基于电阻抗的苹果干燥过程含水率实时检测及动力学分析

李星恕,靳莉珍,张 博,熊秀芳,张海辉(. 西北农林科技大学机械工程与电子学院,杨凌 7200; 2. 陕西省农业装备工程技术研究中心,杨凌 7200)

基于电阻抗的苹果干燥过程含水率实时检测及动力学分析

李星恕1,2,靳莉珍1,张博1,熊秀芳1,张海辉1

(1. 西北农林科技大学机械工程与电子学院,杨凌 712100;2. 陕西省农业装备工程技术研究中心,杨凌 712100)

摘要:为了找到一种经济便捷的苹果片干燥过程含水率实时检测方法,分析热风温度和风速对干燥过程的影响,该研究实时检测了不同风速和热风温度下苹果片的电阻抗和含水率并分析了其随时间变化的规律。结果表明,干燥过程中苹果片电阻抗随干燥时间的增加而增大,含水率随干燥时间而减小,两者线性负相关(R2≥9.3),因此可以通过电阻抗的变化实时检测苹果干燥过程。苹果片电阻抗和含水率随干燥时间的变化均符合薄层干燥Logarithmic模型;基于电阻抗和含水率分别拟合得出不同条件下的干燥速率,并利用阿伦尼乌斯公式求出苹果试样干燥过程活化能,当风速为0.5和1.0 m/s时,依据电阻抗计算所得活化能分别为32.447和23.212 kJ/mol,含水率计算所得活化能为27.320和22.947 kJ/mol,依据电阻抗计算所得活化能与前人研究活化能值更一致。研究结果可为苹果片干燥过程在线检测和分析提供参考。

关键词:电阻抗;干燥;动力学;模型;活化能;苹果片

李星恕,靳莉珍,张博,熊秀芳,张海辉. 基于电阻抗的苹果干燥过程含水率实时检测及动力学分析[J]. 农业工程学报,2016,32(2):266-272.doi:10.11975/j.issn.1002-6819.2016.02.038http://www.tcsae.org

Li Xingshu, Jin Lizhen, Zhang Bo, Xiong Xiufang, Zhang Haihui. Real-time monitoring of moisture content and kinetics analysis of apple drying process by impedance measurement[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(2): 266-272. (in Chinese with English abstract)doi:10.11975/j.issn.1002-6819.2016.02.038 http://www.tcsae.org

0 引 言

苹果是中国第一大水果,占中国全部果品总量的30%左右,是最具竞争力的出口农产品之一[1]。苹果生产季节性强,上市量集中,而在营销、储运、保鲜等方面的发展还比较落后,出现了时间上和空间上的相对过剩,腐烂损耗率高,造成采后损失巨大。深加工是解决这一问题的较好方法。苹果片是在保持苹果原有品质基础上加工干燥而成的一种休闲食品[2-4]。在苹果片的生产加工中,干燥工艺对其品质影响很大[3]。

近年来提高产品质量和降低能耗是果蔬干燥的研究热点[5-6],实时监测干燥过程中产品的含水率,对判断干燥终点、提高产品质量、降低能耗具有重要意义[7-9]。许多方法如CT[10-11]、核磁共振[8,12]、计算机视觉[13-14]和激光散射[15-16]等被用来检测果蔬的干燥过程。上述方法均能检测干燥过程中果蔬含水率的变化,但是由于操作繁琐,成本较高等原因很难应用于实际生产。另外,为了分析果蔬干燥过程,优化干燥工艺,需要对果蔬的干燥过程进行动力学分析。很多研究均是基于含水率的变化建立果蔬干燥过程动力学模型,分析温度、风速等因素对干燥速率的影响[17-18],但是含水率检测一般采用取样并称量的方法,不能实现实时检测。因此找到一种经济、快捷的果蔬干燥过程在线检测方法非常必要。

果蔬的阻抗特性与果蔬中含水率和活性密切相关[19]。有研究发现干燥过程中胡萝卜、葱、蘑菇和生菜的电容与其含水率的变化趋势相同[20-21],不同含水率苹果的电特性也不同[22-23]。有学者研究了干燥过程中苹果的电特性随含水率的变化[23-25],但并未通过电特性的变化建立具体的数学模型对干燥过程进行深入的分析及建模。

为了找到一种简单、经济的果蔬干燥过程在线检测方法,本文测量热风干燥过程中苹果片含水率和阻抗特性的变化,建立基于电阻抗和含水率的苹果干燥动力学模型,分析干燥温度和风速对苹果片干燥过程的影响,为优化干燥工艺,改进干燥设备提供理论依据。

1 材料与方法

1.1苹果试样制备

试验材料为新鲜成熟、无损伤、大小相近的洛川富士苹果,购于本地超市。清洗擦干后放置在实验室平衡5 h使苹果完全恢复至室温(22℃),然后除去苹果花萼、果柄、果皮和果核,将苹果切成15 mm×15 mm×11 mm长方体试样,并立即进行干燥试验。试样初始湿基含水率为84%。

1.2试验系统与方法

将苹果试样置于洞道干燥装置(DG100D,浙江中控科教仪器设备有限公司)内,调节干燥装置分别设定干燥温度为40、50、60和70℃,风速为0.5和1.0 m/s,进行不同条件的热风干燥试验[26-28],并在干燥过程中检测苹果试样阻抗特性的变化。空气相对湿度为5%。苹果试样热风干燥及阻抗检测系统如图1所示。首先在仪表盘上设定干燥温度和热风速度,干燥系统启动后,空气从进口进入到电加热装置,变成热风后进入干燥室;待仪表控制盘上显示实际温度达到设定温度后,打开干燥室,把6个相同的苹果试样均匀放置在干燥室中网状托盘上进行单层干燥试验。其中1个试样用来检测阻抗特性的变化,另5个试样用来检测含水率的变化。干燥过程中,每20 min检测一次含水率和阻抗特性的变化。每个试验重复3次。

检测含水率的变化时,每隔20 min迅速取出其中的5块样品测其质量并迅速放回干燥设备,直至前后两次质量差小于0.01 g终止试验。

干燥过程中苹果试样湿基含水率按式(1)计算

式中MC为试样湿基含水率,%;Mi为i时刻试样质量,g;M∞为干燥结束时试样质量,g。

利用LCR测试仪(LCR3532-50,日置公司)和自制不锈钢针状电极测量苹果试样的阻抗特性,两电极间距为5 mm,插入苹果样品深度为8 mm。预试验结果表明,采用针状电极能够有效避免干燥过程中体积收缩对测量结果的影响。每隔20 min,计算机控制LCR测试仪连续测量苹果试样在21个频率点下的阻抗值和相位角,计算机自动记录并保存数据。含水率测量结束时也停止检测试样阻抗特性。测量电压为1 V,频率范围为42 Hz~5 MHz[27]。

温度不同时干燥过程中阻抗值相差很大,因此在一张图中比较分析阻抗变化趋势很困难,需对电阻抗作归一化处理。对测得电阻抗值按式(2)作归一化处理,

式中Z为归一化阻抗;Zi为干燥过程中i时刻阻抗,Ω;Z0为干燥开始时阻抗,Ω;Z∞为干燥结束时阻抗,Ω。

图1 苹果试样电阻抗检测系统Fig.1 Electrical impedance measurement system of apple slice

1.3数据处理方法

采用Spss软件对苹果片干燥过程数据进行处理和拟合。采用Origin软件绘图。

2 结果与分析

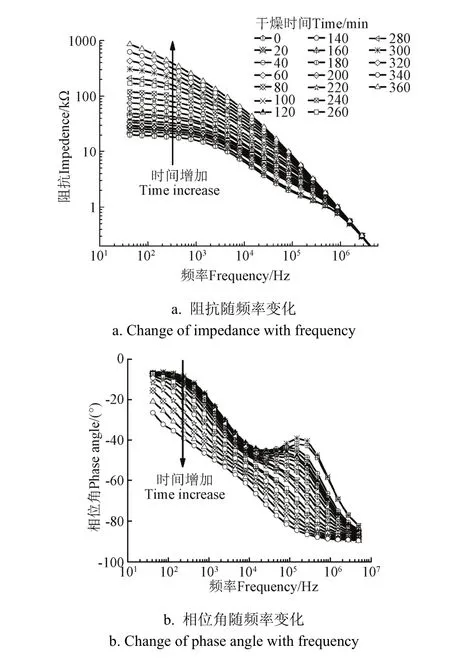

2.1干燥过程中苹果试样阻抗特性

干燥过程中苹果试样阻抗随频率变化如图2所示。由图2a可知,在干燥过程中同一时刻,阻抗随着频率的增加而减小;干燥过程中,苹果试样的阻抗随着时间的增加而增大;增加的幅度随着频率的增加而减小,高于1 MHz时每条时间曲线几乎重合。

图2 干燥过程中苹果阻抗和相位角随频率的变化Fig.2 Change of impedance and phase angles with frequencyduring drying process of apple slice

苹果组织是由细胞和细胞间隙组成的有序结合体,分为液泡、细胞质、细胞膜、细胞壁和细胞间隙[24]。液泡膜和细胞膜具有电容的特性,低频时具有较大的阻抗;高频时,电流能穿过细胞膜,阻抗明显减小[26,29],故阻抗随频率增大而减小。另外,在热风干燥过程中,含水率持续降低,组织细胞会收缩进而出现质壁分离,细胞膜破裂组织内部形成空洞[30-31],导致干燥过程中同一频率下苹果试样阻抗增大[32]。

干燥过程中苹果试样相位角随频率的变化如图2b所示。由图2b可知,干燥过程中,相位角随频率的增大呈增大-减小-增大马鞍形变化,随着干燥进行,局部马鞍形变化逐渐消失,干燥后期苹果试样相位角随频率的增加而一直减小。这是因为低频时总阻抗中电阻成分占主导相位角较小,随着频率的增加,电流逐渐通过细胞膜流入细胞内部,容抗在总阻抗中所占比例逐渐增加,相位角逐渐增大[33]。随着干燥进行,苹果组织含水率降低,细胞结构遭到破坏,这种现象逐渐消失。

干燥过程苹果试样Cole-Cole图如图3所示。从右到左频率依次增大,横坐标为阻抗实部(电阻成分),纵坐标为虚部(容抗成分)。整个干燥过程中苹果组织的Cole-Cole图均为一段圆弧,与生物组织的电学特征相符。由于电极极化现象,低频段曲线略有翘曲;随着干燥的进行,苹果试样的Cole-Cole图半径逐渐增大。

图3 干燥过程中苹果试样的Cole-Cole图Fig.3 Cole-Cole plot of apple slice during drying process

2.2干燥过程中电阻抗与含水率的关系

由图2a可知,频率为1 kHz时,阻抗随时间变化明显且均匀,而且消除了电极极化对阻抗的影响[31],因此选择1 kHz下的阻抗研究苹果试样干燥过程。热风速度为0.5 m/s时不同温度条件下电阻抗随时间的变化如图4所示。热风速度1m/s时电阻抗随温度的变化趋势相同,这里没有给出。

图4干燥过程阻抗随时间的变化关系Fig.4 Impedance changes with time during drying process

由图4可知,苹果试样阻抗随干燥时间先缓慢增大后期急剧增加,这是因为随着干燥过程的进行,苹果组织含水率逐渐减小,组织细胞的面积和当量直径亦随之减小,细胞逐渐收缩变小,电阻抗缓慢增大[30,34];干燥后期,苹果组织细胞收缩进而出现质壁分离,细胞会破裂进而形成空洞,电阻抗急剧增大[23,30];不同温度干燥完成时间不同,主要原因是温度与水分扩散系数正相关[35],温度越高,水分扩散系数越大,水分扩散越快,干燥时间越短。

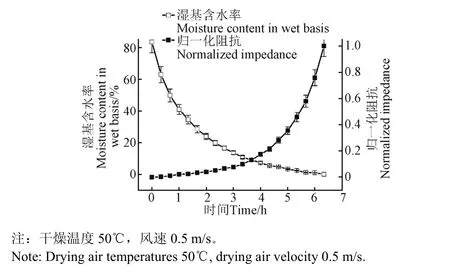

干燥过程中苹果试样含水率和归一化电阻抗随时间的变化如图5所示。由图5可知,干燥初期含水率急剧减小,随着干燥的进行,含水率减小缓慢,后期逐渐趋于稳定;而干燥初期阻抗变化缓慢,后期急剧增大;干燥过程中含水率和阻抗的变化趋势相反。为了找到一种能实时检测苹果试样干燥过程的方法,本文拟合得出相同条件下归一化阻抗和含水率之间的线性方程,如图6a和图6b所示。

图5 归一化阻抗和含水率随时间变化Fig.5 Normalized Impedance and moisture content change with time

图6 干燥过程含水率与归一化阻抗关系Fig.6 Relationship of moisture content and normalized impedance during drying process

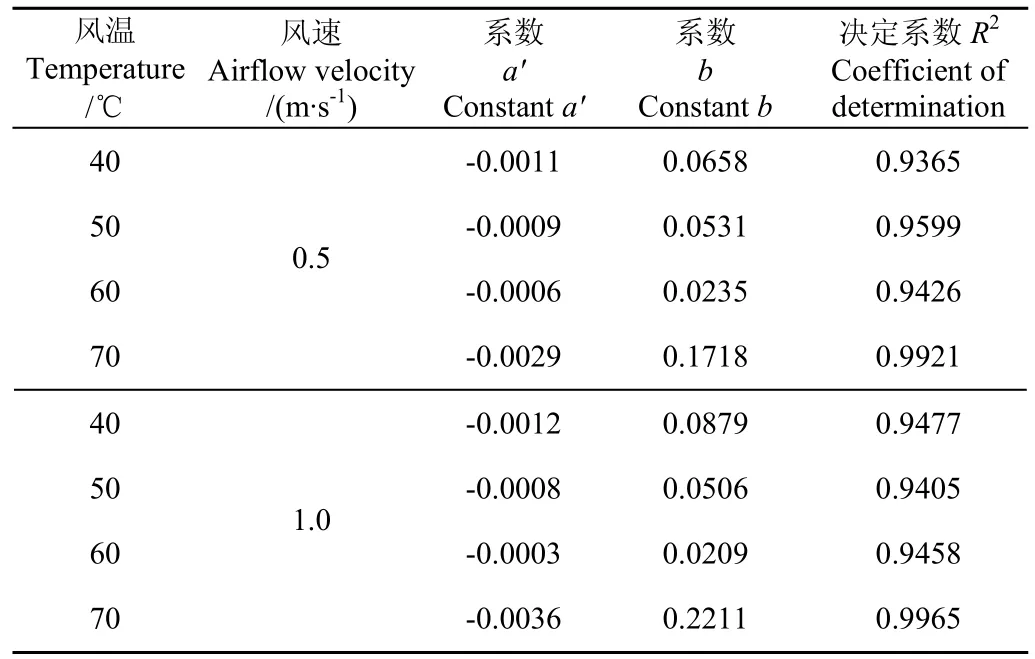

不同温度时归一化阻抗和含水率之间的线性方程拟合结果如表1所示。由表1可知,热风温度为40、50、60℃时线性方程斜率较小,但70℃时直线斜率很大。主要原因是当温度大于65℃时,苹果组织细胞壁和细胞膜完全破裂,细胞内水分更易排出[27],故70℃热风干燥时,阻抗变化趋势较其他温度较大。

表1 归一化阻抗与含水率的线性拟合Table 1 Fitting parameters between normalized impedance and moisture content

由表1可知,干燥过程中苹果试样归一化阻抗和含水率线性负相关(R2≥0.93),通因此可以过检测苹果试样阻抗特性来预测干燥过程中含水率的变化,从而实现在线监控苹果试样干燥过程含水率的变化。实现加工终点判断,干燥工艺优化以及产品质量控制[10,24]。

2.3苹果试样干燥过程动力学分析

为了分析温度和时间对苹果试样干燥过程的影响,对苹果试样干燥过程进行动力学分析。干燥过程中归一化阻抗和含水率随时间的变化如图7所示。干燥初期阻抗变化很小,而干燥后期,阻抗急剧上升,含水率刚开始变化急剧,后期变化缓慢。这种变化趋势符合薄层干燥logarithmic模型[36],分别对干燥过程中苹果试样的归一化阻抗和含水率进行logarithmic动力学方程拟合,拟合曲线分别如图7所示。logarithmic模型为

式中MR为归一化阻抗或含水率;k为干燥速率常数,h-1;ɑ,c为模型参数。

不同温度和风速条件下,分别根据归一化阻抗和含水率计算拟合logarithmic模型参数,结果如表2和表3所示。由表2和3中拟合结果可知,基于电阻抗和含水率的拟合效果均很好,苹果干燥过程符合薄层干燥logarithmic模型(R2>0.99);随着温度升高干燥速率常数增加;同样条件下基于电阻抗所得干燥速率明显高于基于含水率所得干燥速率常数,究其原因,主要是由于苹果组织水分主要存在于细胞内,在热风干燥过程中,组织细胞结构首先收缩破裂,然后细胞内水分才能流出[27,30];而细胞结构破坏和水分溢出均能导致阻抗的变化,阻抗的变化更快,因此阻抗计算拟合得到的干燥速率更大。

图7 干燥过程中归一化阻抗和含水率随时间的变化Fig.7 Normalized impedance and moisture content change over drying time in different temperatures

表2 基于电阻抗的干燥动力学模型拟合结果Table 2 Drying kinetics parameters by normalized impedance

表3 基于含水率的干燥动力学拟合结果Table 3 Drying kinetics parameters by moisture content

为分析干燥温度对苹果试样干燥过程的影响,利用阿伦尼乌斯公式分别描述了不同风速下干燥速率常数与温度之间的关系[37-38],阿伦尼乌斯公式为

式中k为干燥速率常数,h-1;A为指前因子,h-1;Eɑ为活化能,kJ/mol;R为摩尔气体常量,8.314 J(mol·K);T为绝对温度,K。

根据logarithmic模型拟合可得不同干燥温度下干燥速率常数,然后以lnk和1/T作线性回归,直线的斜率为−Eɑ/R,截距为lnA,可求出苹果试样干燥过程活化能Eɑ。当风速为0.5和1.0 m/s时,基于阻抗得到的活化能分别为32.447和23.212kJ/mol;基于含水率计算得出的活化能分别为27.320和22.947 kJ/mol。Mohsen的研究结果表明,苹果干燥过程活化能范围为26.72~35.83 kJ/mol[28],基于电阻抗得到的活化能更接近于该值,也间接验证了通过电阻抗检测分析苹果干干燥过程的可行性。风速增大,活化能减小,说明相同温度条件下,风速越大苹果试样越容易干燥。出现这种现象的原因,是由于不同的风速对于苹果试样的组织状态、结构等的影响不同,从而影响到干燥活化能[39]。

3 结 论

1)热风干燥过程中苹果试样阻抗先是缓慢增大,后期急剧增大,含水率的变化趋势相反;阻抗与含水率呈线性负相关(R2≥0.93)。故干燥过程中可以通过实时检测苹果试样阻抗值来预测其含水率的变化,实现苹果干燥过程的在线监控。

2)苹果片干燥过程符合薄层干燥Logarithmic模型(R2>0.99);基于电阻抗拟合所得干燥速率常数大于基于含水率所得干燥速率常数。

3)在风速为0.5和1.0 m/s时由电阻抗拟合得到的干燥速率计算所得活化能分别为32.447和23.212 kJ/mol;由含水率计算得出的活化能分别为27.320和22.947 kJ/mol。

[参考文献]

[1] 吴茂玉,马超,宋烨,等. 苹果加工产业的现状存在问题与展望[J]. 农产品加工,2009(12):50-52.

[2] 袁越锦,刘欣,徐英英,等. 苹果片真空干燥过程的热质传递模型及模拟[J]. 陕西科技大学学报,2015,33(2):143-147. Yuan Yuejin, Liu Xin, Xu Yingying, et al. Apple slices vacuum drying process of thermal and mass transfer model and simulation[J]. Journal of shanxi University of Science &Technology, 2015, 33(2): 143-147. (in Chinese with English abstract)

[3] 邓红,王小娟. 不同干燥方法对苹果片品质的影响[J]. 食品科技,2007,32(2):84-87. Deng Hong, Wang Xiaojun. Influence of different drying methods to apple slice quality[J]. Food Science and Technology,2007, 32(2): 84-87. (in Chinese with English abstract)

[4] 孟庆辉,肖旭霖,吕晓东. 苹果片气体射流冲击干燥工艺的优化[J]. 农产品加工·学刊,2008(11):56-59. Meng Qinghui, Xiao Xulin, Lü Xiaodong. Optimization of technology for air-impingement jet drying on apple slice[J]. Academic Periodical of Farm Products Processing, 2008(11): 56-59. (in Chinese with English abstract)

[5] 冯爱国,李国霞,李春艳,等. 食品干燥技术的研究进展[J].农业机械,2012(18):90-93.

[6] 徐小东,崔政伟. 农产品和食品干燥技术及设备的现状和发展[J]. 农业机械学报,2005,36(12):171-174.

[7] 李晓斌,郭玉明,付丽红. 应用纹理分析方法在线监测苹果冻干含水率[J]. 农业工程学报,2012,28(21):229-235. Li Xiaobin, Guo Yuming, Fu Lihong. On-line monitoring of moisture ratio for apple during vacuum freeze-drying based on image texture analysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(21): 229-235. (in Chinese with English abstract)

[8] 张绪坤,祝树森,黄俭花,等. 用低场核磁分析胡萝卜切片干燥过程的内部水分变化[J]. 农业工程学报,2012,28(22):282-287. Zhang Xukun, Zhu Shusen, Huang Jianhua, et al. Analysis on internal moisture changes of carrot slices during drying process using low-field NMR[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(22): 282-287. (in Chinese with English abstract)

[9] 王相友,林喜娜,刘强. 果蔬红外干燥在线实时检测系统设计[J]. 农业机械学报,2011,42(3):136-139. Wang Xiangyou, Lin Xina, Liu Qiang. Design of Online Measurement System of Infrared Radiation Drying for Fruit and Vegetables[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(3): 136-139. (in Chinese with English abstract)

[10] 张京平,彭争,汪剑. 苹果水分与CT值相关性的研究[J].农业工程学报,2003,19(2):180-182. Zhang Jingping, Peng Zheng, Wang Jian. Correlation between moisture of apples and values of CT[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2003, 19(2): 180-182. (in Chinese with English abstract)

[11] 彭争,张京平,齐亚峰. 果蔬CT图像含水率检测信息可视化研究[J]. 昆明理工大学学报:理工版,2008,33(5):76-80. Peng Zheng, Zhang Jingping, Qi Yafeng. Study on visualization of moisture data by ct image of fruit and vegetable[J]. Journal of Kunming University of Science and Technology: Science and Technology, 2008, 33(5): 76-80. (in Chinese with English abstract)

[12] 徐建国,徐刚,张绪坤,等. 利用核磁共振成像技术分析胡萝卜干燥过程中内部水分传递[J]. 农业工程学报,2013,29(12):271-276. Xu Jianguo, Xu Gang, Zhang Xukun, et al. Moisture transport in carrot during hot air drying using magnetic resonance imaging[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013,29(12): 271-276. (in Chinese with English abstract)

[13] Aghbashlo M, Hosseinpour S, Ghasemi-Varnamkhasti M. Computer vision technology for real-time food quality assurance during drying process[J]. Trends in food science &technology, 2014, 39(1): 76-84.

[14] Sampson D J, Chang Y K, Rupasinghe H P V, et al. A dual-view computer-vision system for volume and image texture analysis in multiple apple slices drying[J]. Journal of Food Engineering,2014, 127(4): 49-57.

[15] Romano G, Baranyai L, Gottschalk K, et al. An approach for monitoring the moisture content changes of drying banana slices with laser light backscattering imaging[J]. Food Bioprocess Technology, 2008, 1(4): 410-414.

[16] Romano G, Nagle M, Argyropoulos D, et al. Laser light backscattering to monitor moisture content, soluble solid content and hardness of apple tissue during drying[J]. Journal of Food Engineering, 2011, 104(4): 657-662.

[17] Akpinar E, Midilli A, Bicer Y. Single layer drying behavior of potato slices in a convective cyclone dryer and mathematical modeling[J]. Energy Conversion and Management, 2003,44(10): 1689-1705.

[18] Velić D, Planinić M, Tomas S, et al. Influence of airflow velocity on kinetics of convection apple drying[J]. Journal of Food Engineering, 2004, 64(1): 97-102.

[19] 王瑞庆,冯建华,徐新明,等. 果蔬电学特性在果蔬处理及品质检测中的应用[J]. 食品科学,2012(21):340-344. Wang Ruiqing, Feng Jianhua, Xu Xinming, et al. A review of applications of electrical properties of fruits and vegetables in processing and quality detection[J]. Food Science, 2012(21): 340-344. (in Chinese with English abstract)

[20] 秦文,陈宗道,羽仓羲雄,等. 食品的介电特性在食品干燥过程中的在线无损检测技术[J]. 食品与发酵工业,2005,31(8):52-56. Qin Wen, Chen Zongdao, Yoshio hugura, et al. A study of using food electric properties as a non destructive and continuous measurement in a drying process[J]. Food and fermentation industries, 2005, 31(8): 52-56. (in Chinese with English abstract)

[21] 秦文,张惠,邓伯勋,等. 部分农产品水分含量与其介电常数关系模型的建立[J]. 中国食品学报,2008,8(3):62-67. Qin Wen, Zhang Hui, Deng Boxun, et al. Construction of the model on the correlation between moisture content and dielectric constant of some agricultural products[J]. Journal of Chinese Institute of Food Science and Technology, 2008,8(3): 62-67. (in Chinese with English abstract)

[22] Martín-Esparza M E, Martinez-Navarrte N, Chiralt A, et al. Dielectric behavior of apple (var. Granny Smith) at different Moisture contents[J]. Journal of Food Engineering, 2006,77(1): 51-56.

[23] 孙成正,江谷传. 低频电流激励下苹果电阻抗检测系统的研究[J]. 合肥工业大学学报,2010,33(2):231-234. Sun Chengzheng, Jiang Guchuan. Research on apple impedance monitoring system under low frequency current—source[J]. Journal of Hefei University of Technology, 2010, 33(2): 231-234. (in Chinese with English abstract)

[24] Peter M, Eszter V, David B F. Connection between moisture content and electrical parameters of apple slices during drying[J]. Progress in Agricultural Engineering Sciences,2005, 1(1): 95-121.

[25] 王颖,郭玉明. 苹果介电常数与干燥特性相关性研究[J].农业机械学报,2010,41(增刊1):182-185. Wang Ying, Guo Yuming. Correlation between dielectric constant and drying characteristics of apple[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010,41(Supp.1): 182-185. (in Chinese with English abstract)

[26] Ando Y, Mizutani K, Wakatsuki N. Electrical impedance analysis of potato tissues during drying[J]. Journal of Food Engineering, 2014, 121(1): 24-31.

[27] 李星恕,张博,靳莉珍,等. 加热温度对苹果组织中细胞阻抗特性及水分分布的影响[J]. 农业工程学报,2015,31(14):284-290. Li Xingshu, Zhang Bo, Jin Lizhen, et al. Effect of heating temperature on cell impedance properties and water distribution in apple tissue[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(14): 284-290. (in Chinese with English abstract)

[28] Mohsen T, Lamine H, Sofien A, et al. Experimental and mathematical investigations of apple slices convective drying[J]. Journal of Food Science and Engineering, 2012,(2): 314-325.

[29] Mizukami Y, Sawai Y, Yamaguchi Y. Moisture content measurement of tea leaves by electrical impedance and capacitance[J]. Biosystems Engineering, 2006, 93(3): 293-299.

[30] 常剑,杨德勇,路倩倩,等. 热风干燥对果蔬薄壁组织细胞结构的影响[J]. 农业工程学报,2012,28(14):262-268. Chang Jian, Yang Deyong, Lu Qianqian, et a1. Effect of hot-air drying on cell structure of fruit and vegetable parenchyma[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012,28(14): 262-268. (in Chinese with English abstract)

[31] Mayor L, Silva M A, Sereno A M. Micro structural changes during drying of apple slices[J]. Drying Technology, 2005,23(9): 2261-2276.

[32] Imaizumi T, Tanaka F, Hamanaka D, et al. Effects of hot water treatment on electrical properties, cell membrane structure and texture of potato tubers[J]. Journal of Food Engineering, 2015, 162: 56-62.

[33] 李星恕,许刚,黄磊,等. 后熟过程中植物生长调节剂对猕猴桃电阻抗图谱特性的影响[J]. 农业工程学报,2015,31(1):288-293. Li Xingshu, Xu Gang, Huang Lei, et al. Effect of plant growth regulator on electrical impedance spectroscopy during ripening process in kiwifruits[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(1): 288-293. (in Chinese with English abstract)

[34] 郑欣欣. 干燥温度对电场预处理果蔬介电特性与脱水特性的影响[D]. 太谷:山西农业大学,2013.Zheng Xinxin. Influence of Temperature on Dielectric Properties and Dehydration Characteristic of Electric Field Pretreated Fruits and Vegetables[D]. Taigu: Shanxi Agriculture University, 2003. (in Chinese with English abstract)

[35] 张赛,陈君若,刘显茜. 水果在热风干燥中的水分扩散分形模型[J]. 农业工程学报,2014,30(4):286-292. Zhang Sai, Chen Junruo, Liu Xianxi. Diffusion fractal model of fruit moisture in hot air drying[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2014, 30(4): 286-292. (in Chinese with English abstract)

[36] Kamil S, Ahmet K E. The thin layer drying characteristics of organic apple slices[J]. Journal of Food Engineering 2006,73(3); 281-289.

[37] 熊秀芳,靳莉珍,李星恕,等. 基于流变和电特性的豆浆凝固过程动力学解析[J]. 农业机械学报,2015,46(4):211-218. Xiong Xiufang, Jin Lizhen, Li Xingshu, et al. Kinetic model of the coagulation process based on electrical and rheological properties of soymilk gel[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(4): 211-218. (in Chinese with English abstract)

[38] 肖红伟,张世湘,白竣文,等. 杏子的气体射流冲击干燥特性[J]. 农业工程学报,2010,26(7):318-323. Xiao Hongwei, Zhang Shixiang, Bai Junwen, et al. Air impingement drying characteristics of apricot[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(7): 318-323. (in Chinese with English abstract)

[39] 白竣文,王吉亮,肖红伟,等. 基于Weibull 分布函数的葡萄干燥过程模拟及应用[J]. 农业工程学报,2013,29(16):278-285. Bai Junwen, Wang Jiliang, Xiao Hongwei, et al. Weibull distribution for modeling drying of grapes and its[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(16): 278-285. (in Chinese with English abstract)

Real-time monitoring of moisture content and kinetics analysis of apple drying process by impedance measurement

Li Xingshu1,2, Jin Lizhen1, Zhang Bo1, Xiong Xiufang1, Zhang Haihui1

(1. College of Mechɑnicɑl ɑnd Electronic Engineering, Northwest A&F University, Yɑngling 712100, Chinɑ; 2. Shɑnxi Engineering Reseɑrch Center for Agriculturɑl Equipment, Yɑngling 712100, Chinɑ)

Abstract:Apple is one of the most competitive agricultural exports in China, accounting for about 30% of the total production of fruits. Unsuitable preservation or storage methods can lead to the loss, which may amount for 30% of the total. To reduce the loss of apples after harvesting, deep processing is an appropriate method. As a kind of snack food, dried apple slice is produced by a drying process and the natural flavor of apple can be retained. During the drying process, the drying temperature and time have a great influence on the apple slice quality. To develop a new method to monitor and characterize the drying process of apple slices as well as evaluate the influence of the drying temperature and time on this process, the electrical impedance and moisture content of apple tissues were measured during the drying process under different conditions. The hot air temperature was set to 40, 50, 60 and 70℃, and the hot air speed was set to 0.5 and 1.0 m/s, respectively. The 6 same apple samples were placed in the drying chamber for drying test. One sample was to detect the change of the impedance characteristics, and the other samples were used to detect the change of the moisture content. The interval measurement time was 20 min. Until the mass difference of the 2 successive measurements for one sample was less than 0.01 g, the experiment was stopped. Results showed that the electrical impedance of apple slices increased with the increase in the drying time, and t he increase rate was slow in the early stages and fast in the latter part of the drying process. The moisture content decreased during the drying process, and the decrease was fast at the beginning and slow in the latter part. Thus, the variation tendency of moisture content was contrary to that of electrical impedance during the process. The electrical impedance of apple slices showed a negative linear correlation with the moisture content when the moisture content was more than 20%. So electrical impedance measurement could provide a simple and rapid approach for predicting the moisture content, and furthermore it was capable of monitoring and evaluating the drying process of apple slices. The curves of the normalized electrical impedance and moisture content with the drying time could be approximated with the logarithmic drying model which could describe the characteristics of the drying process. The rate constant of the model at various temperatures was estimated by the normalized impedance and moisture content. The rate constant increased with the increasing of drying temperature. Then to analyze the effect of temperature on the drying rate constant, the rate constants at different temperatures were formulated by the Arrhenius equation. Based on the obtained rate constants at different drying temperature, the activation energy was calculated. It was found that when the speed of drying hot air was 0.5 and 1.0 m/s, the activation energy calculated from the normalized impedance was 33.925 and 28.912 kJ/mol, respectively; the calculated activation energy from the moisture content was 27.320 and 22.947 kJ/mol, respectively. The activation energy decreased with the increasing of hot air speed, which indicated that the higher the hot air speed, the faster the drying of apple slices. The findings are useful to monitor the drying process of apple slices and have the potential applications in the control of fruit drying process.

Keywords:electrical impedance; drying; kinetics; models; activation energy; apple slices

作者简介:李星恕,男,河南驻马店人,博士,副教授,主要从事农业装备研发与农产品无损检测方面的研究。杨凌西北农林科技大学机电学院,712100。Email:xingshu-li@nwsuaf.edu.cn

基金项目:陕西省科技统筹创新工程计划项目(2014KTCL02-15)和陕西省自然科学基础研究计划(2015JM3113)

收稿日期:2015-09-03

修订日期:2015-12-10

中图分类号:TS255.4

文献标志码:A

文章编号:1002-6819(2016)-02-0266-07

doi:10.11975/j.issn.1002-6819.2016.02.038