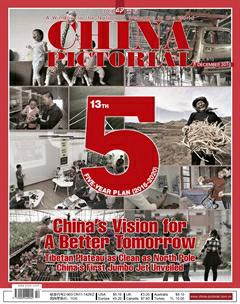

China’s Own Dreamliner Ready for Take-off

by+Wang+Jiayin

At 10 a.m. on November 2, 2015, dragged by a tractor, Chinas first home-made large passenger aircraft, the C919, rolled off the final assembly line of the Commercial Aircraft Corporation of China, Ltd. (COMAC) in Pudong District, Shanghai. The C919 project was launched in November 2008. After seven years of effort, Chinas own jumbo jet was finally unveiled.

Better Design

The C919 features a streamlined body, a two-pilot cockpit, and a LCD dashboard, with seating capacity of 168 people in the all-economy class layout and 156 people in the hybrid class layout – equal to the seating capacity of Boeing 737 and Airbus A320. The basic version is designed to cover 4,075 kilometers, while the superior version can extend to 5,555 kilometers.

Although a newcomer in the commercial jumbo jet market, the C919 has its advantages compared to its Airbus and Boeing rivals. According to Zhou Liangdao, vice chief designer of the C919, the aircraft adopts full-time full-authority fly-by-wire flight control system and advanced active control technology, which make it technologically more advanced than Boeing 737.

Its engines are provided by CFM International, which are fuel efficient and can help cut costs by 10 percent compared to current similar passenger aircraft.

Moreover, the C919 uses large amounts of advanced materials, especially third-generation aluminum-lithium alloy and composite materials. The aircraft is more environmentally friendly, enabling a 50 percent reduction in nitrogen oxide discharge in line with ICAO CAPE6 standards and a 12 percent reduction in carbon dioxide emission compared to most aircraft in service of its class.

According to COMAC chairman Jin Zhuanglong, the C919 will undergo various ground and flight tests and wont be put into operation until it obtains relevant certificates and passes the authentication of the Civil Aviation Administration of China (CAAC). “The first C919 aircraft will be used for flight tests, which is scheduled to take place in 2016,” Jin explains. “Before that, it needs to complete system debugging and installation of flight test instruments.”

High-end “Made in China”

The development of large passenger aircraft requires profound technology accumulation and involves various sectors and industries. Chinese aircraft technicians finally realized their dream when the C919 rolled off the final assembly line. However, some argue that the aircraft is merely assembled from foreign components because many of its parts were imported.

Chen Yingchun, vice executive chief designer of the C919, likens the development of the aircraft to making dumplings.“Although flour and pork are bought in the market, the dumplings are still what you make yourself,” he grins. “After making dumplings becomes a flourishing industry, we can develop many supplementary industries, such as pig husbandry, wheat cultivation, and vegetable plantation. Behind the C919 is a complete industrial chain.”

The development of the C919 involved 16 multinational airborne system providers and a dozen joint ventures, as well as more than 200 Chinese companies and 36 universities and research institutions. Through integrating innovative factors, the C919 thus enjoys advantages in market competition.

Zhou Liangdao believes that the C919 will exert far-reaching influence on Chinas development of large airliners and even its high-end manufacturing industry. Moreover, the C919 will create a “catfish effect” to stimulate all firms in the industrial chain to better themselves if they want to join the project.

Road to Market

The C919s debut not only actualized the Chinese aircraft manufacturers dream of developing their own large airliners, but also sends a message: The fast-growing aviation industry of the worlds second largest economy is creating opportunities for development, and China is willing to share those opportunities with the rest of the world.

It is estimated that China will put into operation at least 5,500 passenger aircraft worth US$ 670 billion in next two decades. So far, only the United States and Russia, as well as Airbus jointly established by France, Germany, Britain, and Spain, are capable of producing large passenger jets. As the worlds second largest aviation market, China has yet to put into operation a domestically-made large airliner.

It is the tremendous market that compelled China to develop its own large passenger airliners. The C919 is expected to break the duopoly of Boeing and Airbus in the market. The estimates show that more than 2,000 C919 airplanes will be sold over the next two decades.

Despite the fact that the C919 has yet to make its first test flight, the market has high expectations. Statistics released by COMAC show that a total of 517 of the type have been ordered by 21 customers including Air China, China Eastern Airlines, China Southern Airlines, and Hainan Airlines. Besides domestic airlines, Germanys PuPen Airlines and Thailands City Airways have signed letters of intent with COMAC to purchase seven and 10 C919 aircraft, respectively.

For the C919, the biggest rivals are Boeing 737 and Airbus A320. In the future, the C919 will challenge its counterparts produced by Boeing and Airbus. In this context, the two aerospace giants have taken counter-action by releasing B737MAX and A320neo, respectively.

Even so, both Boeing and Airbus expressed welcome to the competition from COMAC. Despite its advantages over its international competitors in terms of technology and price, the C919 will face enormous challenges as a newcomer in the market. “Boeing and Airbus boast strong technology accumulation,” opines Zou Maogong, an aviation expert in China. “It remains hard for China-made large airliners to overtake the two giants, which needs to move forward step by step.”

Since Chinas passenger aircraft industry is in a nascent stage, it will face various challenges, such as lack of experience and capacity, and increasing international competition. What cannot be denied is that China has begun competing with global forerunners in the aircraft market; and they are creating opportunities for each other.

Ouyang Xupo, vice director of CAAC Shanghai Aircraft Airworthiness Certification Center and head of the C919 Qualification Assessment Team, said that rolling off the final assembly line merely means the C919 is ready for ground tests and that it can prepare for flight tests. There is still a long way for the aircraft to go before it begins commercial operation.