Technological risk regulation of the subgrade base stability in permafrost areas

S.Ya.Lutskiy,T.V.Shepitko,Alexey Y.Burukin

1.Federal State-Funded Educational Institution of Higher Vocational Education'Moscow State University of Railway Engineering'MGUPS(MIIT),Moscow 127994,Russia

2.Public Joint Stock Company'MOSTOTREST'(PJSC'MOSTOTREST'),Moscow 121087,Russia

Technological risk regulation of the subgrade base stability in permafrost areas

S.Ya.Lutskiy1,T.V.Shepitko1,Alexey Y.Burukin2*

1.Federal State-Funded Educational Institution of Higher Vocational Education'Moscow State University of Railway Engineering'MGUPS(MIIT),Moscow 127994,Russia

2.Public Joint Stock Company'MOSTOTREST'(PJSC'MOSTOTREST'),Moscow 121087,Russia

Maintenance and risk estimation of a weak roadbed condition during the construction period are described.Risk-management procedure for unstable,weak soils is proposed through adjusting the technological loads and real-time monitoring of their influence.The efficiency of implementing maximum allowable vibroloads and the drainage system for strengthening weak soils is shown in the example of the Northern Latitudinal Railway area.

roadbed;technology;risk;stability

1 Introduction

Earthworks on weak and collapsible soils are under high risk of becoming unstable and weak while being affected by natural and technological processes (Shakhunyants,1987;Ashpiz,2002).The soil condition fully depends on the construction technology and the effect of machines on the physical,mechanical, and thermophysical characteristics(Goldstein,1979). Depending on the intensity of execution,these nonstationary stochastic processes change the initial boundary conditions for the roadbed design.In the design model of the foundation,we have to take into account the random factors that define the stress−strain state of the whole structure,such as anisotropy,the nature of the soil layers,soil instability,plastic and rheological properties of the foundation soil,and the possibility of their change during construction and maintenance.According to the code(NIIOSP them.N.M. Gersevanov,2012a,b;Tsernant,2013),indeterminacy of the soil properties and loads is considered by using the safety factors in the calculation.

2 Analysis of methods and results

Technological risk is the probability of exceeding of the weak soil's load capacity by the heavy vibrorollers,especially under the effect of the interconnected stochastic changing processes in humidity and density along the depth of the foundation.

Moreover,the most dangerous load period for the permafrost is simultaneous with the melting and freezing fronts moving through all permafrost layers(Lutskiyet al.,2013).

The constructional safety risk for geotechnical structures under high technological loads reveals itself as a mismatch between the project and the real strength and strain characteristics,and,consequently,collapse of the unfinished objects,soil rheology,and thixotropic changes(Liu and Peng,2009).The outcome analy-sis of the engineering survey on the construction areas of the Northern Latitudinal Railway and the foundation stability calculation shows that roadbed design under the second rule(with the hypothesis of melting) on high temperature permafrost leadsto a longstanding progress of taliks(Khrustalev,2005;Burukinet al.,2015).The task was to develop a risk assessment and control method for unstable areas.

3 Methods

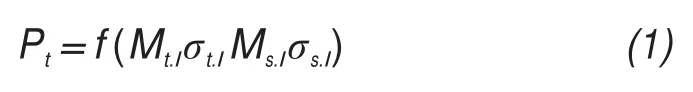

For the technological risk estimation,let's introduce statistical analysis of the random variables distribution into the foundation stability calculation:(1) safety loadQs.l,that changes on the worksite and depends on strength properties(cohesionC;angle of the internal frictionφ),humidityW,thickness of the soil layersh(Lutskiy,2005;Isakov,2010;Lutskiyet al., 2013);(2)technological loads and impacts on the soilQt.l,first of all from the vibroroller.Generally,the probability of the foundation becoming unstable during the periodtis equal to

whereМt.l,ϭt.l,Мs.l,ϭs.lare mathematical expectation and standard deviation of the technological and safe load on the foundation.

The risk-decreasing concept consists of structural loads control in such a way that the secure load will not be exceeded,and at the same time the vibroroller pressure will be kept on the maximum acceptable level within design reliability margin.Geotechnical technology is specific by its discrete management. Variable parameters for the process of soil compaction by modern rollers are the disturbing force,frequency,velocity,and the number of vibroroller passes (Burukinet al.,2015).In the discrete technological mode(at the beginning of the work day and,in case of critical ground condition,during the work),onboard computers allow control of the loads.Thus,it is possible to predict condition of physical,mechanical, and thermophysical characteristics of soils on the basis of the ground mechanics lows and to make decisions in real time.

The design scheme for estimating the ground stability risk at every time-step represents the comparison of the random variables:secure loadQs.land controlled technological ground loadQt.lby the ground load capacity criteria under these loads.Results of the statistic risk calculations are the composition parametersРcof the distributionsQs.landQt.l.The probability of foundation stability failure is determined by integration of the probability densityРcin the interval of negative valuesРc[−∞,0]using Laplace's functions.

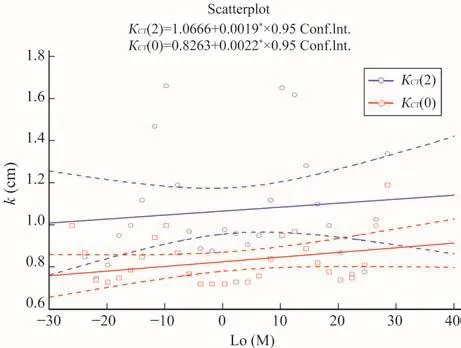

Let's consider the calculation algorithm using the example of the engineering survey of the Nadym−Salekhard Highway and new Obskaya−Salekhard Railway roadbeds.As an initial data estimation of the foundation stability,coefficientKКsis taken as a ratio of a secure load for every point of the foundation(depending onС,φ,h)and an operation load.To estimate the ground inhomogeneity under the load on the experimental area,the statistical analysis ofКschange is performed in the active foundation zone on depth of 0~2 m,through the protective layer in the 50-meter area of vibroroller compaction(Figure 1).Not only unstable areas(Кs<1)but also significant variations about the average value are determined(more than 52%),which shows the level of inhomogeneity and the necessity of including it in constructional and technological solutions for the strengthening of weak grounds.

Figure 1 Changing of the stability coefficient Кsat the foundation of the Salekhard−Nadym Highway roadbed(Кs0refers to the surface,through the protective layer;Кs2refers to a 2-m depth;Larefers to distance from the roadbed axis)

One effective foundation-strengthening method is making the drainage system and intensive technology of ground compaction through the protective layer by the maximum acceptable technological loadQt.l(Lutskiy,2005).Technical regulation includes monitoring of physical−mechanical and thermo-humidity ground characteristics on the experimental area before the beginning of the workday and adjustment of the amplitudeA,frequencyϑ,and velocityνof the vibroroller.However,the significant variation of theКsvalues with respect to regression makes us assume the possibility of ground-destabilization risk during the vibrocompaction.According to the technology regulations (Lutskiyet al.,2013),the Dynaрac CA 2800D with the driving force 135 kN and the amplitude range 1~2 mm is picked for the intensive ground compaction.Its weight is considered as 20%lower than weak-ground resistance by taking the average design reliabilitycoefficientКr.Let's show the necessity of the differentiatedКrcalculations with the foundation-strength inhomogeneity influence estimation.

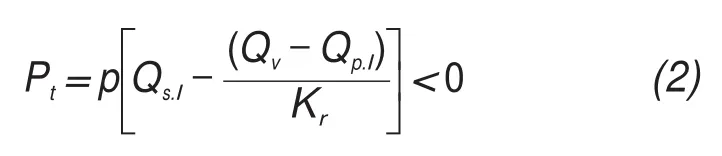

Statistical calculation of the ground-destabilization risk is performed for the critical state when the pressure and the stress to the ground from the vibroroller exceed the secure load.The risk is equal to the probability of the negative difference,at the moment of technological operation in a determined critical area,between the secure loadQs.l(accounting for the pore pressure)and the stress from the technological load(vibrorollerQvand protective layerQp.l):

In this formula,we should determine the combination of the distributionsQs.landQt.l.The risk is regulated by the reliability coefficientКrthat determines the secure load.For example,by the engineering survey data on the experimental area of the Obskaya−Salekhard Railway,theQs.l(Мs.l=154 kPa,ϭs.l= 42.3 kPa)distribution is lognormal(Figure 2).If the technological regime is discrete,and vibrocompaction parameters and design valueКr=1,2,…are fixed for the workday,Qt.ldistribution(Мt.l=128 kPa,ϭt.l=30.3 kPa)depends on the ground inhomogeneity.The combination of distributions shows that the load design reserve is not enough.The riskP1that the vibroroller will exceed the secure load is determined in the negative area of the distributionsQs.landQt.lcompositionРcas 38%.

Figure 2 Technological risk-distribution parameters (P1=0.38 when Кr=1.2;P2=0.2 when Кr=1.5)

The increase of risk leads us to the conclusion that the reliability coefficient cannot be averaged and become constant.Кrvalue should be determined subject to the acceptable risk at the experimental area and corrected according to the ground characteristics change and technological load increase.Such an iterative mode for the technological stage will provide maintenance stability of the foundation with the determined risk level.Applicable to the calculation(2)the allowable risk levelP2,equal to 20%will be achieved whenКr=1.5(Figure 2),and the mathematical expectationМt.ldoes not exceed 110 kPa.In that case,the parameters of the distributions compositionРcare equal toМр=51 kPa;ϭ=46 kPa.It is important to note thatКrvalue is picked differentially,depending on the allowable risk.

Let's consider another possibility of the foundation-destabilization probability decreasing.The correlation between ground and technological parameters that have influence on the risk should be determined during the technological control.The controlled vibrocompaction process allows the humidity to decrease and,at the same time,the density to increase,so the foundation strength increases.Such correlation is discovered on the roadbed construction areas of the Obskaya−Salekhard Railway differentially for the melted and frozen ground layers in the shape of function 'density−humidity'with the correlation coefficients 0.82~0.85.Gradual improvement of the physical−mechanical characteristics(humidity,yield ratio,and density)during the intensive ground compaction technology gives the possibility of the correlated increase of the secure load and at the same time the maximum acceptable vibroroller pressure.

4 Results

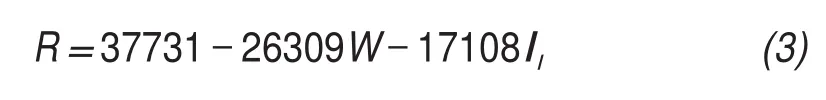

Thus,therisk-estimation method developed for weak soils is tested by being included in the technological regulation of the foundation-compaction with active-load characteristics control.Mutual addition of two positive processes ground strengthening and acceptable vibroroller load increase affects the weak ground state change.In the statistical calculations,the distributionscompositionvariancedecreasesand decreases the risk of the ground destabilization.To take this load correlation into account,the correlation coefficientc,which directly decreases the varianceDc,should be included in the algorithm for calculating the composition of distributionsPc.Statistical analysis of the engineering survey data showed regressive dependence between the melted cohesive soils resistance and the humidity change:

whereRis resistance,kPа;Wis humidity,unit fraction;andILis yield ratio.

This correlation between the processes of humidity decrease and strength increase(d=0.8;F=28;N=48) while using the intensive roadbed foundation-strength-eningtechnologyshowsrisk-decreasingpossibility.The calculation of the compositionРdstandard deviation (with the load inhomogeneity characteristicsϭs.l=42.3 kPа;ϭt.l=30.3 kPа;c=0.8)showed the change ofϭcfrom 52 kPa to 25 kPa,and probabilityPtdecreased. And then there appears the possibility to decrease the design reserve(through decreasing the coefficientКr) from 1.5 to 1.2 and increase the allowable technological compaction load from 110 kPa to 124 kPa.

5 Discussion

First of all,the probability method is necessary for the structural stability calculation,foundation stability calculation,and reliability coefficients explanation,which provide the risk-compensating reserve in the design projects(Kondratiev,2001;Khrustalev, 2005).The risk assessment and management are extremely important when using the intensive foundation-strengthening technology(Lutskiy,2005),the main principle of which is to control maximum allowable vibroloads.Active technological control allows risk management by load monitoring and strengthening the foundation using intensive technology.The technical possibility of risk decrease is provided by the modern vibrorollers(Schreder,2011).An onboard compaction and positioning-control computer system allows control of the vibroroller parameters(such as amplitudes and frequencies)by the secure values of coefficientКrin the dangerous foundation area.

6 Conclusions

(1)Weak roadbed foundation strengthening during the constructional period is considered as the techno-natural ground system and technological loads operating with random characteristics and determined secure state probability system.

(2)It is suggested to take in account the ground anisotropy and inhomogeneity through the statistical distributions and their parameters'correlation.The unstable zones and significant stability coefficient variations are found in the areas that are designed by the second rule of the Obskaya−Salekhard Railway roadbed.The reliability coefficient cannot be accepted as average and constant.Кrvalue should be determined considering the allowable risk on the experimental area and corrected according to the ground characteristic and maximum technological load change.

(3)The risk estimation method is developed for technological regulation of the foundation compaction with active load characteristics control.The loads that cannot be controlled increase the technological risk during intensive ground compaction by increasing the ground-destabilization probability.

Ashpiz ЕS,2002.Subgrade Monitoring during Operation of Railroads.Moscow:in Press.

Burukin AY,Lutskiy SY,Khripkov KN,2015.In-depth improvement of soil at the base of roads on taliks.Cold Regions Science and Technology,7(5):475−481.DOI:10.3724/SP.J.1226.2015. 00475.

Goldstein МN,1979.Mechanical Properties of Soils.Moscow: Stroyizdat.

Isakov AL,2010.Comparative analysis of soil deformation models for the calculation of stress-strain deformed condition of subgrades.In:Isakov АL,Kovalev YL(eds.).Report of Siberian State University of Railway Engineering(SSURE).Novosibirsk:SSURE,23:63−68.

Khrustalev LN,2005.Basic Geotechnics in Cryolithozone.Мoscow:Lomonosov Moscow State University(MGU).

Kondratiev VG,2001.Active Methods of Embankment Base Reinforcement on Permafrost Soils.Chita,Russia:Zabtrans Co..

Liu JK,Peng LY,2009.Experimental study on the unconfined compression of a thawing soil.Cold Regions Science and Technology,58:92−96.DOI:10.1016/j.coldregions.2009.03.008.

Lutskiy SYa,2005.Guidelines on Intensive Technology and Monitoring of Construction of the Earthwork Structures on Weak Base.Moscow:TIMR.

Lutskiy SYa,Apshiz ЕS,Dolgov DV,2005.Road Bed and the Construction Method for It.Patent No.2005104907/09(006247). Moscow:FIIP.

LutskiySYa,ShepitkoTV,CherkasovAM,2013.Compositetechnology of earthwork construction on taliks in cryolithic zones.Cold RegionsScienceandTechnology,5:577−581.DOI:10.3724/SP. J.1226.2013.00577.

NIIOSP them.N.M.Gersevanov,2012a.GOST 20276-2012,Soils. Field methods for determining the strength and deformability. Moscow:Research,Design and Survey and Design Institute of Technology Foundations and Underground Structures(NIIOSP)them.N.M.Gersevanov.

NIIOSP them.N.M.Gersevanov,2012b.SP 25.13330.2012,Code of Practice:Foundations and Groundwork on Permafrost Soil. Moscow:Research,Design and Survey and Design Institute of Technology Foundations and Underground Structures(NIIOSP)them.N.M.Gersevanov.

Schreder R,2011.Compaction.Augsburg,Germany:HAMM AG/ Wirtgen Group.

Shakhunyants GM,1987.Railway Track.Мoscow:Transport.

Tsernant АА,2013.Innovative technologies for the control of soil mass temperature for transport infrastructure facilities in Arctic regions.Construction Materials,Equipment and Technologies of the ХХI Century,3:26−31.

:Lutskiy SY,Shepitko TV,Burukin AY,2017.Technological risk regulation of the subgrade base stability in permafrost areas.Sciences in Cold and Arid Regions,9(3):0321-0324.

10.3724/SP.J.1226.2017.00321.

November 31,2016Accepted:December 31,2016

*Correspondence to:Alexey Y.Burukin,Ph.D.,Project manager of KUP Skolkovo,Public Joint Stock Company'MOSTOTREST'(PJSC'MOSTOTREST').No.6 Barclay Street,Moscow 121087,Russia.Tel:+7(495)669-79-99;E-mail: dom_teh@mail.ru

Sciences in Cold and Arid Regions2017年3期

Sciences in Cold and Arid Regions2017年3期

- Sciences in Cold and Arid Regions的其它文章

- Laboratory and field performance of recycled aggregate base in a seasonally cold region

- Laboratory investigations of the thermal strain of frozen soils, using fiber-optic strain gauges based on Bragg gratings

- Subgrade-reinforcement techniques for the dangerously deforming sections of railway lines in the north of the Russian Far East

- Systematization of features and requirements for geological survey of railroad subgrades functioning in cold regions

- Application of a nondestructive method to evaluate the active layer in a cold region

- Soil freezing process and different expressions for the soil-freezing characteristic curve