A Preliminary Study on lntensive Curing with Alcohol-based Fuels

Jiping ZHAN,Chaofan DU,Yu LU,Linrong JlANG

Longyan Tobacco Industrial Co.,Ltd.,Longyan 364000,China

A Preliminary Study on lntensive Curing with Alcohol-based Fuels

Jiping ZHAN*,Chaofan DU,Yu LU,Linrong JlANG

Longyan Tobacco Industrial Co.,Ltd.,Longyan 364000,China

The research investigated application effects of alcohol-based fuels in in-tensive curing.The results showed that alcohol-based fuels allow flexible adjustment of temperature and heat supplying.What's more,in treatment A,the cured tobac-cos are softer and brighter,with more oil content and higher proportion of first-class tobaccos.Per leaf weight increased by 0.13 g and output value per kang (a heat-able brick bed)deducting energy cost grew by 188.66 yuan.In addition,the con-tents of reducing sugar and potassium enhanced within the ranges of high-quality tobacco,and chemical components are more coordinated.

Cured tobacco;Alcohol-based fuels;Application effects

C urrently,curing of tobacco is mainly based on coals[1-2].Ho-wever,such practice con-sumes lots of coals and causes envi-ronment pollution.What's worse,coal is a non-renewable resource,and it becomes necessary to seek alterna-tive energy[3].For the researches avail-able,highlights are given to com-pressed straw stalk[4],straw gasifica tion[2]and biomass fuel[3],but less at-tention is paid to replacement of coal by alcohol-based fuels.The research investigated application ofalcohol-based fuels in intensive flue-cured to-bacco barns,providing theoretical sup-ports for application of alcohol-based fuels.

Materials and Methods

Test materials

The testmaterials included a burner,a set of U-shaped pipeline ra-diator,a set of weighing tool,1 t me-thanol,1 t honeycomb briquette and 2 hm2Yunyan No.87(growing in moder-ate-fertility farmlands).Besides,to-baccos were cured in two intensive flue-cured tobacco barns meeting na-tional standards.

Test design

The test designed two treatments. Specifically,treatment A contained a burner,a set of U-shaped pipeline ra-diator,and the tobaccos were cured in an intensive barn ready for heat-sup-plying system transformation,with methanol.In treatment B(CK),tobac-cos were cured in an intensive barn with honeycomb briquette.

According to Three-stage Curing of flue-cured Tobacco in Intensive Barns in Longyan City,tobaccos should be harvested as per ripeness demands upon tobacco species and location.After harvesting,tobaccos should be classified,and then,130 up-per leaves are strung onto every to-bacco stick and 100 middle or lower-part leaves are strung onto every stick. Tobacco leaves from 320 tobacco sticks should be collected for every curing.In the test,typical tobacco leaves were selected and signed as test samples,and then hung from tier-poles 2,4 and 6 m away from door. Two sticks were hung in every location and every barn contained 18 sticks,totaling 126 sticks.Upper,middle and lower-parts tobacco leaves were cured respectively.

Measurement items

In the test,heat supply with alco-hol-based fuels,tobacco load of barns,dry tobacco quantity,energy con-sumption,cured quality of tobacco and average price were measured.As for fresh/dry weight,sample stick was weighed before curing;fresh tobacco and sample stick were weighed and then the weight of sample stick and cured tobaccos were weighed.Finally,fresh tobacco on everystickand weight of cured tobacco can be com-puted.

Tobacco grade and appearance quality were appraised by technicians organized by Longyan Tobacco In-dustrial Co.,Ltd.,on basis of color,ripeness,structure,identity,oil content and chromaticity[6].Chemical compo-nents were measured by related method[7].

Results and Analysis

Analysis on heat supply effect

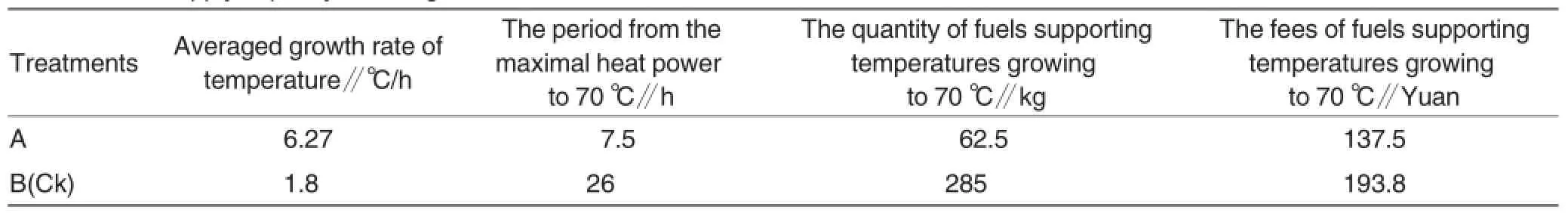

In curing barns,as shown in Table 1,treatments A and B (CK)both en-hanced room temperatures from 23℃to 70℃with maximal heat power,with an average rate of 6.27℃/h.In control group,it took about 26 h and the aver-age rate increased 1.8℃/h,which indi-cated that alcohol-based fuels per-formed better in heat supply.

Curing costs

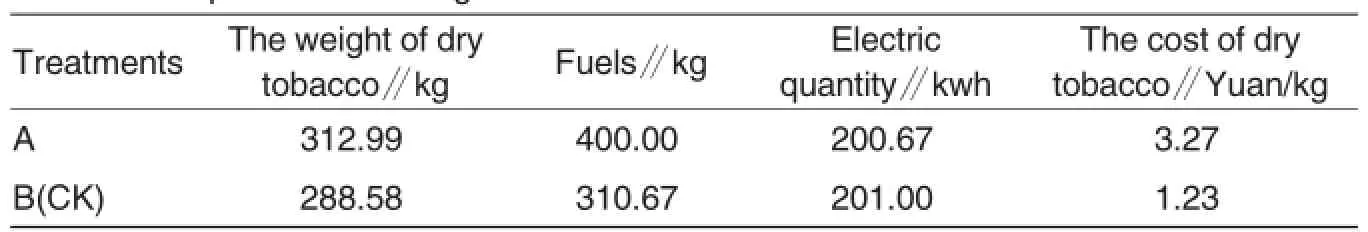

As shown in Table 2,tobacco weight kept 24.41 kg higher relative to control after alcohol-based fuels were fired in barn.Specifically,the costs of dry tobaccos(1 kg)in barns were 3.27 and 1.23 yuan by alcohol-based fuels and coals.

Table 1 Heat supply capacity of curing barns in different treatments

Table 2 Comparisons of curing costs

Appearance quality of cured tobac-cos

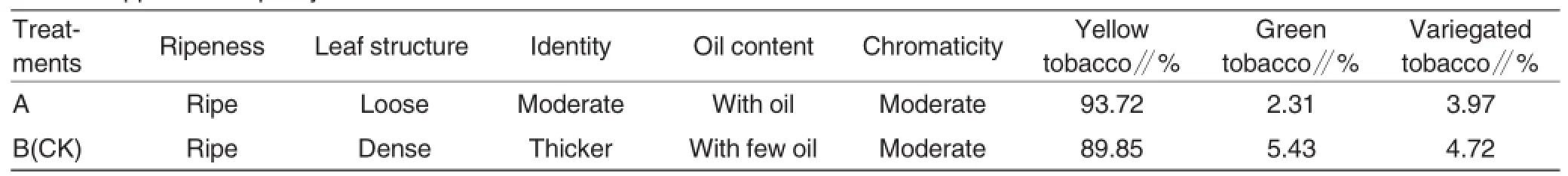

As shown in Table 3,leaf struc-ture,identity,and oil content of cured tobaccos were better in treatment A than those of treatment B.What's more,the rate of yellow tobacco in treatment A maintained higher than that of treatment,but the rates of green tobacco and variegated tobacco were 3.12%and 0.75%lower.

As shown in Table 3,leaf struc-ture,identity and oil contents all kept higher in treatment A than those of treatment B;the rate of yellow to-baccos was 3.87%higher in treat-ment A,but the rates of green and variegated tobaccos were 3.12%and 0.75%lower.

Economic profits of cured tobaccos

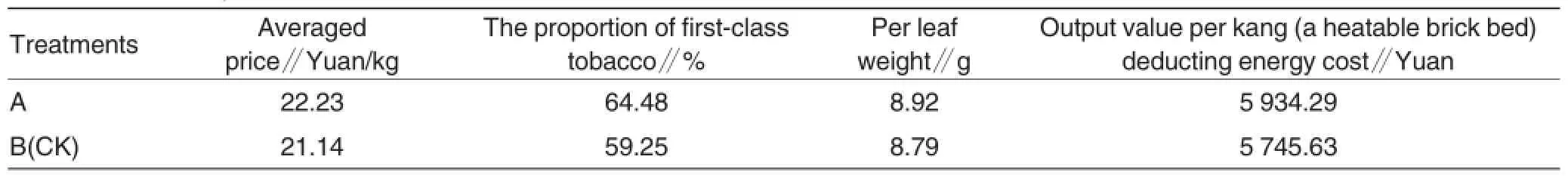

As shown in Table 4,treatment A performed better in terms of averaged price,the proportion of first-class to-bacco,per leaf weight,and output val-ue per kang(a heatable brick bed)de-ducting energy cost,which kept 1.09 yuan/kg,5.23%,0.13 g and 188.66 yuan higher than those of treatment B. Chemical components of cured to-baccos

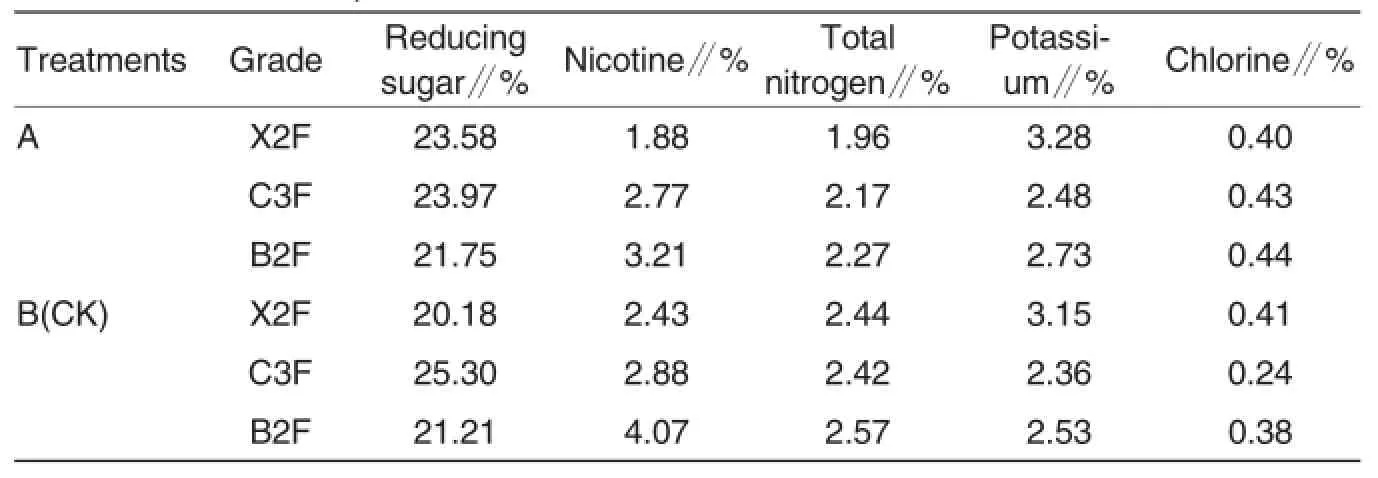

The coordination ofchemical components directly reflects tobacco ripeness,as well as taste quality[8].It can be concluded from Table 5 that bothoftwochemicalcomponents met the demands of high-quality to-bacco tobaccos.Specifically,reduc-ing sugar and potassium contents in treatment A maintained higher,but nicotine and total nitrogen were low-er.Therefore,chemical components of tobaccos in treatment A are much more coordinated.

Table 3 Appearance quality of cured tobaccos

Table 4 Economic profits of cured tobaccos

Conclusion and Discussion

In the research,alcohol-based fu-els allow flexible adjustment of tem-perature and heat supplying.What's more,in treatment A,the cured tobac-cos are softer and brighter,with more oil content and higher proportion of first-class tobaccos.Per leaf weight increased by 0.13 g and output value per kang (a heatable brick bed)de-ducting energy cost grew by 188.66 yuan.In addition,the contents of re-ducing sugar and potassium enhanced within the ranges of high-quality to-bacco,and chemical components are more coordinated.

Alcohol-based fuel heating sys-tem is on basis of methanol,discharg-ing CO2and water.It is obvious thatthe fuel is a clean energy,reducing la-bor intensity.Furthermore,the cured tobaccos tend to be sifter and brighter with more oils.Besides,the treatment with alcohol-based fuel heating system performed better in the proportion of first-class tobacco,averaged price,per leaf weight and output value per kang(a heatable brick bed)deducting ener-gy cost,possibly caused by flexible temperature adjustment,good heating effects and simple curing techniques.

Table 5 Chemical components of cured tobaccos

Nevertheless,because methanol is flammable liquid,the potential safety hazard should be taken into considera-tion for further promotion.Besides,al-cohol-based fuels are energy con-suming,and methanol is expensive. Therefore,further exploration should be conducted on energy saving of al-cohol-based fuels.

[1]Tobacco Research Institute,Chinese Academy of Agricultural Sciences(中国农业科学院烟草研究所).Shandong Tobacco(山东烟草)[M].Beijing:China Agriculture Press(北京:中国农业出版社),1999.

[2]CUI ZJ(崔志军),MENG QH(孟庆洪),LIU M(刘敏),et al.Tobacco straw gasifica-tion as an alternative to coal in tobacco curing(烟草秸梗气化替代煤炭烘烤烟叶研究初报)[J].Chinese Tobacco Science(中国烟草科学),2010,31(3):70-72,77.

[3]FEI H(飞鸿),CAI ZD(蔡正达),HU J(胡坚),et al.Study on Tobacco Baking With Biomass Energy(利用生物质烘烤烟叶的研究)[J].Contemporary Chemi-cal Industry(当代化工),2011(6):565-567,592.

[4]GUO SP(郭仕平),XIE LW (谢良文),ZENG SH(曾淑华),et al.Research on application effect of flue-cured tobacco straw briquetting replacing coal on to-bacco flue curing(烤烟秸秆压块代煤在烟叶烘烤中的应用效果研究).Modern Agricultural Science and Technology(现代农业科技),2015,0(6);178-179.

[5]TAN FL(谭方利),FAN SJ(樊士军),DONG YH(董艳辉).Practical Effect of Biomass Briquette Fuel and Coal for Tobacco Curing(生物质压块燃料及煤炭燃料在烟叶烘烤中的应用效果对比研究).Modern Agricultural Science and Technology(现代农业科技),2014,(10);201-201.

[6]WANG YT(王彦亭),XIE JP(谢剑平),LI ZH(李志宏).Tobacco regionalization in China(中国烟草种植区划)[M].Beijing:Science Press(北京:科学出版社),2010:24-29,36-37.

[7]WANG RX(王瑞新),HAN FG(韩富根),YANG SQ (杨素勤),et al.Chemical quality analysis of tobaccos (烟草化学品质分析)[M].Zhengzhou:Henan Sci-ence and Technology Press(郑州:河南科学技术出版社),1998.

[8]SUN FS(孙福山).Research on relation-ship of tobacco quality with tempera-ture,humidity,and yellowing degree(烤烟变黄期温湿度、变黄程度与烟叶品质关系研究)[J].Tobacco Science and Technology(烟草科技),1991(4):39-42.

Responsible editor:Xiaoxue WANG

Responsible proofreader:Xiaoyan WU

醇基燃料密集烘烤应用效果初报

詹吉平*,杜超凡,卢雨,姜林荣 (福建省烟草公司龙岩市公司,福建龙岩364000)

研究了醇基燃料密集烘烤的应用效果,结果表明:使用醇基燃料进行烟叶烘烤,温度调控性灵敏、供热效果好,烤后叶片更柔软,油份更足,颜色橘黄鲜亮,上等烟比例提高5.23%,单叶重增加0.13 g,单炕扣除能耗成本后产值增加188.66元,其还原糖及钾的含量在优质烟适宜范围内有所增加,内在化学成分更为适宜和协调。

烤烟;醇基燃料;密集烘烤;应用效果

福建省龙岩市烟草公司科技项目(2014-18)。

詹吉平(1979-),男,福建龙岩人,硕士,主要从事烤烟生产与烟叶烘烤技术研究工作。*通讯作者,E-mail:zhanjp9811022@126. com。

2015-08-06

Supported by Longyan Tobacco Company S&T Project(2014-18).

*Corresponding author.E-mail:zhanjp9811022@126.com

Received:August 6,2015 Accepted:September 16,2015

修回日期 2015-09-16

Agricultural Science & Technology2015年10期

Agricultural Science & Technology2015年10期

- Agricultural Science & Technology的其它文章

- Effects of Different Light Emitting Diodes on Growth and Quality of Lettuce

- Analysis on Carotenoids Content and Other Quality Traits of 185 Wheat Varieties

- Extraction and Structure Elucidation of Phenols from Dendrobium thyrsiflorum

- lnfluences of Different Habitats on Asexual Propagation of Wild Gastrodia elata f.glauca being Domesticated in Ganzi

- Breeding and Evaluation of New lron Yam(Dioscorea opposita Thunb)Varieties

- Evaluation on ldeal Test Sites and Regional Characteristics of Cotton Fiber Quality in Jiangsu Province