Effect of cryostructures on the uniaxial compressive strength of frozenclay

JianWei Wang,HaiPeng Li*,Lei Song,Shuai Dou,XinLei Na

1.State Key Laboratory of Geo-mechanics and Deep Underground Engineering,China University of Mining and Technology,Xuzhou,Jiangsu 21116,China

2.Golder Associates,Inc.,Anchorage,Alaska 99508,USA

Effect of cryostructures on the uniaxial compressive strength of frozenclay

JianWei Wang1,HaiPeng Li1*,Lei Song1,Shuai Dou1,XinLei Na2

1.State Key Laboratory of Geo-mechanics and Deep Underground Engineering,China University of Mining and Technology,Xuzhou,Jiangsu 21116,China

2.Golder Associates,Inc.,Anchorage,Alaska 99508,USA

Unconfined uniaxial compressive tests were performed to study the influence of cryostructure on frozen clay's behavior, such as strain−stress,compressive strength,and failure characteristics,at temperatures varying from−10 to−2°C and strain rates varying from 1.0×10−5to 1.0×10−3s−1.Artificial samples were prepared of three types:(1)integral structure,(2) laminar structure,and(3)reticular structure.The impact of temperature,strain rate,and cryostructure on the mechanical properties is discussed.In general,frozen clay with various cryostructures shows strain-softening behavior in the range of testing temperatures and strain rates.For frozen clay of different cryostructures,the ultimate compressive strength increases with increasing strain rate and decreasing temperature.Under the same testing conditions,the ultimate compressive strengths from high to low are in integral samples,laminar samples,and reticular samples.Failure strain of frozen clay generally increases with increasing temperature and does not indicate any correlation with cryostructure or strain rate. The failure mode of integral and reticular samples was shear failure,while laminar samples showed tensile failure.

frozen clay;cryostructure;strain−stress relationship;ultimate compressive strength;failure strain

1 Introduction

Cryostructure is the pattern of ice inclusion within a frozen soil.Due to different soil types,moisture levels,and freezing conditions,the forms of ice occurrence in the formation process of frozen soil differ.According to the existing form and distribution of ice, Tsytovich(1985)classified the structures of frozen soil as integral,laminar,and reticular.The ice formation in frozen soil with integral structure is distributed evenly.The ice formation in laminar frozen soil is distributed as ice lens.With the reticular frozen soil, the size,shape,and direction of the ice formations vary because the vein ice separating soil particles reticulates.It is commonly acknowledged that ice formation and distribution characteristics control the contact and connection of soil particles.Therefore,these three types of cryostructure reflect different mechanical properties of frozen soil,such as its strength and deformation.

Many studies have reported on the mechanical properties of frozen soils.Akili(1971)studied the strength of frozen clay and clayey silt at different strain rates.Zhu(1992)studied the stress−strain behavior of frozen soil under constant-strain-rate uniaxial compression tests.Andersenet al.(1995)investigated small-strain behavior of frozen sand in triaxial compression tests and found that the Young's modulus is independent of strain rate and temperature.Li and Yang(1995)summarized the difference in strain rateunder different temperature conditions versus the stress−strain curve.Results showed that the compressive strength of frozen soil was very sensitive to the changes of strain rate.Zhanget al.(2003)carried out uniaxial compressive strength tests on saturated frozen soil(loess)in Lanzhou under a constant strain rate.Liet al.(2004)also performed a uniaxial compressive strength test on three types of saturated frozen clay with different dry densities under a constant strain rate.Xiao(2008)conducted uniaxial compressive tests on artificial frozen soil with different water contents at various temperatures.Chenet al.(2009) tested two typical Shanghai saturated frozen soft soil by uniaxial unconfined compressive tests.Yanget al. (2015)investigated mechanical properties of seasonally frozen and permafrost soils at a high strain rate.Results showed that the ultimate compressive strength of horizontal permafrost specimens is substantially higher than that of vertical specimens at the same testing temperature.

Most of the studies just mentioned were based on integral frozen soil and did not specially conduct research on frozen soil with segregated ice.In earlier years,a few researchers were concerned with the effect of cryogenic texture on mechanical properties of frozen soil(Pekarskaya,1963;Jumikis,1979;Radd and Wolfe,1979).More recently,Liet al.(2007)investigated the influence of loading directions on the compressive strength of frozen silt with layered structures.Maet al.(2008)analyzed damage type and the stress−strain curve of frozen clay with high ice content at high temperature under the uniaxial compression test.Xuet al.(2011)carried out a series of triaxial compression tests on frozen sandy soil with a volumetric ice content of about 50%at a temperature of−2.0°C to investigate the properties of ice-saturated frozen sandy soil.Duet al.(2014,2015)conducted a series of uniaxial compressive tests on ice-rich,frozen silty sands.

It is well known that the ice matrix formed during freezing greatly influences the mechanical behaviors of frozen soil.At present,studies on mechanical properties of frozen clay with different cryostructures are rarely performed and compared.To quantitatively evaluate the impact of cryostructure on the strength and deformation of frozen soil,frozen clay samples with integral structure,laminar structure,and reticular structure were prepared.A series of uniaxial compressive strength tests were carried out at temperatures varying from−2 to−10°C and strain rates varying from 1.0×10−5to 1.0×10−3s−1.Test results including stress−strain relationship,ultimate compressive strength,and failure characteristics are presented;and variables effecting the results are discussed.

2 Experiment

2.1 Materials used

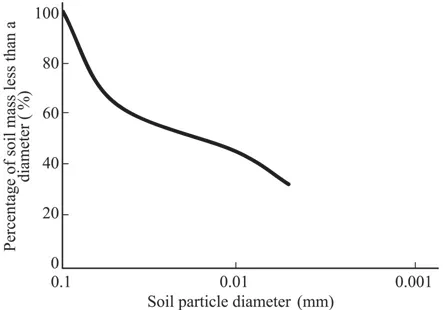

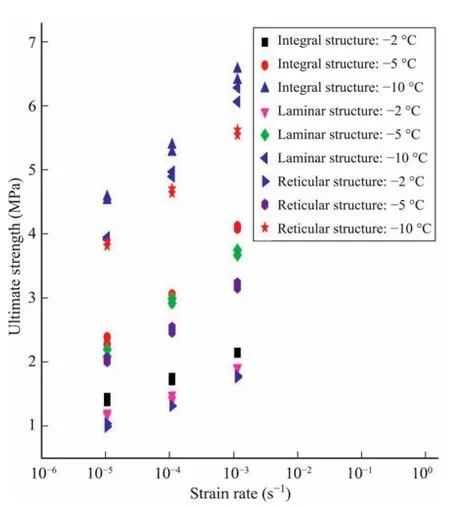

The samples used in the experiments were Quaternary red clay.The physical and mechanical properties of the tested soils are shown in Table 1,and the grainsize distribution of samples is shown in Figure 1.

Figure 1 Gradation curve of the soil

Table 1 The physical and mechanical parameters of soils

2.2 Sample preparation

For preparing samples with water content of 20%, air-dried samples were mixed with distilled water andequilibrated for 24 hours.The samples were packed in a cubic mold with an internal space of 100mm× 100mm×100mm at a given bulk dry density(1.72 g/ cm3).To reduce shrinkage cracks and moisture transferring during freezing,the samples were kept at 0.5°C in a constant-temperature chamber for 24 hours.To make the integral cryostructure,samples were quickly frozen at−35°C and kept at the same temperature for 24 hours.

For laminar samples,soils with water content of 15%were prepared and divided into five layers to pack in a cubic mold.The first soil layer was compressed to 18-mm thick,then placed in a constanttemperature chamber at−35°C for 15 minutes.Afterthe first soil layer was frozen,20 g of distilled water was put into the mold.The face of first soil layer was kept smooth and horizontal to distribute the water evenly,and then the sample was frozen in the constant temperature chamber for 5 minutes.In the same way,other ice and soil layers were prepared.

For reticular samples,the unidirectional,slowfreezing method was performed.First,samples were prepared according to the required bulk dry density (1.72 g/cm3)and water content(20%).The samples were placed in the constant-temperature chamber,and a piece of freezing board was placed on the top of samples.Effort was made to reduce thermal disturbance from the bottom and sides of the cubic mold by sealing them with heat-insulated materials.The freezing board maintained the temperature as cold as−3.5°C,andthesample was frozenfor72hours.

Figure 2 shows the representative samples with different cryostructures.The samples are cubes with dimensions of 100 mm in height,100 mm in width and 100 mm in length;bulk dry density is 1.72 g/cm3; and the water content is 20%.Laminar samples(Figure 2b)include four ice layers with a thickness of 2 mm each.Reticular samples(Figure 2c)include a large quantity of ice wedges.There are more ice wedges of lower angle than that of higher angle.

Figure 2 Frozen clay samples of(a)integral structure,(b)laminar structure,and(c)reticular structure

2.3 Test method

The uniaxial compressive tests were conducted by an MTS 810 machine,which can perform strain-controlled and stress-controlled tests.The load capacity is up to 250 kN,and the maximum displacement is 85 mm;the working temperature range is from−30°C to 30°C;the accuracy is±3%.

All uniaxial compressive tests were carried out by strain-controlled loading at a constant strain rate of 1×10−5,1×10−4,and 1×10−3s−1;and the experimental temperatures are−2,−5,and−10°C.Before the test, the sample was wrapped in a plastic membrane and placed in the chamber at the tested temperature for 12 hours.Silicon grease was applied on the loading face of the steel platen to lubricate the interface of platen and sample.The axial load and deformation were acquired and recorded automatically by the testing system during compression.

3 Test results

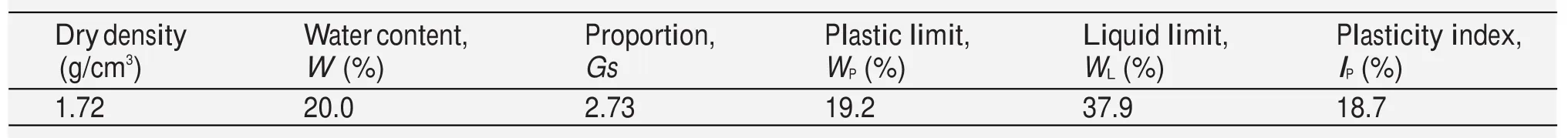

Figure 3 shows stress−strain curves for frozen clay of different cryostructures at various temperatures and strain rates.As shown in Figure 3,stress−strain curves generally included three stages:linear elastic deformation,plastic yielding,and failure.In the linear elastic deformation stage,the slope of stress−strain curves increases with decreasing temperature and increasing strain rate.All the curves showed strain-softening behaviors within the scope of test temperatures and strain rates.

Figure 3 Stress−strain curves for frozen clay with(a)integral structure,(b)laminar structure,and(c)reticular structure

Test results included test temperature(T),strain rate(ε),ultimate strength(σm),and failure strain(εf) and are summarized in Table 2,where CI,CL, and CW represent integral samples,laminar samples,and reticular samples,respectively.Ultimate strength(σm)and failure strain(εf)were defined as stress and strain at the peak of the stress−strain curves.

Table 2 Ultimate strength and failure strain of frozen clay

4 Discussion

4.1 Ultimate strength

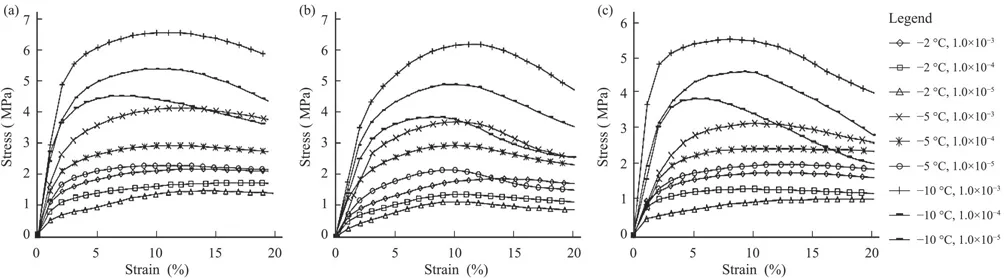

Figure 4 shows the ultimate compressive strength-versus-strain rate at various temperatures for frozen clay of different cryostructures.As shown in Figure 4, the ultimate compressive strength increases with decreasing temperature and increasing strain rate.The relationships can be described as follows:

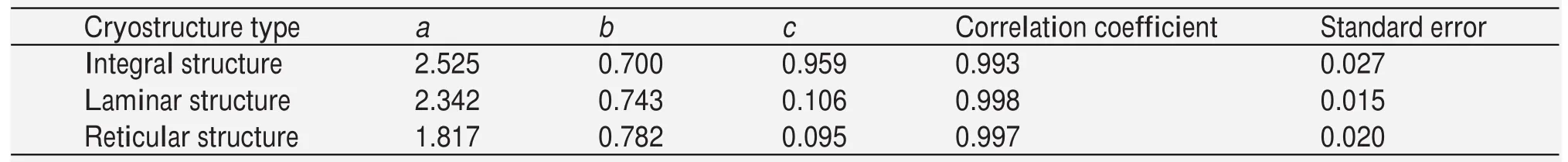

whereT0=−1°C is the reference temperature;a,b, andcare parameters related to cryostructure,and their values are listed in Table 3.

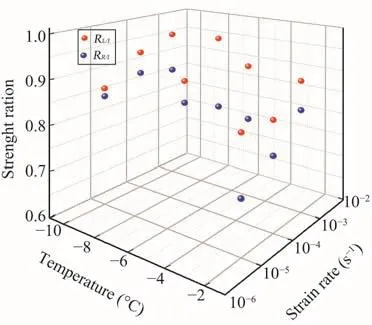

Table 2 shows the ultimate compressive strength from high to low is ordered integral samples,laminar samples,and reticular samples,given the same strain rate under the same temperature.Figure 5 shows the strength ratios for samples of different structures.The strength ratios of laminar structure to integral structure and of reticular structure to integral structure were expressed by the symbolsRL/IandRR/I.As seen in Figure 5,the strength ratiosRL/IandRR/Ido not correlate with temperature and strain rate.Within the scope of the test temperatures and strain rates,the average values ofRL/IandRR/Iare 0.90 and 0.82,respectively.

Figure 4 Ultimate compressive strength vs.strain rate for frozen clay

Table 3 Values of parameters a,b,and c for frozen clay

Figure 5 Comparison of ultimate compressive strength for frozen clay

4.2 Failure characteristics

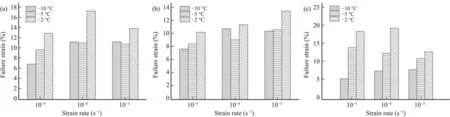

Figure 6 shows failure strain at different strain rates under different temperatures.As shown in Figure 6,failure strain generally increases with increasing temperature,as the brittleness of frozen soil decreases with increasing temperature.One finds that failure strain under a strain rate of 10−5s−1is lower than under other strain rate,while failure strain does not show correlation with cryostructure.

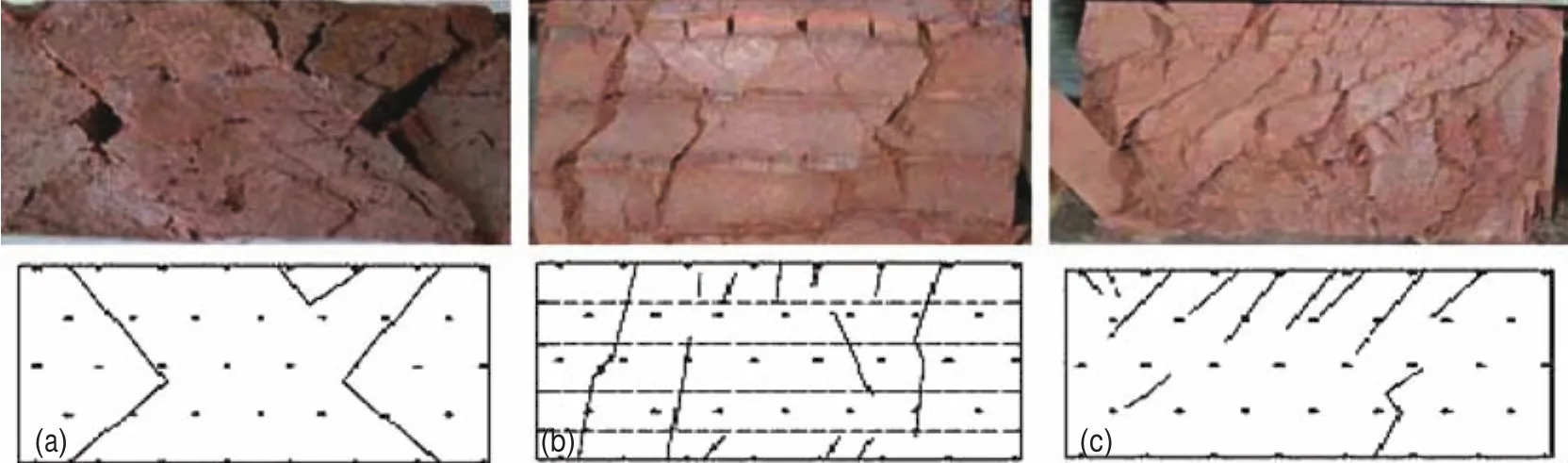

Figure 7 shows representative failure characteristics for different cryostructures.As shown in Figure 7,integral samples show the shear failure mode. There are two main cracks around the specimen's corners,extending from the edge to the center.The angles between the main cracks and the principal stress direction are generally less than 45°.For laminar samples,the failure mode is tensile failure.A few large cracks go through the specimen from top to bottom, nearly parallel to the principal stress.Besides the large cracks,many small cracks exist in the ice layer. The failure mode of the reticular structure is shear failure.Through the specimen,many thin cracks occur along the ice wedge.The angle between the cracks and the principal stress is about 45°.

Figure 6 Failure strain at different strain rates under different temperatures for(a)integral structure,(b)laminar structure, and(c)reticular structure

Figure 7 Failure characteristics of frozen clay of different structures:(a)integral structure,(b)laminar structure, and(c)reticular structure

5 Conclusions

Frozen clay samples with integral,laminar,and reticular cryostructures were prepared in the laboratory.A series of uniaxial compressive tests was conducted under strain rates of 1.0×10−5,1.0×10−4,and 1.0×10−3s−1at temperatures of−2,−5,and−10°C. Stress−strain relations,ultimate compressive strength, and failure characteristics were achieved and analyzed.The following conclusions can be made based on analyses of the test results:

(1)The stress−strain curves of different cryostructures show three typical stages:linear elastic deformation,plastic yielding,and failure.The relationships of stress−strain are strain-softening within the scope of the tested temperatures and strain rates.

(2)The ultimate compressive strength of different cryostructures of frozen clay increases with decreasing temperature and increasing strain rate;their relationships can be described by

(3)The strength ratios of laminar structure to integral structureRL/Iand reticular structure to integral structureRR/Ido not correlate with temperature and strain rate;the average values ofRL/IandRR/Iare 0.90 and 0.82,respectively,within the scope of tested temperatures and strain rates.

(4)The failure strain of frozen clay with different cryostructures increases with increasing temperature, but it is not related to strain rates and cryostructure.

(5)The failure mode of frozen clay with integral or reticular structure is shear failure,while that of frozen clay with laminar structure is tensile failure.

Acknowledgments:

This research was supported by the Natural Science Foundation of China(41171065 and 51323004).We would like to express our gratitude to the anonymous reviewers for providing constructive comments and suggestions.

Akili W,1971.Stress−strain behavior of frozen fine-grained soils. Highway Research Record,360:1−8.

Andersen GR,Swan CW,Ladd CC,et al.,1995.Small-strain behavior of frozen sand in triaxial compression.Canadian Geotechnical Journal,32:428−451.

Chen YL,Chang LQ,Xu S,et al.,2009.Uniaxial compressive strength test of frozen soft soil in Shanghai.Journal of Shanghai University(Natural Science Edition),15(3):310−315.(in Chinese)

Du HM,Ma W,Zhang SJ,et al.,2015.Strength properties of icerich frozen silty sands under uniaxial compression for a wide range of strain rates and moisture contents.Cold Regions Science&Technology,123:107−113.

Du HM,Zhang SJ,Ma W,et al.,2014.Study of the uniaxial compressive strength characteristics of frozen soil with high ice/ water content.Journal of Glaciology and Geocryology,36(5): 1213−1219.(in Chinese)

Jumikis AR,1979.Cryogenic texture and strength aspects of artificially frozen soils.Engineering Geology,13:125−135.

Li HP,Zhu YL,Zhang JB,et al.,2004.Effects of temperature, strain rate and dry density on compressive strength of saturated frozen clay.Cold Regions Science&Technology,39(1):39−45. DOI:10.1016/j.coldregions.2004.01.001.

Li HP,Huang JH,Zhu YL,et al.,2007.Influence of loading directions on compressive strength of frozen silt with layered structures.Journal of China University of Mining and Technology, 36(5):573−576.DOI:j.issn.1000-1964.2007.05.057305.(in Chinese)

Li HS,Yang HT,Chang C,et al.,1995.Effects of temperature, strain rate and dry density on compressive strength of saturated frozen clay.Journal of Glaciology and Geocryology,17(1): 40−47.

Ma XJ,Zhang JM,Chang XX,et al.,2008.Experimental research on strength of warm and ice-rich frozen clays.Rock and Soil Mechanics,29(9):2498−2502.DOI:10.16285/j.rsm.2008.09. 041.(in Chinese)

Pekarskaya NK,1963.Shear strength of frozen ground and its dependence on texture.Izd-Vo Akad Nauk,SSSR,Moscow,U.S. Army Cold Regions Research and Engineering Laboratory, Draft Translation,115:60−77.

Radd FJ,Wolfe LH,1979.Ice lens structures,compression strength and creep behavior of some synthetic frozen silty soils.Engineering Geology,13:169−183.

Tsytovich HA,1985.Mechanics of Frozen Ground.Beijing:Science Press,pp.48−49.

Xiao HB,2008.Relationship between uniaxial compressive strength and temperature and water content of artificial frozen soil. Mineral Exploration,11(4):62−63.(in Chinese)

Xu XT,Lai YM,Dong YH,et al.,2011.Laboratory investigation on strength and deformation characteristics of ice-saturated frozen sandy soil.Cold Regions Science&Technology,69(1): 98−104.DOI:10.1016/j.coldregions.2011.07.005

Yang ZH,Still B,Ge X,2015.Mechanical properties of seasonally frozen and permafrost soils at high strain rate.Cold Regions Science&Technology,113:12−19.DOI:10.1016/j.coldregions.2015.02.008.

Zhang JB,Li HP,Lin CN,et al.,2003.Compressive strength of saturated frozen silt under constant strain rate.Chinese Journal of rock mechanics and engineering,22(z2):2865−2870.

Zhu YL,Zhang JY,Peng WW,et al.,1992.Constitutive of frozen soil in uniaxial compression.Journal of Glaciology and Geocryology,14(3):210−217.

:Wang JW,Li HP,Song L,et al.,2017.Effect of cryostructures on the uniaxial compressive strength of frozen clay.Sciences in Cold and Arid Regions,9(3):0267-0272.

10.3724/SP.J.1226.2017.00267.

November 22,2016Accepted:December 22,2016

*Correspondence to:HaiPeng Li,China University of Mining and Technology.No.1,Daxue Road,Xuzhou,Jiangsu 211116,China.Tel:+86-13645202599;E-mail:lihaipeng1991@163.com

Sciences in Cold and Arid Regions2017年3期

Sciences in Cold and Arid Regions2017年3期

- Sciences in Cold and Arid Regions的其它文章

- Laboratory and field performance of recycled aggregate base in a seasonally cold region

- Laboratory investigations of the thermal strain of frozen soils, using fiber-optic strain gauges based on Bragg gratings

- Subgrade-reinforcement techniques for the dangerously deforming sections of railway lines in the north of the Russian Far East

- Systematization of features and requirements for geological survey of railroad subgrades functioning in cold regions

- Application of a nondestructive method to evaluate the active layer in a cold region

- Soil freezing process and different expressions for the soil-freezing characteristic curve