Development of sodium sulfur battery (NAS® battery) and application

TAMAKOSH Tomio

Development of sodium sulfur battery (NAS®battery) and application

(NAS Battery Div., NGK Insulators, LTD, Japan)

NGK has developed a sodium sulfur battery (NAS® battery) for load leveling applications, allowing the grid to deal with increasing peak. The recent growth in environmentally friendly renewable energies causes network instability. A secondary battery based energy storage system is seen as one of the strongest solutions to stabilize the network while improving the efficiency and usability of these renewable energy technologies. The NAS battery features long duration discharge, compactness, and a long lifespan of 15 years. The capacity for long duration discharge is one of the most notable features of this technology, a feature which becomes more important as renewable energy generation increases. In this paper, recent design of the NAS® battery system is detailed, and a few applications are described.

sodium sulfur battery; energy storage

1 Introduction

NAS® battery is high temperature secondary battery which had been developed by NGK in cooperation with Tokyo Electric Power Company. A total of 530MW/3700MW·h of NAS® battery systems have been installed worldwide since the commercialization startedin 2002. Major applications are peak shaving, emergency power supply and voltage sag prevention, leveraging the large energy capacity. Right now renewable energy generation suchas wind and solar is increasing everywhere in theworld, driving a need for improved network stability. A secondary battery is considered as one of the strongest potential solutions to this emergent need, stabilizing transient energy production as well as absorbing over generation caused by renewables[1-2].

2 Principle and features of NAS® battery

The principle of a sodium sulfur battery was discovered by Ford Motors in 1967. Fig.2 shows the reaction of discharge and charge in a sodium sulfur battery. A sodium sulfur battery consists of beta alumina as solid electrolyte, sodium as the negative electrode and sulfur as the positive electrode. In discharge, sodium ion moves from negative electrode to positive electrode through beta alumina, and creates sodium polysulfide. When charging, the sodium ions returnto the negative electrode. Operation temperature of sodium sulfur battery should be kept more than300 ℃ because the melting point of sodium polysulfide is 285 ℃[3-4].

NAS® battery features:①Large capacity with 6hrs of discharge;②High energy density, 3 times of lead acid;③Fast response, less than 1ms from 0 to 100%;④Long life of 15 years or 4,500 full discharge cycles (no cycle limitation for short time discharge/charge cycle);⑤No self-discharge, therefor no need for uniform charge;⑥Applicable to wide range of ambient temperature thanks to high temperature battery and exceptional insulation.

3 NAS® battery design

3.1 Cell

Fig.3 shows the structure of a NAS® cell. The cell is cylindrical in shape and consists of sodium at the center, sulfur at the outside. Beta alumina ceramics work as the solid electrolyte. Sulfur is soak into carbon felt to keep electron conductivity.

3.2 Module

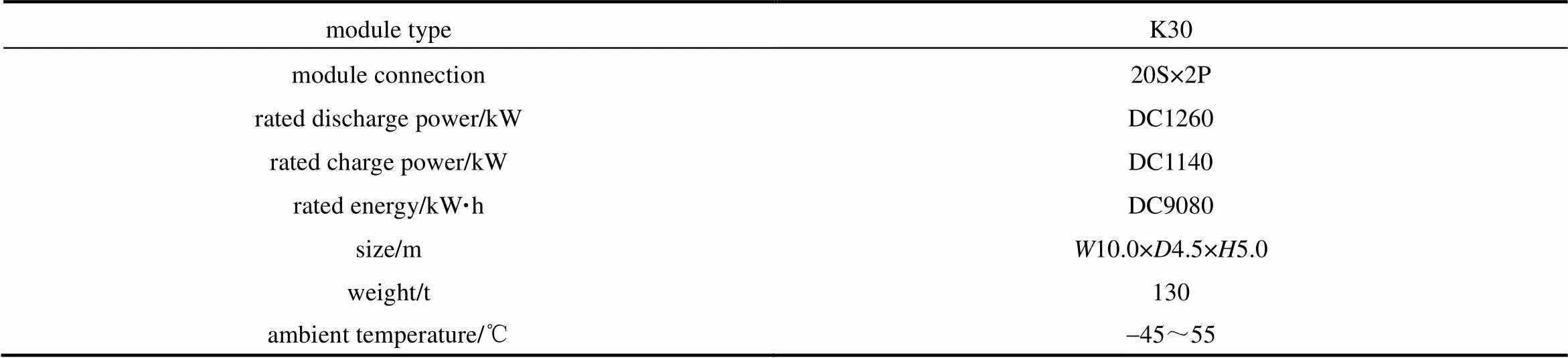

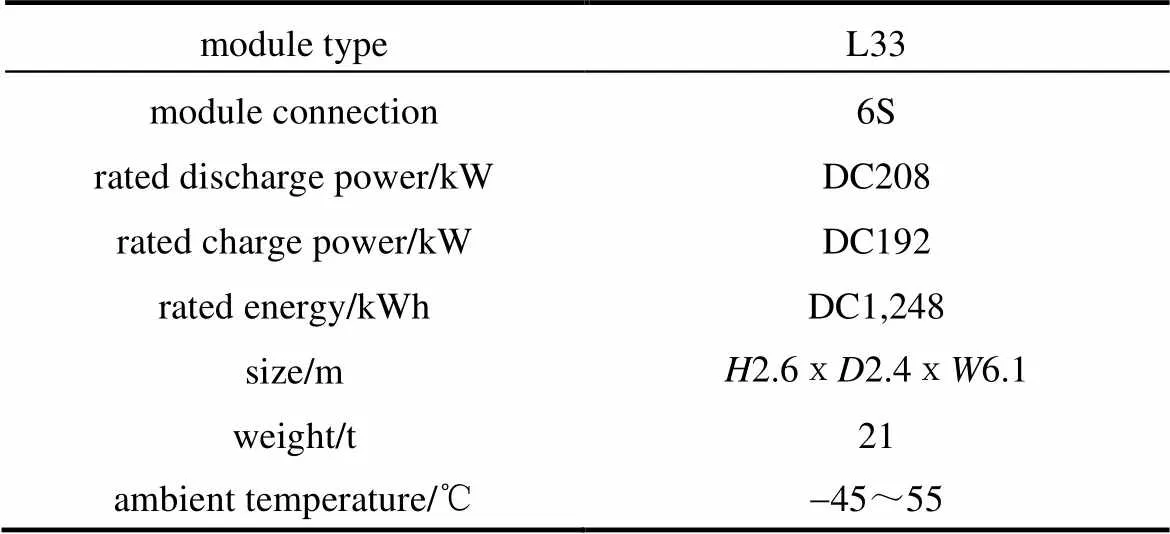

A module contains many cells within a temperature controlled vacuum insulated container. As previously noted, the cells must remain above 300 ℃. The structure of a K30 module is shown in Fig.4. The outer double layer vacuum insulation container minimizes heating power, dramatically improving system efficiency. Fuses are located at every series cell connection to prevent overcurrent. Dry sand fills the module between and above cells. It serves several purposes, it increases the thermal mass of the system and in an emergency, it will absorb any leaked material. Specification of the K30 module is detailed in Table 1. The newly designed L33 module is shown in Fig.5. The improved features of the L33 module allow it to more efficiently control the internal temperature of the cells, extending the capability of the overall NAS® system. Heating power is decreased by more than 50% by the improved vacuum insulation. Additionally, a cooling fan is installed in this module to release the heat generated during the discharge. The fan is automatically operated by the BMS to keep the cells within the optimal operating temperature range. This thermal control system enhances efficiency even in short duration discharge conditions.

Table 1 Specification of module

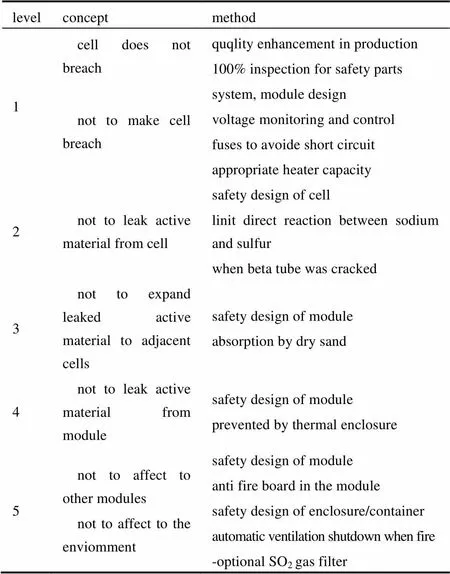

3.3 Safety design

Generally, energy storage batteries have very high energy density, making it absolutely critical to implement appropriate safety measures to prevent uncontrolled release of energy. Originally designed for use in the earthquake prone densely populated city of Tokyo and surrounding areas, it is no surprise that the NAS® battery has been designed with multiple counter measures for various imaginable potential accidents or malfunctions. Many of the multiple counter measures are shown in Table 2. NGK designed the system with the following two guiding principles.① Prevent any malfunction from occurring;②Even in the worst case, a malfunction shall not spread, it shall be confined to a very limited area.

Table 2 Multiple safety concepts and methods

The BMS is tasked with managing the modules to prevent voltage and current of an individual cell from exceeding design limit values.As with many battery technologies,grossly exceeding these chemical limitations can cause combustion. Following NGK’s design principals, the BMS and strategically placed fuses prevent a malfunction from occurring. However, if a malfunction does develop, NGK has adopted anti-fire sheet around every single cell, which has been tested to demonstrate that a cell fire will not to expand to adjacent cells (Refer to Table 3 of self-extinguishment test result).

Safety of NAS® battery is evaluated and certified by HMSTA (Hazardous Material Safety Techniques Assosiation) in Japan. Table 3 shows some of the result of the many safety tests.

Table 3 Safety test result

4 Specification of NAS® battery system

4.1 Enclosure type NAS® battery

Standard size of enclosure type NAS® battery system is 1200kW. This system is comprised of 40 sets of K30 modules in an outdoor enclosure. Specification and external view of 1200kW NAS® battery system is shown in Table 4 and Fig.6, respectively.

Table 4 Specification of 1200 kW NAS® battery

4.2 Container type NAS battery

In response to numerous customer requests, and to shorten the construction period, a containerized system was developed. Six modules and controllers are assembled and tested in the factory. These modules are then integrated into a 20-foot shipping container and tested again. This standard 20-foot ISO container can be transported by sea, vehicle or train. With this plug and play unit, transportation cost and construction cost can be noticeably reduced. Table 5details the specifications and Fig.7 show the external view of a 200kW container unit.

Table 5 Specification of 200kW NAS® battery unit

This unit can be adapted for very severe environments, including high ambient temperatures of 55℃(131℉) or highly corrosive marine environments. This is achieved by adding additional available climate control options including an air conditioner or salt capturing filter as needed for the application.

The 200kW units can be connected in series up to four units in a string.

5 Application of NAS® battery

5.1 Usage of NAS® battery

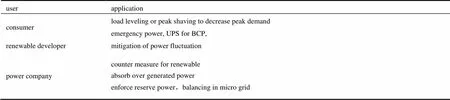

NAS® battery has been developed for load leveling or peak shaving as an alternative to pumped hydro generator. Recently, secondary batteries have become a viable solution for power fluctuation or over generation caused by renewable energy.Fig.9 shows various applications for NAS® batteries.

Table 6 Application of NAS® battery

5.2 Micro grid application

A hybrid system of 4.2MW NAS® and 2.0MW lithium battery entered service in September 2015 at Oki Island as an environment ministry funded demonstration. In this particular demonstration, the NAS® battery has been implemented to compensate slow change in renewable energy, and the lithium ion battery has been implemented to mitigate sudden changes. The efficiency and effectiveness of the combination of energy battery and power battery will be evaluated in this micro grid which also contains diesel generation and increasing renewable energy.

5.3 Transmission application

In Italy, renewable energy is increasing in the southern part of peninsula. There have been transient transmission issues due to insufficient transmission capacity. Therefore, Italian TSO TERNA selected a 35MW NAS® battery and deployed it at the transmission bottleneck as shown in Fig.11. Major benefits from the NAS® battery include:① Send clean energy, utilizing storage as a buffer not to exceed transmission capacity;②Support primary reserve with fast response supplementation from the energy storage system;③Defer investment for transmission asset.

35MW NAS® battery began its operation in 2015.

5.4 Grid scale application for renewable

Kyushu Electric Power Company decided to deploy NAS containerized batteries with a total output of 50000 kW and a storage capacity of 300,000 kW·h (enough to supply electricity to approximately 30000 households). The completed system is expected to be the largest storage battery facility in the world and is scheduled to begin operation by March 31, 2016. Kyushu electric will connect the NAS battery system to its power gridto improve theelectricity supply-demand balance, control the grid voltage and smooth the delivery of renewable energy to its power grid. The system will be capable of storing electricity equivalent to a pumped hydroelectric power generation facility.

6 Summary

NGK has competed reliable and safe design and production of NAS battery. It is proved by the fact that530MW/3700MW·h NAS battery operation as of 2015 worldwide.

Development of containerized system will work as a plug and play battery which could reduce the project cost and installation period.

NGK is also conducting cost down program which is supported by Japanese government in order to achieve JPY 23000 by 2020.

Today more and more renewable are planned in order to reduce carbon emission in every country. NGK hope that NAS battery will contribute to renewable rich infrastructures for reliability and stability.

References:

[1] HIMELIC J,NOVACHEK F. Sodium sulfur battery energy storage and its potential to enable further integration of wind, xcel energy renewable development fund contract[R]. #RD3-12 Final Report,2011.

[2] IIJIMA Y,SAKANAKA Y,KAWAKAMI N,FUKUHARA M,OGAWA K,BANDO M,MATSUDA T. Development and field experiences of NAS battery and inverter for power stabilization of a 51 MW wind farm[C]//Power Electronics Conference(IEPC),2010.

[3] CAROLINA A. The case for energy storage the perspective of the TSO[R]. Energy Storage World Forum London,2014.

[4] TAMAKOSHI T. Development of containerized 200 kW NAS battery[C]//CNESA Annual Meeting,2015.

date:2016-04-07.

10.3969/j.issn.2095-4239.2016.03.010

TM 912 Document code: A Artical ID: 2095-4239(2016)03-329-06