高掺量粉煤灰和矿渣高强混凝土抗渗性和抗冻性试验

秦 力,丁婧楠,朱劲松

高掺量粉煤灰和矿渣高强混凝土抗渗性和抗冻性试验

秦 力1,丁婧楠1,朱劲松2

(1. 东北电力大学建筑工程学院,吉林 132012; 2. 天津大学建筑工程学院,天津 300072)

采用粉煤灰和矿渣2种掺合料的40%和50% 2种质量比例掺量,制备了高掺合料C50高强混凝土,并利用扫描电镜和X射线衍射技术分析了高比例掺合料对高强混凝土强度的影响,最后通过抗氯离子渗透试验和快速冻融试验综合分析了高掺合料C50高强混凝土的耐久性。结果表明:当复掺掺合料总质量占胶凝材料总质量的50%时,随着粉煤灰与矿渣掺入量比值的减小混凝土养护28 d强度有所增加;在掺合料总质量不变的情况下,混凝土的抗冻性和抗氯离子渗透性能均随着粉煤灰掺入量的增加和矿渣掺入量的减小而逐渐提升,但掺合料总质量的增加会降低抗氯离子渗透性能;采用抗冻耐久性指数与电通量的比值法可较好的综合评价高掺合料高强混凝土的耐久性,耐久性较好的适宜配合比为掺合料总量50%,粉煤灰与矿渣掺量比为4:1。研究可为高掺量粉煤灰和矿渣在高强混凝土中的应用提供依据,同时达到提高高强混凝土的经济性和节约资源的目的。

粉煤灰;矿渣;混凝土;微观结构;氯离子渗透;抗冻性

0 引 言

高强混凝土具有强度高、耐久性好、流动性佳、抗渗性高等诸多优点,广泛应用于高层建筑结构、大跨度桥梁结构及某些特种结构。但由于高强混凝土水灰比较低,水泥用量较高,混凝土构件浇筑时水化热较大,导致高强混凝土内部界面微裂缝增加、孔结构粗化,耐久性降低。现有研究成果表明高强混凝土中掺入矿物掺合料可有效提高其耐久性,与此同时高比例掺合料会降低混凝土的早期强度[1-4],但其后期强度增长较快,增长率较高[5],在28 d强度会达到或超过设计强度值[6-7],且掺合料对混凝土强度的影响与水灰比关系较大[8-10]。普通混凝土中适量加入掺合料会提高其抗冻性和抗氯离子渗透性能[11-16],其中矿渣与引气剂共同使用可以改善混凝土的孔结构,提高其抗冻性[11,17],而大掺量粉煤灰反而会加速氯离子的渗透[18-20]。高强混凝土随着掺合料总量的增大,其抗氯离子侵蚀性能增强[21],抗冻融次数有所增长[22-23],C50高强混凝土在复合掺合料掺量为45%时的抗冻融性能较掺量为25%时有较大程度的提高[24]。

综上所述,高强混凝土中掺入高比例矿物掺合料可有效提高其耐久性,但现有研究成果大部分只针对单一种类矿物掺合料,采用不同种类矿物掺合料时也只是设定某一种复掺比例,未考虑不同种类掺合料高掺量对高强混凝土耐久性的影响。本文采用粉煤灰和矿渣2种掺合料的40%和50% 2种高比例掺量制备高掺合料C50高强混凝土,分析高比例掺合料对高强混凝土强度的影响,通过抗氯离子渗透试验和快速冻融试验综合评价高掺合料C50高强混凝土的耐久性。

1 材料与方法

1.1 材 料

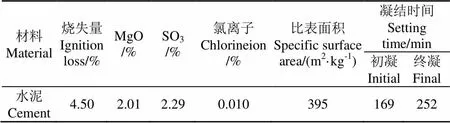

采用冀东P·O42.5普通硅酸盐水泥,水泥胶砂在28 d抗折强度10.68 MPa,抗压强度55.56 MPa,水泥化学成分及物理性能见表1;掺合料采用I级粉煤灰和S95矿渣检验结果为粉煤灰密度2 100 kg/m3,比表面积470 m2/kg,需水量比93.8%,含水量0.1%,烧失量4.88%,SO3含量0.41%;矿渣密度为2 800 kg/m3,比表面积为417 m2/kg,含水量为0.3%,烧失量为0.9%,SO3含量2.1%,流动度比为102%,7 d活性指数为81%,28 d活性指数为98%;细骨料采用松花江河砂,细度模数2.9,属于中砂;粗骨料采用平均直径为20 mm的机械破碎级配碎石;外加剂采用液态聚羧酸高性能减水剂,减水率实测值28.5%,掺量取胶凝材料总量的1%;研究表明,减水剂的使用会与引气剂产生联动效应[25],影响各自性能的发挥,因此本文试验混凝土中均未掺引气剂。

表1 水泥化学成分及物理性能

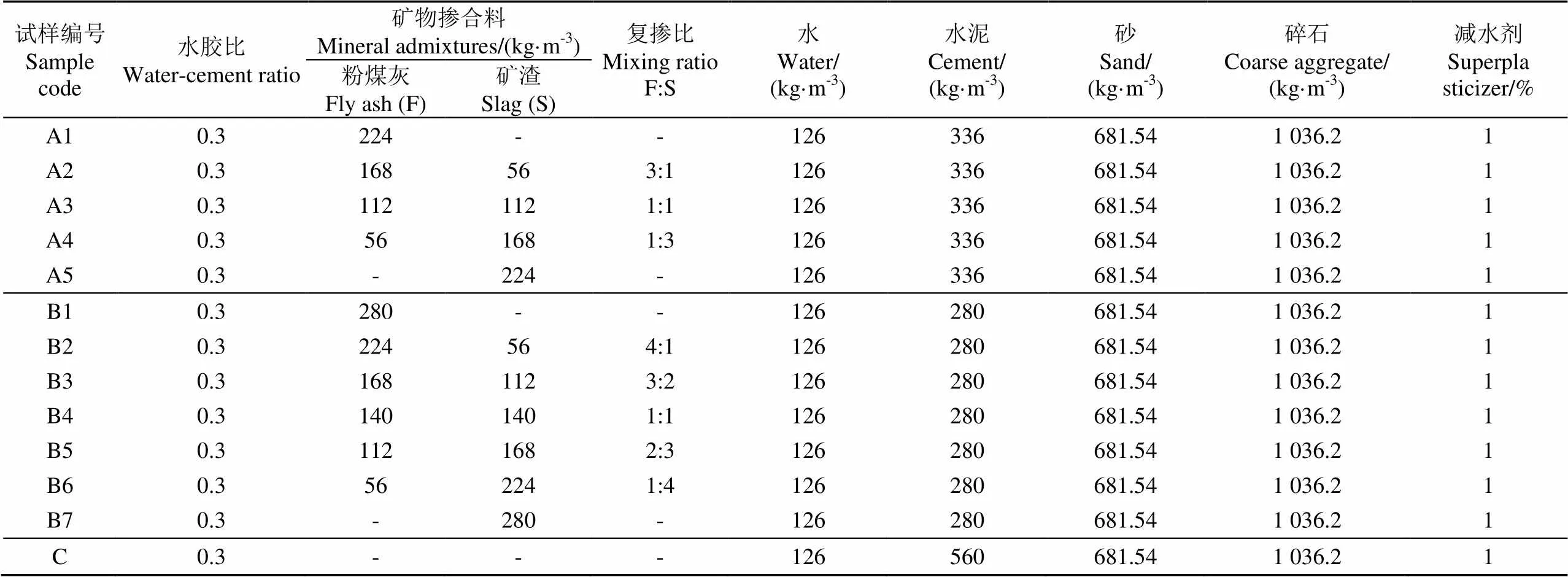

本文设计配合比如表2所示,胶凝材料总量为560 kg/m3,A、B组掺合料总质量分别占胶凝材料总质量的40%和50%,C组为未掺加任何掺合料的基准混凝土。制作完成的混凝土按照GB/T 50080-2002《普通混凝土拌合物性能试验方法标准》的要求进行坍落度试验,坍落度值基本都在190 mm左右,参照CECS 104-1999《高强混凝土结构技术规程》中坍落度不应小于140 mm的规定,说明本文所配制的混凝土流动性较好。

1.2 试验方法

按照表2所列配合比制作150 mm×150 mm×150 mm的混凝土立方体试块,并在标准养护条件下养护。按照JGJ/T 281-2012《高强混凝土应用技术规程》中的要求,参照GB/T50081-2002《普通混凝土力学性能试验方法标准》测定养护7和28 d时混凝土的抗压强度,筛选出养护28 d强度达到C50高强混凝土强度要求的配合比。

表2 不同混凝土试件配合比

注:A1~A5掺合料总量占胶凝材料总质量的40%,B1~B7掺合料总量占胶凝材料总质量的50%,C为基准混凝土。下同。

Note: A1-A5 with content of admixture is 40% of total cementitious materials, B1~B7 with content of admixture is 50% of total cementitious materials. C is reference concrete. The same as below.

为了从微观角度进一步分析掺合料对C50高强混凝土性能的影响,对部分混凝土试样进行了微观试验。取A1、B7和C组混凝土养护7 d抗压强度试验时剥落的碎渣过0.16 mm的砂石筛,然后用研钵研磨至0.08 mm以下,经干燥处理后进行X射线衍射试验。在A2、A4和B2组混凝土试件中心部位取5 mm左右薄片,经干燥处理后粘贴在导电胶上,利用型号为JSM6510A的扫描电镜观察拍照。

对C50高强混凝土抗氯离子渗透性的研究参照ASTMC1202标准,制作直径100 mm,高度50 mm的圆柱体试件,真空饱水后运用电通量测定仪测定混凝土6 h的总导电量。

对C50高强混凝土抗冻性的研究按照JGJ/T 281-2012《高强混凝土应用技术规程》中的要求,参照GB/T 50082-2009《普通混凝土长期性能和耐久性能试验方法标准》,制作100 mm×100 mm×400 mm的棱柱体试件,采用快冻法进行抗冻性试验,每冻融循环50次测定质量和动弹性模量,并计算质量损失率和相对动弹性模量。

2 结果与分析

2.1 掺合料对高强混凝土强度的影响

混凝土立方体抗压强度试验结果如表3所示,按照JGJ 55-2011《普通混凝土配合比设计规程》中的规定,计算得C50混凝土养护28 d的配制强度为59.87 MPa,其中A5、B1和B7组混凝土的养护28 d强度值分别为55.60、56.90和55.80 MPa,未达到C50高强混凝土的标准,而其他各组配合比均能配制出达到设计强度的高强混凝土。

由表3可以看出掺加矿物掺合料的混凝土与基准混凝土C相比早期强度较低,养护28 d时掺合料混凝土强度增长较快,增长率为27%~56%。表中A1的养护7和28 d强度均大于同期B1的强度,A5的7 d强度大于同期B7的强度,二者养护28 d强度相差不大,由此可以看出,单掺矿物掺合料掺量的增大不利于混凝土强度的增长。复掺掺合料总量为40%(A组)时,随着粉煤灰掺量的减小和矿渣掺量的增大,混凝土养护28 d抗压强度降低,由A2的67.40 MPa降至A4的60.30 MPa,而复掺总量为50%(B组)时,随着复掺比F:S的减小,混凝土养护28 d抗压强度有所增长,由B2的63.50 MPa增长至B6的73.00 MPa。试验中,混凝土养护28 d受压破坏形态如图1所示,随着试验机施加压力的增加,混凝土侧表面出现如图1所示的垂直承压面的裂纹,然后裂纹不断发展,混凝土表面出现外鼓,有的试件(如图1a~1c)在试验结束时有少量碎屑剥落,整体较为完整,而部分试件(如图1d~1f)在砂浆和骨料的胶结面发生破坏,大块混凝土碎块剥落。

从水化的角度进一步分析以上现象产生的原因,主要是由于掺合料减缓了水泥早期的水化,因此随着单掺粉煤灰或矿渣掺量的增加,水泥的水化产物减少,如图2混凝土的X射线衍射试验结果所示,图2c 中Ca(OH)2衍射峰的峰值较图2a与图2b高,其中图2b 中Ca(OH)2衍射峰值对应数据最小,而粉煤灰和矿渣水化需要Ca(OH)2的参与,由此导致养护28 d强度未达到混凝土的设计强度要求。随着时间的推移,掺合料的二次水化不断进行,由图3的扫描电镜图像可以明显的看到养护7 d时粉煤灰和矿渣表面较光滑,而在养护28 d时其表面附着大量凝胶,出现了较多水化产物如针棒状钙矾石,填充了水泥颗粒空隙,提高了胶结面的凝聚力,使混凝土结构愈加致密。说明粉煤灰与矿渣复掺产生了超叠加效应,使得混凝土养护28 d强度较高且增长较快。

表3 混凝土抗压强度试验结果

a. B3b. B4c. A4 d. A5e. A3f. C

图1 混凝土养护28 d受压破坏形态

Fig.1 Compression failure pattern of concrete after 28 d curing

2.2 掺合料对高强混凝土抗氯离子渗透性能的影响

掺与不掺矿物掺合料的C50高强混凝土抗氯离子渗透性能的试验结果如图4所示。由图4可看出基准混凝土电通量值为633.12 C,掺合料混凝土的电通量值在231.22~525.62 C之间,说明掺加矿物掺合料可以降低混凝土中的电通量值,提高其抗氯离子渗透性能,这是由于粉煤灰和矿渣具有微珠结构和较光滑的表面(见图3),能够分散到各个孔隙孔道中,增大了氯离子在混凝土中扩散的阻力,随着水化的不断进行,水化产物不断填充水泥石的空隙,使得结构更加密实[26],阻止了侵蚀性介质的进入。

图4中掺加矿物掺合料总量为50%的B组混凝土的电通量值整体高于掺加总量为40%的A组混凝土,可以看出掺合料总量的增加对混凝土抗氯离子渗透性能有不利影响。在掺加总量一定时,A组和B组混凝土的电通量值均随着复掺比F:S的减小而不断增大,混凝土的抗氯离子渗透性能降低。对比A2和B3,A3和B5以及A4和B6的电通量值,结果为B3>A2,B5>A3,B6>A4,由此可以看出,粉煤灰掺量相同时,矿渣掺量较高的混凝土电通量值较大,说明矿渣对混凝土抗氯离子渗透性能的损伤较粉煤灰严重。

2.3 掺合料对高强混凝土抗冻性的影响

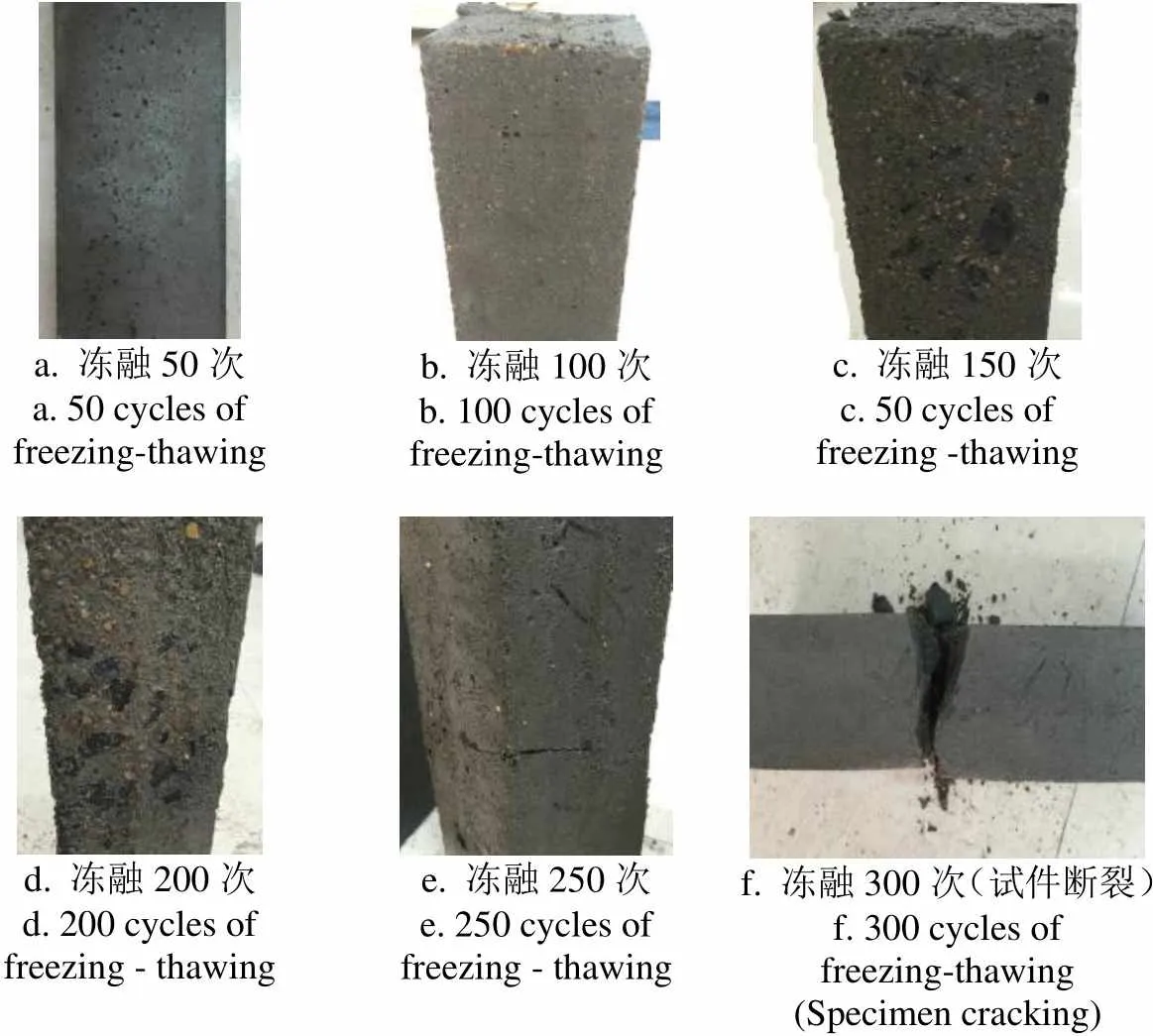

图5所示为冻融循环过程中混凝土表面形态变化,图6和图7分别为快速冻融试验所得不同冻融循环次数下混凝土的质量损失率和相对动弹性模量的变化规律。由图5可以看出,冻融循环50次(图5a)后,混凝土表面出现了细小的孔洞,试件完整。冻融达150次(图5c)时,试件出现掉渣,表面脱落的现象。冻融200次(图5d)时损伤加速,部分试件表面水泥砂浆剥落严重,骨料外露,肉眼能够观察到砂粒与石子。冻融循环250次(图5e)时,所有试件均出现不同程度的表面脱落,个别试件表面出现横向裂缝,并且逐渐贯通,最终导致混凝土试块在长度方向上发生断裂而破坏(图5f)。

由图6和图7可以看出,冻融300次后,所有混凝土试件的质量损失率均不超过1.2%,相对动弹性模量均大于60%,证明C50高强混凝土抗冻性较好。由图6可以知冻融循环小于150次时混凝土质量损失率差异并不大,但冻融300次时,基准混凝土C的质量损失率大于掺合料混凝土;掺合料总量不变时,随复掺比F:S的减小,混凝土质量损失率增大,且B6组混凝土在冻融300次时发生断裂(如图5f所示)。对比图7中2图可以看出,图7b中相对动弹性模量下降较图7a平缓,且图7b中冻融300次时相对动弹性模量数值较大,随着F:S的减小,混凝土的相对动弹性模量下降幅度由17%(总掺量40%)和13%(总掺量50%)增大到21%。

以上现象可以看出,复掺掺合料可以进一步提高高强混凝土的抗冻性,但粉煤灰掺量减小且矿渣掺量增大对其抗冻性有所损伤。如图8不同掺合料复掺时的养护28 d微观形貌所示,掺合料总量增大后,虽然水泥的水化产物有所减少,但掺合料的二次水化产物增多[27],图8b中可以看到大量致密的凝胶类物质包裹着掺合料颗粒,界面并不十分清晰,其混凝土结构与图8a相比更加致密,这使得多次冻融循环后,混凝土内部裂缝发展缓慢,动弹性模量较高,抗冻性较好。

a. 冻融50次a. 50 cycles of freezing-thawingb. 冻融100次b. 100 cycles of freezing-thawingc. 冻融150次c. 50 cycles of freezing -thawing d. 冻融200次d. 200 cycles of freezing - thawinge. 冻融250次e. 250 cycles of freezing - thawingf.冻融300次(试件断裂)f. 300 cycles of freezing-thawing (Specimen cracking)

3 D值法综合评价C50高强混凝土的耐久性

通过上述试验数据可以看出,粉煤灰和矿渣的掺量及掺量比对抗冻性指标和抗氯离子渗透性的影响趋势并非一致。比如B3混凝土电通量值较低,仅为241.51 C,其抗氯离子渗透性较好,但其冻融循环300次后质量损失率为0.88%,相对较大,且冻融循环后表面剥蚀严重,其他几组试验抗氯离子渗透性和抗冻性指标的排序也不一致,因此采用单一指标综合评价高掺合料C50高强混凝土耐久性存在一定的缺陷。

CCES01-2004《混凝土结构耐久性设计与施工指南》中定义了混凝土抗冻耐久性指数为300次快速冻融循环后的动弹性模量与初始值的比值[28],文献[28-31]采用值法评判混凝土的耐久性能,取为与氯离子扩散系数NEL的比值。值法只适用于采用NEL法测定混凝土抗氯离子渗透性能的情况,不适用于电通量法,因此本文类比值法[11,29-30],引入与电通量Q的比值这一指标来综合评价混凝土的抗冻性和抗氯离子渗透性能,定义为,即

,≥5%

式中为冻渗比;为抗冻耐久性系数;Q为电通量,C;为试件相对动弹性模量低于75%或质量损失大于5%时的冻融循环次数,为质量损失率。

值越大,说明混凝土的抗冻性和抗氯离子渗透综合性能越好。图9所示为不同掺量及复掺比的混凝土所对应的值。由图可以看出除了B6组试件外,掺加掺合料的混凝土值均大于基准混凝土的值,对应了掺合料能够提高混凝土耐久性能的结论,而B6组混凝土冻融循环300次前已发生断裂,耐久性能不及基准混凝土,说明养护28 d强度高与耐久性好没有必然联系。随着粉煤灰与矿渣掺量比的增大,值减小,说明抗冻性和抗氯离子渗透综合性能降低。

从图9中数据可以看出B2组值最大,说明粉煤灰与矿渣的掺量存在一个最佳值,即总掺量为50%,粉煤灰与矿渣掺量比4:1。这10组配合比按照值大小排序为:B2>A2>B3>A1>A3>B4>A4>B5>C>B6,这一结果与冻融试验结果和电通量值的排序都不同,值是从抗冻性和抗氯离子渗透性的角度出发,包含掺合料的影响因素,在一定程度上可以较好地表征高掺合料高强混凝土与基准混凝土的差异与性能,定性的评价掺合料混凝土抗冻与抗氯离子渗透综合性能的优劣,并且值法运算过程简便,结果一目了然,计算公式中电通量值来源于电通量法,此方法已成为当前国际上最有影响的混凝土抗氯离子渗透试验方法[31-32],也已被中国水运工程及铁路工程相关标准采纳,说明值法同时具备较强的实用性[33]。

4 结 论

1)粉煤灰与矿渣复掺可以促进掺合料的二次水化,生成较多的水化产物,使得混凝土后期强度增长较快,增长率为27%~56%;总掺量为40%时,随着粉煤灰与矿渣掺量比F:S的减小,混凝土养护28 d强度由67.40 MPa降至60.30 MPa,总掺量为50%时,随着F:S的减小,混凝土养护28 d强度由63.50 MPa增长至73.00 MPa。

2)掺合料总量的增加有利于提高C50高强混凝土的抗冻性而不利于提高其抗氯离子渗透性能;在掺合料总量不变的前提下,随着粉煤灰与矿渣掺量比的减小,C50高强混凝土中的电通量值不断增大,冻融后质量损失率也显著增长,且相对动弹性模量下降幅度由17%(总掺量40%)和13%(总掺量50%)增大到21%,说明减少粉煤灰掺量的同时提高矿渣的掺量能够降低混凝土的抗氯离子渗透和抗冻性能。

3)采用值法可较好地综合评价高掺合料C50高强混凝土的耐久性,耐久性较好的适宜配合比为掺合料总量50%,粉煤灰与矿渣掺量比为4:1。

[1] 陈益民,贺行洋,李永鑫,等. 矿物掺合料研究进展及存在的问题[J]. 材料导报,2006,20(8):28-31.

Chen Yimin, He Xingyang, Li Yongxin, et al. Research progress and shortcoming of mineral admixtures[J]. Material Reserve, 2006, 20(8): 28-31. (in Chinese with English abstract)

[2] Khokhar M, Roziere E, Turcry P. Mix design of concrete with high content of mineral additions: optimisation to improve early age strength[J]. Cement & Concrete Composites, 2010, 32(5): 377-385.

[3] Shen D, Shi X, Zhu S, et al. Relationship between tensile Young’s modulus and strength of fly ash high strength concrete at early age[J]. Construction & Building Materials, 2016, 123: 317-326.

[4] 吴福飞,侍克斌,董双快,等. 掺合料和水胶比对水泥基材料水化产物和力学性能的影响[J]. 农业工程学报,2016,32(4):119-126.

Wu Fufei, Shi Kebin, Dong Shuangkuai, et al. Influence of admixture and water-cement ratio on hydration products and mechanical properties of cement-based materials[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(4): 119-126. (in Chinese with English abstract)

[5] 张苹. 超细矿渣粉对混凝土结构、组成与性能影响研究[D]. 沈阳:东北大学,2012.

Zhang Ping. Study on Influence of Superfine-Slag Powder on Structure, Composition and Properties of Concrete[D]. Shenyang: Northeastern University, 2012. (in Chinese with English abstract)

[6] Singh B, Rahman M R, Paswan R, et al. Effect of activator concentration on the strength, ITZ and drying shrinkage of fly ash/slag geopolymer concrete[J]. Construction & Building Materials, 2016, 118: 171-179.

[7] 施惠生,许碧莞,阚黎黎. 矿渣微粉对混凝土气体渗透性及强度的影响[J]. 同济大学学报:自然科学版,2008,36(6):782-786.

Shi Huisheng, Xu Biwan, Kan Lili. Effect of slag powder on gas permeability and compressive strength of high performance concrete[J]. Journal of Tongji University: Natural Science, 2008, 36(6): 782-786. (in Chinese with English abstract)

[8] Shehab H K, Eisa A S, Wahba A M. Mechanical properties of fly ash based geopolymer concrete with full and partial cement replacement[J]. Construction & Building Materials, 2016, 126: 560-565.

[9] Wang X Y,Park K B. Analysis of compressive strength development of concrete containing high volume fly ash[J]. Construction and Building Materials, 2015, 98: 810-819.

[10] 胡琼,宋灿,邹超英. 再生混凝土力学性能试验[J]. 哈尔滨工业大学学报,2009,41(4):33-36.

Hu Qiong, Song Can, Zou Chaoying. Experimental research on the mechanical properties of recycled concrete[J]. Journal of Harbin Institute of Technology, 2009, 41(4): 33-36. (in Chinese with English abstract)

[11] 杨文武,钱觉时,范英儒. 磨细高炉矿渣对海工混凝土抗冻性和氯离子扩散性能的影响[J]. 硅酸盐学报,2009,37(1):29-34.

Yang Wenwu, Qian Jueshi, Fan Yingru. Effect of ground granulated blastfurrnace slag on both froat-resistance and chloride ions diffusion properties of marine concrete[J]. Journal of the Chinese Ceramic Society, 2009, 37(1): 29-34. (in Chinese with English abstract)

[12] 涂文懋,彭惠惠,徐兵波,等. 复掺矿物掺合料对C50海工混凝土性能影响[J]. 武汉理工大学学报,2007,29(6):43-45.

Tu Wenmao, Peng Huihui, Xu Bingbo, et al. Influence of mineral admixtures composite technique on C50 sea construction high performance concrete[J]. Journal of Wuhan University of Technology, 2007, 29(6): 43-45. (in Chinese with English abstract)

[13] Nath P, Sarker P. Effect of fly ash on the durability properties of high strength concrete[J]. Procedia Engineering, 2011, 14(3): 1149-1156.

[14] Chung C W, Shon C S, Kim Y S. Chloride ion diffusivity of fly ash and silica fume concretes exposed to freeze–thaw cycles[J]. Construction & Building Materials, 2010, 24(9): 1739-1745.

[15] 金祖权,孙伟,赵铁军,等. 在不同溶液中混凝土对氯离子的固化程度[J]. 硅酸盐学报,2009,37(7):1068-1072.

Jin Zuquan, Sun Wei, Zhao Tiejun, et al. Chloride binding in concrete exposed to corrosive solutions[J]. Journal of the Chinese Ceramic Society, 2009, 37(7): 1068-1072. (in Chinese with English abstract)

[16] 洪雷,危行财,汪明刚. 单轴压荷载下掺合料对混凝土渗透性的影响[J]. 建筑材料学报,2013,16(1):143-146.

Hong Lei, Wei Xingcai, Wang Minggang. Influence of mineral admixtures on permeability of concrete under sustained uniaxial compressive load[J]. Journal of Building Materials, 2013, 16(1): 143-146. (in Chinese with English abstract)

[17] 张粉芹,王海波,王起才. 掺合料和引气剂对混凝土孔结构与性能影响的研究[J]. 水力发电学报,2010,29(1):180-185.

Zhang Fenqin, Wang Haibo, Wang Qicai. Study on effects of mineral admixture and air-entraining agent on the pore structure and performance of concrete[J]. Journal of Hydroelectric Engineering, 2010, 29(1): 180-185. (in Chinese with English abstract)

[18] 孙丛涛,宋华,牛荻涛,等. 粉煤灰混凝土的氯离子结合性能[J]. 建筑材料学报,2016,19(1):35-39.

Sun Congtao, Song Hua, Niu Ditao, et al. Chloride binding capacity of fly ash concrete[J]. Journal of Building Materials, 2016, 19(1): 35-39. (in Chinese with English abstract)

[19] Uysal M, Akyuncu V. Durability performance of concrete incorporating class F and class C fly ashes[J]. Construction & Building Materials, 2012, 34(34): 170-178.

[20] 曹长伟,张文献,王雁飞. 高掺量粉煤灰混凝土路面应用性能的试验研究[J]. 同济大学学报:自然科学版,2007,35(1):50-55.

Cao Changwei, Zhang Wenxian, Wang Yan fei. Experimental study on application of high content fly ash concrete to road pavement[J]. Journal of Tongji University: Natural Science, 2007, 35(1): 50-55. (in Chinese with English abstract)

[21] 何富强,元强,郑克仁,等. 掺矿物掺合料混凝土ASTM C1202测试指标的相关性[J]. 东南大学学报:自然科学版,2006(增刊2):105-109.

He Fuqiang, Yuan Qiang, Zheng Keren, et al. Correlations of test parameters of concrete with mineral admixtures according to ASTM C1202[J]. Journal of Southeast University: Natural Science Edition, 2006(Supp.2): 105-109. (in Chinese with English abstract)

[22] 刘俊龙,麻海燕,王甲春. 干燥环境条件下大掺量矿物掺合料高强混凝土的抗冻性[J]. 混凝土,2009,232(2):69-72.

Liu Junlong Ma Haiyan, Wang Jiachun. Freeze-thaw durability of high strength concrete with high volume mineral admixtures at dry environment[J]. Concrete, 2009, 232(2): 69-72. (in Chinese with English abstract)

[23] Yazıcı H. The effect of silica fume and high-volume Class C fly ash on mechanical properties, chloride penetration and freeze-thaw resistance of self-compacting concrete[J]. Construction & Building Materials, 2008, 22(4): 456-462.

[24] 冷发光,田冠飞,丁威,等. 大掺量复合掺合料混凝土性能研究[J]. 低温建筑技术,2008,30(4):1-4.

Leng Faguang, Tian Guanfei, Ding Wei, et al. Study on concrete with high volume compound mineral admixture[J]. Low Temperature Architecture Technology, 2008, 30(4): 1-4. (in Chinese with English abstract)

[25] 李雪峰,付智. 高原低气压环境对引气混凝土含气量及气泡稳定性的影响[J]. 农业工程学报,2015,31(11):165-172.

Li Xuefeng, Fu Zhi. Effect of low atmospheric pressure of plateau environment on air content and bubble stability of air-entrained concrete[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(11): 165-172. (in Chinese with English abstract)

[26] 秦力,李敏,丁婧楠. 高温高湿养护对高强混凝土耐久性的影响[J]. 东北电力大学学报,2016,36(1):18-22.

Qin Li, Li Min, Ding Jingnan. The effect from curing of high temperature and high humidity to durability of high strength concrete[J]. Journal of Northeast Dianli University, 2016, 36(1): 18-22. (in Chinese with English abstract)

[27] 范志宏,黎鹏平,苏达根,等. 胶凝材料组成对钢筋混凝土耐久性的影响[J]. 华南理工大学学报:自然科学版,2012,40(4):85-89. Fan Zhihong, Li Pengping, Su Dagen, et al. Influence of cementitious Material Composition on durability of reinforced concrete[J]. Journal of South China University of Technology: Natural Science Edition, 2012, 40(4): 85-89. (in Chinese with English abstract)

[28] 中国工程院土木水利与建筑学部. 混凝土结构耐久性设计与施工指南[M]. 北京:中国建筑工业出版社,2004.

[29] 杨文武,钱觉时,黄煜镔. 海洋环境下硅灰混凝土的抗冻性与氯离子扩散性[J]. 重庆大学学报:自然科学版,2009,32(2):158-162.

Yang Wenwu, Qian Jueshi, Huang Yubin. Frost resistance and chloride ion diffusion of silica-fume concrete in a marine environment[J]. Journal of Chongqing University: Natural Science Edition, 2009, 32(2): 158-162. (in Chinese with English abstract)

[30] 杨文武,黄煜镔,郭立杰. 海洋环境下粉煤灰混凝土的抗冻性与抗氯离子渗透性的耦合[J]. 海洋科学,2009,33(12):83-88.

Yang Wenwu, Huang Yubin, Guo Lijie. Characteristics of frost resistance and resistance to chloride-ion penetration of fly ash concrete in a marine environment[J]. Marine Sciences, 2009, 33(12): 83-88. (in Chinese with English abstract)

[31] 何富强,元强,郑克仁,等. 掺矿物掺合料混凝土ASTM C1202测试指标的相关性[J]. 东南大学学报:自然科学版,2006(增刊2):105-109.

He Fuqiang, Yuan Qiang, Zheng Keren, et al. Correlations of test parameters of concrete with mineral admixtures according to ASTM C1202[J]. Journal of Southeast University: Natural Science Edition, 2006(Supp.2): 105-109. (in Chinese with English abstract)

[32] 杨绿峰,周明,陈正. 海洋混凝土结构耐久性定量分析与设计[J]. 土木工程学报,2014(10):70-79.

Yang Lüfeng, Zhou Ming, Chen Zheng. Quantitative analvsis and design for durability of marine concrete structures[J]. China Civil Engineering Journal, 2014(10): 70-79. (in Chinese with English abstract)

[33] 冷发光,田冠飞. 混凝土抗氯离子渗透性试验方法[J]. 东南大学学报:自然科学版,2006(增刊2):63-69.

Leng Faguang, Tian Guanfei. Investigation of test methods of chloride ion penetration in concrete[J]. Journal of Southeast University: Natural Science Edition, 2006(Supp.2): 63-69. (in Chinese with English abstract)

Experiment on anti-permeability and frost resistance of high strength concrete with high-ratio of fly ash and slag

Qin Li1, Ding Jingnan1, Zhu Jinsong2

(1.,,132012,; 2.,300072,)

As civil engineering develops toward high rise, large span, heavy load and lightweight structure, higher requirements in strength and performance of concrete has been put forward. Mineral admixture as the fifth component of concrete is gaining popularity in practical application and helps to improve the strength and durability of concrete. At present, researches are mainly focus on the kind of mineral admixture and its influence on concrete performance. Application of an amount of admixture is an important developing direction of high strength concrete. We prepared 2 kinds of high strength concrete containing 40% and 50% fly ash and slag respectively to identify the best quality proportion of mineral admixture in high strength concrete C50. Microstructures in different ages and phase in early age were observed with scanning electron microscopy and-ray diffraction respectively so as to evaluate the influence of high quality proportion of admixture on high strength concrete from a microscopic perspective. Durability was assessed through chloride-ion penetration resistant test and rapid freezing-thawing test. And the comprehensive capability to resist frost and chloride ion permeation was reflected by the ratio of frost-resistant durability coefficient to electric flux value. The results showed that mineral admixture reduced the early hydration of cement. Peak value of calcium hydroxide was lower in the concrete with mineral admixture than that in the reference concrete, which led to the decrease in early strength of the concrete. Due to the super-composite effect of fly ash and slag, the later strength increased more rapidly and the structure became more compact, with some samples reaching or exceeding the reference concrete strength after 28 d curing. The strength would continue to improve in the long run. With the decline of the ratio of fly ash to slag, the strength of concrete after 28 d curing with 40% admixture decreased, while that of concrete with 50% admixture increased. Capability to resist chloride ion permeation improved as the increase of fly ash and the decrease of slag in concrete with a fixed share of total mineral admixture. The fixed share of fly ash and the increase of slag led to the decrease in that capability, suggesting fly ash had a better performance than slag in this respect. But the increase of total mineral admixture would undermine the capability of concrete to resist chloride ion permeation. Mineral admixture could better improve the frost-resistant performance of high strength concrete C50. With the decrease of the ratio of fly ash to slag, there were a greater mass loss, a greater decrease of relative dynamic elastic modulus and a greater decline of frost resistance after freeze-thawing. Concrete with higher percentage of mineral admixture had a slower decrease of relative dynamic elastic modulus, with a high value even after freeze-thawing of 300 times. The mixing quality of fly ash and slag was not consistent with the effect tendency of the frost resistance index and chloride ion permeability. But we found that the higher the ratio of frost-resistant durability coefficient to electric flux value, the better the comprehensive performance of frost resistance and chloride ion permeation resistance. Ratio of frost-resistant durability coefficient to electric flux value decreased in an approximately linear way with the increase of the ratio of fly ash to slag. D-value which was the ratio of frost-resistant durability coefficient to electric flux value could effectively evaluate the durability of high strength concrete C50 with high ratio admixture, and we proposed the proper mixing proportion was 50% for admixture amount and the content ratio of fly ash to slag was 4:1.

fly ash; slags; concretes; microstructure;chloride penetration; frost resistance

10.11975/j.issn.1002-6819.2017.06.017

TU528.0

A

1002-6819(2017)-06-0133-07

2016-10-17

2016-11-15

国家自然科学基金资助(51178305,51578370);东北电力大学研究生创新基金资助(Y2015025)

秦 力,男,辽宁葫芦岛人,教授,从事高强混凝土材料耐久性、碳纤维复合芯导线运行特性研究。吉林 东北电力大学建筑工程学院,132012。Email:jilinql@163.com