基于图像和光谱信息融合的红茶萎凋程度量化判别

宁井铭,孙京京,朱小元,李姝寰,张正竹,黄财旺

基于图像和光谱信息融合的红茶萎凋程度量化判别

宁井铭1,孙京京1,朱小元1,李姝寰1,张正竹1,黄财旺2

(1. 安徽农业大学茶树生物学与资源利用国家重点实验室,合肥 230036; 2. 安徽祁门金东茶厂,祁门 245600)

为了实现对红茶萎凋程度量化判别,该研究提出了一种将图像和光谱信息融合后分别与线性判别分析法和偏最小二乘法结合的技术,进行工夫红茶萎凋程度定性判别及儿茶素与氨基酸比值定量预测研究。通过对图像进行主成分分析,筛选出5个特征波长和对应的光谱特征值,基于灰度共生矩阵提取5个特征波长图像的纹理特征值,并采用连续投影算法优选出14个纹理特征值,然后分别以光谱和纹理特征值融合数据建立红茶萎凋程度的线性判别模型和儿茶素与氨基酸比值的偏最小二乘预测模型。结果表明:采用所研究的方法和建立的模型对工夫红茶萎凋程度判别准确率达到94.64%,儿茶素与氨基酸比值预测相关系数为0.8765,预测均方根误差为0.434,预测结果较好。证明应用这两种方法能实现对红茶萎凋程度量化判别。

数据融合;判别分析方法;图像分析;偏最小二乘法;红茶;萎凋;儿茶素与氨基酸比值

0 引 言

红茶加工分为初制和精制2个过程,初制过程包括萎凋、揉捻(揉切)、发酵和干燥4道工序,其中萎凋是红茶初制的首要工序和品质形成的基础。茶鲜叶在萎凋过程中,既有物理变化,也有化学变化。物理变化表现为叶质变软,叶色从翠绿变为暗绿;同时,随着鲜叶含水量的降低,内部化学成分也发生一系列变化,萎凋适度的鲜叶中儿茶素与氨基酸比值也会保持在一定的比例范围。鲜叶如萎凋不足,叶质硬脆,揉捻时芽叶易断碎,茶汁易流失,成品茶香气低,有苦涩味;鲜叶如萎凋过度,叶质干硬,成品茶色泽灰枯,叶底花杂[1],鲜叶只有萎凋适度才能加工出色、香、味俱佳的红茶。目前,对于红茶萎凋程度的判断主要依赖人工味觉、嗅觉等经验判别,其结果容易受到判别者心情、身体状况以及性别等诸多因素的影响,缺乏量化的指标,难以进行在线快速判别。

高光谱图像技术融合了光谱信息和图像信息,既能利用光谱信息分析样品的内部品质信息,也能基于图像信息表征样品的外部品质特征[2]。近年来,高光谱图像技术在农业生产方面得到了广泛应用[3-7]。高光谱图像技术在茶叶上应用主要集中在茶叶分类、品质检测及茶园管理等方面。章海亮等融合光谱主成分信息和图像信息实现了6种名优绿茶的有效鉴别[8]。陈孝敬等也通过分析茶叶颜色特征,实现了茶叶分类[9]。蒋帆等利用高光谱技术结合支持向量机分类算法对机炒龙井茶等级进行了分类识别[10]。赵杰文等利用高光谱技术对茶树叶片中叶绿素含量及分布规律进行了研究,并建立了茶树缺氮诊断模型[11]。王晓庆等分析了炭疽病胁迫下的茶树叶片高光谱特征,为茶园病害的预防提供了可能[12]。谢传奇等利用高光谱图像技术实现了茶叶在干燥过程中叶色和含水量的实时检测[13-14]。萎凋是红茶加工的首要工序,对萎凋程度的判断直接影响后续加工工序的进行,将高光谱图像技术应用到判别红茶萎凋程度的研究,未见相关报道。

本研究采集不同萎凋程度样本的高光谱图像,利用主成分分析法优选特征波长和对应的光谱特征值,并提取特征波长下的图像纹理值,融合光谱和纹理特征值,结合化学计量学方法建立红茶萎凋程度的快速判别模型,并尝试分析萎凋程度和儿茶素与氨基酸比值的关系,实现对红茶萎凋程度量化判断。

1 材料与方法

1.1 试验材料

试验材料取自安徽祁门金东茶厂2015年4月8日和2016年4月19日生产样。萎凋方式为萎凋槽萎凋,萎凋热风温度30~32 ℃,摊叶厚度为10~15 cm。萎凋1 h后取若干样品作为萎凋不足样,萎凋适度取样后,继续萎凋至过度,萎凋适度的判别由两名经验丰富的师傅和1名专家共同决定。达到萎凋适度时,萎凋叶表面失去光泽,叶色暗绿,青草气减退;叶形皱缩,叶质柔软,折梗不断,紧握成团,松手可缓慢松散。最终获得168个样品,其中萎凋不足样品55个,萎凋适度样品61个,萎凋过度样品52个。按照2∶1的比例将样品随机分成校正集(112个)和预测集(56个),利用校正集的样品建立判别模型,预测集的样品用来测试模型的性能。

1.2 高光谱图像采集和处理

高光谱图像系统主要由光谱成像仪(Imspector V17E, Spectral Imaging Ltd., Oulu, Finland)、2个150 W的卤素灯(3900, Illumination Technologies Inc., New York, USA)、移动平台、暗箱、图像采集和分析软件(Spectral Image Software, Isuzu Optics Corp., Taiwan, China)等组成。

为了保证采集的图像的质量,首先要对相机的曝光时间以及移动平台的移动速度等参数进行设置。经过反复调节,最终曝光时间设置为2 ms,物镜的高度设为31 cm。称取(15±0.5) g的样品均匀平铺在规格为×h:9 cm×1 cm的培养皿中,置于移动平台上以9.5 mm/s的速度开始采集高光谱图像。系统的光谱分辨率为5 nm,光谱范围为908~1 735 nm,共508个波段。而前后波段受噪声影响较大,因此在后续的数据处理过程中,选取947~1 696 nm波段范围内,共448个波段的高光谱图像进行分析。

在对高光谱图像处理前,先要按照式(1)对像素点进行黑白校正。

R=(1)

式中R表示校正后的图像像素点,表示原始的图像像素点,表示黑板校正的图像像素点,表示白板校正的图像像素点。

1.3 化学成分检测

样品进行高光谱图像采集后,立即微波固样2 min,并在105 ℃的烘箱中烘至足干。茶叶样经磨碎后过筛至于密封袋中放在4 ℃的条件下备用。检测的化学成分为儿茶素和氨基酸,儿茶素检测采用ISO 14502-2方法,氨基酸的检测采用Waters公司柱前衍生化法[15],共检测18种氨基酸,并计算儿茶素总量和氨基酸的总量及两者的比值,同时利用SPSS进行相关的统计分析。

1.4 数据分析方法

1.4.1 特征波长选择

高光谱数据量庞大,且相邻波段间相关性强易造成冗余的数据,会影响后期数据的处理。因此,对高光谱数据进行降维,去除冗余信息,优选特征波长是十分必要的。主成分分析法[16](principal component analysis,PCA)是一种常用的数据降维方法,主要是通过协方差最大的方向将高维数据空间向低维数据空间投影,将原始数据转化到新的坐标系统中,得到的各主成分变量彼此间不相关,且都是原始数据的线性组合,如公式(2)所示

PC=(2)

式中PC表示第个主成分图像,表示原始图像的波段数,α表示第个波段处图像的权重系数,I表示第个波段处的原始图像。本研究根据方差贡献率提取主成分图像,并通过比较主成分图像下各波长的权重系数的绝对值大小来优选特征波长。

1.4.2 纹理特征提取

基于灰度共生矩阵(grey level co-occurrence matrix, GLCM)来提取特征波长图像的纹理值。灰度共生矩阵[17]是通过计算特定像素间距离和角度的函数。本研究中,距离设置为1,提取0°、45°、90°和135°4个角度的对比度、相关性、能量和同质性4个纹理变量。利用连续投影算法(successive projections algorithm,SPA)对纹理特征进行优选,减少变量间的冗余信息。连续投影算法[18-19]是一种前向特征变量选择算法,在优选光谱变量时应用广泛[20-21],本研究用于纹理变量的筛选,以校正集样本的纹理特征和类别赋值为输入,并以预测集的纹理特征和类别作为验证,设置选择的变量数范围为1~20。

1.4.3 建模方法选择

线性判别分析法[22](linear discriminat analysis,LDA)是模式识别中常用的线性分类方法。支持向量机[23](support vector machine,SVM)的主要思想是建立一个分类超平面为决策曲面,在分类问题上能提供较好的泛化性能。本研究的SVM实现采用的是LIBSVM工具箱[24],设置为RBF核函数,通过交互验证寻找最佳的惩罚参数c和核函数参数g。极限学习机[25](extreme learning machine,ELM)是针对单隐含前馈神经网络(single hidden layer feedforward neural network,SLFN)的算法,只需要设置隐含层的神经元个数便能得到最优的唯一解。偏最小二乘法[26](partial least squares,PLS)是结合主成分分析和多元线性回归的化学计量学方法,需要设置合理的PLS因子数来达到最佳的模型效果。不同方法建立的模型,判别结果可能也会存在差异。

1.5 数据处理

采用ENVI 4.7(ITT Visual Information Solutions, Boulder, USA),Matlab 2014a(The Mathworks Inc., Massachusetts, USA)和IBM SPSS(Version 20.0, Inc., Chicago, IL, USA)软件对数据进行处理。

2 结果与分析

2.1 不同萎凋程度样品儿茶素与氨基酸比值分析

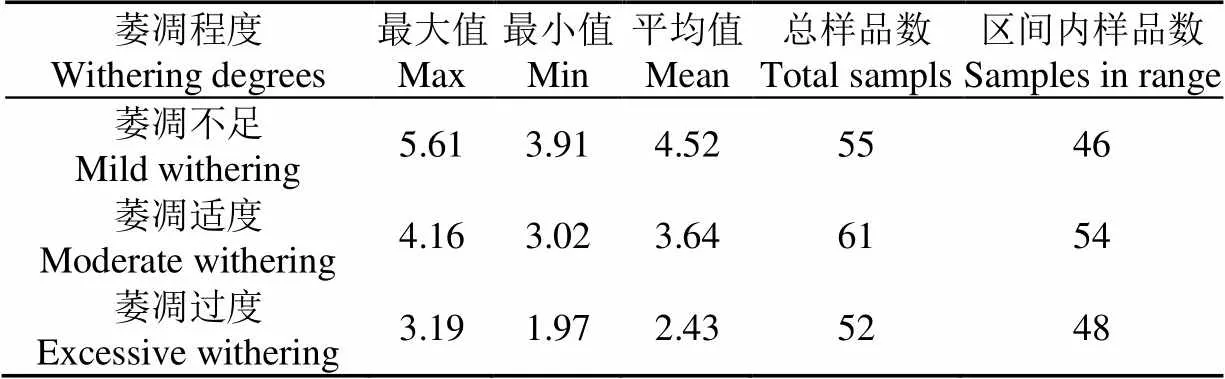

不同萎凋程度样品儿茶素与氨基酸比值的统计结果如表1所示。从表1可以看出,适度萎凋鲜叶的儿茶素与氨基酸的平均比值在3.64左右,不同萎凋程度样品的儿茶素与氨基酸比值之间重叠较少,因而可以利用儿茶素与氨基酸比值来区分萎凋程度。

茶鲜叶在萎凋过程中随着水分的减少,细胞液浓缩,鲜叶内源酶浓度增加,酶活性增强。一方面儿茶素类部分降解,同时蛋白水解酶活性增加,部分水溶性蛋白分解,氨基酸含量增加,因而儿茶素总量呈下降趋势,氨基酸含量呈现增加的趋势[27]。本研究计算出儿茶素与氨基酸比值,萎凋不足样品的儿茶素与氨基酸比值集中分布在5~4之间,萎凋适度样品的儿茶素与氨基酸比值集中分布在4~3之间,萎凋过度样品的儿茶素与氨基酸比值集中分布在3~2之间,这与刘少群等[28]分析的单芽型红茶在萎凋过程中儿茶素与氨基酸的变化结果一致。

表1 儿茶素与氨基酸比值统计结果

2.2 光谱特征波长的筛选

选择校正后的图像中间100×100像素范围为感兴趣区域(region of interest, ROI),提取ROI区域的所有像素的光谱平均值作为该样本的光谱值。计算3种萎凋程度样本的平均值,样品的原始光谱如图1所示,不同萎凋程度样本的光谱曲线趋势相似,在1 182和1 449 nm处出现明显的吸收峰。为了消除光谱中的噪声信息,采用标准正态变量法(standard normal variate, SNV)对原始光谱进行预处理[29]。

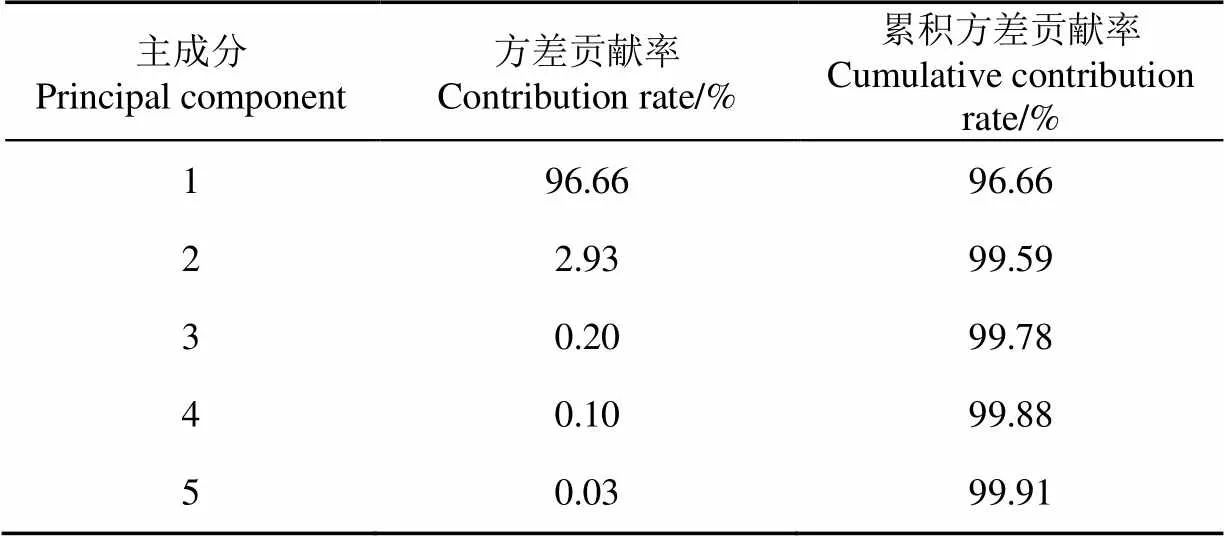

对不同萎凋程度样本的图像进行主成分分析,不同主成分数对应的方差贡献率结果如表2所示。

表2 前5个主成分的方差贡献率

由表2可知,第一主成分(principal component1, PC1)的方差贡献率为96.66%,PC2的方差贡献率为2.93%,前2个主成分的累积方差贡献率达99.59%,几乎可以代表全部信息。由于前2个主成分能解释原始数据的绝大部分信息,因而可以利用前2个主成分来寻找特征波长。如图2所示,根据前2个主成分图像下各波长的权重系数的绝对值的大小优选5个特征波长,分别是1 040、1 182、1 249、1 449、1 655 nm。

2.3 图像纹理特征值分析

基于灰度共生矩阵从5个特征波长图像分别提取4个角度的对比度、相关性、能量和同质性,共提取了80个纹理特征值。为进一步分析纹理特征值中哪些特征值与萎凋程度关系更为密切,本研究采用SPA算法来优选纹理特征值,当变量个数为14时,均方根误差(root mean square error, RMSE)最小,为0.421 09,所以最终优选出14个纹理特征值,分别为:1 040 nm处图像下45°的相关性和135°的对比度,1 182 nm处图像下0°的对比度,1 249 nm处图像下45°和135°的对比度、90°的相关性和能量,1 449 nm处图像的0、45°、90°和135°的对比度、45°的相关性,1 655 nm处图像下的0°的能量和45°的对比度。由优选得到的纹理特征值可知,纹理特征值主要集中在灰度共生矩阵的对比度和相关性上。

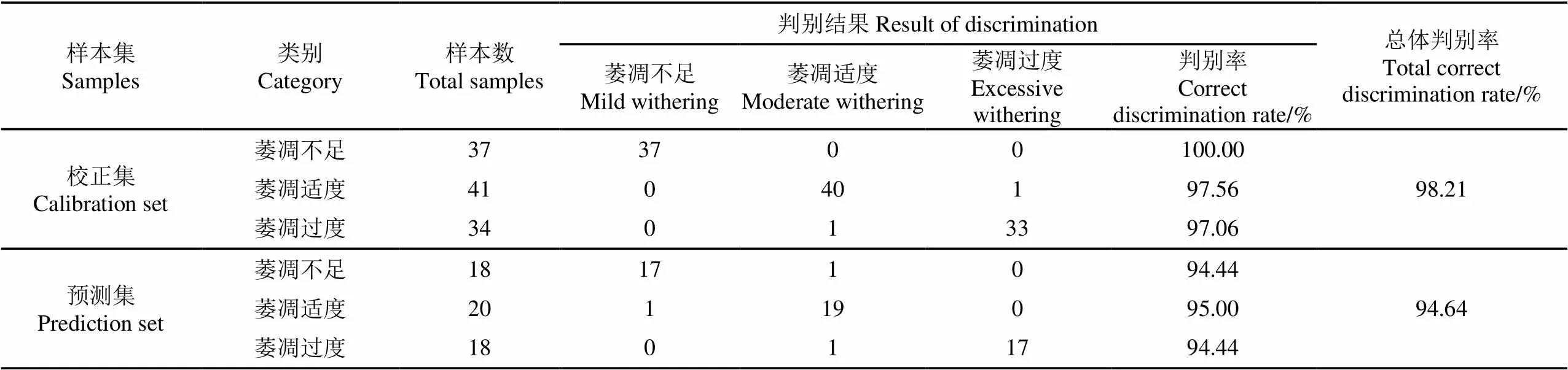

2.4 萎凋程度定性判别模型建立

光谱特征能表征萎凋叶的内部品质,纹理特征能表现萎凋叶的外部特点,为了更好的表示萎凋程度的变化,本研究将优选的5个光谱特征值和14个纹理特征值在特征层[30]进行融合。分别将光谱特征值、纹理特征值以及光谱和纹理特征值融合的数据作为LDA、SVM和ELM模型的输入值,建立萎凋程度判别模型,结果如表3所示。从表3可以看出,单独的光谱特征值为模型的输入值时,LDA和SVM模型预测集的判别率都为91.07%,略高于ELM模型预测集的判别率。单独的纹理特征值为模型的输入值时,LDA模型预测集的判别率为89.29%,高于ELM和SVM模型预测集的判别率。比较单独的光谱特征值和纹理特征值建立的模型,可知基于光谱特征值建立的模型优于基于纹理特征值建立的模型。基于光谱和纹理特征值融合的数据的LDA模型,预测集的判别率最高,如表4所示,总体判别率达到94.64%,有1个萎凋不足的样本被误判为萎凋适度、1个萎凋适度的样本被误判为萎凋不足、1个萎凋过度的样本被误判为萎凋适度,可见误判发生在相邻程度的样本间。通过比较可知,综合光谱和纹理特征值的融合数据为模型输入时,模型的效果优于基于单一特征值建立的模型。这可能是融合数据综合萎凋叶内外部的特征,能更加全面的反映出萎凋叶的变化。

2.5 萎凋程度定量预测模型建立

鲜叶在萎凋的过程中,随着含水量的减少,儿茶素逐步降解,同时氨基酸会少量增加。在萎凋过程中,儿茶素与氨基酸比值一直处于变化之中,萎凋适度鲜叶的比值会相对稳定地分布在一定范围内,所以也可以通过定量检测儿茶素与氨基酸比值来判别萎凋程度。为了更加准确地判别红茶的萎凋程度,对萎凋后茶样中儿茶素与氨基酸比值进行了定量预测。采用偏最小二乘法基于光谱和纹理特征值融合的数据建立儿茶素与氨基酸比值的预测模型,以相关系数(correlation coefficient,),验证均方根误差(root mean square error for validation, RMSECV),预测均方根误差(root mean square error of prediction, RMSEP)为模型的评价指标,模型的评价结果如图3所示。预测集的p=0.8765,RMSEP=0.434,这表示优选出的融合数据用来预测儿茶素与氨基酸比值是可行的。我国茶区分布较广,不同茶区、不同茶树品种鲜叶之间内含成分存在着差异,因而,预测模型的建立需要针对某一茶类,同时模型的性能还需要不断地优化。

表3 不同特征值模型对萎凋程度的识别结果

注:LDA、SVM和ELM分别表示线性判别分析法、支持向量机和极限学习机,下同。

Note: LDA, SVM and ELM represent linear discriminat analysis, support vector machine and extreme learning machine respectively, the same as below.

表4 光谱和纹理信息融合的LDA模型预测集的判别率

3 结 论

本研究基于光谱信息和图像信息融合技术结合模式识别,判别红茶的萎凋程度。通过主成分分析法优选5个特征波长及对应光谱特征值,利用灰度共生矩阵提取5个特征波长下的图像纹理特征值,并通过连续投影算法优选出14个纹理特征值,融合光谱和纹理特征值结合LDA模型算法,建立红茶萎凋程度的判别快速模型,模型的判别率分别达到94.64%。模型的输入值仅为19个变量,大大减少了建模所需的时间。利用光谱和纹理特征值融合的数据建立儿茶素与氨基酸的比值的定量预测模型,相关系数为0.8765,均方根误差为0.434,预测结果较好。

[1] 安徽农业大学. 制茶学(第3版)[M]. 北京:中国农业出版社,2016.

[2] Gowen A A, O’Donnell C P, Cullen P J, et al. Hyperspectral imaging-an emerging process analytical tool for food quality and safety control[J]. Trends in Food Science and Technology, 2007, 18: 590-598.

[3] 张红涛,毛罕平,韩绿化. 近红外高光谱成像技术检测粮仓米象活虫[J]. 农业工程学报,2012,28(8):263-268.

Zhang Hongtao, Mao Hanping, Han Lühua. Detection of live(L.) in stored wheat by near- infrared hyperspectral imaging[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(8): 263-268. (in Chinese with English abstract)

[4] 郭澎涛,苏艺,茶正早,等. 基于BP神经网络的橡胶苗叶片磷含量高光谱预测[J]. 农业工程学报,2016,32(增刊1):177-183.

Guo Pengtao, Su Yi, Cha Zhengzao, et al. Prediction of leaf phosphorus contents for rubber seedlings based on hyperspectral sensitive bands and back propagation artificial neural network[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(Supp.1): 177-183. (in Chinese with English abstract)

[5] 陈志强,王磊,白由路,等. 玉米叶片的光谱响应及其氮素含量预测研究[J]. 光谱学与光谱分析,2013,33(4):1066-1070.

Chen Zhiqiang, Wang Lei, Bai Youlu, et al. Spectral response of maize leaves and prediction of their nitrogen content[J]. Spectroscopy and Spectral Analysis, 2013, 33(4): 1066-1070. (in Chinese with English abstract)

[6] 李金梦,叶旭君,王巧男,等. 高光谱成像技术的柑橘植株叶片含氮量预测模型[J]. 光谱学与光谱分析,2014,34(1):212-216.

Li Jinmeng, Ye Xujun, Wang Qiaonan, et al. Development of prediction models for determining N content in citrus leaves based on hyperspectral imaging technology[J]. Spectroscopy and Spectral Analysis, 2014, 34(1): 212-216. (in Chinese with English abstract)

[7] 张瑶,郑立华,李民赞,等. 基于光谱学原理与小波包分解技术预测苹果树叶片氮素含量[J]. 农业工程学报,2013,29(增刊1):101-108.

Zhang Yao, Zheng Lihua, Li Minzan, et al. Predicting apple leaf nitrogen content based on hyperspectral and wavelet packet analysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(Supp.1): 101-108. (in Chinese with English abstract)

[8] 章海亮,李晓丽,朱逢乐,等. 应用高光谱成像技术鉴别绿茶品牌研究[J].光谱学与光谱分析,2014,34(5):1373-1377.

Zhang Hailiang, Liu Xiaoli, Zhu Fengle, et al. Identification of green tea brand based on hyperspectral imaging[J]. Spectroscopy and Spectral Analysis, 2014, 34(5): 1373-1377. (in Chinese with English abstract)

[9] 陈孝敬,吴迪,何勇,等. 基于多光谱图像颜色特征的茶叶分类研究[J]. 光谱学与光谱分析,2008,28(11):2527-2530.

Chen Xiaojing, Wu Di, He Yong et al. Study on discrimination of tea based on color of multispectral image[J]. Spectroscopy and Spectral Analysis, 2008, 28(11): 2527-2530. (in Chinese with English abstract)

[10] 蒋帆,乔欣,郑华军,等.基于高光谱分析技术的机炒龙井茶等级识别方法[J]. 农业工程学报,2011,27(7):343-348.

Jiang Fan, Qiao Xin, Zheng Huajun, et al. Grade discrimination of machine fried Longjing tea based on hyperspectral technology[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(7): 343-348. (in Chinese with English abstract)

[11] 赵杰文,王开亮,欧阳琴,等. 高光谱技术分析茶树叶片中叶绿素含量及分布[J]. 光谱学与光谱分析,2011(2):512-515.

Zhao Jiewen, Wang Kailiang, Ouyang Qin, et al. Measurement of chlorophyll content and distribution in tea plant’s leaf using hyperspectral imaging technique[J]. Spectroscopy and Spectral Analysis, 2011(2): 512-515. (in Chinese with English abstract)

[12] 王晓庆,冉烈,彭萍,等. 炭疽病胁迫下的茶树叶片高光谱特征分析[J].植物保护,2014,40(6):13-17.

Wang Xiaoqing, Ran Lie, Peng Ping, et al. Analysis of the hyperspectral characteristics of tea leaves under anthracnose disease stress[J]. Plant Protection, 2014, 40(6): 13-17. (in Chinese with English abstract)

[13] Xie Chuanqi, Li Xiaoli, Shao Yongni, et al. Color measurement of tea leaves at different drying periods using hyperspectral imaging technique[J]. PLOS ONE, 2014, 9(12): e113422.

[14] Xie Chuanqi, Li Xiaoli , He yong, et al. Application of time series hyperspectral imaging (TS-HSI) for determining water content within tea leaves during dying[J]. Transactions of the ASABE, 2013, 56(6): 1431-1440.

[15] 宁井铭,颜玲,张正竹,等. 祁门红茶加工中氨基酸和儿茶素快速检测模型建立[J]. 光谱学与光谱分析,2015(12):3422-3426.

Ning Jingming, Yan Ling, Zhang Zhengzhu, et al. Rapid and dynamic determination models of amino acids and catechins concentrations during the processing procedures of keemun balck tea[J]. Spectroscopy and Spectral Analysis, 2015(12): 3422-3426. (in Chinese with English abstract)

[16] 吴龙国,王松磊,康宁波,等. 基于高光谱成像技术的灵武长枣缺陷识别[J]. 农业工程学报,2015,31(20):281-286.

Wu Longguo, Wang Songlei, Kang Ningbo, et al. Non-destructive detection of defects inMill cv.based on near-infrared hyperspectral imaging[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(20): 281-286. (in Chinese with English abstract)

[17] Haralick R M, Shanmugam K, Dinstein I. Textural features for image classification[J]. IEEE Transactions on Systems, Man, and Cybernetics, 1973, 3(6): 610-621.

[18] Soares S F C, Gomes A A, Galvao A R, et al. The successive projections algorithm[J]. TRAC-Trends in Analytical Chemisty, 2013, 42(42): 84-98.

[19] 金瑞,李小昱,颜伊芸,等. 基于高光谱图像和光谱信息融合的马铃薯多指标检测方法[J]. 农业工程学报,2015,31(16):258-263.

Jin Rui, Li Xiaoyu, Yan Yiyun, et al. Detection method of multi-target recognition of potato based on fusion of hyperspectral imaging and spectral information[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(16): 258-263. (in Chinese with English abstract)

[20] Shao Y N, Li Y, Jiang, L J, et al. Identification of pesticide varieties by detecting characteristics ofusing Visible/Near infrared hyperspectral imaging and Raman microspectroscopy technology[J]. Water Research, 2016, 104: 432-440.

[21] 文韬,洪添胜,李立君,等. 基于高光谱技术的霉变稻谷脂肪酸含量无损检测[J]. 农业工程学报,2015,31(18):233-239.

Wen Tao, Hong Tiansheng, Li Lijun, et al. Non-destructive detection of fatty acid content in mould paddy based on high-spectral technology[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(18): 233-239. (in Chinese with English abstract)

[22] Wei X, Liu F, Qiu Z J, et al. Ripeness classification of astringent persimmon using hyperspectral imaging technique[J]. Food Bioprocess Technology, 2014(7): 1371-1380.

[23] Wang L, Sun D W, Pu H B, et al. Application of hyperspectral imaging to discriminate the variety of maize seeds[J]. Food Analyticla Methods, 2016(9): 225-234.

[24] Chang C C, Lin C J. LIBSVM: a library for support vector machines[J]. ACM Transactions on Intelligent Systems and Technology, 2011, 2(3): 389-396.

[25] Huang G, Huang G B, Song S J, et al. Trends in extreme learning machines: A review[J]. Neural Networks, 2015, 61: 32-48.

[26] 刘燕德,熊松盛,吴至境,等. 赣南脐橙园土壤全磷和全钾近红外光谱检测[J]. 农业工程学报,2013,29(18):156-162.

Liu Yande, Xiong Songsheng, Wu Zhijing, et al. Detection of total potassium and total phosphorus in soil in GAN NAN navel orange orchard using near infrared spectroscopy[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(18): 156-162. (in Chinese with English abstract)

[27] 黄藩,董春旺,朱宏凯,等. 红茶萎凋中鲜叶理化变化及工艺技术研究进展[J]. 中国农学通报,2014,30(27):275-281.

Huang Fan, Dong Chunwang, Zhu hongkai, et al. A review on the black tea withering technology and the changes of physics and chemistry of leaves[J]. Chinese Agricultural Science Bulletin, 2014, 30(27): 275-281. (in Chinese with English abstract)

[28] 刘少群,孙彬妹,段莹,等. 不同萎凋程度处理对单芽红茶品质的影响[J]. 茶叶通讯,2015,42(4):30-34.

Liu Shaoqun, Sun Binmei, DuanYing, et al. Effect of withering degree on the quality of single bud black tea[J]. Journal of Tea Communication, 2015, 42(4): 30-34. (in Chinese with English abstract)

[29] Huang L, Zhao J W, Chen Q S, et al. Rapid detection of total viable count (TVC) in pork meat by hyperspectral imaging[J]. Food Research International, 2013, 54(1): 821-828.

[30] Xiong Z J, Sun D W, Pu H B, et al. Combination of spectra and texture data of hyperspectral imaging for differentiating between free-range and broiler chicken meats[J]. LWT-Food Science and Technology, 2015, 60(2): 649-655.

Discriminant of withering quality of Keemun black tea based on information fusion of image and spectrum

Ning jingming1, Sun Jingjing1, Zhu Xiaoyuan1, Li Shuhuan1, Zhang Zhengzhu1, Huang Caiwang2

(1.230036;2.245600,)

Withering is the first procedure and the key step in processing of black tea. It is crucial for the quality of black tea product. Usually, the judgment of the withering degree relies on the processor’s judgment, rather than a quantitative analysis by fast evaluation method. In order to develop the digitized discrimination on withering degrees, different degrees of withering samples were collected in our research. In this study, 168 samples provided by Jindong tea factory in Qimen County were investigated. All of the samples belonged to different withering degrees (55 samples of mild withering, 61 samples of moderate withering and 52 samples of excessive withering). The samples were randomly divided into two subsets at the ratio of 2:1. 112 samples were chosen as the calibration set and the remaining 56 samples were prediction set. The calibration set was used to develop the model, while the prediction set was applied to test the robustness of the model. The withering degree was nondestructively evaluated by hyperspectral imaging technology at the range of 908-1735 nm. It was suggested that the ratio of catechins/amino acids was correspondingly decreased with the development of withering degrees. Furthermore, the contents of catechins and amino acids of these samples were detected by high-performance liquid chromatography (HPLC). The characteristic spectra were extracted from the region of interest (ROI), and standard normal variate (SNV) method was preprocessed to reduce background noise. All of the hyperspectral images of tea samples with different withering degrees were analyzed by principal component analysis (PCA). The first two principal component (PC) images were selected because PC1 and PC2 contributed to 99.59% variance of the total. Therefore, the first two PC images were used for selecting dominate wavelengths. And five dominant wavelengths (1 040, 1 182, 1 249, 1 449 and 1 655 nm) were selected as spectral features. Textual features were collected by Grey level co-occurrence matrix (GLCM) from five dominant wavelengths of images. Fourteen dominant textual features were selected by successive projections algorithm (SPA). Subsequently, linear discriminant analysis (LDA), support vector machine (SVM) and extreme learning machine (ELM) classification models were developed based on spectral features, textural features and data fusion, respectively. Compared with the results of the models built with spectral features or textural features, the LDA, SVM and ELM models based on data fusion showed higher correct discrimination rate in prediction set. The correct discrimination rate of LDA, SVM and ELM based on data fusion were 94.64%, 91.07% and 92.86%, respectively. The results indicated that hyperspectral imaging combined with LDA was a potent tool in the discrimination of withering degrees. At the same time, catechins/amino acids ratio was also applied in the discrimination of withering degrees. The study showed that correlate coefficient of prediction set by catechins/amino acids ratio was 0.8765, and root mean square error of prediction was 0.434. The results in this study provide a new method with fast and scientific of digitized discrimination for withering degree during black tea processing.

data fusion; discriminant analysis; image analysis; partial least squares approximations; black tea; withering; ratio of catechins to amino acids

10.11975/j.issn.1002-6819.2016.24.041

TS272.7; S123

A

1002-6819(2016)-24-0303-06

2016-09-30

2016-11-17

国家重点研发计划(2016YFD0200900);国家现代农业(茶叶)产业体系(CARS-23)

宁井铭,男,汉族,安徽泗县人,副教授,博士,主要从事茶叶加工、茶叶品质分析及红外光谱技术在茶叶上应用研究。合肥 茶树生物学与资源利用国家重点实验室,安徽农业大学,230036。Email:ningjm@ahau.edu.cn