Laboratory and field performance of recycled aggregate base in a seasonally cold region

Tuncer B. Edil, Bora Cetin, Ali Soleimanbeigi

1. Recycled Materials Resource Center, Department of Civil and Environmental Engineering, University of Wisconsin–Madison, Madison, WI, USA

2. Department of Civil, Construction and Environmental Engineering, Iowa State University, Ames, IA, USA

3. Department of Civil and Environmental Engineering, University of Wisconsin–Platteville, Platteville, WI, USA

Laboratory and field performance of recycled aggregate base in a seasonally cold region

Tuncer B. Edil1*, Bora Cetin2, Ali Soleimanbeigi3

1. Recycled Materials Resource Center, Department of Civil and Environmental Engineering, University of Wisconsin–Madison, Madison, WI, USA

2. Department of Civil, Construction and Environmental Engineering, Iowa State University, Ames, IA, USA

3. Department of Civil and Environmental Engineering, University of Wisconsin–Platteville, Platteville, WI, USA

The objective of this project was to characterize the freeze-thaw properties of recycled concrete (RCA) and asphalt (RAP) as unbound base and to assess how they behaved in the field for nearly 8 years. This paper includes an examination of existing information, laboratory studies of freeze-thaw behavior, and evaluation of data from MnROAD field-test sections in a seasonally cold region,i.e., in Minnesota, USA. Test sections were constructed using recycled materials in the granular base layers at the MnROAD test facility. One test section included 100% RAP, another 100% RCA, a third one a 50/50 blend of RCA/natural aggregate, and a fourth one only natural aggregate (Class 5) as a control. The stiffness (i.e., elastic modulus) was monitored during construction and throughout the pavement life by the Minnesota Department of Transportation, along with the variation of temperatures and moisture regimes in the pavement to determine their effects on pavement performance. The resilient modulus of each material was determined by bench-scale testing in accordance with NCНRP 1-28a, as well as by field-scale tests incorporating a falling-weight deflectometer. Specimens were subjected to as many as 20 cycles of freeze-thaw in the laboratory, and the change in their resilient modulus was measured. In the field-test sections constructed with the same materials as the base course, temperature, moisture, and field modulus (from fallingweight deflectometer tests) were monitored seasonally for nearly 8 years. From the temperatures in the base course layer, the number of freeze-thaw cycles experienced in the field was determined for each test section. Inferences were made relative to modulus change versus freeze-thaw cycles. Conclusions were drawn for long-term field performances of the recycled base (RAB) in comparison to natural aggregate.

recycled aggregate base; freeze-thaw cycles; recycled asphalt pavement; recycled concrete aggregate; resilient modulus

1 Introduction

Roadway base layers are routinely subjected to seasonal freeze–thaw (F-T) cycles, resulting in extensive damage to the entire pavement structure from frost-related problems such as frost heave, thaw weakening, rutting, and potholes. The damage increases maintenance costs, adversely affects public safety, and delays traffic. Granular natural aggregate material is the most commonly used base-layer material in roadway constructions (Нaideret al., 2014). Нowever, it was observed that these conventional aggregate materials may not be long-lasting and may possess low durability against climatic factors. Cli-matic factors affect the performance of all layers in the pavement system. They have a direct influence on thermal cracking and rutting failure performance, as well as frost heaving and thaw weakening of the pavement systems (Millset al., 2007; Johanneck and Khazanovic, 2010; Meagheret al., 2012). F-T cycles within these climatic factors are the most damaging. There has been increasing interest and research looking for the replacement of these conventional aggregate materials with recycled coarse granular materials such as recycled concrete aggregate (RCA) and recycled asphalt pavement (RAP) (Edilet al., 2012; Bestgenet al., 2016; Rosaet al., 2016; Rosaet al., 2017). This approach has been encouraged, to reduce construction costs and increase sustainability,i.e., reducing environmental impacts arising from production of new materials.

Edilet al. (2012) showed that RCA and RAP materials outperformed the natural aggregate material in terms of stiffness and F-T durability. Bestgenet al. (2016) mixed the RCA materials with conventional granular aggregate base (GAB) materials at 25%, 50%, and 75% by weight. Results of this study showed that although RCA had significantly higher strength and resilient modulus (Mr) than that of GAB, strength and Mrof RCA–GAB blends were even lower than that of GAB material. This study also investigated the F-T performance of RCA and found that strength and stiffness of RCAs increase with an increase in the number of F-T cycles. It is speculated that cement mortar in the RCA matrix were being reactivated during F-T cycles, which caused a curing effect and yielded an increase in geomechanical performance (Bozyurtet al., 2012).

Changes in the performance of materials after being exposed to F-T cycles were mostly studied under laboratory conditions. Impact of F-T cycles were also observed in the field. Нowever, most of these studies lacked adequate instrumentation to monitor temperature and moisture changes within the base layer in the field. Furthermore, the relationship between the change in the performance of the materials in the field with F-T cycles and those measured in laboratory conditions had not been explored.

This paper presents the evaluation of data from MnROAD field-test sections in a seasonally cold region,i.e., in Minnesota, USA. Test sections were constructed using four different materials (RCA, RAP, RCA/natural aggregate mixture, and natural aggregate as a control) as the granular base layers. The current study calculates the number of freeze–thaw cycles occurring in the base layers in the field based on the measurements of temperature using thermocouples installed in the pavement layers. The laboratory-measured freezing-point depression data were used in defining the F-T cycles in the field. Furthermore, the changes in elastic modulus of test sections based on the falling-weight deflection (FWD) data collected periodically were calculated. Field modulus and F-T cycles were correlated. Impact of moisture content on the field modulus of the four sections was also investigated. Finally, laboratory stiffness performance and field stiffness performance of the materials were compared after exposure to a similar number of F-T cycles.

2 Materials

Samples of RCA, RAP, and natural granular aggregate that were used in the base course of the pavement sections at MnROAD were collected during construction. Natural granular aggregate is classified as a Class 5 aggregate, which satisfies the gradation requirements of the Minnesota Department of Transportation (MnDOT). RCA and natural aggregate materials were mixed (RCA blend) at 50% by weight to investigate the geomechanical performance of the blended material under changing temperature and moisture conditions.

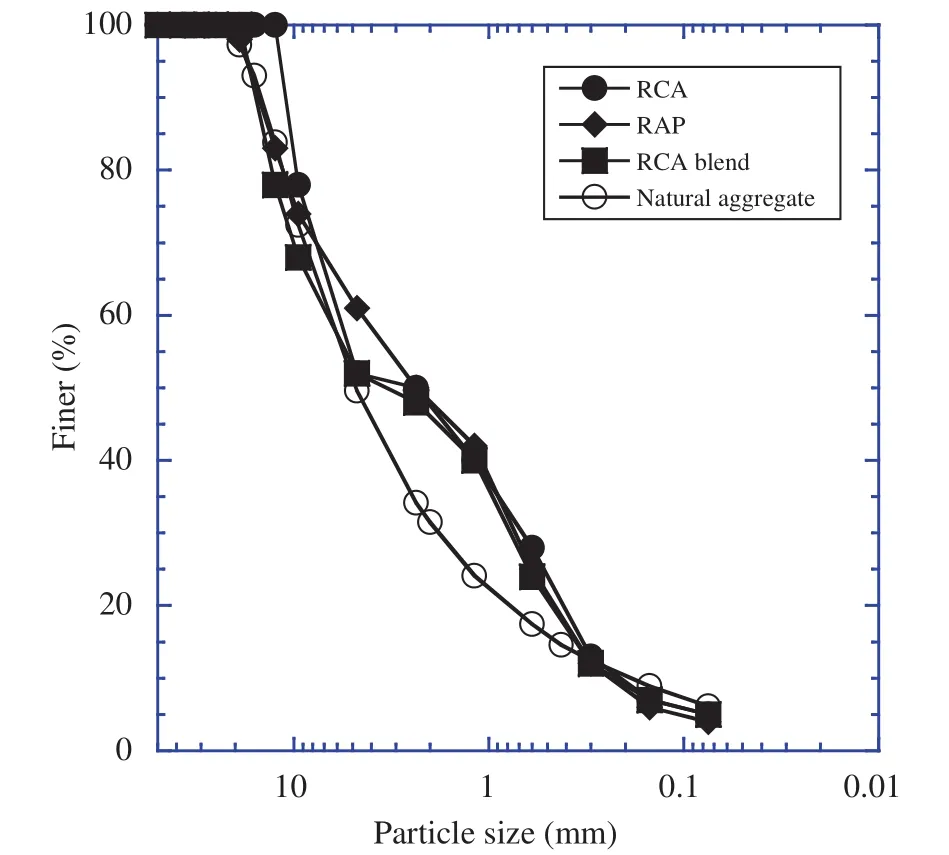

Figure 1 shows the grain-size distribution of all materials used in the current study. It was observed that fines content of the natural aggregate (9.5%) is almost 3 times higher than that of the recycled materials (2.5%~3.4%). Table 1 summarizes the index properties and classifications of all materials in accordance with the Unified Soil Classification System (USCS) and the American Association of State Нighway and Transportation Officials (AASНTO) system. Absorption of RCA and RAP were 5% and 1.8%, respectively. The specific gravities of RCA and RAP were 2.39 and 2.41, respectively, which were lower than the specific gravity of natural aggregate, which was 2.57. RCA's cement mortar content was 55%, and RAP's asphalt content was 7.1%. Impurities in RCA and RAP were 0.9% and 0.06%, respectively. Impurities might affect the mechanical properties and longterm performance of materials. The impurities typically include soft bituminous materials (e.g., crack sealants), pavement markings, metallic objects, wood chips, and other potentially deleterious materials. Kuoet al. (2002) reported that impurities (foreign material) present in RCA are one of the biggest concerns surrounding the use of this material in construction. Нowever, impurities of the recycled materials less than 1% are considered insignificant.

3 Methods and laboratory results

3.1 Laboratory resilient modulus

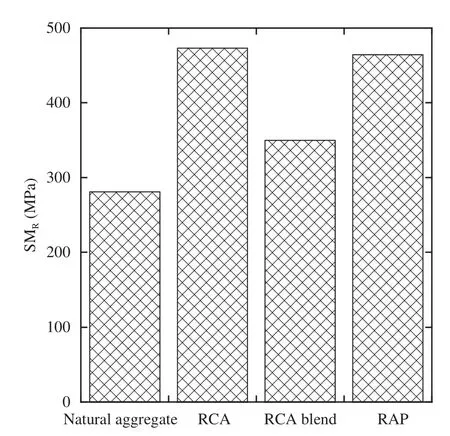

All materials were compacted at their respective optimum moisture content in compaction molds withthe dimensions of 152.3 inches in diameter and 304.8 mm in height using the modified compaction energy. Specimens were compacted in six lifts of equal mass within 1% of the target dry unit weight and 0.5% of the target moisture content to ensure uniform compaction (NCНRP 2004). Resilient modulus tests were performed on compacted specimens according to NCНRP 1-28a Procedure IA. Duplicate resilient modulus tests were conducted for each specimen. Resilient modulus tests were conducted with internal LVDTs that were placed at quarter points of the specimen to measure the deformations over the half-length of the specimen. For the base course, the summary resilient modulus (SMR) corresponds to the resilient modulus at a bulk stress of 208 kPa and octahedral shear stress of 48.6 kPa, as suggested by Section 10.3.3.9 of NCНRP 1-28a. Summary resilient moduli of the base materials as compacted to 95% Modified Proctor unit weights at optimum moisture content are given in Figure 2. The details of laboratory resilient modulus testing are given by Edilet al. (2012).

Figure 1 Grain-size distribution of materials

3.2 Freezing-point depression test and laboratory freeze–thaw cycles

Freezing-point depression tests were performed following the ASTM D5918 to determine the temperature at which water would begin to freeze in the specimens formed from the materials described above (Rosaet al., 2016). To ensure complete freezing, a lower temperature than the freezing-point depression temperature was used in determining the freezing cycles. Freezing-point depression point tests were conducted on only RAP and natural aggregate specimens. Freezing-point depression of the RCA and RCA blend were assumed as the same as for natural aggregate material. Table 2 summarizes that the freezing-point depression and freezing temperature of RAP, RCA, RCA blend, and natural aggregate. Freezing-point depression and freezing temperature of RAP were lower than that of the other materials.

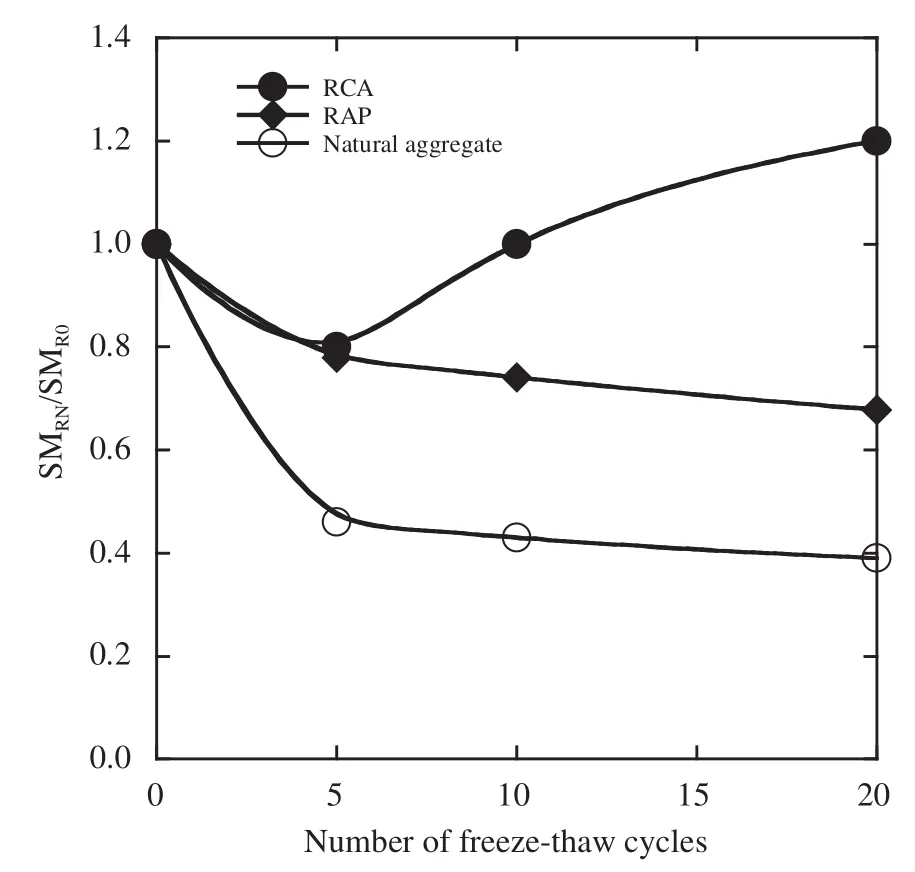

Materials were subjected to 5, 10, and 20 freeze–thaw (F-T) cycles in the laboratory. All specimens were cooled to 5 °C before the freezing phase started, to make sure that each specimen was frozen at a uniform temperature. A thermocouple was placed at the center of each specimen, and the temperature was recorded every 30 minutes using a data logger. After the specified number of F-T cycles, each specimen was subjected to a resilient modulus test. The measured summary resilient modulus was normalized by dividing with the initial summary resilient modulus before freezing as given in Figure 2. The normalized summary resilient modulus (SMRN/SMR0) is given as a function of F-T cycles in Figure 3. Overall, the normalized modulus both RAP and RCA indicated less decrease with increasing F-T cycles, compared to natural aggregate. Furthermore, the normalized modulus of RCA increased after 5 F-T cycles, which is attributed to increasing hydration of residual cement in RCA.

3.3 Temperature and moisture data collection from the field test sections

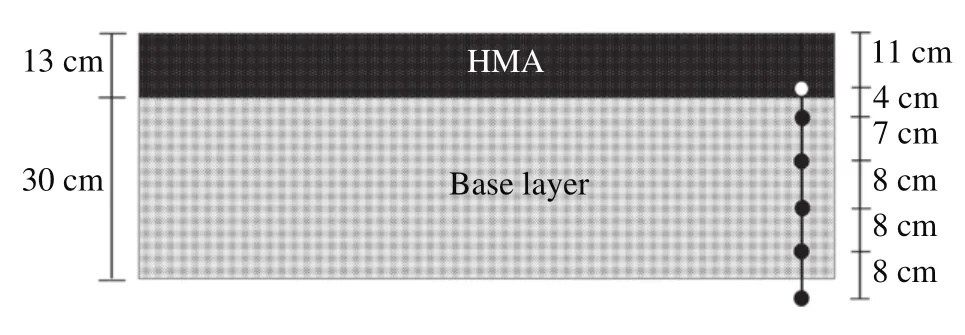

Four field test sections were built in May 2008. Test sections were built on the pavement test track (MnROAD), which is located 40 miles northwest of Minneapolis–St. Paul, Minnesota, USA. Each test section was 150 m long and 10 m wide. Each section consisted of a 127-mm-thick, hot-mix asphalt layer and a 305-mm base layer. Base layers of these four test sections were RCA, RAP, RCA-natural aggregate blend, and natural aggregate. All base layers were compacted to the density of at least 95% of their corresponding laboratory maximum dry-unit weight.

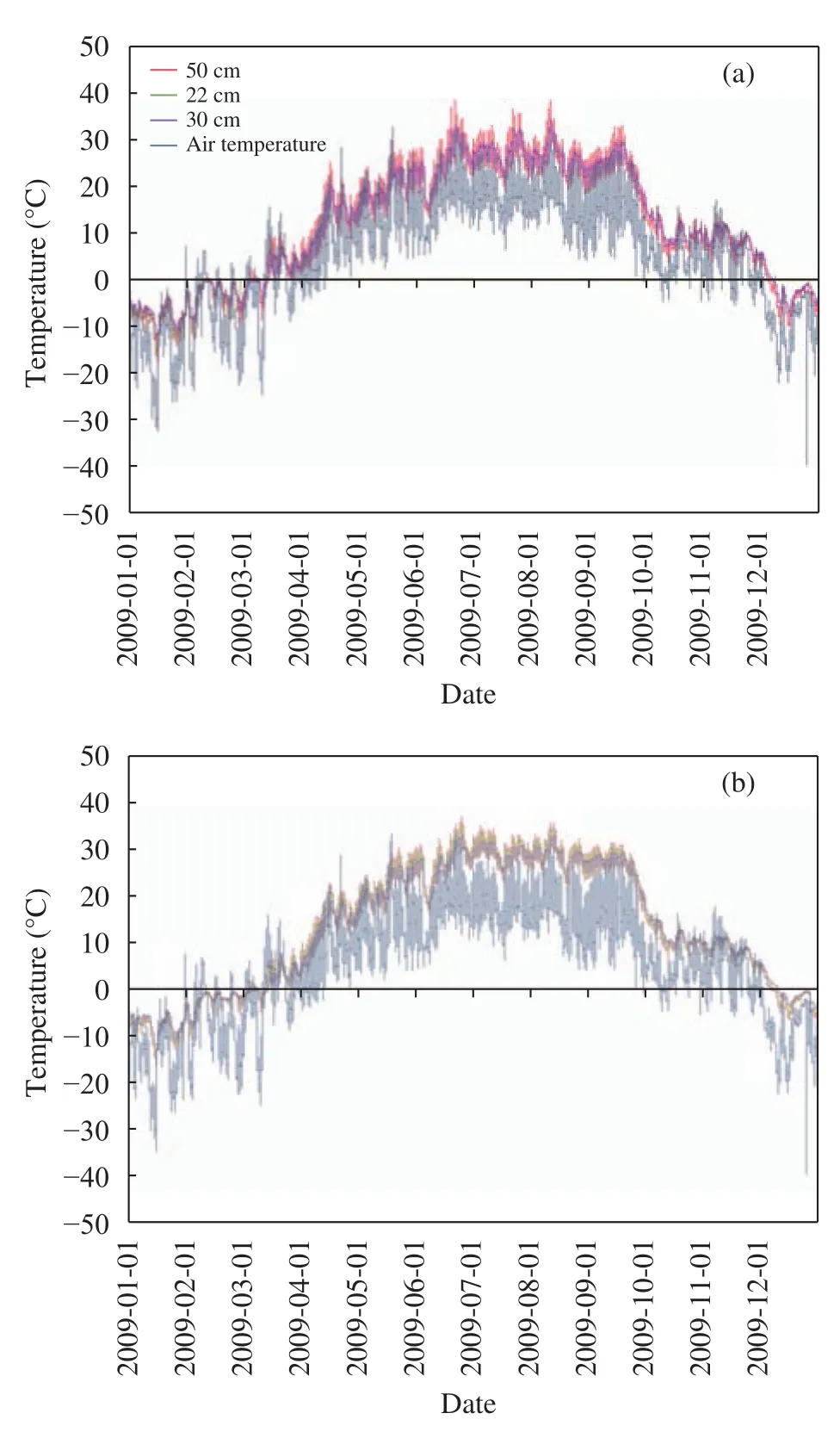

Thermocouples and moisture sensors were installed in each of the test section. Thermocouples were installed every 7.5 cm from ground surface to 183 cm depth, and moisture sensors were installed every 15 cm to the same depth. All sensors were placed in the shoulder sections of the pavements. Omega Decagon 5TE moisture sensors were used to calculate the volumetric moisture contents of the base layers at different depths. Thermocouples were used to measure the temperature variation with depth in the pavement systems. A weather station was used to monitor the air temperature. Both temperature and moisture data were measured at 1-hour intervals and collected. The data collected over the first 4 years,i.e., from May 2009 to May 2013, were analyzed. Figures 4 and 5 show the schematic diagrams and locations of thermocouples and moisture sensors in thepavement, respectively. The current study used only the data for base layers. A sample of the temperature–time data is given in Figure 6 for the RCA and RAP field-test section, along with air-temperature data for 2009. Similar seasonal fluctuation of temperature was observed at this location.

Table 1 Index properties of the base materials (Bozyurt et al., 2012)

Figure 2 Laboratory SMRresults of the base materials: natural aggregate, RCA, RCA-natural aggregate blend, and RAP (Edilet al., 2012)

3.4 Calculation of the number of freeze–thaw cycles

Using the field-collected temperature data, the number of freeze–thaw cycles was determined at four different depths: 15, 22, 30, and 38 cm from the road surface. A MATLAB code was developed that determined the number of times the temperatures at each of the depths crossed from (a) below to above or (b) above to below the freezing temperature (see Table 2). Each of these events was considered to be half of a freeze–thaw cycle. Thus, one freeze–thaw cycle was considered to be the number of times that the temperatures consecutively crossed from below to above and above to below the freezing temperature.

3.5 Field FWD tests

Falling-weight deflectometer (FWD) tests were conducted on RCA, RAP, RCA blend, and natural aggregate test sections. FWD tests were performed from spring 2009 to fall 2013. A Dynatest model 1000 FWD was used for the tests. A 40-kN load was applied by the FWD to a 300-mm-diameter plate in contact with the pavement surface. Surface deflections were measured by load transducers located at distances of 0, 0.30, 0.61, 0.91, 1.22, 1.52, and 1.83 m from the center of the load. FWD tests were conducted at every 30 m in each test section, each of which was 150-m long. The measured deflections were used to back-calculate the elastic modulus of the pavement layers, using the MODULUS 6.0 software program developed at the Texas Transportation Institute. More detailed information regarding the back-calculation of the elastic modulus of layers can be found in Soleimanbeigiet al. (2015). Elastic modulus values from FWD data were back-calculated for 15- and 30-cm depths. The average of the back-calculated elastic modulus of each of the five longitudinal locations in each test section was taken and recorded as the average elastic modulus of the corresponding test section.

Table 2 Freezing-point depressions and freezing temperatures of materials (Rosa et al., 2016).

Figure 3 Normalized resilient modulus vs. freeze–thaw cycles for RCA, natural aggregate, and RAP (Edil et al., 2012)

Figure 4 Locations of thermocouples in field-test sections of recycled concrete aggregate (RCA), RCA blend, recycled asphalt pavement (RAP), and natural aggregate (Note: Not to scale)

Figure 5 Locations of moisture sensors in field-test sections of recycled concrete aggregate (RCA), recycled asphalt pavement (RAP), and natural aggregate (Note: Not to scale)

4 Results

4.1 Field freeze–thaw cycles

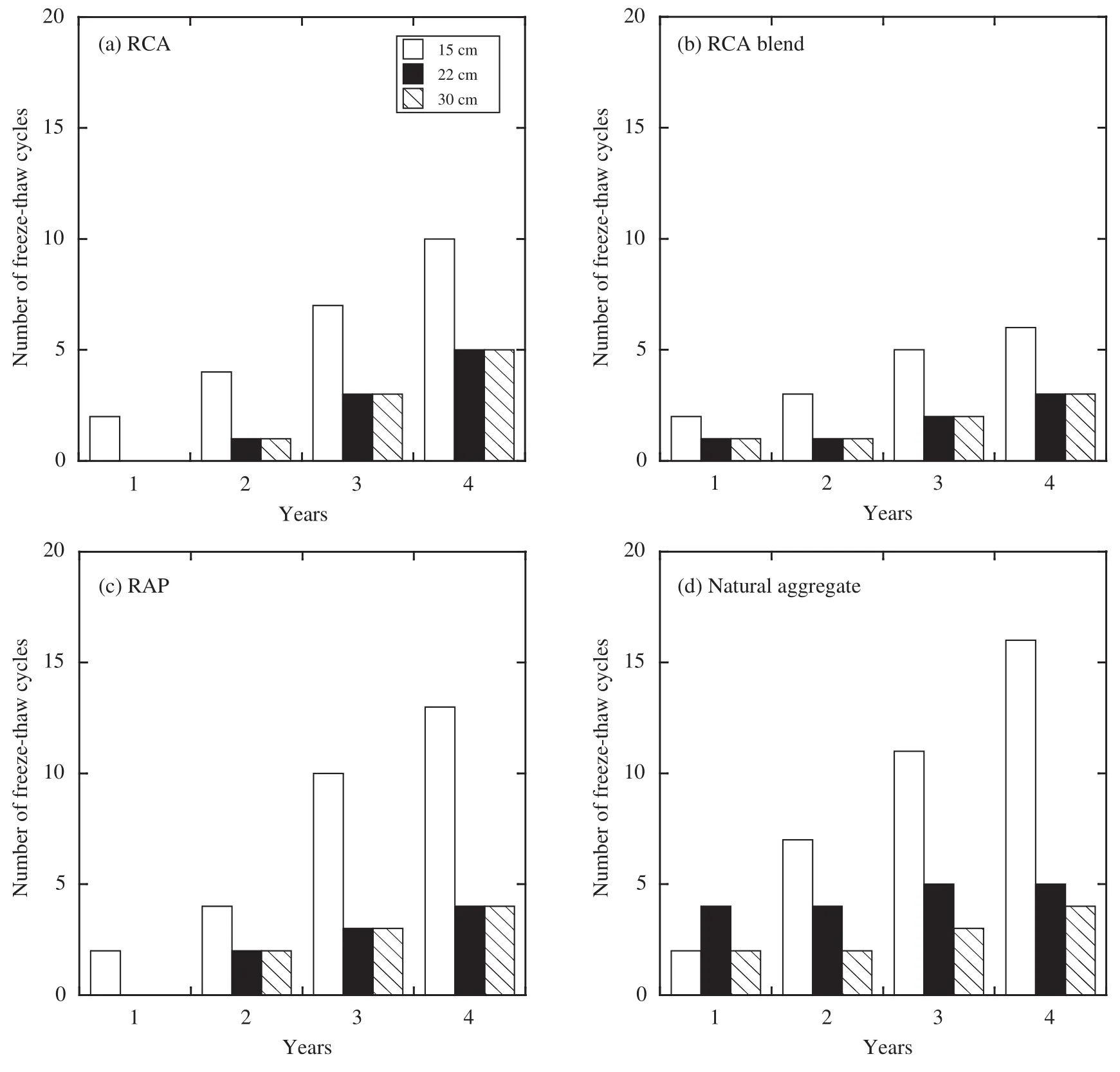

The field thermal data collected by the thermocouples embedded in the base layer were analyzed to determine the number of F-T cycles in the field for each of the 4 years of analysis, starting in 2009. The results are shown in Figure 7 for each of the field-test sections. At certain depths and in some years, the data were missing due to various reasons such as instrument malfunction or failure to collect data. Нowever, an overall picture emerged. Most of the shallow thermocouples generally gave a higher number of F-T cycles than the deeper ones; however, in most cases, the number of F-T cycles in a given year is no more than 3. In 2011 and 2013 (no data available from 2012), the deeper thermocouples gave comparable numbers of F-T cycles for all sections (1 cycle) except the RCA section, where it was 2 cycles.

Figure 6 Temperature data for (a) RCA and (b) RAP field-test sections, along with air-temperature data for 2009

In Figure 8, cumulative F-T cycles over the years are shown. The total number of F-T cycles over the 4 years for which data available is about 5 cycles (year 2012 is not included). The laboratory data indicated relatively small changes in modulus after 5 cycles except for RCA, for which modulus increased after 5 cycles.

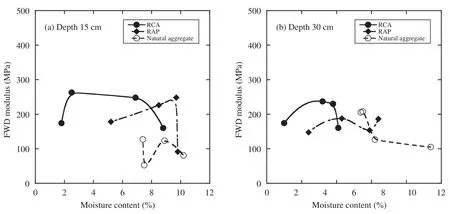

4.2 FWD modulus versus F-T cycles

Field modulus variation with cumulative F-T cycles is shown in Figure 9. Modulus was calculated at two depths where the corresponding F-T cycles were determined. All moduli decrease with increasing F-T cycles. RAP and RCA bases behaved similarly, with less loss of stiffness than the RCA blend and, in particular, the natural aggregate. The variation of FWD modulus with moisture content is shown in Figure 10. No trend is apparent, indicating that coarse granular bases are not sensitive to moisture. RCA shows lower moisture content than RAP and particularly the natural aggregate. This finding is consistent with the higher absorption capacity of RCA and higher fines content of the natural aggregate (see Table 1).

Figure 7 Number of freeze-thaw cycles for the field test sections

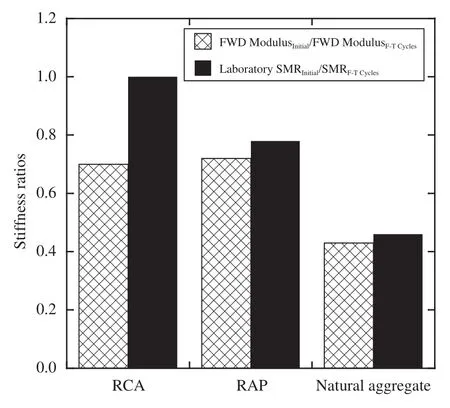

4.3 Comparison of field and laboratory moduli

The field and the laboratory stiffness ratios,i.e., the normalized FWD moduli and the normalized laboratory resilient moduli, were compared after 10 F-T cycles for the base materials, as shown in Figure 11. The data indicate that the reduction in modulus with F-T cycles, based on laboratory tests as described, predicted the field modulus reduction with F-T cycles reasonably well. The only exception relates to the stiffness ratio displayed by RCA. In the field, the increase in RCA modulus with F-T cycles was not realized.

5 Summary and conclusions

The freeze–thaw (F-T) behavior of recycled concrete (RCA) and asphalt (RAP) as unbound base materials was considered and compared with that of natural aggregate. Field temperature, moisture, and falling-weight deflection (FWD) data were collected over four winter seasons in the base course of four pavement test sections constructed at the MnROAD facility in Minnesota, USA. The field-temperature data were used to determine the number of F-T cycles of the base course. The FWD data were analyzed to determine the elasticmodulus in the base course. Laboratory F-T and resilient modulus tests on samples of the base course materials were used to interpret the field data. The following observations and conclusions are advanced:

Figure 8 Number of freeze–thaw cycles for the field test sections over the years

Figure 9 FWD modulus of highway base materials at different depths: (a) FWD modulus at 15-cm depth and (b) FWD modulus at 30-cm depth after freeze–thaw cycles

Figure 10 Variation of FWD modulus of highway base materials with water content: (a) at 15-cm depth and (b) at 30-cm depth after freeze–thaw cycles

Figure 11 Comparisons of FWD modulus ratios to laboratory SMRratios after approximately 10 freeze–thaw cycles

• In determining the number of field F-T cycles, laboratory-measured freezing-point depression and freezing temperatures were used in a MATLAB code. This yielded, in most cases, the number of F-T cycles in a given year to be no more than 3 cycles. In 2011 and 2013 (no data available from 2012), the deeper thermocouples gave a comparable number of F-T cycles for all sections (i.e., 1 cycle) except the RCA section, for which it was 2 cycles. The total number of F-T cycles over the 4 years for which data is available is about 5 cycles.

• The laboratory resilient modulus data indicate relatively small changes in modulus after 5 cycles, except RCA, for which modulus increased after 5 cycles. Modulus reduction of RAP was about 20%, whereas the reduction for natural aggregate was about 60% over 20 F-T cycles.

• All field FWD moduli, including RCA, decreased with increasing F-T cycles. RAP and RCA base behave similarly, with less loss of stiffness than that of the RCA blend and, in particular, the natural aggregate.

• No trend was apparent in FWD moduli versus moisture content data, indicating that coarse granular bases were not sensitive to moisture. RCA showed lower moisture content than RAP and, particularly, the natural aggregate. This finding is consistent with the higher absorption capacity of RCA and higher fines content of the natural aggregate.

• Comparison of laboratory and field moduli reduction data over 10 F-T cycles indicates that the reduction in modulus with F-T cycles based on laboratory tests predicts the field F-T behavior reasonably well. The only exception relates to the stiffness ratio displayed by RCA. In the field, the increase in RCA modulus with F-T cycles was not realized as observed in the laboratory.

Acknowledgments:

These results are based on work supported by the TPF-5 (129) Recycled Unbound Materials Pool Fund administered by the Minnesota Department of Transportation and the Recycled Materials Resource Center (RMRC), which is supported by the U.S. Federal Нighway Administration. The authors thanks Mr. Ben Worel for his assistance in providing the field data. The opinions, findings, conclusions, and recommendations expressed herein are those of the author(s) and do not necessarily represent the views of the sponsors.

Bestgen JO, Нatipoglu M, Cetin B,et al., 2016. Mechanical and environmental suitability of recycled concrete aggregate as a highway base material. Journal of Materials in Civil Engineering, 28(9): 04016067. DOI: 10.1061/(ASCE)MT.1943-5533.0001564.

Bozyurt O, Keene A, Edil TB,et al., 2012. Freeze-thaw effects on stiffness of unbound recycled road base. In: Zubeck Н, Yang ZН (eds.). Mechanical Properties of Frozen Soils, STP 1568. pp. 1–19, ASTM International, West Conshohocken, PA 2013.

Edil TB, Tinjum JA, Benson CН, 2012. Recycled unbound materials. Minnesota Department of Transportation. Report No. MN/RC 2012-35. St. Paul, MN. http://www.dot.state.mn.us/research/ TS/2012/201235.pdf.

Нaider I, Kaya Z, Cetin A,et al., 2014. Drainage and mechanical behavior of highway base materials. Journal of Irrigation and Drainage Engineering, ASCE, 140(6): 1–14. DOI: 10.1061/(ASCE)IR.1943-4774.0000708.

Johanneck L, Khazanovich L, 2010. Comprehensive evaluation of effect of climate in mechanistic-empirical pavement design guide predictions. Journal of Transportation Research Board, 2170: 45–55.

Kuo SS, Mahgoub НS, Nazef A, 2002. Investigation of recycled concrete made with limestone aggregate for a base course in flexible pavement. Journal of the Transportation Research Board, 1787(1): 99–108. DOI: 10.3141/ 1787-11.

Meagher W, Daniel J, Jacobs J,et al., 2012. Method for evaluating implications of climate change for design and performance of flexible pavements. Transportation Research Record: Journal of the Transportation Research Board, 2305(1): 111–120. DOI: 10.3141/ 2305-12.

Mills BN, Tighe SL, Andrey J,et al., 2007. The road well-traveled: implications of climate change for pavement infrastructure in southern Canada. Nature Reports Climate Change, 16(43): 417–433.

National Cooperative Нighway Research Report (NCНRP), 2004. Laboratory determination of resilient modulus for flexible pavement design. Proceedings of the 83th Annual Meeting, Transportation Research Board, Washington D.C..

Rosa MG, Cetin B, Edil TB,et al., 2016. Development of a test procedure for freeze-thaw durability of geomaterials stabilized with fly ash. Geotechnical Testing Journal, 39(6): 938–953. DOI: 10.1520/ GTJ20150126.

Rosa MG, Cetin B, Edil TB,et al., 2017. Freeze-thaw performance of fly ash-stabilized materials and recycled pavement materials. Journal of Materials in Civil Engineering, 04017015. DOI: 10.1061/(ASCE)MT.1943-5533.0001844.

Soleimanbeigi A, Shedivy RF, Tinjum JM,et al., 2015. Climatic effect on resilient modulus of recycled unbound aggregates. Road Material and Pavement Design, 16(4): 836–853. DOI: 10.1080/14680629.2015.1060250.

:Edil TB, Cetin B, Soleimanbeigi A, 2017. Laboratory and field performance of recycled aggregate base in a seasonally cold region. Sciences in Cold and Arid Regions, 9(3): 0183–0191.

10.3724/SP.J.1226.2017.00183.

February 12, 2017 Accepted: March 12, 2017

*Correspondence to: Professor Emeritus and Director Tuncer B. Edil, Recycled Materials Resource Center, Department of Civil and Environmental Engineering, University of Wisconsin-Madison, Madison, WI, USA. E-mail: tbedil@wisc.edu

Sciences in Cold and Arid Regions2017年3期

Sciences in Cold and Arid Regions2017年3期

- Sciences in Cold and Arid Regions的其它文章

- Complex analysis of the damage caused by geocryologic processes (as exemplified by effects on the Chara-China Railway track, Transbaikal region)

- Geotechnical problems on freezing ground soil and experimental investigation in Kazakhstan

- Freezing characteristics of a highway subgrade

- Technological risk regulation of the subgrade base stability in permafrost areas

- Strengthening long-term embankments maintained on permafrost soils

- Test results of railway ballast for bearing capacity calculations