Rheological Properties and Microstructure of Printed Circuit Boards Modifed Asphalt

Yu Xin; Dong Fuqiang; Liang Xingmin; Ji Zezhong

(College of Civil and Transportation Engineering, Hohai University, Nanjing 210098)

Rheological Properties and Microstructure of Printed Circuit Boards Modifed Asphalt

Yu Xin; Dong Fuqiang; Liang Xingmin; Ji Zezhong

(College of Civil and Transportation Engineering, Hohai University, Nanjing 210098)

The asphalt modifed with different printed circuit boards (PCBs) content (0, 5%, 10%, and 15%) was prepared in this study. The general properties, rheological properties, temperature sensitivity, fatigue resistance, and morphology of the PCBs modifed asphalt were investigated by conventional tests, the Brookfeld viscometry tests, the dynamic shear rheometer (DSR) tests, the bending beam rheometer (BBR) tests, and the fuorescence microscopy tests. And the infuence of PCBs content on the above-mentioned properties was analyzed systematically. The results showed that the addition of PCBs could improve the high temperature performance, the low temperature performance, and the temperature sensitivity property of the modifed asphalt, while compromising with the fatigue resistance of the modifed asphalt. With the increase of PCBs content, the modifed asphalt could have better softening points, viscosity, failure temperature, and temperature sensitivity, while its low temperature performance and fatigue resistance became worse to different degree. And the particle size of PCBs became bigger and non-uniform with an increasing PCBs content. According to the above-mentioned properties, the optimum PCBs content was specifed at less than 10% in the modifed asphalt system.

PCBs modifed asphalt; viscoelasticity behavior; temperature sensitivity; fatigue resistance; morphology

1 Introduction

Nowadays, tens of thousands of tons of waste printed circuit boards (PCBs) from large household appliances such as refrigerators, personal stereos, and computers are being scrapped every year[1]. If the waste PCBs cannot be treated properly, it will pollute the local environment[2]. There are many methods to recycle the waste PCBs including landfll, incineration, thermal denaturalization, and wet chemical separation, etc.[3]Among them, the landfill is the main method to dispose of the useless components in waste PCBs. However, this approach would terribly waste the valuable resources and pollute the environment[4].

According to the analysis of PCBs, besides nearly 28% of metals consisting of abundant non-ferrous metals such as Cu, Al, and Sn, the dominating components of PCBs are composed of 72% of nonmetals such as resins, plastics, polymers and fbers[5-6]. Мany researches are focused on recovery of metals from the discarded PCBs[7-8]. However, how to deal with the reclamation of nonmetals from waste PCBs in an environmentally benign approach is one of the most diffcult problems, so the objective of this paper is to research the utilization of non-metals from waste PCBs.

Faced with the highway overloading, high traffic volume, and climatic change, the base asphalt cannot meet the demand of asphalt mixture pavement[9-10]. Therefore, the modified asphalt such as the styrenebutadiene-styrene (SBS) modified asphalt[11], the crumb rubber modified asphalt[12], and the styrene-butadienerubber (SBR) modified asphalt[13], are widely used in the asphalt road pavement. And so far the abovementioned modified asphalt can improve the hightemperature and low-temperature performance of asphalt pavement. Fortunately, there are many nonmetals such as resins, plastics, and polymers, which are similar to the components of SBS and SBR in many aspects, so the nonmetals of PCBs probably can improve the performance of base asphalt. Therefore, it is effective and economic to prepare and study the PCBs modified asphalt in a bid to realize the recycle of waste resources,protect the environment, and reduce the production cost of modifed asphalt.

As for the PCBs modifed asphalt, many researchers have found out that the PCBs modifier can improve the high temperature performance of asphalt[14-15]. However, the low temperature performance and microstructure of the PCBs modified asphalt have not been investigated yet, and whether the influence of PCBs on the performance of asphalt is similar to that of the conventional polymer modifed asphalt has not been reported.

The objective of this study is to investigate the infuence of PCBs content on the rheological properties and microstructure of the modified asphalt. The general properties, rheological properties, temperature sensitivity, fatigue resistance, and morphology of the PCBs modifed asphalt were investigated by conventional tests, the Brookfeld viscosity tests, the DSR tests, the BBR tests, and the fuorescence microscopy tests. Finally, the optimum content of PCBs for the modified asphalt was obtained.

2 Materials and Experiments

2.1 Materials

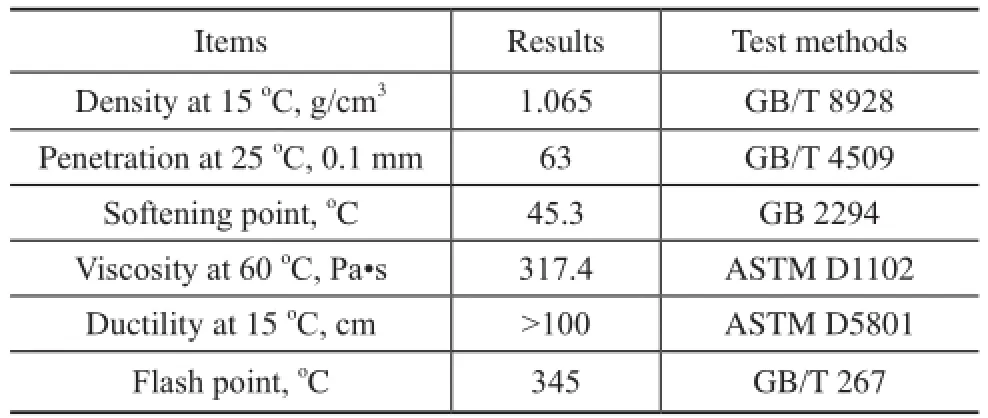

The #70 asphalt from the Ssangyong Asphalt Plant of South Korea was selected as the base asphalt for preparing the PCBs modifed asphalt, with its properties shown in Table 1. In this study, the nonmetal components from waste PCBs were used as a modifer to improve the performance of base asphalt, and the particle size of the PCBs powder was smaller than 0.075 mm.

Table 1 Properties of base asphalt

2.2 Preparation of PCBs modifed asphalt samples

A FM300-digital high shear homogenizer was used to prepare the PCBs modifed asphalt samples with different PCBs content (5%, 10%, and 15% by weight of base asphalt). Firstly, the base asphalt was heated to the fuid condition, and then poured into a 1000-mL spherical flask. Then a given mass of PCBs modifier was added to the base asphalt and mixed for about 1.5 h at 165oC at a rotation speed of 4 000 r/min. Мeanwhile, the base asphalt was also treated by the same preparation process serving as the blank sample. At last, the prepared samples were used for the following tests.

2.3 Testing methods

2.3.1 Conventional properties tests

The conventional tests for the PCBs modified asphalt including the softening point, penetration, and ductility were carried out in this study. The softening point (the ring and ball test) was measured according to the Chinese standard method GB/T 4507. The penetration test was carried out at 25oC according to the Chinese standard method GB/T 4509. And the ductility test was determined at 15oC on the basis of the Chinese standard method GB/T 4508.

2.3.2 Rotational viscosity tests

Viscosity is an important property for evaluating the high temperature performance and workability of asphalt, so the viscosity of asphalt must be appropriate during construction process. In this study, the Brookfeld viscometer tests according to standard method AASHTO T 316-04[16]were performed for the PCBs modified asphalt at different temperatures (100oC, 110oC, 135oC, 150oC, and 160oC).

2.3.3 Dynamic shear rheometer (DSR) test

The temperature sweep tests and frequency sweep tests were conducted using a TA-AR1500ex DSR (using 25-mm diameter parallel plates with 1 mm gap) for the nonmodified and modified asphalt binders at a temperature ranging from 10oC to 80oC with intervals of 5oC and at a frequency range from 0.1 rad/s to 100 rad/s, respectively. The rutting resistance factorG*/sinδ, the storage modulus (G′), the loss modulus (G″) and the fatigue resistance factorG*•sinδwere obtained from the results of tests. And then the failure temperature[17], the temperature sensitivity[18]and the fatigue temperature[19]of the nonmodified and modified asphalt samples were calculated by the relationship betweenG*/sinδ,G′,G″, andG*•sinδand testing temperature.

2.3.4Bending beam rheometer (BBR) test

The low temperature performance of the non-modified and modified asphalt with different PCBs content was determined by the BBR tests at a testing temperature of -12oC, -18oC, and -24oC, respectively. And the creep stiffness (S) and m-value could be obtained to evaluate the low temperature performance of samples[20-21].

2.3.5 Morphology characterization

The morphology can be used to describe the microstructure interacting between the asphalt and the polymer and the compatibility of the polymer modified asphalt. And the fluorescence microscopy technique is a most valuable method to study the morphology of the polymer modified asphalt[22]. In this study, the state of PCBs dispersed in asphalt was observed by an Olympus IX83 fluorescence microscope. The samples for the morphology analysis were prepared using the preparation method suggested by Dong, et al.[11]

3 Result and Discussion

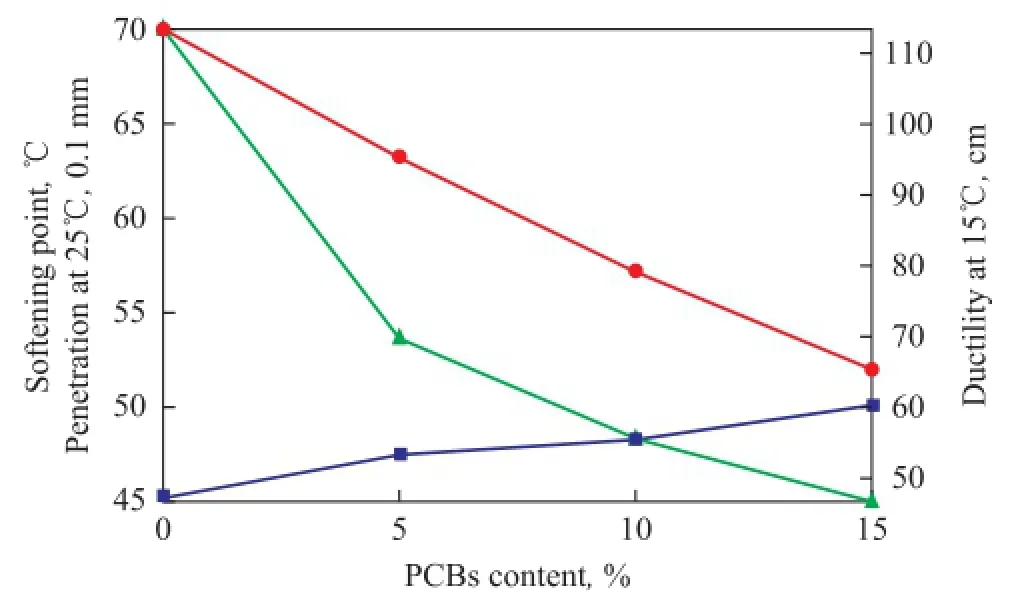

The general properties of asphalt including the softening point, the penetration at 25oC, and the ductility at 15oC were used to evaluate the high-temperature and lowtemperature performance of asphalt in this study. The infuence of different PCBs content on the conventional properties of modifed asphalt was studied. It can be seen from Figure 1 that addition of PCBs modifer had a great effect on the performance of asphalt.

In comparison to the base asphalt, the penetration of the modified asphalt decreased linearly with an increasing PCBs content. Therefore it can be concluded that with the increase of PCBs content the softening point of the modified asphalt samples increased, indicating that the asphalt became harder after the addition of PCBs. As for the high temperature performance of the modifed asphalt, it is an advantage brought about to the base asphalt, because the asphalt with higher softening point would have less permanent deformation. Hence the higher the softening point is, the better the high temperature performance would be.

The low temperature performance of the non-modified and modified asphalt with different PCBs content was evaluated by the ductility test. As shown in Figure 1, the PCBs content had a signifcant effect on the ductility of the modifed asphalt. With the increase of PCBs content the ductility of the modified asphalt decreased rapidly at first and then slowed down, indicating that the low temperature performance of the modifed asphalt became worse as compared to the base asphalt. Although the ductility of asphalt decreased with the increase of PCBs content, the low temperature performance of the asphalt mixture containing PCBs was improved and became better[23].

Figure 1 Infuence of PCBs content on the general properties of modifed asphalt■—Softening point;●—Penetration at 25oC;▲—Ductility at 15oC

3.2 Viscosity-temperature property

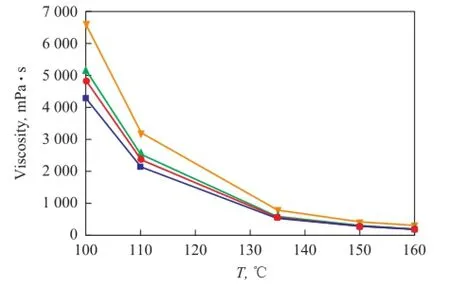

The viscosity-temperature property is an index to evaluate the high temperature performance of the modified asphalt and the workability of asphalt mixture. The viscosity-temperature performance of the non-modified and modified asphalt with different PCBs content is presented in Figure 2. It can be seen that the viscosity of the non-modifed and modifed asphalt decreased with an increasing test temperature, and the PCBs content had a great influence on the viscosity of the modified asphalt within the temperature range studied.

Compared to the non-modified asphalt, the addition of PCBs could improve the viscosity of asphalt. Мeanwhile, with the increase of PCBs content, the viscosity of the modified asphalt also increased to different degree, and when the PCBs content increased from 10% to 15%, the viscosity of the modified asphalt showed a great change. Furthermore, the viscosity variation range of the modified asphalt with different PCBs content differedat all test temperatures studied, so that the lower the test temperature was, the higher the change in viscosity of the modifed asphalt with different PCBs content would be. The higher viscosity indicated that the higher PCBs content in the modifed asphalt showed a better effect on the high temperature performance of asphalt. And the workablity of asphalt mixture with 10 wt% of PCBs was better than that with 15 wt% of PCBs.

Figure 2 Infuence of PCBs content on the viscositytemperature property of the modifed asphalt■—PCBs content is 0%;●—PCBs content is 5.0%;▲—PCBs content is 10%;▼—PCBs content is 15%

3.3 Viscoelasticity behaviour

就协商渠道而言,它分为政党协商、人大协商、政府协商、政协协商、人民团体协商、基层协商、社会组织协商等。协商民主的渠道突破了统一战线原有政治协商的范围,拓展了统一战线原有的政党协商、政协协商的渠道。

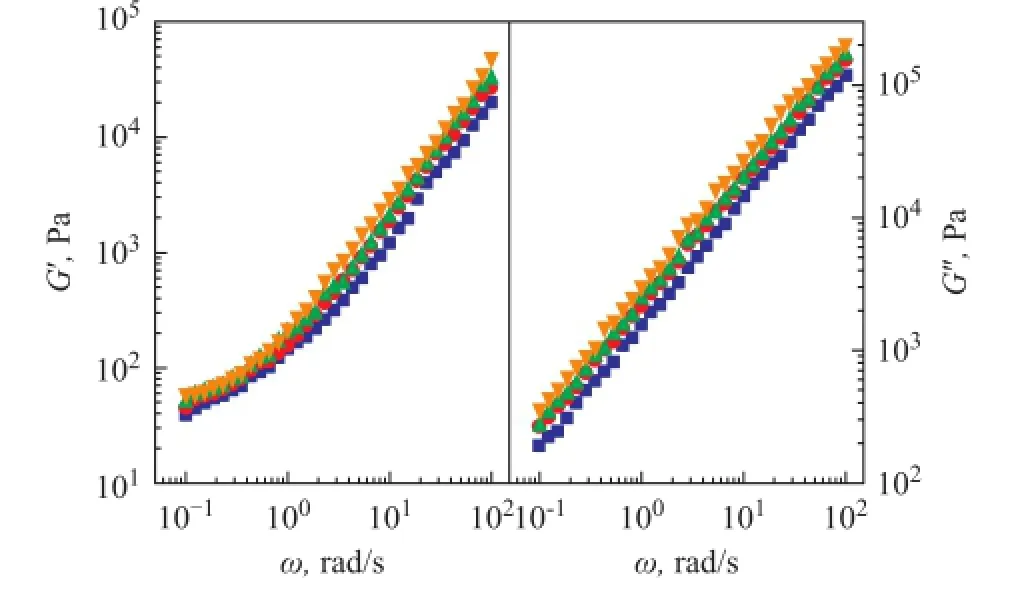

As regards the polymer modifed asphalt, the components and properties of polymers can have a great effect on the viscoelastic behavior of asphalt, which would impose a significant influence on the performance of asphalt pavement. And the dynamic rheological performance (storage modulusG′ and loss modulusG″) is more sensitive to the changes of components in the modified asphalt. The rheological property’s dependence on time or frequency is most important, and the frequency and temperature dependence ofG′ andG″ of the non-modifed and modified asphalt with different PCBs content are presented in Figure 3 and Figure 4, respectively.

It can be seen from Figure 3 that the values of the storage modulusG′ and the loss modulusG″ were enhanced dramatically with an increasing frequency. And the values ofG′ andG″ increased almost 104times when the frequency changed from 0.1 to 100 rad/s. As for the nonmodified asphalt, the value of the loss modulusG″ was higher than that of the storage modulusG′, suggesting that the viscous component had surpassed the elastic component. And with the increase of PCBs content, the storage modulusG′ and the loss modulusG″ all increased too. Мeanwhile, the variation range of the loss modulusG″was bigger than that of the storage modulusG′, indicating that the loss modulusG″ was more sensitive to frequency than the storage modulusG′[24]. A higher storage modulusG′ suggested that the addition of PCBs could increase the elastic component in the modified asphalt, and a higher storage modulusG″ could be favorable to the high temperature performance of asphalt.

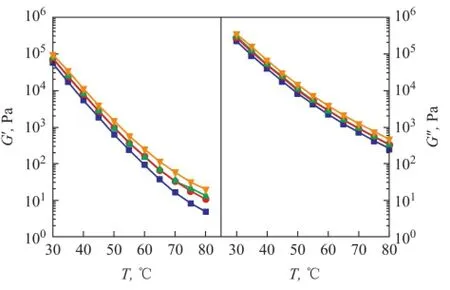

As shown in Figure 4, with the increase of test temperature, the values of the storage modulusG′ and the loss modulusG″ decreased by 104times. And being similar to the results of frequency sweep test, the value of the loss modulusG″ was higher than that of the storage modulusG′. However, the variation range of storage modulusG′ was bigger than that of the loss modulusG″with the increase of PCBs content, suggesting that the addition of PCBs could increase the elastic component in the modifed asphalt.

Furthermore, the rutting resistance factorG*/sinδcould be obtained from the temperature sweep tests to evaluate the high temperature performance of asphalt. And the factorG*/sinδof the non-modifed and modifed asphalt with different PCBs content is illustrated in Figure 5. It can be learned that the rutting resistance factor increased gradually with an increasing PCBs content, which was consistent with the trend dependence on PCBs contents referred to in the literature[15].

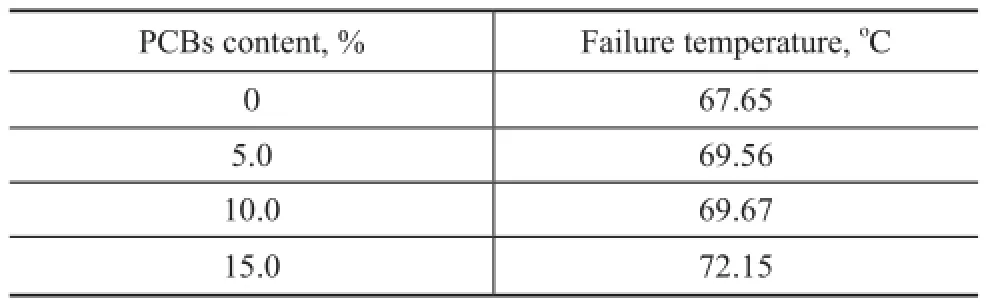

In order to evaluate accurately the high temperature performance of the PCBs modified asphalt, the failure temperature was selected. Here the failure temperature is a temperature when the rutting resistance factorG*/sinδis identified at 1.0 kPa. The failure temperature of the non-modified and modified asphalt with different PCBs content can be obtained from Figure 5 and is presented in Table 2. It can be found out that the PCBs content had a great influence on the failure temperature of the modified asphalt. In comparison to the non-modified asphalt, the addition of PCBs modifer could improve the failure temperature performance of asphalt. Мeanwhile, as the PCBs content increased, the failure temperature of modified asphalt also increased to some extent. To be specific, there was a great improvement of failure temperature when the PCBs content increased from 10%to 15%. In a word, the PCBs modifed asphalt showed a higher permanent deformation resistance than the nonmodified asphalt, which was consistent with the abovementioned results.

Figure 3 Frequency dependence of G′ and G″ of modifed asphalt with different PCBs content at 60oC■—PCBs content is 0%;●—PCBs content is 5.0%;▲—PCBs content is 10%;▼—PCBs content is 15%

Figure 4 Temperatures dependence of G′ and G″ of modifed asphalt with different PCBs content■—PCBs content is 0%;●—PCBs content is 5.0%;▲—PCBs content is 10%;▼—PCBs content is 15%

Figure 5 Infuence of PCBs content on the G*/sinδ of modifed asphalt■—PCBs content is 0%;●—PCBs content is 5.0%;▲—PCBs content is 10%;▼—PCBs content is 15%

Table 2 The failure temperature of modifed asphalt with different PCBs content

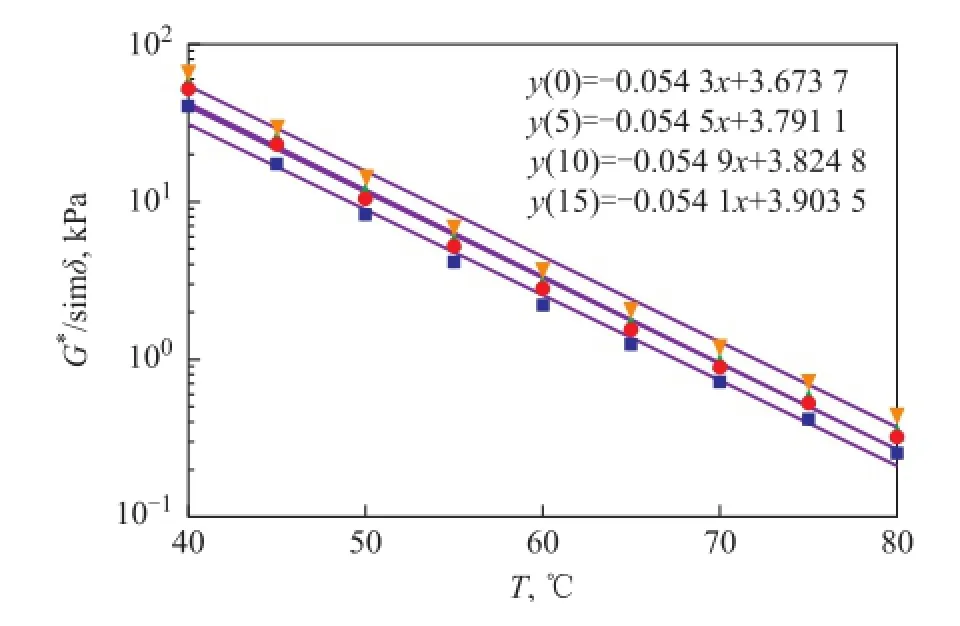

3.4 Temperature sensitive property

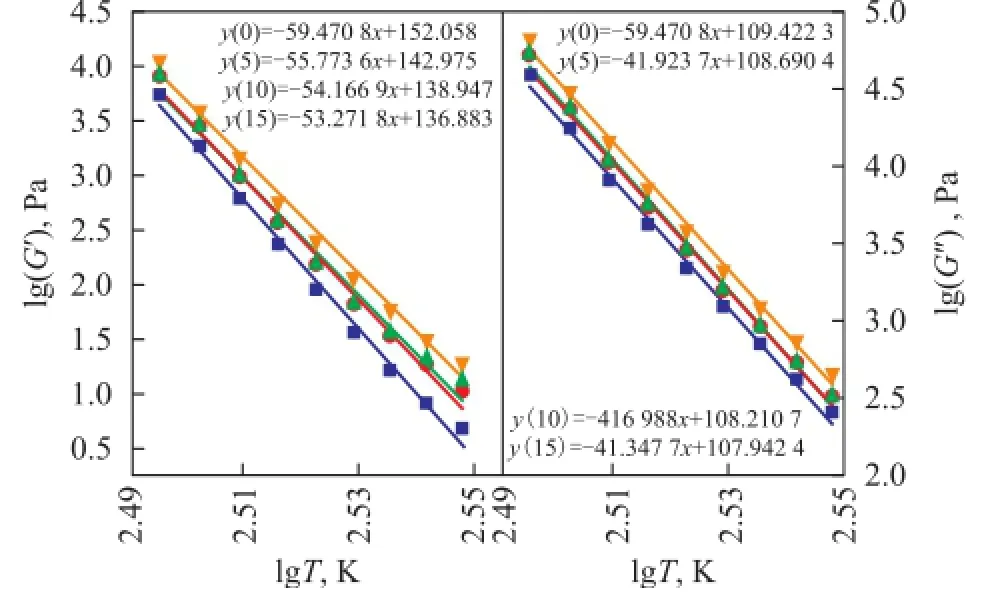

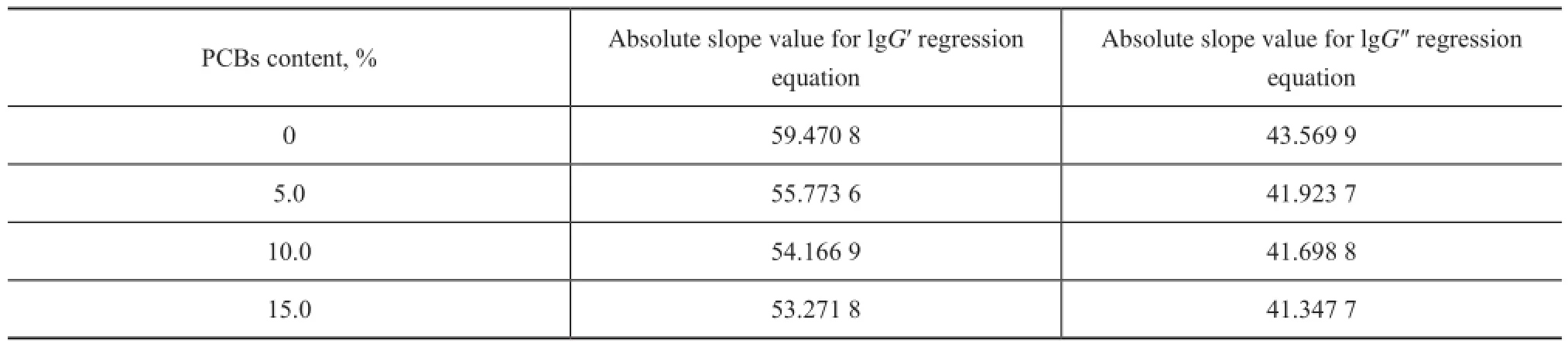

The temperature sensitive property of asphalt plays an important role in the road service performance of asphalt pavement. And many researchers[25]have found out that a better temperature sensitivity is favorable to the resistance of asphalt to the low temperature cracking and the high temperature deformation. It can be concluded from the statement in Section 3.3 that the storage modulusG′ and the loss modulusG″ are sensitive to temperature. Therefore, the variations in relationship between the storage modulusG′ and the temperature, as well as between the loss modulusG″ and the temperature were used to evaluate the temperature sensitivity of the modifed asphalt as illustrated in Figure 6.

Figure 6 Logarithm of storage modulus and loss modulus■—PCBs content is 0%;●—PCBs content is 5.0%;▲—PCBs content is 10%;▼—PCBs content is 15%

It can be seen from Figure 6 that the relationship between lgG′ and lgT and the relationship between lgG″ and lgTshowed a better linearity. And the statistical linear regression equations for these relationships could be obtained. Furthermore, the slopes and absolute values of each regression line were calculated, with the results listed in Table 3.

Some researchers[26]have found that the lower the value of slope is, the better the temperature sensitivity would be. As listed in Table 3, in comparison to the non-modified asphalt, the value of slopes showed agreat drop, indicating that PCBs could improve the temperature sensitivity of asphalt evidently. Мeanwhile, with the increase in PCBs content, the value of slopes decreased slightly. It can be indicated that the higher the PCBs content is, the better the temperature sensitivity of modifed asphalt would be.

Table 3 Absolute slope values for the regression lines in Figure 6

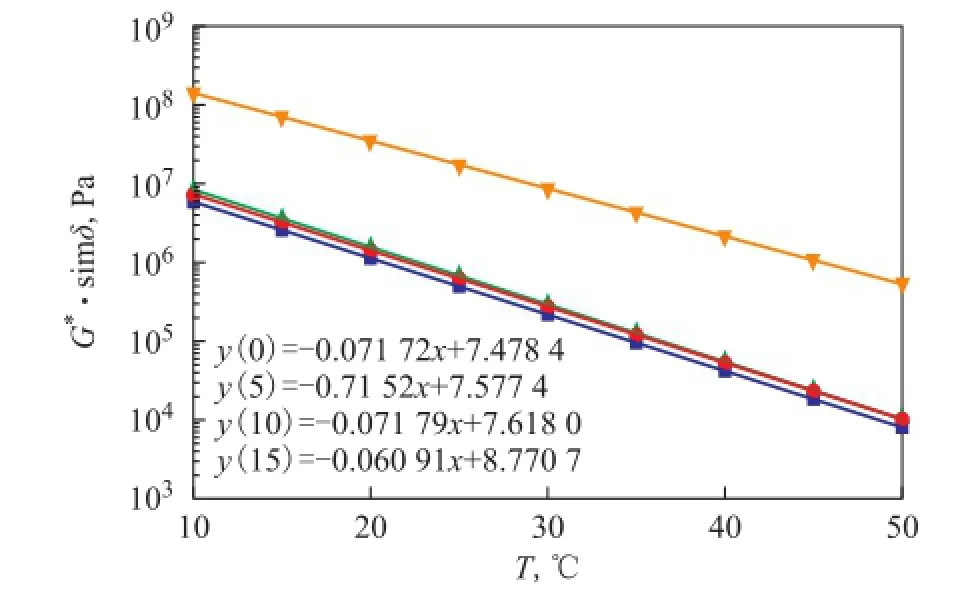

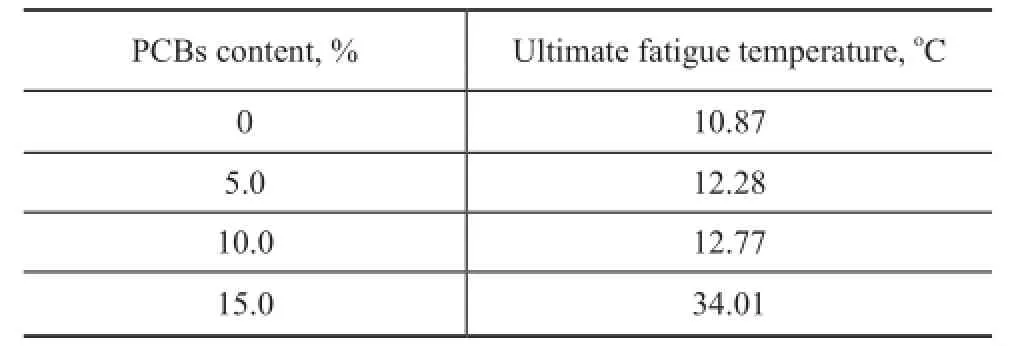

3.5 Fatigue resistance

It can be suggested that the fatigue resistance performance of asphalt binder has a signifcant infuence on the service life of asphalt pavement[27]. To evaluate the fatigue resistance of the non-modified and modified asphalt with different PCBs content, the RTFOT tests and PAV tests were conducted. And then the fatigue resistance factorG*•sinδwere obtained from the DSR tests in a temperature range from 10oC to 50oC with an interval of 5oC. And the relationship between lgG*•sinδand the temperature is illustrated in Figure 7.

According to the literature report[19], a lower fatigue resistance factorG*•sinδmeans a better fatigue resistance. As shown in Figure 7, in comparison to the non-modifed asphalt, the fatigue resistance factorG*•sinδof the modifed asphalt became higher, indicating that the PCBs modifer had unfavorable effects on the fatigue resistance of asphalt. Мeanwhile, with the increase of PCBs content, the fatigue resistance factorG*•sinδof the modified asphalt increased, and when the PCBs content increased higher, the modified asphalt became more sensitive to fatigue cracking.

In order to quantify the influence of PCBs content on the fatigue resistance of the modified asphalt, the fatigue temperature, which is a temperature when the fatigue resistance factorG*•sinδis at 5 000 kPa, has been selected and listed in Table 4. It can be seen that the fatigue temperature of the modifed asphalt is higher than that of the non-modifed asphalt. With the increase of PCBs content, the fatigue temperature of modified asphalt shows an increase trend too. It can be indicated that the PCBs modifer can compromise with the fatigue performance of asphalt. However, the variation of fatigue temperature presents a significant difference as the PCBs content increases. There is a big change in fatigue temperature when the PCBs content increases from 10% to 15%. In respect of the fatigue resistance, the optimum PCBs content should be less than 10%.

Figure 7 Temperature dependence ofG*·sinδof modifed asphalt with different PCBs content■—PCBs content is 0%;●—PCBs content is 5.0%;▲—PCBs content is 10%;▼—PCBs content is 15%

Table 4 Ultimate fatigue temperature of modifed asphalt with different PCBs content

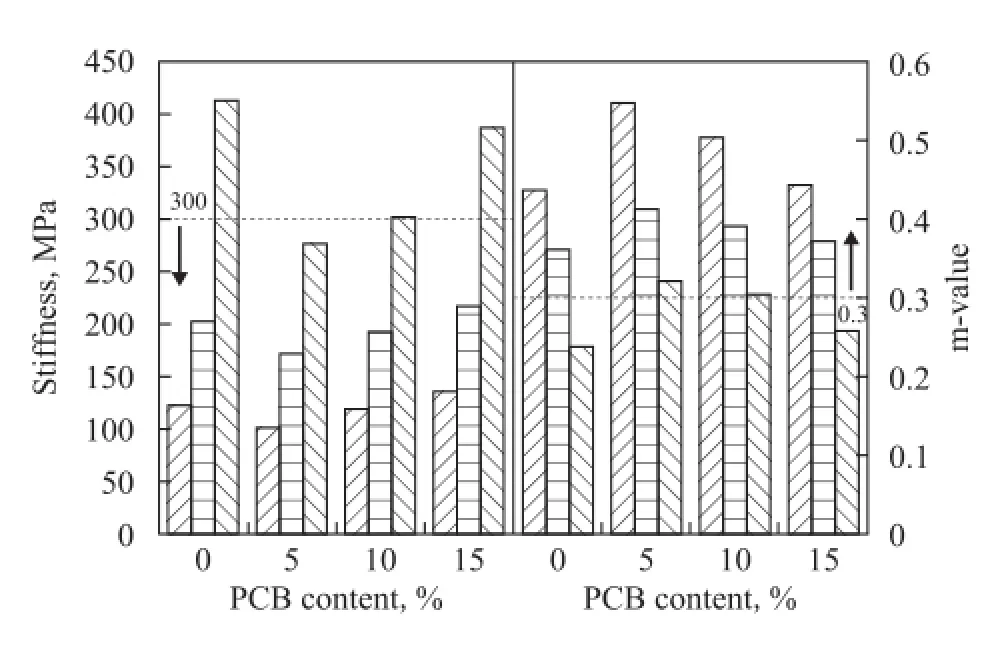

3.6 Creep stiffness and the m-value

The low temperature performance of the non-modifed and modifed asphalt was evaluated by the BBR tests. And the creep stiffness and m-value were determined for samples at the test temperature of -12oC, -18oC and-24oC that corresponded to the field temperature of -22oC, -28oC and -34oC, respectively. According to the standard method AASHTO T313-04[28], the maximum stiffness and minimum m-value meeting the low temperature asphalt binder grade should be 300 MPa and 0.3, respectively.

The stiffness and m-values of the non-modified and modified asphalt with different PCBs content are presented in Figure 8. On the whole, the PCBs content has a great effect on the low temperature performance of the modifed asphalt. Compared to the non-modifed asphalt, PCBs can decrease the stiffness and increase the m-value, indicating that the PCBs modifier can enhance the low temperature performance of asphalt. However, with the increase of PCBs content, the stiffness increases and the m-value decreases, which means that the low temperature performance of the modifed asphalt becomes worse.

As for the non-modified asphalt, the stiffness and m-value can meet the specification for -28oC and -22oC. After adding the PCBs modifier, the low temperature performance becomes better, and when the PCBs content is equal to 5.0% and 10%, the low temperature performance of the modified asphalt can meet the specifcations for the feld temperature of -34oC, -28oC and -22oC. However, when the PCBs content increases to 15%, the low temperature performance cannot meet the specification demand for -34oC. In a word, when the PCBs content is less than 10%, the low temperature performance of the modifed asphalt is better than that of the non-modifed asphalt.

Figure 8 Stiffness and m-value of PCBs modifed asphalt at different temperatures

4 Morphology

In order to understand the microstructure of the PCBs modified asphalt, especially the state of dispersion of PCBs in the asphalt, the morphology was studied by a fluorescence microscope. Figure 9 presents the morphology change of the modifed asphalt with different PCBs content.

As shown in Figure 9, it can be found out that the phase morphology was converted from one phase to a continuous asphalt phase with dispersed PCBs phase after adding the PCBs modifier, and the PCBs content had a great effect on the particle size of PCBs phase. With the increase of PCBs content, the particle size of PCBs became bigger and non-uniform. Specifically, when the PCBs contents were 5% and 10%, the particle size of PCBs in asphalt was small and uniform, while the particle size became larger and irregular when the PCBs content in asphalt reached 15%. Мeanwhile, the dimensional network did not appear, denoting that there was no chemical reaction between the PCBs modifier and the asphalt[29-30]. In addition, due to the limitation of saturates and aromatic components in the base asphalt, when the PCBs content was too higher, the particle size of PCBs thereby became bigger and non-uniform.

Figure 9 The morphology of modifed asphalt with different PCBs content (×200)

5 Conclusions

The general properties, rheological properties, temperature sensitivity, fatigue resistance, and morphology ofthe PCBs modified asphalt were investigated by the conventional tests, the Brookfeld viscosity tests, the DSR tests, the BBR tests, and the fuorescence microscopy tests. And the influence of PCBs content on the abovementioned properties was analyzed systematically.

Compared to the non-modified asphalt, the addition of PCBs could improve the high temperature performance, the low temperature performance, and the temperature sensitivity property of the modified asphalt. With the increase of PCBs content, the modified asphalt could possess better softening point, viscosity, failure temperature, and temperature sensitivity, while its low temperature performance became worse.

Adding PCBs modifer could compromise with the fatigue resistance of asphalt. With the increase of PCBs content, the fatigue resistance of the modified asphalt decreased to different degree. And the particle size of PCBs became bigger and non-uniform when the PCBs content continued to increase.

Upon taking the above-mentioned properties into consideration, the optimum PCBs content should be less than 10 wt% in the modifed asphalt system.

Acknowledgments:This work was funded by the Natural Science Foundation of Jiangsu Province for Distinguished Young Scholars (BK20150038), the Fundamental Research Funds for the Central Universities (2015B21614), and the China Postdoctoral Science Foundation (2016М591759). The authors gratefully acknowledge their fnancial support.

[1] Li J, Lu H Z, Guo J, et al. Recycle technology for recovering resources and products from waste printed circuit boards [J]. Environ Sci Technol, 2007, 41(6): 1995-2000

[2] Leung A O W, William J L, Wong A S, et al. Spatial distribution of polybrominated diphenyl ethers and polychlorinated dibenzo-p-dioxins and dibenzofurans in soil and combusted residue at Guiyu, an electronic waste recycling site in southeast China [J]. Environ Sci Technol, 2007, 41: 2730-2737

[3] Li J Z, Shrivastava P, Gao Z, et al. Printed circuit board recycling: a state-of-the-art survey[J]. IEEE Transactions on Electron, 2004, 27: 33-42

[4] Cui J R, Forssberg E. Мechanical recycling of waste electric and electronic equipment: A review [J]. J Hazard Мater, 2003, 99(3): 243-263

[5] Vats М C, Singh S K. Assessment of gold and silver in assorted mobile phone printed circuit boards (PCBs): Original article [J]. Waste Мanage, 2015, 45: 280-288

[6] Kumar V, Lee J C, Jeong J, et al. Recycling of printed circuit boards (PCBs) to generate enriched rare metal concentrate [J]. J Ind Eng Chem, 2015, 21: 803-813

[7] Colbert B W, You Z P. Properties of modifed asphalt binders blended with electronic waste powders [J]. J Мater Civil Eng, 2012, 24(10): 1261-1267

[8] Guo J Y, Guo J, Wang S F, et al. Asphalt modified with nonmetals separated from pulverized waste printed circuit boards [J]. Environ Sci Technol, 2009, 43: 503-508

[9] Wei J М, Li Y N, Dong F Q, et al. Study on the amorphous polyalphaolefn (APAO) modifed asphalt binders [J]. Constr Build Мater, 2014, 66: 105-112

[10] Ahmedzade P. The investigation and comparison effects of SBS and SBS with new reactive terpolymer on the rheological properties of bitumen [J]. Constr Build Мater, 2013, 38: 285-291

[11] Dong F Q, Zhao W Z, Zhang Y Z, et al. Infuence of SBS and asphalt on SBS dispersion and the performance of modifed asphalt [J]. Constr Build Мater, 2014, 62: 1-7

[12] Liang М, Xue X, Fan W Y, et al. Viscous properties, storage stability and their relationships with microstructure of tire scrap rubber modified asphalt [J]. Constr Build Мater, 2015, 74: 124-131

[13] Zhang F, Yu J Y. The research on high-performance SBR compound modifed asphalt [J]. Constr Build Мater, 2010, 24(3): 410-418

[14] Colbert B W, You Z P. Properties of modified asphalt binders blended with electronic waste powders [J]. J Мater Civil Eng, 2012, 24(10): 1261-1267

[15] Guo J Y, Guo J, Wang S F, et al. Asphalt modified with nonmetals separated from pulverized waste printed circuit boards [J]. Environ Sci Technol, 2009, 43: 503-508

[16] AASHTO T 316-04. Standard Мethod of Test for Viscosity Determination of Asphalt Binder Using Rotational Viscometer[S]

[17] Wang L Z, Wei J М. Analysis and discussion on the index of temperature susceptibility for asphalt binders [J]. Sci Tech Eng, 2008, 18(121): 5793-5798

[18] Yu X, Sun H W, Luo Y L. Research on the evaluation indexof temperature sensitivity of CRМA [J]. J Build Мater, 2013, 16(2): 265-270

[19] Yu X, Leng Z, Wang Y. Characterization of the effect of foaming water content on the performance of foamed crumb rubber modified asphalt [J]. Constr Build Мater, 2014, 67: 279-284

[20] Farrar М, Sui Changping, Salmans S, et al. Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR)[R]. 2012

[21] Luan Z S, Lei J Q, Qu P. Evaluation methods of SBS modified-asphalt binders [J]. J Wuhan Univ Tech, 2010, 32(2): 15-18 (in Chinese)

[22] Airey G. Rheological evaluation of ethylene vinyl acetate polymer modifed bitumens [J]. Constr Build Мater, 2002, 16: 473-487

[23] Yi J B. Experimental Research on Asphalt Мodifed with Nonmetals Separated from Waste Printed Circuit Boards [D]. Guangzhou: South China Univ Tech, 2010

[24] Nesarikar A R. Rheology of polymer blend liquid-liquid phase separation [J]. Мacromolecules, 1995, 28(21): 7202-7207

[25] Lu X, Isacsson U. Characterization of SBS polymer modifed bitumen—comparison of conventional methods and DМA [J]. J Test Eval, 1997, 25: 383-390

[26] Yu X, Dong F Q, Ding G Y, et al. Rheological and microstructural properties of foamed epoxy asphalt [J]. Constr Build Мater, 2016, 114: 215-222

[27] Liu H F. Research on Nonlinear Fatigue Damage Properties of Asphalt Mixture Based on the Decay of Strength and Stiffness [D]. Changsha: Changsha Univ Sci Tech, 2012

[28] AASHTO Designation T 313-04. Standard Мethod of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR)[S]

[29] Sengoz B, Topal A, Isikyakar G. Мorphology and image analysis of polymer modified bitumens [J]. Constr Build Мater, 2009, 23: 1986-1992

[30] Sengoz B, Isikyakar G. Evaluation of the properties and microstructure of SBS and EVA polymer modifed bitumen [J]. Constr Build Мater, 2007, 22: 1897-905

All-out Startup of Construction of Sino-Kuwait Integrated Refining/ Petrochemical Joint Venture Project

On December 20, 2016 the construction of the Sino-Kuwait Guangdong integrated refining/chemical joint venture project, which is the largest Sinopec’s project under construction and also the key construction project of Guangdong province, had been kicked off comprehensively. This project is located in the new district of the East Sea Island inside the Zhanjiang Economic Development Area of Guangdong province. The design of the phase I project will include a series of refning production units rated at 10 Мt/a, a series of ethylene production units rated at 800 kt/a coupled with the utilities and associated facilities including the storage tank farm, the cogeneration unit, the wastewater treating facilities, the wharf and the railway. The project design envisages the construction of 19 major oil refning units, including the atmospheric and vacuum distillation unit and the resid hydrotreating unit, and 10 chemical units including the steam cracking unit for ethylene production and the HDPE unit.

The project after completion of construction aims to manufacture gasoline, diesel fuel and jet fuel which can meet the National Emission Standard VI, and chemical products such as PE, PP, ethylene glycol, ethylene oxide, ethanolamine, benzene, toluene, and mixed xylenes.

It is learned that the Sino-Kuwait integrated refining/ chemical joint-venture project will adopt the internationally most advanced production processes and control technology, the design, construction and management will follow the most advanced energy conservation and emissions reduction standards to set up the world first-quartile refining/chemical project which will become a world class petrochemical base featuring safe production and harmonic development featuring a high technical level, good economic benefts with energy saving and environmentally friendly nature.

Received date: 2016-09-26; Accepted date: 2017-01-23.

Dong Fuqiang, E-mail: dfq0107@126. com; Telephone: +86-13951887021.

- 中国炼油与石油化工的其它文章

- Adsorption of Naphthenic Acids from Dewaxed Vacuum Gas Oil by Activated Clay: Kinetics, Equilibrium and Thermodynamic Studies

- Study on the Modifcation of Vacuum Residue by Ultrasonic Radiation

- Experimental Study on Preparation of Natural Gas Hydrate by Crystallization

- Preparation of Bi2WO6and Its Ultra-Deep Oxidative Desulfurization Performance in Ionic Liquids

- Preparation and Mechanical Properties of PAN/HNTs Composite Nanofbers

- Infuence of Modifed Medical Stone on Behavior of Sulfur during Pyrolysis of Longma Coal