厌氧膜生物反应器在污水处理中的应用

何丽玲, 陈 辉, 刘安娜, 陈倩倩, 金仁村

(杭州师范大学生命与环境科学学院,浙江 杭州 310036)

厌氧膜生物反应器在污水处理中的应用

何丽玲, 陈 辉, 刘安娜, 陈倩倩, 金仁村

(杭州师范大学生命与环境科学学院,浙江 杭州 310036)

厌氧膜生物反应器(AnMBRs)是一种高效新型的废水生物处理技术,但膜污染与高成本等问题严重限制了其工业化应用.文章从性能、微生物、反应器模型几方面阐述了AnMBRs的研究进展与技术特点,并指出未来的研究方向应集中于针对工程应用中的难题进行技术突破以及降低膜成本等方面.

污水处理;厌氧膜生物反应器;膜污染;性能;成本

水资源短缺是一个日益严重的全球性问题,可以通过合适的方法对污水进行处理再利用从而得以缓解.在诸多污水处理工艺中,厌氧工艺具有能降解市政污水和工业废水中有机物并回收能源的优点.但是,由于产生的甲烷(CH4)尚不能抵消加热所需能量,厌氧工艺运用于市政污水仍受限.且该工艺仅适用于气候温暖的国家和地区[1-2].此外,厌氧工艺还受很多因素的影响,如污水的类型和不稳定性、污水中有机污染物的种类以及污水pH值等[3].

早在20世纪90年代初,好氧膜生物反应器(AMBRs)工艺即被广泛工业化应用.相比传统的活性污泥(AS)处理工艺,它具有很多优势:反应器启动快[4],占地空间小,污染物去除率高,出水水质良好.膜的高效截留作用,使微生物完全截留在生物反应器内,实现了反应器固体停留时间(SRT)和水力停留时间(HRT)完全分离,保持了较高的混合液悬浮固体浓度(MLSS)[5-7].如果在厌氧条件下运行,MBRs的优点能够得到强化[1].因此,这项技术得到了广泛关注.

本文阐述了厌氧膜生物反应器(AnMBRs)技术的现状,特别强调了工业化规模应用时的性能和瓶颈.

1 AnMBRs的性能

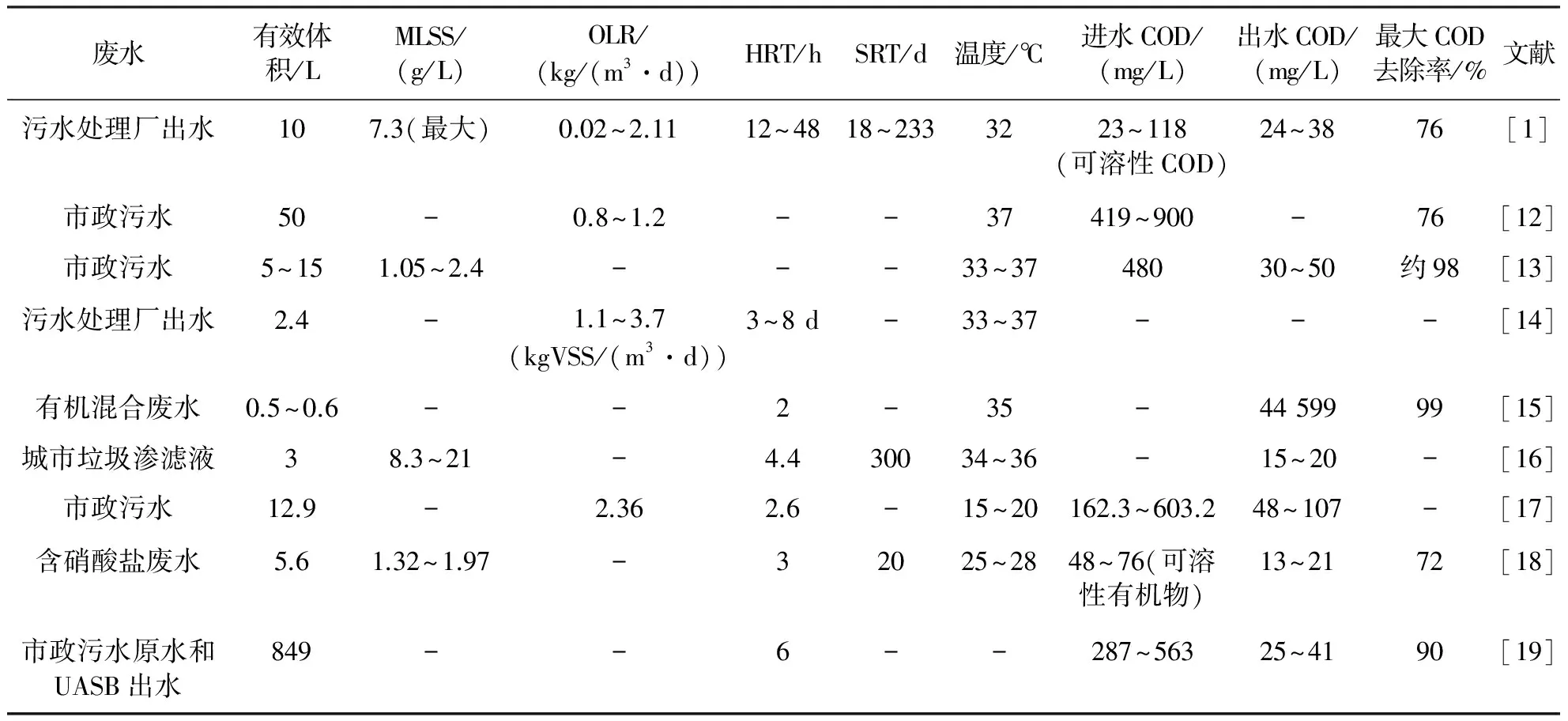

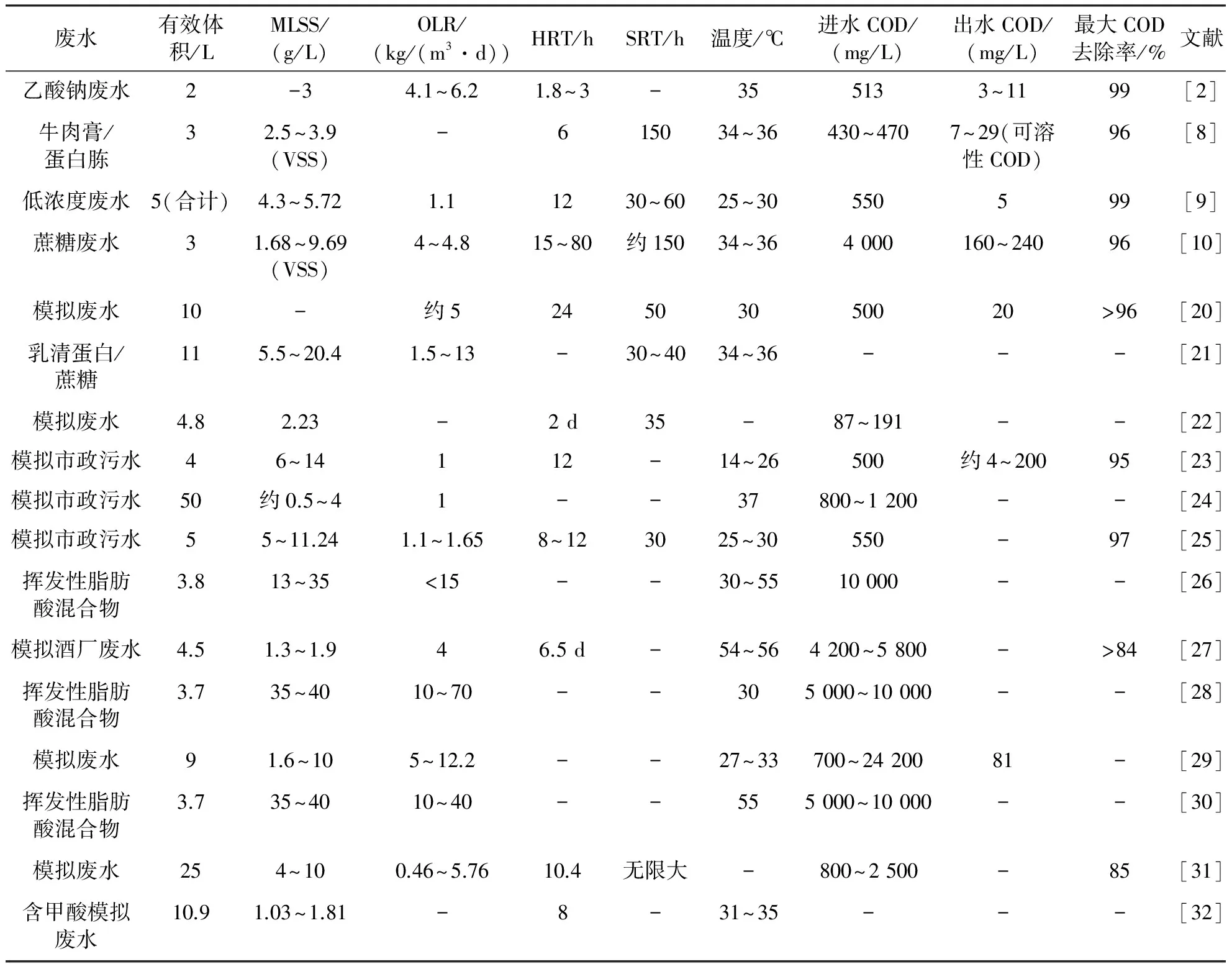

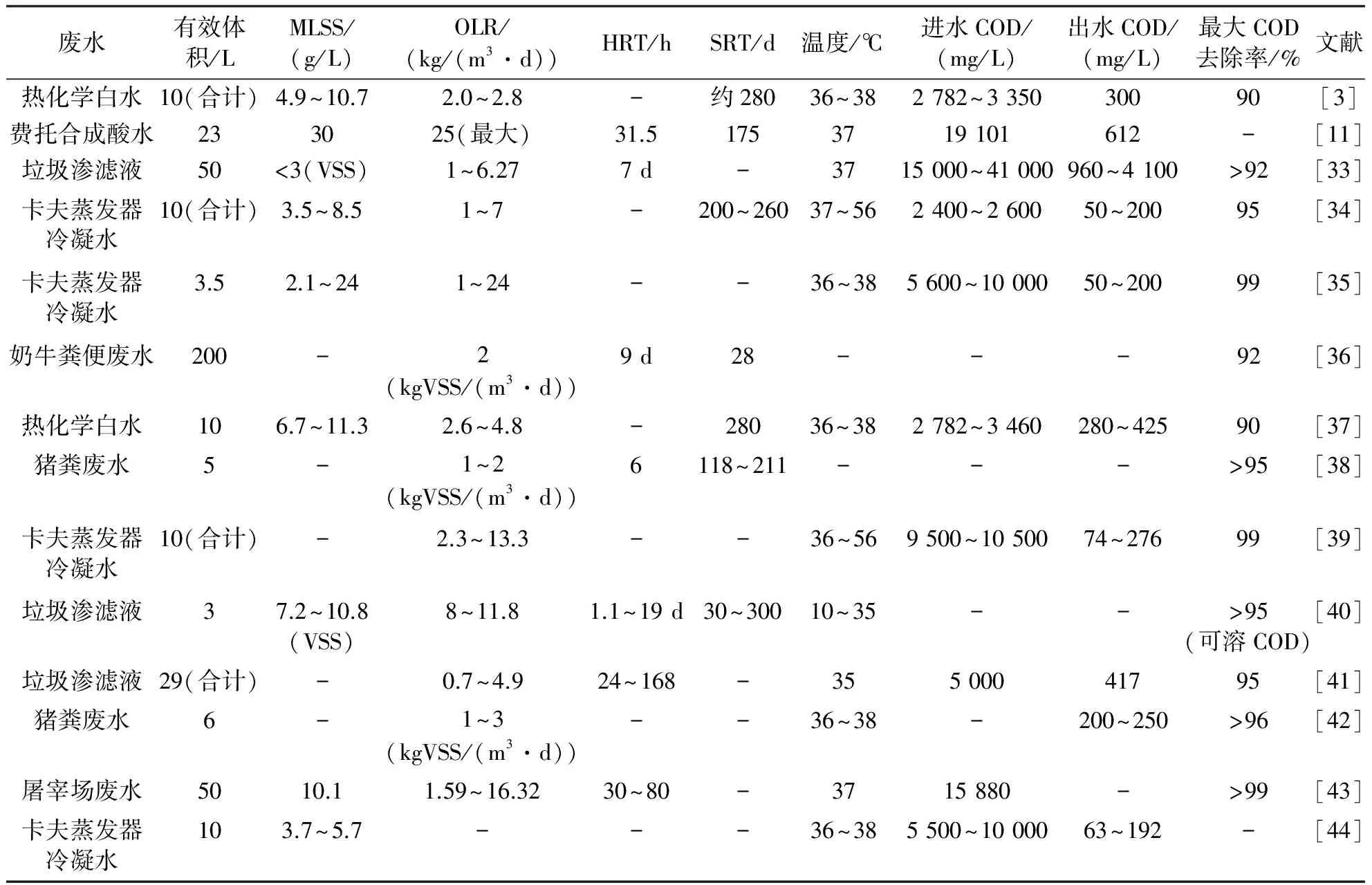

第一个工业的AnMBR由Dorr-Oliver建于20世纪80年代初,用来处理高浓度的乳制品加工废水.此后,AnMBRs用于研究处理各种不同污染物负荷的市政污水和工业废水,包括低浓度废水[8-9]、中等浓度废水[10]和高浓度废水[11](表1,2,3).

表1 AnMBRs处理市政污水概况

COD:化学需氧量;HRT:水力停留时间;MLSS:混合液悬浮固体浓度;OLR:有机负荷率;SRT:污泥停留时间;UASB:升流式厌氧污泥床反应器;VSS:挥发性悬浮固体.以下同.

表2 AnMBRs处理模拟废水概况

表3 AnMBRs处理其它废水概况

1.1 AnMBRs与其他污水处理技术比较

厌氧微生物具有较低的生长速率,因此微生物持留对高效厌氧污水处理是至关重要的.基于颗粒化和生物膜的技术代表了传统的微生物持留方法,能使生物反应器在高微生物浓度下运行,从而实现高有机负荷[7].但是,在高盐度或高温等特定条件下,生物膜和颗粒形成效果不佳,而AnMBRs可以在这种非常规条件下实现污泥持留[7].AnMBRs可以在较长SRT运行,这不仅意味着所有微生物能持留,更能提供微生物快速生长的机会,显著提高厌氧处理效果.

Cornelissen等曾预测AnMBRs将是一种非常有前景的工艺[45].现阶段MBRs广泛应用于污水处理系统[20],而AnMBRs仍处于开发阶段.其发展和应用受限的主要原因在于厌氧消化(AD)是一个复杂的过程[21].过去AD通常被排斥,因为厌氧细菌增长缓慢,倍增时间可以长达12 h到一周[33].AnMBRs有效解决了这个问题,让所有微生物完全持留在反应器内,但是膜污染问题似乎比AMBRs更严重[21].此外,污水中的毒性也是AD应用不普遍的主要原因之一,产甲烷菌很容易受毒性物质的抑制[46].好氧系统与厌氧系统相比建立更容易、更快速,因为好氧系统在较短的SRT能灵活地自我调节净细菌增长速率,而且在较低的温度下也可以有效运行[47-48].

1.2 能源回收

AnMBRs在能源回收方面有重要作用,可以将进水中98%的COD转化成沼气[49],而且由于厌氧微生物的低生长速率,系统中剩余污泥产率低[11].一般来说,AnMBRs可以产生优质燃料沼气,其中CH4高达80%甚至90%[34-35],这些沼气可以直接燃烧发电,所产能量可补偿所有膜过滤能耗,甚至实现污水处理厂产能[11]. Zyl等的研究表明,模拟污水处理过程中产电率为2.02 kWh/kgCOD去除,产生的电量大约是系统运行所需电耗的7倍[11].CH4产生量的差异在于所降解有机物的不同导致CO2/CH4比例变化幅度较大.富含碳水化合物的有机污染物(如谷物青贮饲料)能提高沼气产量和CH4比重[50].此外,沼气的成分与反应器运行条件有关.相比传统的厌氧处理工艺,AnMBRs能在较短的HRT借助膜实现固液分离,产生的CH4含量高.根据亨利定律,CO2的溶解度比CH4高约10倍,这使更多的CO2随着水的流出被排出.

1.3 处理污水类型

2006年以来,只有很少一部分研究[12,36]涉及中试规模的AnMBRs,尚无研究涉及工业化规模的试验,几乎所有的研究者从事实验室规模的装置的研究[13,22-23].AnMBRs可用于处理各种类型的污水,如生活污水[12-13,51]、制浆造纸厂废水[37]、石油化工污水[11]等(表1,2,3).特别是对市政污水,传统的MBRs和AnMBRs都可以在类似条件下操作最终获得相近的溶解性COD去除率,然而AnMBRs减少了曝气的费用[51].但是,当污水成分发生较大波动或当进水中存在有毒物质时,AnMBRs中的微生物可能无法适应这种变化,此时系统很难达到稳态[24].毒性一般关注毒性水平,而不是毒性物质,任何物质在其浓度高过一定水平后均有可能是有毒的.然而,毒性影响可以通过一些措施得到缓解,例如增大SRT.一般而言,当污水中化合物浓度超出毒性浓度,使用AMBRs可能更可取;但是,可以采用一些控制方法,如稀释污水至毒性浓度以下[46],或在厌氧处理之前去除有毒的化合物[34],保证AnMBRs的稳定运行.

此外,如果污水有机物含量较低,建议在接近常温下操作,因为CH4产量低可能无法补偿加热成本.尽管在常温下操作技术上似乎可行,但需要增大SRT.另一方面,AnMBRs可以在高浓度MLSS下稳定运行,如49 g/L的猪粪[38]和50 g/L的城市垃圾[14].

1.4 操作条件

迄今为止,已经报道了许多不同组合工艺.HRT可以从2 h[2]到20 d[15],SRT可以从18[51]到300 d[16]甚至更长时间,这说明在MBR运行期间几乎没有剩余污泥产生[25].需要强调的是,绝大多数研究中的SRT都保持在150 d以上.通常情况下AnMBRs在较大SRT运行可以产生更多沼气,如果减小SRT,反应程度也将下降[50].所以,较小的SRT不足以实现稳定的消化过程[52].例如,Huang等曾报道AnBMR在SRT为30和60 d时,CH4的产率分别为0.023和0.028 L CH4/(gMLVSS·d)[9].

绝大多数AnMBRs的操作温度在35 ℃左右的中温范围[26,39],或者55 ℃的高温范围[27-28,39],甚至20 ℃的低温[40].混合液的温度直接影响COD去除率,温度越高,COD去除率也越高.例如,运行温度为25和15 ℃的两个AnMBRs,其COD的去除率分别是95%和85%[47].此外,AnMBRs在高温下运行可以比中温运行时达到更高的容积负荷.Jeison等发现高温条件下AnMBRs的容积负荷维持在14 g COD/(L·d),中温运行时则低于10 g COD/(L·d)[26].一般来说,当有机负荷增加,由于挥发性脂肪酸(VFAs)积累,可能会增加反应器性能恶化的风险,而且由于微生物活性受抑制,COD去除率也会降低[29,36,41].

1.5 去除效率

AnMBRs最主要的目标是在污水最终排放或重复利用前减少有机物含量.为有效评估这个目标,大多数研究者测定了反应器进出水有机物浓度来计算整体去除效率.就受试污水水质而言,反应器进水COD范围从162[17]到10 000 mg/L[39],甚至在高浓度石油化工废水达到18 000 mg/L(主要是C2到C6的短链脂肪酸)[11],去除率为76%~99%(表1,2,3).此外,有报道称BOD去除率高于99%[39].需要说明的是,与混合溶液中悬浮微生物相比,附着在膜上的微生物对有机物去除的贡献可以忽略[23].

文献报道了很高的总悬浮固体(TSS)去除率,甚至高于99%[13].另外,病原体(如大肠杆菌和肠球菌)可以完全去除.所以,绝大多数经过处理的污水可以无限制地使用于农作物灌溉[12].

需要强调的是,pH冲击会对COD去除造成严重的、长期的负面影响[3].Gao等进行了一个pH冲击试验,结果导致沼气产量和膜过滤性能的变化[3].其中,pH8.0的冲击对COD去除率影响最小,pH9.1和pH10的冲击有明显的负面影响.pH9.1的冲击下,COD的去除率从90%急剧下降到75%,pH10的冲击下,COD的去除率更是从90%下降到30%.

1.6 能源消耗和费用

迄今有关AnMBRs过程能耗问题的研究不是很多,但是AnMBRs过程是一种能量可持续的工艺.笔者认为进一步研究AnMBRs的能耗是非常有益的.Kim等在AnMBRs之前设置了一个传统的厌氧流化床反应器,结果发现,两个反应器运行一共消耗能量0.058 kWh/m3,其中AnMBRs消耗的能量为0.028 kWh/m3,产生的CH4中30%用于提供消耗所需的能量[2].而Jeison等认为,膜成本远远高于AnMBRs的能耗成本,处理1 m3污水其成本分别为0.5和0.046欧元[30].因此,尽管膜费用逐渐地降低了,但仍然是限制AnMBRs广泛应用的一个重要因素.

值得一提的是,AnMBRs操作的灵活性使它有望与其他技术相结合.AnMBRs可与水解反应器连接形成组合工艺[16],进而水解污水中的有机物;可以和氢输送系统[18]组合进行反硝化处理市政污水;也可以与产酸体系串联,采用组合工艺的方法进行优化[15],提高CH4的产量.

2 微生物问题

AnMBRs是适合培养生长速率较小的微生物的系统[53].微生物量随时间逐渐增加,它们可以是悬浮的,也可以粘附在膜上,其中悬浮的微生物在有机物去除过程中发挥着最重要的作用[23],其产甲烷活性更高,且活性随温度的升高而增强.Ho等发现运行温度25 ℃条件下比15 ℃条件下的产甲烷率高[54].此外,较长的SRT和较短的HRT对产甲烷菌的活性也有促进作用,具体表现在沼气的产量增加[25].然而相对AMBRs,AnMBRs中SRT增加可能导致惰性固体物质积累[55-56].Padmasiri等发现横向流速增加会使AD性能降低,VFAs积累,反应器内和出水的溶解性COD都升高了,沼气的产量也随之降低[42].

在AnMBRs中,滤饼层和主体反应器内部的微生物群落之间有显著的差异,并且滤饼层会随着深度而逐渐变紧密.研究发现其中最主要的细菌种类属于厚壁菌门(Firmicutes),占42.3%,α蛋白细菌(Alpha-proteo-bacteria)所占比例30.8%,而古菌则大多属于产甲烷八叠球菌科(Methano sarcinales)和产甲烷螺菌科(Methano spirillaceae)[42].文献报道Sphingomonadaceae和产甲烷古菌(Methanogenicarchaea)是生物膜中的主要微生物,化学清洗后也是如此[19].

关于超声波的应用对微生物活性的影响,存在一些分歧.Sui等发现超声波可能对厌氧细菌活性有较弱的抑制作用,但没有导致COD去除率的明显下降[31].但Xu等发现超声不仅不会影响厌氧微生物,还能够提高其消化性能[14].

3 AnMBRs模型

尽管学者付出诸多努力,关于AnMBRs系统中数学模型的信息仍比较缺乏.Arros-alileche等尝试通过评估膜对溶质的可控停留的潜力构建AnMBRs模型[57],发现MF膜或UF膜需要较大的HRT保证良好的出水水质,而纳滤膜(NF)或反渗透膜(RO)则需要较小HRT.Jeong等研究了优化工艺和浸没式AnMBRs耦合的可行性,用来处理高浓度有机废水,确保良好渗透性能的同时保证了CH4的产量[15].

4 总结和展望

迄今为止,绝大部分学者只对实验室规模的AnMBRs的性能进行研究,中试规模的研究较为有限,尚无工程应用的报道.总的来说,AnMBRs能有效处理各种高浓度污水,处理后的污水水质良好,此外,AnMBRs能产生高质量燃料级别的沼气.但是膜污染和膜对有毒物质的敏感性等仍是技术瓶颈.因此,还应开展更多关于AnMBRs运行能耗方面的研究.AnMBRs产生沼气达到什么程度才能够实现能源的可持续性运行也需要进一步分析.现阶段有关AnMBRs运行模型的研究还比较少,亟需强化.此外,膜的高成本仍然是阻碍MBRs工业化的重要因素.

[1] LIAO B Q, KRAEMER J T, BAGLEY D M. Anaerobic membrane bioreactors: applications and research directions[J]. Crit Rev Env Sci Tec,2006,36(6):489-530.

[2] KIM J, KIM K, YE H, et al. Anaerobic fluidizedbed membrane bioreactor for wastewater treatment[J]. Environ Sci Technol,2011,45(2):576-581.

[3] 张珏,陈辉,姬玉欣,等.厌氧氨氧化脱氮工艺研究进展[J].化工进展,2014,33(6):1589-1595.

[4] BELLA G D, DURANTE F, TORREGROSSA M, et al. Start-up with or without inoculum? Analysis of an SMBR pilot plant[J]. Desalination,2010,260(1/2/3):79-90.

[5] MENG F G, CHAE S R, DREWS A, et al. Recent advances in membrane bioreactors (MBRs): membrane fouling and membrane material[J]. Water Research,2009,43(6):1489-1512.

[6] DOMINGUEZ L, CASES V, BIREK C, et al. Influence of organic loading rate on the performance of ultrafiltration and microfiltration membrane bioreactors at high sludge retention time[J]. Chem Eng J,2012,181:132-143.

[7] JEISON D, DIAZ I, VAN LIER J B. Anaerobic membrane bioreactors:are membranes really necessary?[J]. Electron J Biotechn,2008,11(4):1-7.

[8] AQUINO S F, HU A Y, AKRAM A, et al. Characterization of dissolved compounds in submerged anaerobic membrane bioreactors (SAMBRs)[J]. J Chem Technol Biot,2006,81(12):1894-1904.

[9] HUANG Z, ONG S L, NG H Y. Feasibility of submerged anaerobic membrane bioreactor (SAMBR) for treatment of low-strength wastewater[J]. Water Sci Technol,2008,58(10):1925-1931.

[10] AKRAM A, STUCKEY D C. Biomass acclimatisation and adaptation during start-up of a submerged anaerobic membrane bioreactor (SAMBR)[J]. Environ Technol,2008,29(10):1053-1065.

[11] VAN ZYL P J, WENTZEL M C, EKAMA G A, et al. Design and start-up of a high rate anaerobic membrane bioreactor for the treatment of a low pH, high strength, dissolved organic waste water[J]. Water Sci Technol,2008,57(2):291-295.

[12] SADDOUD A, ELLOUZE M, DHOUIB A, et al. A comparative study on the anaerobic membrane bioreactor performance during the treatment of domestic wastewaters of various origins[J]. Environ Technol,2006,27(9):991-999.

[13] KOCADAGISTAN E, TOPCUB N. Treatment investigation of the Erzurum city municipal wastewaters with anaerobic membrane bioreactors[J]. Desalination,2007,216(1/2/3):367-376.

[14] XU M L, WEN X H, YU Z Y, et al. A hybrid anaerobic membrane bioreactor coupled with online ultrasonic equipment for digestion of waste activated sludge[J]. Bioresource Technol,2011,102(10):5617-5625.

[15] JEONG E, KIM H W, NAM J Y, et al. Enhancement of bioenergy production and effluent quality by integrating optimized acidification with submerged anaerobic membrane bioreactor[J]. Bioresource Technol,2010,101(S1):7-12.

[16] TRZCINSKI A P, STUCKEY D C. Anaerobic digestion of the organic fraction of municipal solid waste in a two-stage membrane process[J]. Water Sci Technol,2009,60(8):1965-1978.

[17] AN Y, WANG Z W, WU Z C, et al. Characterization of membrane foulants in an anaerobic non-woven fabric membrane bioreactor for municipal wastewater treatment[J]. Chem Eng J,2009,155(3):709-715.

[18] REZANIA B, OLESZKIEWICZ J A, CICEK N. Hydrogen-driven denitrification of wastewater in an anaerobic submerged membrane bioreactor: potential for water reuse[J]. Water Sci Technol,2006,54(11/12):207-214.

[20] GAO D W, ZHANG T, TANG C Y Y, et al. Membrane fouling in an anaerobic membrane bioreactor: differences in relative abundance of bacterial species in the membrane foulant layer and in suspension[J]. J Membrane Sci,2010,364(1/2):331-338.

[21] SPAGNI A, CASU S, CRISPINO N A, et al. Filterability in a submerged anaerobic membrane bioreactor[J]. Desalination,2010,250(2):787-792.

[22] WANG T, ZHANG H M, YANG F L, et al. Start-up of the anammox process from the conventional activated sludge in a membrane bioreactor[J]. Bioresource Technol,2009,100(9):2501-2506.

[23] HO J, SUNG S. Methanogenic activities in anaerobic membrane bioreactors (AnMBRs) treating synthetic municipal wastewater[J]. Bioresource Technol,2010,101(7):2191-2196.

[24] SADDOUD A, ABDELKAFI S, SAYADI S. Effects of domestic wastewater toxicity on anaerobic membrane-bioreactor (MBR) performances[J]. Environ Technol,2009,30(13):1361-1369.

[25] HUANG Z, ONG S L, NG H Y. Submerged anaerobic membrane bioreactor for low-strength wastewater treatment: effect of HRT and SRT on treatment performance and membrane fouling[J]. Water Res,2011,45(2):705-713.

[26] JEISON D, VAN BETUW W, VAN LIER J B. Feasibility of anaerobic membrane bioreactors for the treatment of wastewaters with particulate organic matter[J]. Sep Sci Technol,2008,43(13):3417-3431.

[28] JEISON D, VAN LIER J B. Cake formation and consolidation: main factors governing the applicable flux in anaerobic submerged membrane bioreactors (AnSMBRs) treating acidified wastewaters[J].Sep Purif Technol,2007,56(1):71-78.

[29] WIJEKOON K C, VISVANATHAN C, ABEYNAYAKA A. Effect of organic loading rate on VFA production, organic matter removal and microbial activity of a two-stage thermophilic anaerobic membrane bioreactor[J]. Bioresource Technol,2011,102(9):5353-5360.

[30] JEISON D, VAN LIER J B. Thermophilic treatment of acidified and partially acidified wastewater using an anaerobic submerged MBR: factors affecting long-term operational flux[J]. Water Res,2007,41(17):3868-3879.

[31] SUI P Z, WEN X H, HUANG X. Feasibility of employing ultrasound for on-line membrane fouling control in an anaerobic membrane bioreactor[J]. Desalination,2008,219(1/2/3):203-213.

[32] PEVERE A, GUIBAUD G, VAN HULLEBUSCH E, et al. Identification of rheological parameters describing the physico-chemical properties of anaerobic sulphidogenic sludge suspensions[J]. Enzyme Microb Tech,2007,40(4):547-554.

[33] ZAYEN A, MNIF S, ALOUI F, et al. Anaerobic membrane bioreactor for the treatment of leachates from Jebel Chakir discharge in Tunisia[J]. J Hazard Mater,2010,177(1/2/3):918-923.

[34] LIAO B Q, XIE K, LIN H J, et al. Treatment of kraft evaporator condensate using a thermophilic submerged anaerobic membrane bioreactor[J]. Water Sci Technol,2010,61(9):2177-2183.

[35] XIE K, LIN H J, MAHENDRAN B, et al. Performance and fouling characteristics of a submerged anaerobic membrane bioreactor for kraft evaporator condensate treatment[J]. Environ Technol,2010,31(5):511-521.

[36] WONG K, XAGORARAKI I, WALLACE J, et al. Removal of viruses and indicators by anaerobic membrane bioreactor treating animal waste[J]. J Environ Qual,2009,38(4):1694-1699.

[37] LIN H J, LIAO B Q, CHEN J R, et al. New insights into membrane fouling in a submerged anaerobic membrane bioreactor based on characterization of cake sludge and bulk sludge[J]. Bioresource Technol,2011,102(3):2373-2379.

[38] ZHANG J, PADMASIRI S I, FITCH M, et al. Influence of cleaning frequency and membrane history on fouling in an anaerobic membrane bioreactor[J]. Desalination,2007,207(1/2/3):153-166.

[39] LIN H J, XIE K, MAHENDRAN B, et al. Sludge properties and their effects on membrane fouling in submerged anaerobic membrane bioreactors (SAnMBRs)[J]. Water Res,2009,43(15):3827-3837.

[40] TRZCINSKI A P, STUCKEY D C. Treatment of municipal solid waste leachate using a submerged anaerobic membrane bioreactor at mesophilic and psychrophilic temperatures: analysis of recalcitrants in the permeate using GC-MS[J]. Water Res,2010,44(3):671-680.

[41] BOHDZIEWICZ J, NECZAJ E, KWARCIAK A. Landfill leachate treatment by means of anaerobic membrane bioreactor[J]. Desalination,2008,221(1/2/3):559-565.

[42] PADMASIRI S I, ZHANG J Z, FITCH M, et al. Methanogenic population dynamics and performance of an anaerobic membrane bioreactor (AnMBR) treating swine manure under high shear conditions[J]. Water Res,2007,41(1):134-144.

[43] SADDOUD A, SAYADI S. Application of acidogenic fixed-bed reactor prior to anaerobic membrane bioreactor for sustainable slaughter house wastewater treatment[J]. J Hazard Mater,2007,149(3):700-706.

[44] LIN H J, XIE K, MAHENDRAN B, et al. Factors affecting sludge cake formation in a submerged anaerobic membrane bioreactor[J]. J Membrane Sci,2010,361(1/2):126-134.

[45] CORNELISSEN E R, VAN BUGGENHOUT S, VAN ERMEN S, et al. Anaerobic treatment of brewery wastewater with an internal membrane bioreactor[J]. Meded Rijksuniv Gent. Fak Landbouwk Toegep Biol Wet,2001,66(3a):135-138.

[46] DE LEMOS CHEMICHARO C A. Biological wastewater treatment series, anaerobic reactors:vol.4[M]. London:IWA Publishing,2007.

[47] SANTOS A, MA W, JUDD S J. Membrane bioreactors: two decades of research and implementation[J]. Desalination,2011,273(1):148-154.

[48] CHANG S. Application of submerged hollow fiber membrane in membrane bioreactors: filtration principles, operation, and membrane fouling[J]. Desalination,2011,283(S):31-39.

[49] SUTTON P M, MELCER H, SCHRAA O J, et al. Treating municipal wastewater with the goal of resource recovery[J]. Water Sci Technol,2011,63(1):25-31.

[50] ZHOU H D, LI H, WANG F F. Anaerobic digestion of different organic wastes for biogas production and its operational control performed by the modified ADM1[J]. J Environ Sci Heal A,2012,47(1):84-92.

[51] BAEK S H, PAGILLA K R. Aerobic and anaerobic membrane bioreactors for municipal wastewater treatment[J]. Water Environ Res,2006,78(2):133-140.

[52] APPELS L, BAEYENS J, DEGREVE J, et al. Principles and potential of the anaerobic digestion of waste-activated sludge[J]. Prog Energ Combust,2008,34(6):755-781.

[53] MEULEPAS R J, JAGERSMA C G, GIETELING J A, et al. Enrichment of anaerobic methanotrophs in sulfate-reducing membrane bioreactors[J]. Biotechnol Bioeng,2009,104(3):458-470.

[54] HO J, SUNG S. Methanogenic activities in anaerobic membrane bioreactors (AnMBRs) treating synthetic municipal wastewater[J]. Bioresour Technol,2010,101:2191-2196.

[55] LAERA G, POLLICE A, SATURNO D, et al. Zero net growth in a membrane bioreactor with complete sludge retention[J]. Water Res,2005,39(20):5241-5249.

[56] CASU S, CRISPINO N A, FARINA R, et al. Wastewater treatment in a submerged anaerobic membrane bioreactor[J]. J Environ Sci Heal A,2012,47(2):204-209.

[57] ARROS-ALILECHE S, MERIN U, DAUFIN G, et al. The membrane role in an anaerobic membrane bioreactor for purification of dairy wastewaters: a numerical simulation[J]. Bioresource Technol,2008,99(17):8237-8244.

Anaerobic Membrane Bioreactors for Wastewater Treatment

HE Liling, CHEN Hui, LIU Anna, CHEN Qianqian, JIN Rencun

(College of Life and Environmental Sciences, Hangzhou Normal University, Hangzhou 310036, China)

Anaerobic membrane bioreactor (AnMBRs) is a novel and efficient biotechnology for wastewater treatment. However, membrane fouling and high cost severely limits its industrial application. This review summarizes the research progress and technical properties of AnMBRs from the performance of AnMBRs, microbiological issues and AnMBRs modeling. It also addresses that certain efforts should be made to break the technical bottleneck during engineering practice and reduce the cost of the membranes.

wastewater treatment; anaerobic membrane bioreactor; membrane fouling; performance; cost

2015-07-30

国家自然科学基金项目(51278162);国家级大学生创新创业训练计划项目(201410346017).

金仁村(1979—),男,教授,博士,主要从事环境生物技术和水污染控制工程研究.E-mail:jrczju@aliyun.com

10.3969/j.issn.1674-232X.2016.06.009

X703

A

1674-232X(2016)06-0606-07