 2017

- Defence Technology的其它文章

- Impact-disrupted gunshot residue:A sub-micron analysis using a novel collection protocol

- Ignition and combustion of pyrotechnics at low pressures and at temperature extremes

- Enhanced propellant performance via environmentally friendly curable surface coating

- An approach for optimization of the wallthickness(weight)of a thickwalled cylinder under axially non-uniform internal service pressure distribution

- Trajectory optimization of a de flectable nose missile

- Improved theory of projectile trajectory reference heights as characteristics of meteo-ballistic sensitivity functions