Ultrafiltration of Shiitake Polyphenol with Ultrasound Enhancement

Defang SHl,Hong GAO,Xiuzhi FAN,De YANG,Shujing XUE,Wei CHENG

Agricultural Products Processing Subcenter of Hubei Agricultural Science&Technology Innovation Center,Research Institute of Agricultural Products Processing and Nuclear-Agricultural Technology,Hubei Academy of Agricultural Sciences,Wuhan 430064,China

Ultrafiltration of Shiitake Polyphenol with Ultrasound Enhancement

Defang SHl,Hong GAO,Xiuzhi FAN,De YANG,Shujing XUE,Wei CHENG*

Agricultural Products Processing Subcenter of Hubei Agricultural Science&Technology Innovation Center,Research Institute of Agricultural Products Processing and Nuclear-Agricultural Technology,Hubei Academy of Agricultural Sciences,Wuhan 430064,China

Ultrafiltration(UF)experiments were subjected to the concentration of Shi-itake polyphenol(SP)with ultrasound(US)enhancement,by which the effects of the main parameters such as ultrasonic power,transmembrane pressure,temperature and axial flow-rate on the membrane fluxes were analyzed,and then the SP of the ultrafiltrate after follow-up resin adsorption by HPLC was investigated.The results in-dicated that US could significantly enhance the membrane fluxes.The optimal con-ditions obtained was as follows:0.60 W/cm2US power,axial flow-rate of 80 L/h,operation temperature 30℃,transmembrane pressure 0.10 MPa.US increased the absorption capacity of the absorbent resin during the following stage.The HPLC analysis also showed that catechins were purified to some extent as the ultrafiltrate was treated by US and macroporous resin,indicating the technology of US en-hancement coupled with UF showed the potential for concentration and purification of SP by absorbent resins.

Shiitake;Ultrafiltration;Ultrasound

I n recent year,with increasing at-tention to the issue of food quality and safety,scholars at home and abroad tend to search for efficient free radical scavenger from natural plant resources than before[1].Polyphenolic compounds have been used as a kind of natural products with special physi-ological and pharmacological activi-ties,which becomes the focus of re-search gradually and is widely used in a large range of applications such as in foods,medicine,cosmetics etc[2-4].

Shiitake is a kind of important mushroom,abounds in resources in China,commonly used as the materi-al in food manufacturing,which ex-hibits a wide range of biological and physiological properties due to their a-bility to act as antioxidants,free radical scavengers and antibacterial agent.It is necessary for us to extract natural polyphenol from the massive shiitake to produce a variety of antioxidants. Therefore,the efforts will have great value of application and social bene-fits.

As a fast and efficient separation-enrichment technology,US enhance-ment of UF has been applied and de-veloped in practice,the main advan-tage of which is to do not affect the sensory properties and the activity of the biological compounds,in addition holding the characteristic of overcom-ing the membrane fouling and en-hance UF process[5-7].

Although utilization value of shi-itake has been paid much attention with the expectation,it is seldom men-tioned in the industry of large-scale of extracting from shiitake.For these and many other reasons,the objective of this study was to investigate ultra-sound effect in the UF process to over-come the disadvantage of large molec-ular impurities interference in the pro-cess of purification and extraction with macroporous adsorption resin,improv-ing the purity of product.

Material and Methods

Plant materials

Shiitake:obtained from Hubei YUGUO GUYE Co.,Ltd.,Shuizhou city,Hubei Province,China.

UF with US enhancement

SP extract was prepared accord-ing to the technology described previ-ously[8],ethanol in which was recov-ered by rotary evaporator,the concen-trated solution was treated by Microfil-tration(MF)&UF in sequence,finally resin purification of ultrafiltrate ad-sorption was analysised by HPLC.Ul-trasonic vibration rod inserted can di-rectly affect the liquid in the chamber,as is showed in Fig.1.

Analysis method

The polyphenol content was mea-sured by Folin-Ciocalteau method[9].

Treatment of macroporous resin

Chromatographic column (2.6× 30.0 cm)filled with 30 mL DM-301 pretreated macroporous resin was washed to make it adsorption equilibri-um,column condition as follows:flow rate:2 BV/h(1 BV=30 ml),initial con-centration:3.2 mg/ml,load solution volume:200 ml,load solution PH:3.0,contentoftransudate obtained by fraction collector was measured to draw dynamic adsorption curve using load solution volume as the abscissa,content of transudate as the ordinate.

HPLC analysis

The SP was analyzed by HPLC. Pretreatment:0.010 0 g of the sample was dissolved by deion water in 50℃added in volumetric flask and then cooled to room temperature in 10 ml,subsequently it was filtered off theprecipitate by 0.45 μm fiber mem-brane.Determination:10 ml of sample filtered by microporous membrane was injected into the HPLC system. Separation of polyphenolic com-pounds was performed using a stain-less-steel column (250×4.6 mm I.D.)packed with C18 Altima,5 μm(Alltech,USA)equipped with a pre-column(7.5×4.6mm I.D.)and a solvent system of acetonitrile (ACN)/water plus 2% acetic acid gradient starting at 8%and ending at 31%ACN concentration. Polyphenol peaks were detected at 280 nm (PE-200 UV/VIS detector). Polyphenol were identified by compar-ing theirUV spectra and retention times with those of standards.

Statistical analysis

All experiments were performed in triplicates.

Results and Discussion

Effect of US power on UF process.

The effect of US powers on the UF process was studied first.Fig.2 shows the performances of membrane fluxes for SP extract over time with dif-ferent ultrasonic powers.The experi-ments were performed for 0.32%SP extract with a flow rate of 80 L/h at 0.1 Mpa and 30℃.The results indicated the membrane fluxes all decrease with time during UF,while with the increase of power,the fluxes was increased at different levels,further it can be drawn that US does not alter the basics mod-el of the UF because the trends of the fluxes performance for US-enhanced experiments were similar with that without US-enhanced.This result is to be expected given 0.60 W/cm2power levels used in this experiment.

Effect of transmembrane pressure(TMP)on UF process.

TMP is one important factor in the US-enhanced UF process. Fig.3 showed that membrane fluxes in-creased with increase of pressure,whereas the fluxes presented the de-scent tendency with the time going. The experiments were performed for 0.32%SP extract with a flow rate of 80 L/h at 0.60 W/cm2and 30℃.In the initial period for about 40 min,the flux-es decreased rapidly,which was con-sidered to be a typical process of cake formation,but in the late process the fluxes didn't change distinctly espe-cially when pressure reached above 0.10 MPa.Similar behavior of pres-sure difference characteristics curves was observed in the study of concen-trated difference polarization model generally accepted[10].Synthetically co-nsidered it was suitable to select 0.10 Mpa pressure and to avoid causing damaged membrane by even greater pressure.

Effect of temperature on UF pro-cess

Temperature was confirmed to be an important factor in the US en-hancedUFprocess[11].Theexperiments were performed for 0.32%SP extract with a flow rate of 80 L/h at 0.60 W/cm2and 0.1 Mpa.Fig.4 showed the mem-brane fluxes of SP extract in the range of 30-40℃was much higher than that in 20℃.These differences could be linked to the fact that the lower viscos-ity of the extract would be favor to the outstanding of variation degree of axial velocity along radius distribution be-cause of temperature increasing,thus the materialspresented turbulence status,which gave rise to the en-hanced ability of separation and mass transfer, whereas the increased amountsofmembrane fluxesbe-comed very slow,this phenomenon could attribute to membrane fouling by strengthening of membrane surface adsorption with temperature increas-ing.Therefore,the temperature at 30℃is an optimal value.

Effect of axial flow-rate on UF pro-cess

At first,it was necessary to select appropriate initial concentration in the extract,because the bigger concen-tration gradient made membrane flux-es rapid attenuation,early forming concentrated difference polarization phenomenon,thus leading to pore fouling.During the normal operation,the filtration resistances would be de-termined by fouling mainly composed of pore blocking and gel layer forma-tion.Therefore the initial concentration in the extract was determined to reach 0.32%level in this study.Secondly,it was an effective way to improve axial flow-rate that making the material sta-tus achieve vortex flows,which re-duced the boundary of layer thick,be-cause axial flow-rate played a major part within Reynolds numbers and fluid flow structures.However,according to Reynolds formula comprehensively considered US effect,only when axial flow-rate was beyond 60 L/h could vortex flows existed,vortex flows be-came gradually until constant on con- dition that axial flow-rate reached 80 L/h,as was illustrated in Figure 5.In the test,which were performed for 0.32%SP extract with 30℃ at 0.60 W/cm2and 0.1 Mpa.It was reasonable for axial flow-rate of 80 L/h because the higher fluid velocity caused exces-sive energy consumption[12].

Effect of UF with US on technology of follow-up resin purification

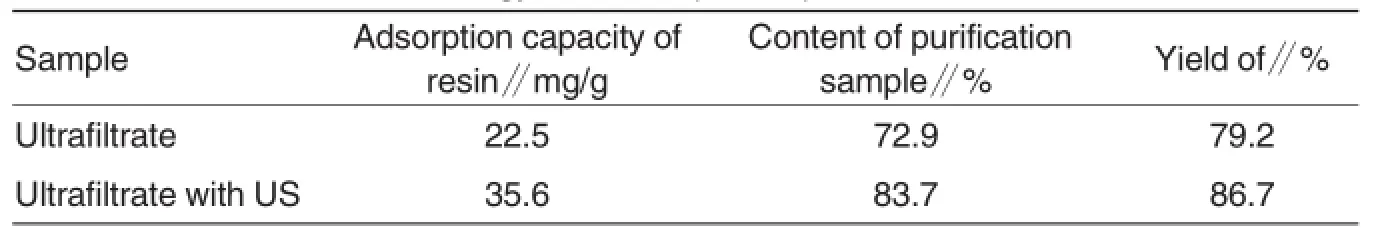

Fig.6 showed comparison of dy-namic adsorption curve of the ultrafil-trate treated by US or not and Table 1 indicated the change of main bio-chemical composition between both.It was found that leak point of ultrafiltrate treated by US was postponed com-pared with that of the ultrafiltrate with-out US.Concentration in transudate didn't reach 10%of sample solution until the elution volume arrived at more than 5 BV (1 BV=30 ml),at this time the absorption capacity of resin was 35.6 mg/g,which was higher than that of the ultrafiltrate without US.The pu-rity of the ultrafiltrate reached 83.7% treated by US and DM-301 resin in contrast to that of the ultrafiltrate only treated by DM-301 resin,purity was increased 10.8%,which was ascribed to ultrasonic energy,helping to dis-place the cake on the membrane struc-ture,in turn promoting fouling preven-tion and facilitating improved separa-tion rates[13].

HPLC analysis

Two kind of sample was prepared for HPLC analysis as follow:A:the ul-trafiltrate treated by US and macrop-orous resin,B:the ultrafiltrate only treated by macroporous resin.Fig.7& Fig.8 showed HPLC results of two kind of sample,indicating sample A con-tained fewer impurities than sample B. It was obvious that the use of US en-hancement was favorable for the ex-traction and its follow-up processes.

Table 1 Effect of US on technology of follow-up resin purification

Conclusion

Experimental results revealed that in the SP extract during the process of ultrafiltration process,US could signifi-cantly enhance the membrane fluxes and improve the purity of SP.The op-timal parameters were found to be 0.60 W/cm2US power,axial flow-rate of 80 L/h,operation temperature at 30℃,under a filtration pressure of 0.10 MPa when the initialconcentration was 3.2 mg/ml,and then,the follow-up resin purification ofthe ultrafiltrate was utilized to obtain SP,whichdemonstrated the technology of US enhancementcould effectively in-crease the absorption capacity of the absorbent resin during the following stage.Therefore the purity of the after resin adsorption reached 83.7%for the ultrafiltrate treated by US,compared to 72.9%for the ultrafiltrate without US. The HPLC chromatograms also showed that catechins were sufficient-ly purified and enriched with US,indi-cating the efficiency of UF with US en-hancement for purification of SP by absorbent resins.

[1]SUN J,YAO JY,HUANG SX,et al.An-tioxidant activity of polyphenol and an-thocyanin extracts from fruits of Kadsura coccinea(Lem.)A.C.Smith[J]. Food Chemistry,2009,117(2):276-281.

[2]ANDR S MOURE,JOSE M.CRUZ,DANIEL FRANCO,et al.Natural antiox-idants from residual sources[J].Food Chemistry,72(2001):145-171.

[3]GIAN CARLO TENORE,PIETRO CAM-PIGLIAB,PAOLA STIUSO,et al..Nu-traceutical potential of polyphenolic frac- tions from Annurca apple (M.pumila Miller cv Annurca).Special Issue:Food QualityEvaluation,Food Chemistry,2013,140(4):614-622.

[4]H TAPIERO,KD TEW,G NGUYEN BA,et al.Polyphenols:Do They Play A Role in the Prevention of Human Pathologies[J].Biomed Pharmacother,2002,56:200-207.

[5]MILICA RAMI,SENKA VIDOVI,ZORAN ZEKOVI,et al..Modeling and optimiza-tion of ultrasound-assisted extraction of polyphenolic compounds from Aronia melanocarpa by-products from filter-tea factory[J].Ultrasonics Sonochemistry,2015,23:360-368.

[6]HOBHA MUTHUKUMARANA,SAND-RA E.KENTISHA,GEOFFREY W. STEVENSA,et al.The application of ul-trasound to dairy ultrafiltration:The in-fluence of operating conditions[J].Jour-nal of Food Engineering,2007,81(2):364-373.

[7]SOHBHA MUTHUKUMARAN,SAND-RA E KENTISH,GEOFF W.STEVENS,et al.Application of ultrasound in mem-brane separation processes:A review[J].Reviews in Chemical Engineering,2006,22(3):155-194.

[8]LM CHEUNG,PETER CK CHEUNG,VINCENT EC OOI.Antioxidant activity and total phenolics of edible mushroom extracts[J].Food Chemistry,2003,81(2):249-255.

[9]SINGLETON VL,ORTHOFER R,LAM-UELA-RAVEMTOS RM.Analysis of to-tal phenols and other oxidation sub-strates and antioxidants by means of Folin-Ciocalteu reagent[J].Methods in Enzymology,1999,299(1):152-178.

[10]JONSSON,A.S.Ultrafiltration of col-loidal dispersions:A theoretical model of the concentration polarization phe-nomena[J].Journal of Colloid&Inter-face Science,1996,180(2):504-518.

[11]CAI M,ZHAO SN,LIANG HH.Mecha-nisms for the enhancement of ultrafil-tration and membrane cleaning by dif-ferent ultrasonic frequencies[J].De-salination 2010,263(1):133-138.

[12]COMPAGNER A,BERDNIKOV A S,TURTIA SB,et al.A numerical model of steady-state permeate fluxes during cross-flow ultrafiltration[J].Desalina-tion,1997,109(3):241-251.

[13]NOR FAIZAH RAZALI,ABDUL WA-HAB MOHAMMAD,NIDAL HILAL.Ef-fects of polyaniline nanoparticles in polyethersulfone ultrafiltration mem-branes:Fouling behaviours by differ-ent types of foulant[J].Journal of In-dustrial and Engineering Chemistry,2014,25(5):3134-3140.

Responsible editor:Xiaoxue WANG

Responsible proofreader:Xiaoyan WU

Cambridge Scientific Abstracts(CSA)

In 2011,Agricultural Science&Technology's full-texts have been included by Cambridge Scientific Abstracts(CSA).CSA is a retrieval system published by Cambridge Information Group.With a history of more than 30 years,the company is an important publisher of publishing abstracts and indexes with agent centers in Britain,France,Australia,Japan,Netherlands,New Zealand,and Hong Kong China.The products include traditional printed abstracting and indexing journals,a variety of electronic database which are retrieved through remote on-line and CD-ROM.Recently,the CSA launched network based (IDS)services,which can retrieve hundreds of databases provided by CSA and CSA publishing partners.

For more information on CSA Full Text please sign in http://www.csa.com/

Supported by Special Fund for Agro-scientific Research in the Public Interest(201303080),Hubei Agricultural Science&Technology Innovation Center Project(2014-620-007-001)and NaturalScience Foundation ofHubeiProvince ofChina(2013CFB053).

*Corresponding author.E-mail:xucheng288@sohu.com

Received:August 4,2015 Accepted:September 16,2015

Agricultural Science & Technology2015年10期

Agricultural Science & Technology2015年10期

- Agricultural Science & Technology的其它文章

- Effects of Different Light Emitting Diodes on Growth and Quality of Lettuce

- Analysis on Carotenoids Content and Other Quality Traits of 185 Wheat Varieties

- Extraction and Structure Elucidation of Phenols from Dendrobium thyrsiflorum

- lnfluences of Different Habitats on Asexual Propagation of Wild Gastrodia elata f.glauca being Domesticated in Ganzi

- Breeding and Evaluation of New lron Yam(Dioscorea opposita Thunb)Varieties

- Evaluation on ldeal Test Sites and Regional Characteristics of Cotton Fiber Quality in Jiangsu Province