Development of shape measurement system for vibrating membranes

Takashi IWASA , Kairi SUSAKI

(1.4-101, Koyama-cho Minami, Tottori, JAPAN; 2.356-1, Furumi, Tottori, JAPAN)

JSMME2014优选论文

Developmentofshapemeasurementsystemforvibratingmembranes

Takashi IWASA1, Kairi SUSAKI2

(1.4-101, Koyama-cho Minami, Tottori, JAPAN; 2.356-1, Furumi, Tottori, JAPAN)

A shape measurement system capable of capturing a wave propagation phenomenon as well as a stationary vibration phenomenon on a vibrating membrane surface with high spatial resolution is constructed. The constructed measurement system comprises a photogrammetric measurement device based on a grating projection method and an experiment device generating a wave propagation phenomenon on the membrane surface. Through the demonstration on a measurement experiment for the vibrating membrane surface, it is presented that the constructed measurement system successfully captures the complicated dynamic responses on the membrane surface in exact detail, while confirming the effectiveness of the shape measurement system.

shape measurement system; vibrating membrane; wave propagation; photogrammetric measurement; grating projection method

A membrane is a flexible material, which has ultra-lightweight and high packaging capability. Due to its distinctive properties, the membrane is expected as one of the effective structural components of the future large structures such as a dome and a space structure[1]. However, since the membrane has negligible bending stiffness and can carry small compressive stresses, a large deformation easily occur once an external force is applied. These membrane behaviors represent strong geometrical nonlinearity, and an analysis on their behaviors is difficult to perform with high accuracy. Accordingly, to clarify the nonlinear mechanical property of the dynamic membrane behavior, an experiment approach is necessary.

However, considering the measurement experiment for the vibrating membrane surface, a traditional contact measurement sensor such as an accelerometer and a strain gage cannot be applied, and a non-contact measurement technique such as a photogrammetric measurement is required. Moreover, since the dynamic membrane behavior is composed of a wave propagation phenomenon, a transition phenomenon from the wave propagation to a stationary vibration and the stationary vibration phenomenon, a non-contact measurement technique capable of capturing a local deformation shape as well as a full-field surface shape of the vibrating membranes with a high spatial resolution is demanded. On the other hand, to obtain the results enough to discuss the nonlinear mechanical property of the dynamic membrane behavior in exact detail, it is also necessary to construct a dedicated experiment device generating the wave propagation phenomenon on the membrane surface with high repeatability.

Thus, in this study, a shape measurement system, which comprises the photogrammetric measurement device based on the grating projection method and the distinctive experiment device generating the wave propagation phenomenon on the membrane surface, is constructed in order to obtain the measurement data enough to discuss the nonlinear mechanical property of the dynamic membrane behavior in exact detail. Through the demonstration on the surface shape measurement for the vibrating membrane surface induced by an impact loading, the effectiveness of the constructed measurement system is discussed with focus on a full-field surface shape, a cross sectional surface shape and a displacement time history at the selected points on the vibrating membrane.

1 Outline of Constructed Shape Measurement System

1.1 Photogrammetric Measurement Device based on Grating Projection Method

To capture the local deformation shape as well as the full-field surface shape of the vibrating membrane in exact detail, a shape measurement device capable of measuring the vibrating membrane surface with high spatial resolution is necessary. As the shape measurement device to satisfy with such a requirement, a photogrammetric measurement using the grating projection method is focused upon. The photogrammetric measurement using the grating projection method has the ability to provide the three-dimensional coordinate of the object on a pixel-to-pixel basis, and is suitable to measure the complicated membrane surface with high spatial resolution.

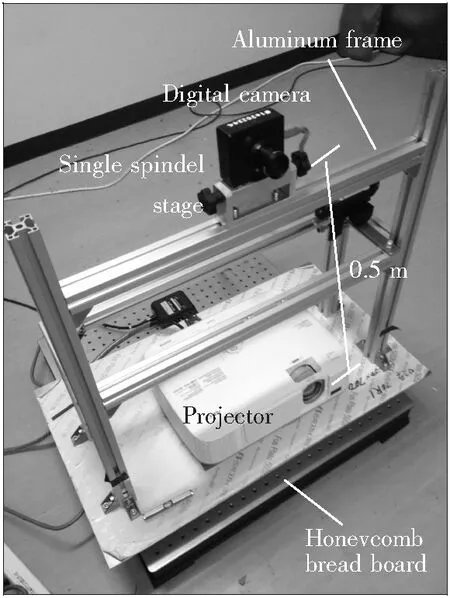

Fig.1 Configuration on Photogrammetric measurement

Figure 1 illustrates the configuration on the photogrammetric measurement device based on the grating projection method. Figure 2 indicates the picture of the photogrammetric measurement device. As shown in Figs.1 and 2, a digital camera and a projector are attached to the measurement jig at a distance of 0.5 m from each other. The measurement jig is installed on the single spindle stage, and can be moved back and forth with repeated positioning accuracy of 6μm. The single spindle stage is fixed on the honeycomb bread board.

Fig.2 Photogrammetric measurement device

The measurement space of the photogrammetric measurement is created by conducting the dedicated calibration using two reference planes (Fig.1). This calibration method was developed by Fujigaki[2], and is capable of measuring the object without any camera lens aberration effects. The x and y axes are defined on the surface of the reference plane, and the z axis is set perpendicular to the reference plane.

After the calibration is complete, these two reference planes are removed, and the membrane to be measured is installed in the measurement space. Then, a grating pattern is projected to the membrane surface by the projector, and the membrane with the projected grating pattern is photographed by the digital camera. By conducting the phase analysis on the phase information of the projected grating pattern, the three dimensional coordinate of the membrane surface shape is given. In this study, z axis coordinate is only treated to capture the surface profile of the vibrating membrane. As the phase analysis method, the sampling moiré method[3]is applied to perform a continuous surface shape measurement for the vibrating membrane surface. The shutter speed of the digital camera is set to be 200 fps. Table 1 lists the specification on the photogrammetric measurement device.

Table 1 Specification on Measurement Device

1.2 Wave Propagation Generator for Membrane Surface

Figure 3 shows the constructed experiment device generating a wave propagation on a membrane surface. As shown in the figure, the experiment device is made up of the aluminum frame. The height and width of the device are 0.60 m and 1.00 m, respectively. The membrane is a rectangular polyimide film whose size is 0.4 m × 0.7 m and thickness is 25 μm. The surface of the membrane is matted with the delustering spray to avoid glossy effects on the photogrammetric measurement.

Fig.3 Constructed experiment device

Figure 4 indicates the picture of the corner of the membrane (left top corner and right bottom corner). As shown in the figure, a square acrylic plate with 3 cm on a side is attached on the four corners of the membrane. The attached region is a square with 1.5 cm on a side. A Kevlar string is connected to the acrylic plate, and the tension loading is applied to the acrylic plate not to cause a wrinkling phenomenon on the membrane surface. The end of the Kevlar string is fixed at the jig.

Fig.4 Method of fixation of membrane

Figure 5 shows the enlarged view of the left top corner of the membrane. As shown in the figure, an impact loading is applied to the acrylic plate by crushing the glass ball. The mass of the glass ball is 4.5 g. The glass ball is connected to the string, and is moved along the circular path due to the pendulum. By adjusting the initial height of the glass ball, the applied impact loading is controlled. The initial height of the grass ball from the crushing point is set to be 7.5cm. Due to this impact loading, the wave propagation phenomenon on the membrane surface is appropriately generated with high repeatability.

Fig.5 Enlarged view of left top corner

Figure 6 is the picture of the constructed shape measurement system, which comprises the photogrammetric measurement device based on the grating projection method and the experiment device generating the wave propagation on the membrane surface. The experiment device is placed on the vibration isolation table to remove the vibration noises transmitted from the floor. The distance between the photogrammetric measurement device and the experiment device is approximately 1.55 m.

Fig.6 Shape measurement system

2 Results and Discussion

2.1 Whole Field Surface Shape

Fig.7 Image data of membrane

Figure 7 indicates the captured image data of the membrane surface with the projected grating pattern. As shown in the figure, a specular reflection is observed in the left bottom area on the membrane surface. This specular reflection occurs depending on the angle between the sight line from the digital camera and the projected line from the projector. However, since the specular reflection on the membrane surface cannot be removed perfectly by the simple adjustment of the position of the digital camera and the projector, the upper area of the membrane surface is selected as the measurement area in this experiment in order to avoid the effects of the specular reflection.

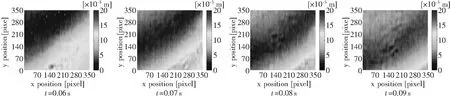

Figure 8 shows the measurement results on the surface contour of the vibrating membrane surface during the first wave propagation. The x and y axes in the figure represent the pixel value. From the figure, the first wave propagates on the membrane surface along the diagonal line. Since the photogrammetric measurement using the grating projection method is capable of providing the measurement results on a pixel-to-pixel basis, the measurement results on the vibrating membrane surface during the first wave propagation can be captured with high spatial resolution.

Fig.8 Membrane surface profile during first wave propagation

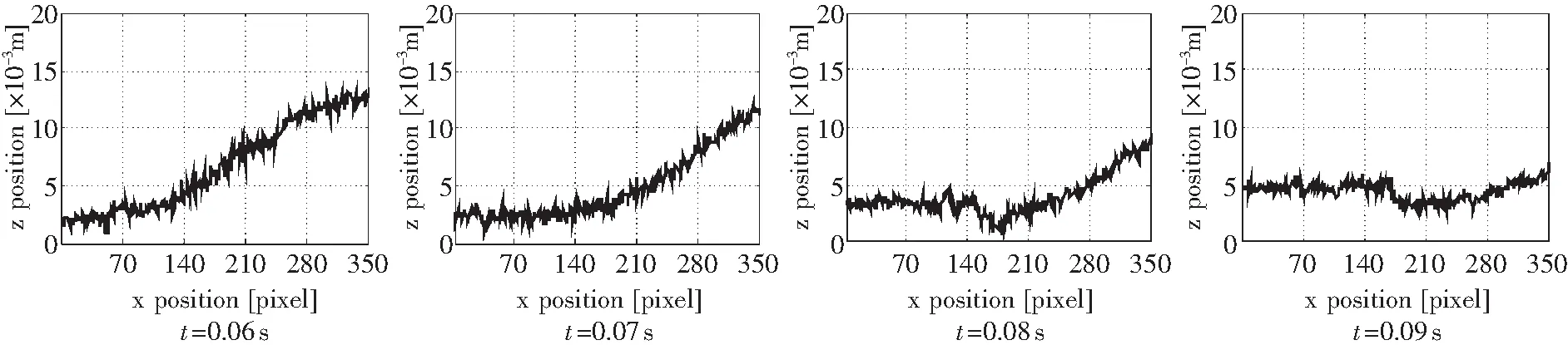

2.2 Cross Sectional Shape

Figure 9 represents the cross sectional shape of the membrane surface during the first wave propagation. This figure indicates the center cross sectional shape of the membrane surface in the horizontal direction (along 175 pixel in y axis in Fig. 8). From the figure, the local deformation shape of the complicated membrane surface can be measured with the photogrammetric measurement using the grating projection method in exact detail. Although the measurement error like a random noise appears in the results, these magnitudes are relatively small compared to the amplitude of the vibrating membrane. These errors are considered to occur due to the optical properties of the membrane surface and are the distinguish errors of the photogrammetric measurement using the grating projection method.

Fig.9 Cross sectional shape of membrane surface during first wave propagation

2.3 Displacement Time History at Selected Point

Figure 10 shows the time history of the displacement response on the center of the vibrating membrane surface. From the figure, the constructed measurement system suitably captures the displacement response on the vibrating membrane surface. Although some measurement errors are observed in the figure, the magnitude of these errors is relatively small, and the measurement result enough to discuss the nonlinear mechanical properties of the vibrating membrane surface is appropriately obtained. From the results, the effectiveness of the constructed

Fig.10 Time history on displacement response

measurement system for capturing the localized and the full-field deformed surface shape of the vibrating membrane is confirmed.

3 Summary

The surface shape measurement system capable of capturing the complicated surface shape of the vibrating membrane induced by the impact loading is constructed. Through the demonstration on the surface shape measurement for the vibrating membranes, it is shown the local deformation shape as well as the full-field surface shape can be suitably measured by the photogrammetric measurement using the grating projection method with high spatial resolution. From the results, the effectiveness of the constructed measurement system is presented.

Acknowledgement

This research was partially supported by “JSPS KAKENHI Grant Number 25420851”.

[1] Santiago-Prowald J, Baier H. Advances in deployable structures and surfaces for large apertures in space [J]. CEAS Space Journal, 2013, 5(3-4): 89-115.

[2] Fujigaki M, Morimoto Y. Shape measurement with grating projection using whole-space tabulation method [J]. Journal of JSEM, 2008, 8(4): 92-98.

[3] Ri S, Fujigaki M. Sampling moiré method for accurate small deformation distribution measurement[J]. Experimental Mechanics, 2010, 50:501-508.

2014-09-20.

JSPS 科学研究费辅助金(25420851).

Takashi IWASA (岩佐贵史) (1971-),男,副教授,E-mail:iwasa@mech.tottori-u.ac.jp.

TH 741.1

A

1671-6620(2015)01-0072-04

10.14186/j.cnki.1671-6620.2015.01.015