Scoping biology-inspired chemical engineering☆

Xiao Dong Chen

Suzhou Key Laboratory of Green Chemical Engineering,School of Chemical and Environmental Engineering,College of Chemistry,Chemical Engineering and Material Sciences,Soochow University,Suzhou 215000,China

1.Introduction

A famous emeritus professor of chemical engineering at Monash University in Australia,Professor David Boger,best know n for his studies on rheology including the conception of the Boger-fluid as w ell as the innovative solutions for solving the massive tailing problems in the mining industry in Australia,once made a comment that“research is conversion of money into know ledge and innovation as the conversion of know ledge into money”(University Research—Then,Now and in the Future,Distinguished Seminar at Monash University,Australia,2014).Though less and less as it seems these days,due to the competitive economic environment in many parts of the world,w e can still see that the curiosity about the unknown drives some of us to acquire new know ledge irrespective of what in the end may or may not turn into material benefits.Some of the knowledge obtained may serve well the commercial or industrial needs at later date.More often,the benefits as perceived in the published works by others w ho have more commercial mindsets,are sufficient to drive them to take the risks to bring the know ledge to the marketable status and occasionally it may become a success.

Bio-mimic or bio-inspired chemical engineering(BioCh E)belongsto a sort of knowledge category that w hile being fascinated by w hat the biological worlds present,one can,explore the understanding till a useful end—engineering solutions and innovations that can creatively serve the society.

Besides the “Bio-inspired”as being a good terminology for BioCh E,there could be other alternatives:bio-mimic,bionic,biomimetic,nature-inspired(which in many cases speaks about biology-inspired anyw ay),biological,biochemical and even biomedical.In line with the most popular term in recent times such as“bio-inspired material creation”,it is appropriate to opt for the “Bio-inspired”as the terminology naming this branch of chemical engineering.It is appropriate at this stage to use ‘BioCh E’so w e may differentiate ‘Biochem Eng’which w e normally use to represent Biochemical Engineering.In essence,BioChE may indeed contain Biochem Eng in a non-aggressive way but certainly has a much greater scope as will be described in the coming text.

In the history of mankind,one has always been amazed by what nature can do and how amazing the biological world is.In many cases,peoplehad implemented what they had learned from the biological world into the actions that benefit themselves.It is known that people in the past had gone on to invent something that could take them to ‘ fly’like birds.In fact,man today can fly in the way that birds can not but the desire to fly and ideas of having wings would have come from man's observation of the flying birds—therefore,man's designs of flying machines were bio-inspired.

Before the scope of BioCh E is rolled out in this paper,it is noted that it is not the intention here to single out this branch of chemical engineering to be exclusive.On the contrary,the idea for the inclusiveness has been promoted w here the multi-scale and multidisciplinary approaches are indeed the common places.There is a focused intention to promote the recognition of this branch of chemical engineering,which can provide a central focus for chemical engineers who are interested in biology and to be inspired by it,to innovate broadly in the chemical engineering field.

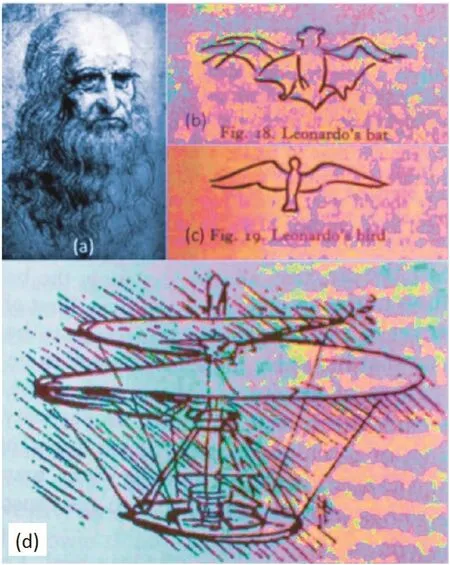

Moving on from the observations made on the flying birds made by Leonardo Da'Vinci(Fig.1(a)),as show n in Fig.1(b)and(c),he drew a machine called as ‘air screw’[1].This is recognized as the earliest ‘design’of a helicopter.While humankind had already know n the making of rotational machines(such as a windmill or a water-w heel)that can‘borrow’forces from a fluid,a combination of the idea of bird's flying and w hat a rotational machine could offer might have helped him generate this idea.Thus it is,a bio-inspired idea.

Fig.1.Leonardo's bio-inspired ‘ flying machine’[1](the pictures were compiled by the author).

In the current article,BioCh Eisscoped through firstly a historical observation of the development of chemical engineering,secondly the clear definition of BioCh E,thirdly the bottlenecks of the subject,fourthly the pathways to generate new ideas based on BioCh Eand finally to a description of future prospective of the subject.

2.Historical Aspects:A ‘Simpleminded’Description of the Evolution of Chemical Engineering

Fig.2(a)is a flow chart prepared by the author illustrating the evolution of chemical engineering.This has been used for some years since 2001,as a resource of the author to introduce chemical engineering to high school students to improve their understanding about chemical engineering.Sometimes a talk on this is also given to the Year 1 chemical engineering students and even to the general public in various countries in an umber of important occasions,in order to trigger innovative thoughts and collaborations.

Essentially,a demarcation from arts or technology to engineering may be recognized at w hen man can actually describe a process or a mechanism using quantitative mathematical theories with appropriate parameters.Notably,it might be the time at which Isaac Newton discovered the mechanics law s—solid mechanics and fluid mechanics.As such,the origin of process engineering may be said to have started from the New ton's law s of mechanics.Since then,one may start to design a building or a bridge to be strong enough,and quantify the need of the materials just sufficient for construction that would not cause wastage,before actually building one.Basically,man can conduct theoretical calculations,which can guide practice.Being human,one has been continuously seeking ways to make man's living environment better.Too hot a weather,a mechanized fan could be used,then evaporation of water or melting of stored ice could be used,and in the end refrigeration devices were invented to make our living in hot summers much more pleasant.The subjects of interest here are called Energy and Mass Transfer.Solid mechanics, fluid mechanics,energy transfer and mass transfer,together with the inventions of the machining mechanisms(or devices)had led to the comprehensive subject of Mechanical Engineering.

Improvement of our lifestyle was never stopped at just using air and water,it started to involve much more.One works on converting‘raw’materials,i.e.those dug out from the earth(for minerals and fuels)or those collected from w hat surrounded us naturally(i.e.plant materials),to convert and purify to make something that one desired to have or to possess.Imagine w hat our ability has become that w e can turn ‘dirt’to iPhones!No wonder for many,Chemistry is a magical subject.

Combining the basics of Mechanical Engineering and the evolving quantitative understanding of Chemistry,gives rise to the critical subject called Chemical Engineering.From Chemical Engineering onwards,there is ‘no stopping’in developing new multidisciplinary subjects that are already known to us.The scope of chemical engineering is indeed very wide and the students can easily find themselves in too many choices to w ear their professional hats in.

Fig.2(b)show s that in ‘combining’biological sciences with material sciences,one works in the area of bio-inspired material engineering,which is a very ‘hot’area in the past 10 years.Lotus-like surfaces have already been one of the most researched areas in material science and processing.Other examples include that the natural world has developed incredibly re fined solutions for underwater adhesion,such as the case of mussels[2],barnacles[3]and sandcastle worms[4].Most recently,the water-resistant adhesives could be formulated by inspirations from understanding kelps[5].Fig.2(b)also show s if one‘connects up’chemical engineering and biological sciences,it is not so difficult to w rite down the discipline Bio-inspired Chemical Engineering.Indeed,one may write down several more cross-disciplinary subjects(indicated by the dashed line in Fig.2(b)).It can be said that Chemical Engineering is such an out-reaching subject that has been one of the few most important engineering subjects relevant to the society.

At very young age of the author in the1980s,before entering university,the author was already very fascinated about biology and the mimicking of biology to create machinesor engineering solutions.To expand on the three key aspects of BioCh Esuggested in the abstract,the following has been written up.

For 1)many functions/working principles in biological systems are delivered through unique physical,chemical and mechanical structures(including micro-and nano-structures)that can beunderstood through the understanding and extension of the principles of chemical engineering unit operations including microfluidics.These understandings can significantly help in advancing quantitative biology including medicinal processes.

For 2)for many years,researchers have identified the uses of biological pathways to produce polymers that are used in our daily life and usually derived from petroleum products.For instance,using fermentation process to grow cells that produce ‘plastics’within the cells,then through separation processes,the polymers can be recovered.Certainly,the making of alcohols can be largely conducted through fermentation processes.Even biodiesel precursors,it is know n that can be made from fermentation of microalgae.

Fig.2.(a)Evolution of various chemical engineering disciplines.(b)Evolution towards the bio-inspired chemical engineering(BioChE).

For 3)new alternative design of process engineering equipment may be inspired by biology that may/can deliver improved performances of the existing designs and/or unique functionalities that can not be delivered through conventional designs.

In fact the measurement techniques may also be invented in a bioinspired manner.Bio-inspired instrumental developments are yet to be explored extensively though certain hot area has been established to benefit the society and industry such as biosensors.

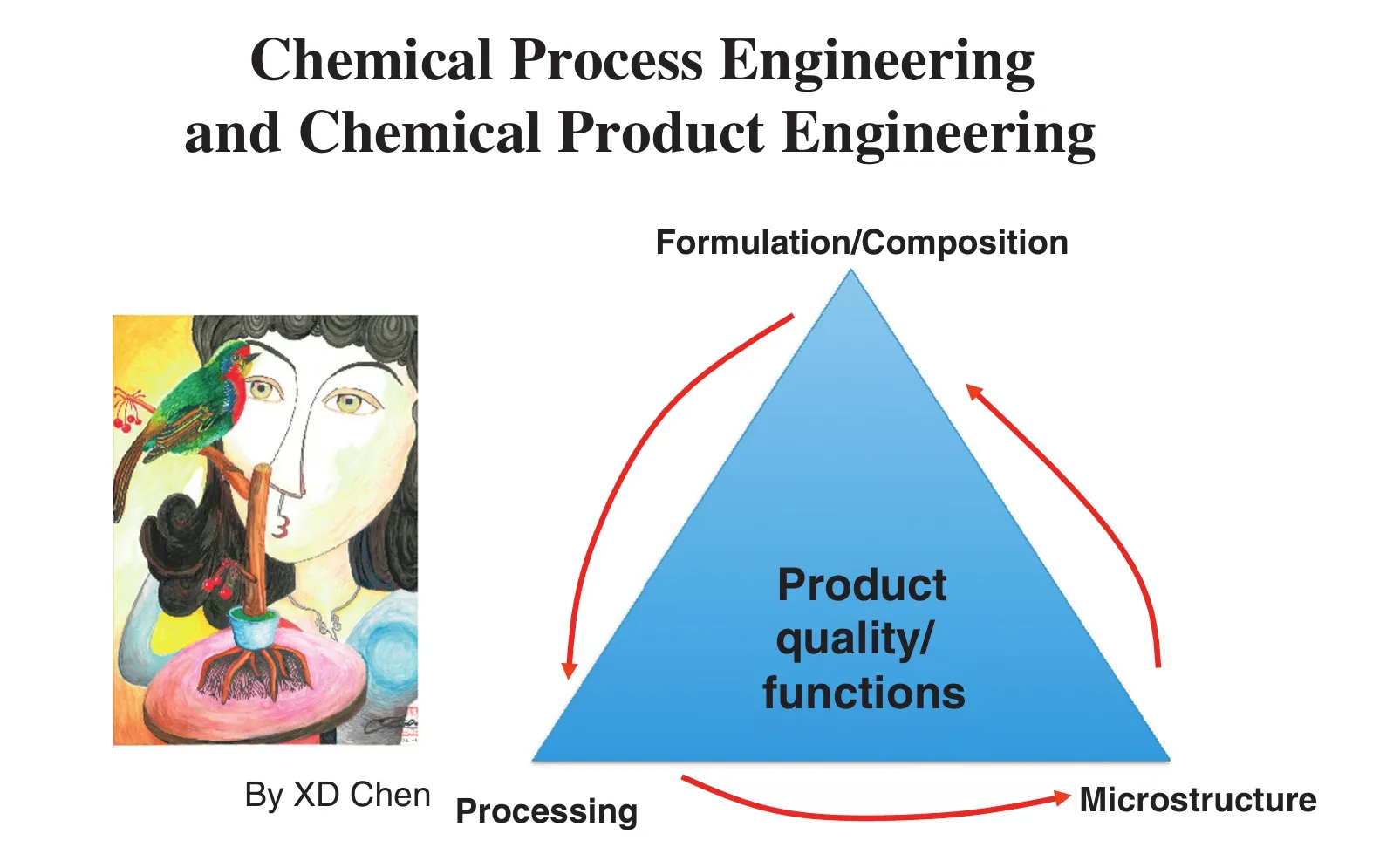

Besides the multi-disciplinary evolution of process engineering,one other development background that is in the arena of teaching chemical engineering which is worth mentioning,is the combination of chemical process engineering and chemical product engineering(see Fig.3).It is obvious today in the rapid economic expansion that teaching the unit operations can no longer be isolated from the understanding about the actual products processed in them.The strong interactions between the process and the product are crucial for any industrial operation these days.The teaching cannot turn a ‘blind eye’on the material science understanding that is relevant to the product being processed in the equipment.This adds to the background that BioCh E should also incorporate the product and process engineering together.

Fig.3.A simple framework showing the principles of Chemical Process Engineering and Chemical Product Engineering combined(the painting on the left is by the author:the bird watched by a lady,2010).

3.Scientific Problems and Bottlenecks

The establishment and development of this new branch of chemical engineering,BioCh E,depends on the parallel yet interactive understanding and practice of both chemical engineering principles and the fundamental biology.It also boils down to the awareness of biology among the chemical engineering researchers and vice versa for the biologists.There is no question that BioCh E is multi-scale and multidisciplinary by nature and the success of BioCh E is thus a difficult topic.Interactive developments of both are the key to future.From chemical engineering viewpoint,there is a tremendous scope in understanding the behavior of the biological systems such as diffusional,convectional,and reactive processes within them.These understandings can bring novel,quantitative assessments of the biological systems.In medical area,it would promote multidisciplinary works between chemical engineering and medical practice;it is know n for instance that blood perfusion process is a chemical engineering unit operation and in tissue engineering including the development of the 3-D ‘blood’supply systems[6,7].In plant biology,how the nutrient transfer and how plants grow under a wide range of environmental influences[8],can also be interpreted using chemical engineering principles.

On the other hand,the mechanisms used by biology can be used to guide the process of solving chemical engineering problems to improve operational efficiency,scalability and robustness.As mentioned earlier on,it is w ell know n already that bio-inspired material can be‘manufactured’to possess unique functions that are beneficial to society.

Similarly,bio-inspired chemical processes can also be designed and constructed to possess superior performances against the conventional processes in terms of efficiencies and environmental friendliness.Many functions and systems that reside in plants,animals,and humans may be ‘mimicked’to initiate novel designs of processing equipment and designs of new chemical production pathways.For instance,transport phenomena are of great importance in living systems as well as reaction engineering to life support systems.Trees and mammalian physiological networks have similar architectural designs that enable them functioning efficiently(see Fig.4(a)and(b)).The vascular and respiratory networks have branched,hierarchical architecture that is fractal between macroscopic and mesoscopic length scales.These have features that appear similar under repeated magnifications.The convectional and diffusional movements of the fluid are vital to the maintenance of the life supports in these systems.The living systems have the ‘designs’that can deliver liquid materials to cells more uniformly.Feeding the cells through trees with larger number of branching generations is an amazing aspect to simulate in chemical engineering.One interesting example is thus that the design of fluid injection distributors for chemical engineering purposes based upon the ‘bio-fractals’such as the channels on trees or plant leaves(Fig.4(c)and(d)).The fractal geometry has been used to construct fractal distributors and gas/liquid injectors for multiphase operations for separation,mixing and reaction processes.For instance,the fractal distributor could uniformly feed air over the catalytic layer of PEM fuel cell,as well as collect water,circumventing non-uniformity issues of channel geometries[9-11].These structures can also be used to homogeneously feed materials to other important processes.

More recently,Shapiro et al.[13]have explored,from the micro-fluid dynamics viewpoint,the mechanistic fitness of corals and their ability to form large reefs.They suggested that the viability of corals depends on their ability to exchange oxygen and nutrients with their oceanic environment.They found that the corals,though apparently lacking ventilating organs,can actually work through their motile epidermal cilia covering their entire surface—cilia beating,to actively enhance mass transport by generating intense vertical flows.This active process allows corals to increase mass transfer and is a basis in relatively stagnant regions.This is an interesting finding which may also inspire the design of new soft and active surfaces in industrial operations w here it may show an advantage.One may ‘plant’soft artificial cilia on soft processing surfaces to make it more effective.The development of as oft reactor will be further described in the following section.

Operated in very large scales,as a typical bio-inspired process though it has never been mentioned this way,fermentation process,i.e.the process that employs the biological pathways influenced by fluid conditions,to produce chemical products,is already w ell know n and has benefited the society considerably.For instances,the works by Zeng et al.[14,15]and many more.One modern example is the utilization of microalgae to produce a wide range of products,which is a green way to proceed(refer to Fig.5).Even the soft-sensors developed for fermentation process were also inspired by biological sciences,e.g.artificial intelligence and genetic algorithm[16].

4.Pathway for Solution

Firstly,w e must clearly de fine this new branch of chemical engineering and to promote multidisciplinary approach.Secondly,pinning down a few narrowly defined sub-subjects of BioChE,to demonstrate how BioChE can be beneficial to advance chemical process industries.Interactively developing the ‘combination’of the understanding of the chemical process engineering principles in biology and the biological principles including biological‘devices’that may be implemented in improving the existing chemical engineering operations.Employing materials and designs that can mimic the superior performances of the biological systems to produce scalable industrial systems is an exciting area.The novel applications of chemical engineering science in understanding biology and the novel applications of the biological concepts in process engineering;both are solutions for future challenges.

A journey for the author and his teams(initially at The University of Auckland in New Zealand,then at the Monash University in Australia,then at Xiamen University and now Soochow University in China respectively)is illustrated,which is about the development of the in vitro digestion systems.

It was recognized that human or an animal digestion track has several interesting soft reactors:oral cavity,stomach and intestine[17].These are unique reactors which do not seem to have had much research from the chemical reactor engineering viewpoint.While working intensively in food related research programs at the time in 2003,it became apparent to the author,after reviewing w hat had been proposed and done in the past,that there was a significant gap in the development of a reliable,relevant digestion track model for in-vitro testing purpose.This gap needs to be filled.Even with some recent published in-vitro models[18-23],the ‘near real’approach was still lacking[24].The ‘near-real’in-vitro digestion models refer to the systems that not only resemble chemical changes but also physically mimic the physical movements and geometrical details of the real GI systems.From a scientific research point of view,trying to assemble a physiological system,one piece at a time,from the know n materials(which may not be of a biological origin),to achieve a biological function,is challenging but certainly helping to improve our quantitative understanding of the real biological functions.This includes the attempts on understanding the‘body parts’that are added one by one,that contribute to the complexity of the functions of an organ inside the living body while the doctors would find it hard to conceive the functions as the organ normally presents itself as a w hole yet already an overly complicated system.

Fig.5.Production routes for making a range of products based on fermentation of microalgae(kindly provided by Dr.Xianhai Zeng,Energy Research Institute,Xiamen University,China,2013).

It is highly desirable to obtain an in-vitro digestion track model that can mimic,to a fullest possible extent,of w hat is going on in a targeted animal or human digestion system,i.e.the ‘near-real’approach.A good system can serve as an effective means to minimize the need for animal testing,and reduce the number of the tests on humans at an early stage of the developing phase of a functional food or a pharmaceutical product[24].

Since it is impossible to obtain a fully equivalent system in-vitro to the in-vivo,the term ‘near-real’system is appropriate.In-vivo studies are crucial in gaining quantitative know ledge of the living organisms.This requires the collaboration between engineers and physicians.

Due to the ethical constraints,costs and the time required by these in-vivo studies do restrict the ability in getting a large number of data within short time frame.There is a great incentive for the pre-clinical studies to be carried out using the ‘near real’in-vitro system if it was available.Rapid generation of useful results with robustness and high repeatability(due to a more precise ‘machine behavior’rather than a biological system behavior)would be in strong demand to meet fast developing industries of pharmaceutics and nutritional products.Such a system may also be highly valuable in examining novel,toxic or unfamiliar compounds.

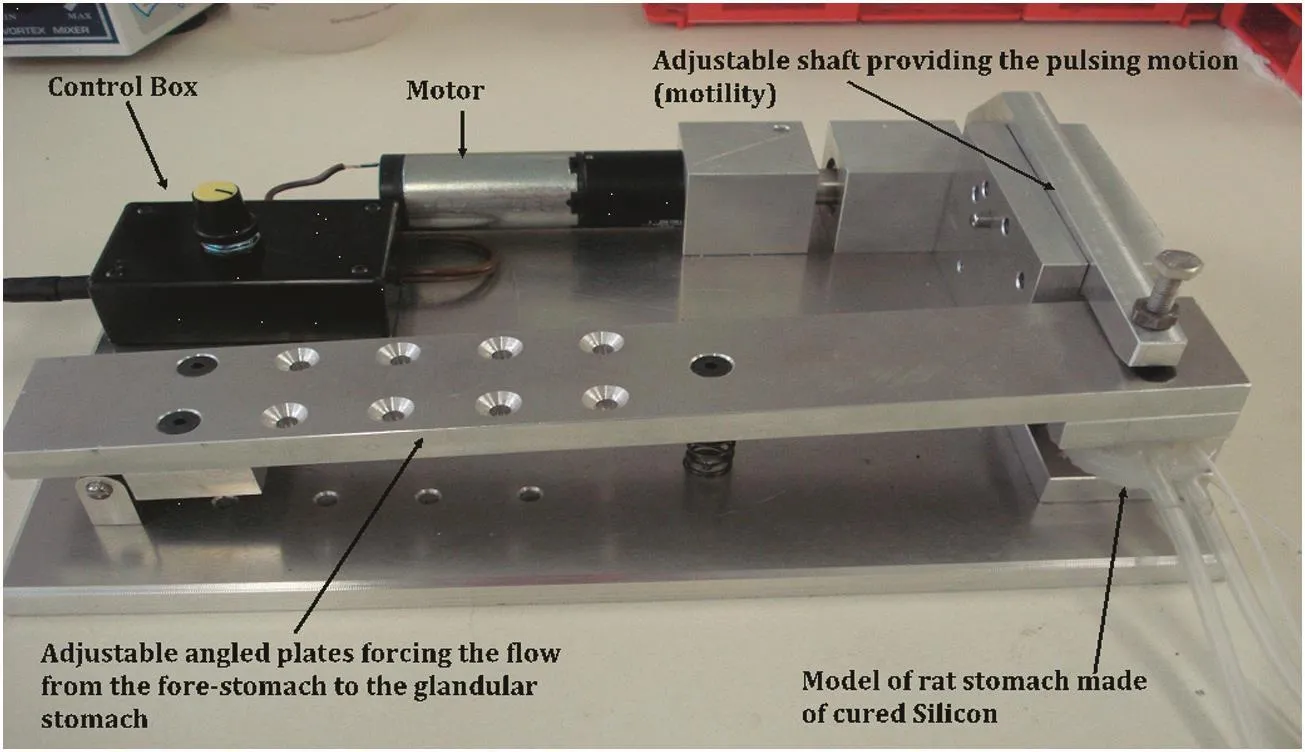

The latest developments in author's laboratory in China have included two soft reactor systems:mechanized in-vitro rat stomach(see Fig.6)and mechanized human stomach(see Fig.7);that have some kind of wall-movements that are intended to simulate the real stomach.Both stomachs can be made from silicon material,which was mold,through a w ax solidification procedure,on real‘deceased’stomachs[25].

Though the rat stomach has movements that seem rather not vigorous,yet it produces digestion reaction rates for homogeneous food solution,that are comparable to a rigorously stirred tank(reactor).This is an exciting area to explore:why and how these soft and seemingly less motivated systems could be so efficient.Anew text on digestion system,which encompasses some chemical engineering principles as w ell,has been written and published by Lentle and Janssen[28];it is interesting to note that the second author of the book is a control engineer in food engineering research area.

Beyond the in-vitro systems,w e have also anticipated the future needs of soft reactors in industry.On fluid mechanics aspects,it can be seen that with the active participation of the w all movements in a soft reactor(such as a stomach ‘reactor’)with or without an agitator in it,the likelihood of a soft reactor being superior to the hard reactor under weak or gentle mixing conditions is high.Substantial work is already underway to fully investigate the soft systems,such as that reported by Deng et al.[29]with a range of geometrical details.Preliminary works have indicated that the soft reactor systems can handle highly viscous material.Furthermore,the intestine-like model reactor may be exploited in the area w here one-dimensional cost-effective reactor is needed.In our laboratory,using the silicon material,w e have also added ‘hairs’on the w all surfaces of an intestine reactor,which is show n to significantly affect the potential for carrying out efficient reactions.This mirrors w hat had been mentioned earlier a study showing the effectiveness of cilia of coral surfaces which act as micro mixers promoting the very survival of the coral reefs.The concept of a soft reactor may also be relevant to small reaction systems such as deformable droplets with in which reactions occur in the microfluidic reactor systems.The scope of work is indeed very wide.

5.Concluding Remarks

BioChE is multi-scale and multidisciplinary,and is innovative.It is possible to bring step-changes in process industry.It may also become an alternative to devise industrial systems that are friendly towards the environment and are of higher efficiencies than the existing industrial systems.Biological systems are usually soft-systems,which are by themselves versatile.As mentioned earlier,bio-inspired ideas for making new materials have already brought along breakthroughs and step changes in functional material development.Similarly,bio-inspiration will also bring revolutions to large-scale industries.To realize a great potential of BioCh E,collaborations are required among engineers,biologists and physicians,benefiting all parties and improving the understanding among all disciplines involved.A series of innovations can be generated in near future,provided suitable investment from government and industries is made.Seemingly a long w ay to go,once the idea is out,the potential is huge.

Fig.6.The mechanized in-vitro rat stomach model(from the author's group at Monash and later Xiamen University,2010-2012 and made by Nantong Dong-Concepts New Material Technology Ltd(China);after Chen et al.[25,26].

Acknowledgments

The author appreciates the setting-up grants from Xiamen University and Soochow University,P.R.China.

Fig.7.The fully mechanized in-vitro human stomach model which has mechanism to provide automated motility of the model;the box below contains the motors and mechanisms that drive the movement of the stomach model;the capillary tubes are for the controlled delivery of the secretions into the stomach(the author's research group)(2010-2013)[27].

[1]G.A.Tokaty,A History and Philosophy of Fluid Mechanics,Dover Publications Inc.,New York,1971.

[2]J.H.Waite,X.Qin,Polyphosphoprotein from the adhesive pads of Mytilus edulis,Biochemistry 40(9)(2001)2887-2893.

[3]K.Kamino,Barnacle underwater attachment,in:A.M.Smith,J.A.Callow(Eds.),Biological Adhesives,Springer,Berlin,Heidelberg 2006,pp.145-166.

[4]H.Shao,K.N.Bachus,R.J.Stewart,A water-borne adhesive modeled after sandcastle glue of P.california,Macromol.Biosci.9(5)(2009)464-471.

[5]S.Dimartino,D.M.Savory,A.J.McQuillan,Preparation of biological samples for the study of w et-resistant adhesives inspired by kelps,Proceedings of the Annual Australasian Chemical Engineering Conference(Chemeca 2014),2014(Full Paper 1109(on CD Rom)).

[6]Z.F.Cui,X.Xu,N.Trainor,J.T.Triffitt,J.P.G.Urban,U.Tirlapur,Application of multiple parallel perfused microbioreactors and three-dimensional stem cell culture for toxicity testing,Toxicol.in Vitro 21(7)(2007)1318-1324.

[7]M.H.Wu,S.B.Huang,Z.Cui,Z.Cui,G.-B.Lee,Development of perfusion-based micro 3-D cell culture platform and its application for high throughput drug testing,Sensors Actuators B Chem.129(1)(2008)231-240.

[8]H.Yang,Y.Jie,Uptake and transport of calcium in plants,J.Plant Physiol.Mol.Biol 31(3)(2005)227-230.

[9]J.R.van Ommen,J.Nijenhuis,C.M.van den Bleek,M.-O.Coppens,Four ways to introduce structure in fluidized bed reactors,Ind.Eng.Chem.Res.46(2007)4236-4244.

[10]D.Christensen,J.Nijenhuis,J.R.van Ommen,M.-O.Coppens,Influence of distributed secondary gas injection on the performance of a bubbling fluidized-bed reactor,Ind.Eng.Chem.Res.47(2008)3601-3618.

[11]M.-O.Coppens,A nature-inspired approach to reactor and catalysis engineering,Curr.Opin.Chem.Eng.1(2012)281-289.

[12]M.-O.Coppens,Scaling-up and-down in a nature-inspired way,Ind.Eng.Chem.Res.44(2005)5011-5019.

[13]O.H.Shapiro,V.I.Fernandez,M.Garren,J.S.Guasto,F.P.Debaillon-Vesque,E.Kramarsky-Winter,A.Vardi,R.Stocker,Vorticalciliary flow s actively enhance mass transport in reef corals,PNAS 111(37)(2014)13391-13396.

[14]X.Zeng,M.K.Danquah,X.D.Chen,Y.Lu,Microalgae bioengineering:from CO2fixation to biofuel production,Renew.Sust.Energ.Rev.15(6)(2011)3252-3260.

[15]X.Zeng,M.K.Danquah,S.Zhang,X.Zhang,M.Wu,X.D.Chen,K.Jing,I.-S.Ng,Y.Lu,Autotrophic cultivation of Spirulina platensis for CO2fixation and phycocyanin production,Chem.Eng.J.183(2012)192-197.

[16]L.Z.Chen,S.K.Nguang,X.D.Chen,Modeling and Optimization of Biological Processes,Springer-Verlag,Berlin,2006.(3-540-30634).

[17]X.D.Chen,J.Y.Yoo,Food engineering—an advancing branch of chemical engineering,Int.J.Food Eng.(2006)(http://ww w.bepress.com/ijfe/vol2/iss2/art1).

[18]C.Krul,A.Luiten-Schuite,R.Baan,H.Verhagen,G.Mohn,V.Feron,R.Havenaar,Research section:application of a dynamic in vitro gastrointestinal tract model to study the availability of food mutagens,using heterocyclic aromatic amines asmodel compounds,Food Chem.Toxicol.38(2000)783-792.

[19]C.A.M.Krul,Mutagenic and antimutagenic activity of food compounds,application of a dynamic in vitro gastrointestinal model,NCA(Netherlands Center Alternatives to Animal Use)Newsl.14(2003)2-4.

[20]C.A.M.Krul,M.J.Zeilmaker,R.C.Schothorst,R.Havenaar,Intragastric formation and modulation of N-nitrosodimethylamine in a dynamic in vitro gastrointestinal model under human physiological conditions,Food Chem.Toxicol.42(2004)51-63.

[21]F.Kong,R.P.Singh,Disintegration of solid foods in human stomach,J.Food Sci.73(2008)67-80.

[22]F.Kong,R.P.Singh,Digestion of raw and roasted almonds in simulated gastric environment,Food Biophys.4(2009)365-377.

[23]F.Kong,R.P.Singh,A human gastric simulator(HGS)to study food digestion in human stomach,J.Food Sci.75(2010)627-635.

[24]X.D.Chen,Adventuresin the developments of“near real”physical-chemical in-vitro GI systems for food applications,Proceedings of the International Congress on Food Engineering and Technology(IFET 2012),March 26-28,2013,Bangkok,Thailand,2012(Keynote paper;on CD Rom).

[25]L.Chen,A.Jayemanne,X.D.Chen,Venturing into an in vitro physiological upper GI System focusing on the motility effect provided by a mechanised rat stomach model,Food.Dig.1-9(2012),http://dx.doi.org/10.1007/s13228-012-0018-9(July issue).

[26]L.Chen,X.Wu,X.D.Chen,Comparison between the digestive behaviors of a new in vitro rat soft stomach model with that of the in vivo experimentation on living rats—motility and morphological influences,J.Food Eng.117(2)(2013)183-192.

[27]L.Chen,The Development and the Preliminary Application of the In Vitro Rat/Human Stomach(PhD Thesis)Department of Chemical and Biochemical Engineering,Xiamen University,Fujian,China,2013.

[28]R.G.Lentle,P.W.M.Janssen,The Physical Processes of Digestion,Springer,New York,2011.

[29]R.Deng,L.Pang,Y.Xu,L.Li,X.Wu,X.D.Chen,Investigation on a soft tubular model reactor based on bionics of small intestine—residence time distribution,International Journal of Food Engineering,De Gruyter,2014,http://dx.doi.org/10.1515/ijfe-2014-0048.

Chinese Journal of Chemical Engineering2016年1期

Chinese Journal of Chemical Engineering2016年1期

- Chinese Journal of Chemical Engineering的其它文章

- Review on the nanoparticle fluidization science and technology☆

- Multi-functional forward osmosis draw solutes for seawater desalination☆

- Bio-inspired enantioseparation for chiral compounds☆

- Process engineering in electrochemical energy devices innovation☆

- In-situ design and construction of lithium-ion battery electrodeson metal substrates with enhanced performances:A brief review☆

- Developments in the understanding of gas-solid contact efficiency in the circulating fluidized bed riser reactor:A review☆