SUJ2轴承钢超长寿命疲劳行为研究

李永德,张莉莉,张 冲,贺莹莹

(1 河北工程大学 装备制造学院,河北 邯郸 056038;2 达力普石油专用管有限公司 技术中心,河北 沧州 061000;3 山东省分析测试中心,济南 250014;4 江苏省(沙钢)钢铁研究院,江苏 张家港 215625)

SUJ2轴承钢超长寿命疲劳行为研究

李永德1,2,张莉莉1,张冲3,贺莹莹4

(1 河北工程大学 装备制造学院,河北 邯郸 056038;2 达力普石油专用管有限公司 技术中心,河北 沧州 061000;3 山东省分析测试中心,济南 250014;4 江苏省(沙钢)钢铁研究院,江苏 张家港 215625)

超长寿命疲劳;夹杂物;GBF相对尺寸;裂纹扩展

随着工业技术的发展,在飞行器、高速列车、汽车、发动机、海洋结构、MEMS以及生物医学等许多工程应用中,材料和结构经常面临着高频低幅载荷,承受重复载荷次数可高达千兆周次,因此对构件的疲劳设计寿命要求通常达到108周次以上,有的甚至达到1011周次[1-7]。美国空军“发动机结构完整性大纲(Engine Structural Integrity Program,ENSIP)”已经增加了条例,规定“发动机部件超高周疲劳寿命应达到109周次”[8]。因此,有必要对材料在108~1011周次之间的疲劳行为和疲劳机理进行系统的研究,并以此作为这一阶段疲劳安全设计的依据。通常,将循环周次超过107周次的疲劳行为称为超长寿命疲劳(Ultra-Long Life Fatigue,ULF)[9],也称为超高周疲劳(Very High Cycle Fatigue,VHCF)[10]、千兆周疲劳(Gigacycle Fatigue,GCF)[5]或超高周疲劳(Ultra High Cycle Fatigue,UHCF)[11]。

对于高强钢的超长寿命疲劳,裂纹通常从内部非金属夹杂物处萌生,断口宏观形貌表现为典型的“鱼眼”状。对于具有较长寿命的样品 (≥106周次),在“鱼眼”内部存在一个特殊形貌区域,Murakami等[12]称之为光学暗区(Optically Dark Area,ODA);Shiozawa等[13]称之为颗粒状亮面(Granular Bright Facet,GBF),其他学者对这一区域也有其他不同命名[14-16]。研究表明[17],GBF中的裂纹萌生与扩展寿命在整个超长寿命疲劳中约占90%以上,可见GBF在超长寿命疲劳中起到了关键作用。关于GBF形成机理的研究,文献[7,12]中提出了几个定性的描述模型。但也有一些不同的报道,认为GBF并不是高强钢超长寿命疲劳的特有形貌,在某些超长寿命疲劳样品的断口上,裂纹源夹杂物的周围并无GBF区[18];GBF形貌与外加应力比和氢浓度有关[18,19]。

1 实验材料及方法

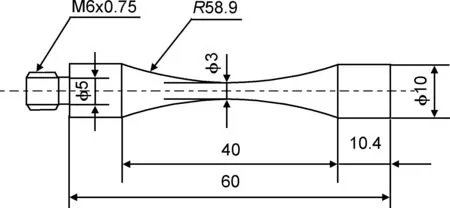

实验材料为SUJ2轴承钢,其化学成分如表1所示。将原始棒材粗加工为标准的拉伸样品(直径为φ5mm)和超声疲劳样品,并留出一定的加工余量。粗加工后进行热处理,工艺为:加热到860℃保温20min油淬,再经180℃回火保温2h后空冷。热处理后金相组织为回火马氏体。超声疲劳试样尺寸如图1所示。实验前依次用800#,1000#和1200#砂纸对试样中间部分进行最终研磨抛光处理, 尽量减小表面加工痕迹对实验的影响。

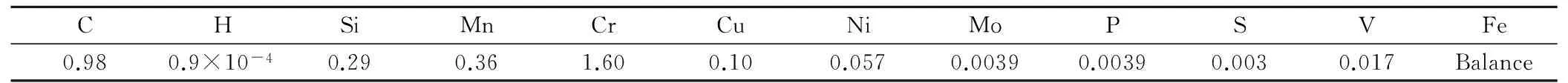

表1 SUJ2轴承钢的化学成分(质量分数/%)Table 1 Chemical composition of SUJ2 bearing steel (mass fraction/%)

图1 超声疲劳样品尺寸Fig.1 Dimension of the sample used in ultrasonic fatigue testing

疲劳实验在USF-2000超声疲劳试验机上进行,共振频率为20kHz,共振间歇时间比为150∶150,载荷比R=-1,最大循环周数为1×109。实验时采用压缩空气冷却,实验环境为室温;在WinWDW-300E万能试验机上进行拉伸实验,位移速率为3mm/min;在SUPRA55热场发射扫描电子显微镜(FESEM)上进行断口形貌观察;用能谱仪(EDS)分析裂纹源区化学成分。为了分析GBF内的裂纹扩展规律,采用两步变幅加载技术(Two-Step Variable Amplitude Loading,TSAL)对样品加载,然后通过观察不同初始寿命时断口上GBF裂纹的尺寸建立GBF裂纹扩展规律,详细介绍见文献[20]。为了与TSAL相区分将恒幅加载方式记为CAL(constant amplitude loading)。

2 实验结果

2.1裂纹源区形貌观察

SUJ2轴承钢的抗拉强度为1745MPa,维氏硬度为7909MPa,采用升降法计算得到疲劳强度为765MPa。本次实验的裂纹源均为内部缺陷,宏观上呈现为典型的“鱼眼”形貌,如图2所示。用能谱分析裂纹源可知,裂纹源有4种:钙、铝和镁的复合氧化物(Al2O3·(CaO)x·(MgO)y)、 铁和铬的合金碳化物((FeCr)xCy)、内部基体和TiCN。大部分裂纹源为Al2O3·(CaO)x·(MgO)y,所占比例为82%。图3为4种裂纹源两端断口的微观形貌。图3 (a-1),(a-2)中裂纹源为Al2O3·(CaO)x·(MgO)y,可见夹杂物仅出现在一端断口上,另一端断口上为夹杂物脱落留下的空洞,表明裂纹从夹杂物与基体界面处萌生,导致夹杂物脱落 (断裂条件:σa=780MPa,Nf=1.76×108)。与图3(a-1),(a-2)相似,图3(b-1),(b-2)中TiCN夹杂物也只出现在一端断口上,另一端断口上为夹杂物脱落留下的空洞,裂纹萌生机理与铝复合夹杂物相同 (断裂条件:σa=740MPa,Nf=5×107未断,σa=1020MPa,Nf=5.57×104)。可知,TiCN夹杂物形状类似于正八面体,较尖锐,在夹杂物与基体界面具有较高的应力集中。图3(a-2),(b-2)中,夹杂物的周围均存在一个特殊形貌区域,与周围裂纹扩展形貌有明显差别,这就是Shiozawa等[13]提到的GBF区域。对比可知,图3(b-2)中GBF边缘比图3(a-2)的GBF边缘更加清晰、尖锐,这也证实了TSAL方法可用于分析GBF裂纹扩展规律。图3(c-1),(c-2)中两端断口裂纹源处均有(FeCr)xCy,表明裂纹萌生是由(FeCr)xCy本身开裂引起的,与Al2O3·(CaO)x·(MgO)y和(FeCr)xCy不同,这与Furuya等[21]报道的实验现象一致(图3(c-1),(c-2)样品的断裂条件:σa=1020MPa,Nf=2.11×105)。图3(d-1),3(d-2)中裂纹源处能谱分析均为基体成分,在裂纹源处可见颗粒状特征的GBF形貌(断裂条件:σa=1060MPa,Nf=4.35×105)。

图2 鱼眼形貌Fig.2 Morphology of fish-eye

图3 裂纹源区微观形貌 (a)钙铝镁复合氧化物;(b)TiCN;(c)铁铬合金碳化物;(d)内部基体;(1)左端;(2)右端Fig.3 Microscopic morphologies of crack origins (a)composite oxide of Ca,Al and Mg;(b)titanium carbonitride;(c)iron chromium carbide;(d)inner matrix;(1)the left side;(2)the right side

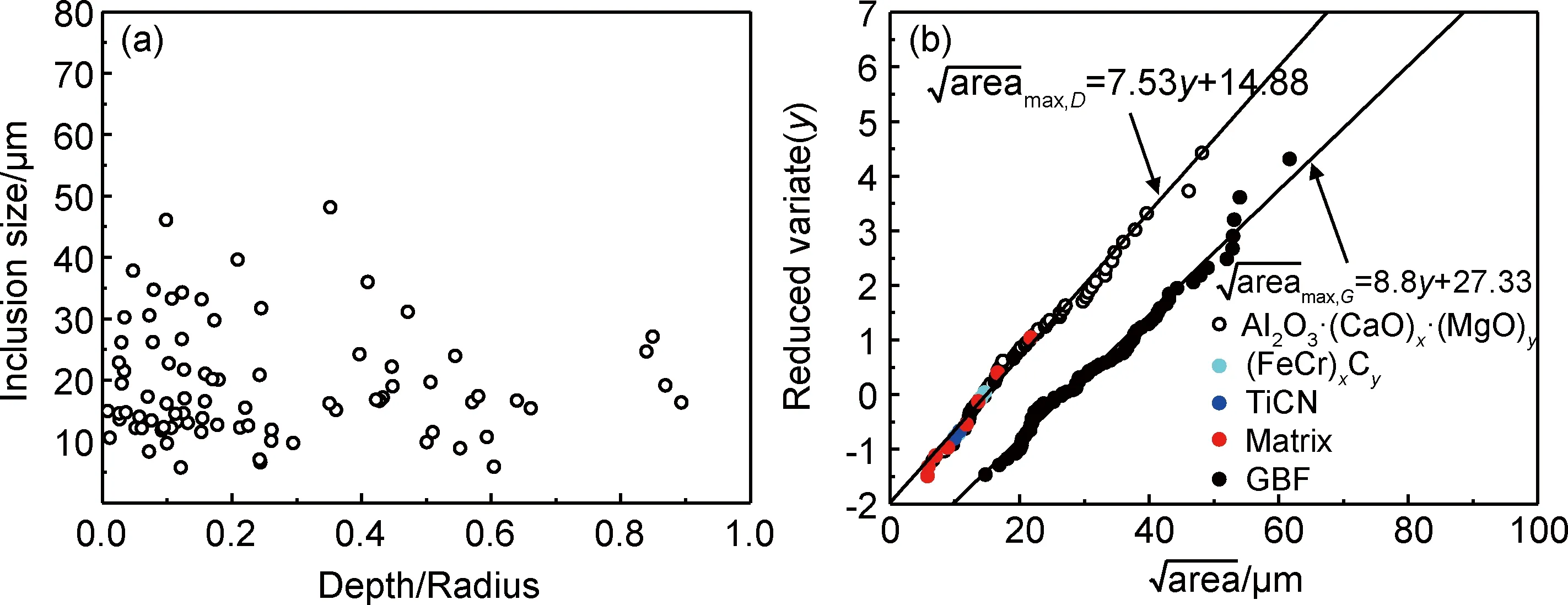

2.2裂纹源尺寸

图4 断口上夹杂物分布(a)与缺陷尺寸极值统计分布(b)Fig.4 Inclusion distribution at the fracture surface(a) and extreme value statistics for defect size at the fracture origin(b)

3 分析讨论

(1)

根据裂纹扩展速率和裂纹尖端塑性区尺寸的相互关系,Yang等[29]提出了GBF尺寸的预测方程,即:

(2)

(3)

(4)

图5 GBF相对尺寸与ΔKinc的关系(a)SUJ2;(b)SUP-QT,SCV-QT和G-QT[25];(c)60Si2CrV,60Si2Cr和60Si2Mn[26];(d)TT150[28]和NSH1[27]Fig.5 Relationship between the relative GBF size and ΔKinc(a)SUJ2;(b)SUP-QT,SCV-QT and G-QT[25];(c)60Si2CrV,60Si2Cr and 60Si2Mn[26];(d)TT150[28] and NSH1[27]

图5中不同颜色实线代表了相应材料按式(4)拟合的曲线,可见实验结果与式(4)能够较好吻合。在拟合式(4)时,近似采用抗拉强度Rm代替ReL,因为对于高强钢而言,一般情况下Rm与ReL相差不大,对于某些高强钢材料甚至没有屈服现象(如本实验材料SUJ2)。在上述讨论中,实验材料均采用淬火+回火的高强钢,没有考虑氢的影响,实际上氢含量CH对GBF尺寸有显著影响,因此图5中实验结果与拟合曲线的偏差被认为是由氢造成的。

图6 夹杂物尺寸与ΔKinc的关系Fig.6 Relationship between the inclusion size and ΔKinc

3.2GBF内裂纹扩展规律

GBF在高强钢的超长寿命疲劳中起到了十分关键的作用,因此关于GBF的形成机理一直是研究的热点之一[7,12,17,21]。研究表明,GBF相对尺寸与疲劳寿命存在一定的对应关系,即随着疲劳寿命的增加,GBF相对尺寸增加。根据实验结果前人分别拟合了GBF相对尺寸与疲劳寿命之间的关系(式(5)[24],(6)[30])。

(5)

(6)

整理式 (6)为

(7)

图7 GBF相对尺寸与疲劳寿命的定量关系及GBF内裂纹扩展规律(a)不同高强钢的疲劳寿命与GBF相对尺寸的关系;(b)相同氢含量时疲劳寿命与GBF相对尺寸的关系;(c)GBF内裂纹扩展规律;(d)GBF内裂纹扩展示意图Fig.7 Relationship between fatigue life and relative GBF size and the crack growth rule in GBF(a)fatigue life vs relative GBF size for different high strength steels;(b)fatigue life vs relative GBF size for high strength steels with the same hydrogen content;(c)crack growth rule in GBF;(d)illustration of crack growth in GBF

(8)

Tanaka等[16,35]认为,GBF中裂纹扩展规律可以用Paris公式来表征,积分整理后得到:

(9)

式中C和m均为材料常数。整理后得到:

(10)

4 结论

(1)不同裂纹源处的开裂机理不同,对于复合氧化物和TiCN来说,裂纹从夹杂物与基体界面处萌生,而铁和铬的合金碳化物则为夹杂物本身开裂。

[1]洪友士,赵爱国,钱桂安. 合金材料超高周疲劳行为的基本特征和影响因素[J]. 金属学报,2009,45(7):769-780.

HONG Y S,ZHAO A G,QIAN G A. Essential characteristics and influential factors for very-high-cycle fatigue behavior of metallic materials[J]. Acta Metallurgica Sinica,2009,45(7):769-780.

[2]王清远,刘永杰. 结构金属材料超高周疲劳破坏行为[J]. 固体力学学报,2010,31(5):496-502.

WANG Q Y,LIU Y J. Understanding fatigue failure in structural metals in ultra-high cycle regime[J]. Chinese Journal of Solid Mechanics,2010,31(5):496-502.

[3]鲁连涛,张卫华. 金属材料超高周疲劳研究综述[J]. 机械强度,2005,27(3):388-395.

LU L T,ZHANG W H. Review of research on very high cycle fatigue of metal materials[J]. Journal of Mechanical Strength,2005,27(3):388-395.

[4]李守新,翁宇庆,惠卫军,等. 高强度钢超高周疲劳性能——非金属夹杂物的影响[M]. 北京:冶金工业出版社,2010.1-6.

[5]BATHIAS C,PARIS P C.Gigacycle Fatigue in Mechanical Practice[M]. New York:Marcel Dekker,2005.1-7.

[6]薛红前,陶华. 超声疲劳试验方法在铸铝疲劳试验中的应用[J]. 机械强度,2004,26(2):203-206.

XUE H Q,TAO H. Ultrasonic fatigue test method for testing of cast aluminum[J]. Journal of Mechanical Strength,2004,26(2): 203-206.

[7]SAKAI T. Review and prospects for current studies on very high cycle fatigue of metallic materials for machine structural use[J]. Journal of Solid Mechanics and Materials Engineering,2009,3(3):425-439.

[8]胡燕慧,张铮,钟群鹏,等. 金属材料超高周疲劳研究综述[J]. 机械强度,2009,31(6):979-985.

HU Y H,ZHANG Z,ZHONG Q P,et al. Recent development of research on very high cycle fatigue of metal materials[J]. Journal of Mechanical Strength,2009,31(6):979-985.

[9]MURAKAMI Y,YOKOYAMA N N,NAGATA J. Mechanism of fatigue failure in ultralong life regime[J]. Fatigue Fracture Engineering Materials Structure,2002,25(8-9):735-746.

[10]STANZL S E,TSCHEGG E K,MAYER H. Lifetime measurements for random loading in the very high cycle fatigue range[J]. International Journal of Fatigue,1986,8(4):195-200.

[12]MURAKAMI Y,NOMOTO T,UEDA T. Factors influencing the mechanism of superlong fatigue failure in steels[J]. Fatigue Fracture Engineering Materials Structure,1999,22(7):581-590.

[13]SHIOZAWA K,LU L,ISHIHARA S. S-N curve characteristics and subsurface crack initiation behaviour in ultra-long life fatigue of a high carbon-chromium bearing steel[J]. Fatigue Fracture Engineering Materials Structure,2002,24(12):781-790.

[14]SAKAI T,SATO Y,OGUMA N. Characteristic S-N properties of high-carbon-chromium bearing steel under axial loading in long-life fatigue[J]. Fatigue Fracture Engineering Materials Structure,2002,25(8-9):765-773.

[15]OCHI Y,MATSUMURA T,MASAKI K,et al. High-cycle rotating bending fatigue property in very long life regime of high strength steels[J]. Fatigue Fracture Engineering Materials Structure,2002,25(8-9):823-830.

[16]TANAKA K,AKINIWA Y. Fatigue crack propagation behaviour derived from S-N data in very highcycle fatigue regime[J]. Fatigue Fracture Engineering Materials Structure,2002,25(8-9):775-784.

[17]CHAPETTI M D,TAGAWA T,MIYATA T. Ultra-long cycle fatigue of high-strength carbon steels. partⅠ:review and analysis of the mechanism of failure[J]. Materials Science and Engineering:A,2003,356(3):227-235.

[18]SANDER M,MULLER T,LEBAHN J. Influence of mean stress and variable amplitude loading on the fatigue behavior of a high-strength steel in VHCF regime[J]. International Journal of Fatigue,2014,62(2):10-20.

[19]李永德,徐娜,郭卫民,等. 高压气相热充氢对SUJ2轴承钢超高周疲劳行为的影响[J]. 材料工程,2014,(2):87-98.

LI Y D,XU N,GUO W M,et al. The influence of high pressure thermal hydrogen charging on very high cycle fatigue behaviors of SUJ2 bearing steel[J]. Journal of Materials Engineering,2014,(2):87-98.

[20]李永德,郭卫民,徐娜,等. SUJ2轴承钢超声疲劳GBF内裂纹扩展规律[J]. 材料热处理学报,2014,35(1):49-54.

LI Y D,GUO W M,XU N,et al. Fatigue crack growth behavior in GBF area of SUJ2 bearing steel in very high cycle fatigue regime[J]. Transactions of Materials and Heat Treatment,2014,35(1):49-54.

[21]FURUYA Y,HIRUKAWA H,KIMURA T,et al. Gigacycle fatigue properties of high strength steels according to ODA and inclusion sizes[J]. Metallurgical and Materials Transactions Part A,2007,38(8):1722-1730.

[22]张继明,张建峰,杨振国,等. 高强钢中最大夹杂物的尺寸估计与疲劳强度预测[J]. 金属学报,2004,40(8):846-850.

ZHANG J M,ZHANG J F,YANG Z G,et al.Estimation of maximum inclusion size and fatigue strength in high strength steel[J]. Acta Metallurgica Sinica,2004,40(8):846-850.

[23]MURAKAMI Y. Metal Fatigue:Effects of Small Defects and Nonmetallic Inclusions[M]. Amsterdam Boston:Elsevier,2002.11-24.

[24]CHAPETTI M D,TAGAWA T,MIYATA T. Ultra-long cycle fatigue of high-strength carbon steels. partⅡ:estimations of fatigue limit for failure from internal inclusions[J]. Materials Science and Engineering:A,2003,356(Suppl 1-2):236-244.

[25]李永德. 高强钢的超高周疲劳性能研究及氢对疲劳性能的影响[D].沈阳:中国科学院金属研究所,2009.

[26]柳洋波. 夹杂物和贝氏体对高强钢的超高周疲劳性能的影响[D].沈阳:中国科学院金属研究所,2011.

[27]聂义宏,惠卫军,傅万堂,等. 中碳高强弹簧钢NHS1超高周疲劳破坏行为[J]. 金属学报,2007,43(10):1031-1036.

NIE Y H,HUI W J,FU W T,et al. Ultra high cycle fatigue behavior of a medium-carbon high strength spring steel NHS1[J]. Acta Metallurgica Sinica,2007,43(10):1031-1036.

[28]HONG Y S,ZHENG Q L,CHENG Q S,et al. Propensities of crack interior initiation and early growth for very-high-cycle fatigue of high strength steels[J]. International Journal of Fatigue,2014,58:144-151.

[29]YANG Z G,LI S X,LIU Y B,et al. Estimation of the size of GBF area on fracture surface for high strength steels in very high cycle fatigue regime[J]. International Journal of Fatigue,2008,30:1016-1023.

[30]MURAKAMI Y,YAMASHITA Y. Prediction of life scatter of fatigue failure originated at nonmetallic inclusions[J]. Procedia Engineering,2014,74:6-11.

[31]ZHOU C,ZHANG Y J,HUI W J,et al. Influence of hydrogen on GBF in very high cycle fatigue of high strength steel[J]. Journal of Iron and Steel Research,International,2013,20(12):92-97.

[32]李伟,李强,鲁连涛,等. GCr15钢超高周的疲劳行为[J]. 北京交通大学学报,2008,32(4):24-32.

LI W,LI Q,LU L T,et al. Fatigue behavior of GCr15 steel in ultra-high life region[J]. Journal of Beijing Jiaotong University,2008,32(4):24-32.

[33]鲁连涛,李伟,张继旺,等. GCr15钢旋转弯曲超长寿命疲劳性能分析[J]. 金属学报,2009,45(1):73-78.

LU L T,LI W,ZHANG J W,et al. Analysis of rotary bending gigacycle fatigue properties of bearing steel GCr15[J]. Acta Metallurgica Sinica,2009,45(1):73-78.

[34]鲁连涛,盐泽和章,姜燕. 深层滚压加工对高碳铬轴承钢超长寿命疲劳行为的影响[J]. 金属学报,2006,42(5):515-520.

LU L T,SHIOZAWA K,JIANG Y.Influence of deeply rolling process on ultralong life fatigue behavior of high-carbon-chromium bearing steel[J]. Acta Metallurgica Sinica,2006,42(5):515-520.

[35]AKINIWA Y,MIYAMOTO N,TSURU H,et al. Notch effect on fatigue strength reduction of bearing steel in the very high cycle regime[J]. International Journal of Fatigue,2006,28(11): 1555-1565.

Ultra-long Life Fatigue Behavior of SUJ2 Bearing Steel

LI Yong-de1,2,ZHANG Li-li1,ZHANG Chong3,HE Ying-ying4

(1 Equipment Manufacturing College,Hebei University of Engineering,Handan 056038,Hebei,China;2 Technology R & D Center,Dalipal Pipe Group Co.,Ltd.,Cangzhou 061000,Hebei,China;3 Shandong Analysis and Test Center,Jinan 250014,China;4 Jiangsu Iron & Steel Research Institute(Shagang),Zhangjiagang 215625,Jiangsu,China)

ultra-long life fatigue;inclusion;relative GBF size;crack propagation

10.11868/j.issn.1001-4381.2016.08.014

TG142.1

A

1001-4381(2016)08-0085-08

国家自然科学基金资助项目(51101094);河北省高等学校科学技术研究重点资助项目(ZD2015045);河北工程大学青年学术骨干基金(HBE-Yooth001);河北工程大学博士专项基金(HBE2014004);河北省自然科学基金(E2015402111)

2014-08-14;

2015-09-23

李永德(1981-),男,博士,研究方向:疲劳与断裂及失效分析,联系地址:河北省邯郸市光明南大街199号河北工程大学 (056038),E-mail:ydli@alum.imr.ac.cn