Effect of pulse frequency on hardness characteristics of Al-Cu alloy HPVP-GTAW joints*

Ouyang Ruijie,Cong Baoqiang,Yang Mingxuan and Qi Bojin欧阳瑞洁,从保强,杨明轩,齐铂金**

Effect of pulse frequency on hardness characteristics of Al-Cu alloy HPVP-GTAW joints*

Ouyang Ruijie,Cong Baoqiang,Yang Mingxuan and Qi Bojin

欧阳瑞洁,从保强,杨明轩,齐铂金**

AA 2219-O Al-Cu alloy single bead weldswere obtained by hybrid ultrahigh frequency pulse variable polarity gas tungsten arc welding(HPVP-GTAW)process with pulse frequency varying from 25 kHz to 70 kHz.Weld hardness characteristicswhichmainly depicted bymicrohardnessand itsgradientwere investigated systematically.The resultsshow that pulse frequency has a greateffecton the hardness characteristics.Theweld zonemicrohardnessand its gradientwith different pulse frequency present an evident fluctuant trend.The fluctuation of gradient is slight,illustrating that themicrostructure is uniform with pulse frequency varied from 35 kHz to 60 kHz.The fusion zonemicrohardnessand itsgradient follow the similar trends but fluctuate greatly.Maximum value of gradient appears around the fusion boundary due to the coarse and nonuniform microstructure.Themaximum gradient at60 kHz is only 25.5%of that at45 kHz.According to the study,the best hardness characteristics are achieved at 60 kHz frequency.

high frequency pulse current,microhardness gradient,variable polarity gas tungsten arc welding,aluminum alloy

0 Introduction

Al-Cu heat-treatable alloys are extensively used in the aerospace industry due to its excellent physicaland chemical properties.Variable polarity gas tungsten arc welding (VP-GTAW)is generally employed in theweld fabrication of Al-Cu alloys[1-2].Hybrid ultrahigh frequency pulse VP-GTAW(HPVP-GTAW)is a novel high-quality welding process,which can eliminate the weld porosity,refine the weld grains and enhance themechanical properties effectively.Previous research revealed that pulse frequency had a significant effect on weld quality.Pulse frequency varied from 30 kHz to 60 kHz,tensile strength and ductility of welded joints were improved and weld metal structures were refined obviously[3-4].However,literature did not reveal detail studies on the influence of pulse frequency on weld hardness characteristicswhichmainly depicted bymicrohardness and its gradient.

The purpose of the present investigation is to study the hardness characteristics ofweld zone(WZ)and fusion zone(FZ)influenced by pulse frequency varied from 25 kHz to 70 kHz.The optimized pulse frequency was obtained for the better hardness characteristics,which is effective to ensure the weld quality in the practical application of HPVP-GTAW process.

1 Experimental procedure

The basematerial used in this study was 4 mm thick AA 2219-O alloy sheetswith a chemical composition of Cu 6.3,Mn 0.3,Si 0.2,Fe 0.3,Zr 0.18 and Al balance (all in wt.%).The filler wire used was AA 2319 alloy having a diameter of 2.4 mm with a chemical composition of Cu 6.3,Mn 0.3,Zr 0.175,Ti0.15,V 0.1 and Al balance(all in wt.%).The dimensions of the basematerial specimen were 120mm×60mm.Single bead welds were produced using HPVP-GTAW process.Prior towelding,the base metal sheets were wiped with acetone thenpickled with a solution of 10%NaOH and 35%HNO3. The filler wire surface was also cleaned using the wire brush.

As shown in Fig.1,the duration of base and peak current is Tband Tp,respectively,deducing the pulse duty cycleδ=Tp/(Tb+Tp)and also fHcalculated by 1/(Tb+Tp)stands for pulse frequency.In this study,fHis considered with an interval of 5 kHz in the range of 25 kHz to 70 kHz,totally ten levels,corresponding sample No.1 to No.10.Other process parameters were given as follows:base current Ibof60 A,peak current Ipof130 A,variable polarity frequency of 0.1 kHz,ratio of positive duration tPto negative duration tNof 4∶1,negative polarity current INof 150 A,pulse durationδof 50%,arc length of 3 mm,welding speed of 0.15 m/min,pure argon as shielding gas flow rate of 15 L/min,wire feed speed of 0.225m/min,the electrodematerialW-2%Cewith diameter of 2.4 mm.

Fig.1 Schematic diagram of welding cur rent waveform

Cross sections were cut along transverse direction. The sampleswere polished using a standard metallographic procedure,which consisted of grinding followed by polishing and etching with the standard Keller's reagent solution(5 mL HNO3,3 mL HCl,2 mL HF and 190 mL H2O).Microstructure was observed and recorded using an opticalmicroscopy(BX51M).Microhardness tests were carried outwith a load of 1.96 N and duration of 15 s using a Vickers digital hardness tester(DHV-1000).

The details of hardness test and its gradient calculation are described as follows.A coordinate system in WZ was established as shown in Fig.2a with the weld center point as origin.According to the actual weld width and depth,the test points were setwith an intervalΔd of 0.2 mm along the x-axis positive direction(horizontal)in the range of0 to2mm and the y-axis positive and negative direction(vertical)in the range of-1 mm to 1 mm,respectively.Microhardness gradient G was calculated using the formula G=|ΔHV/Δd|.A new coordinate system in FZ was also established as shown in Fig.2b,with the intersection of fusion boundary and x-axis as origin.The testwas done with an interval of 0.2 mm along the x-axis in the range of-0.6mm to 0.6mm and its gradientwas also obtained.

Fig.2 Schematic sketch ofMicrohardnessmeasurement

2 Results and discussion

2.1Microhardness characteristics in weld zone

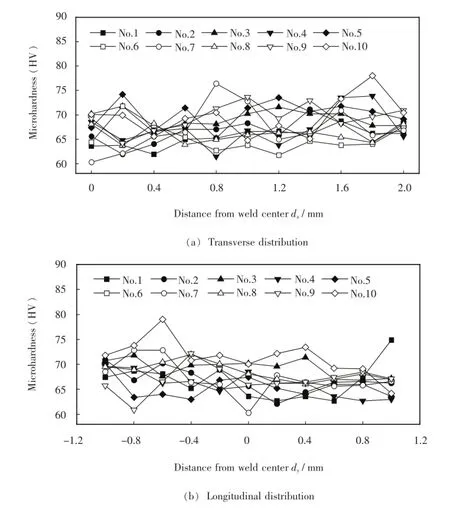

Fig.3 illustrates the microhardness distribution along transverse and longitudinal directions in WZ with variation in pulse frequency,respectively.The average valueswere calculated to be in the range of 65 HV to 70 HV for per pulse frequency,which indicated that pulse frequency hadonly limit effect on the microhardness enhancement in the weld central region.However,there is a certain degree of fluctuation for each pulse frequency.Themaximum values of samples No.7 and No.10 are 20%greater than the minimum values,respectively.It is revealed that the structure uniformity in weld centre is affected by pulse frequency,resulting in the larger difference inmicrohardness and its gradient.

Fig.3 Microhardness distribution in WZ

The transverse G inWZwith differentpulse frequency is shown in Fig.4.It is discerned that the most gradients are less than 30 HV/mm and the larger gradient is produced around the boundary ofmixingmicrostructure.The weld microstructure uniformity can be reflected by the variation of G. The smaller gradient can be obtained from the better uniform microstructure.As shown in the figure,for samples No.4,No.7 and No.10,the fluctuation range of gradient is large,whichmeans the structure uniformity is also poor.

The longitudinal G in WZ is given in Fig.5.It is evident that the gradients fluctuate largely around and below the center region of WZ for samples No.7 and No.10,which means that the microstructure uniformity is poor. The other values which greater than 30 HV/mm appear just near the bottom ofWZ.Meanwhile,the overall gradient ofweld central region has a certain degree of fluctuation and it is larger for 55 kHz and 70 kHz.The gradient of samples No.3 and No.8 in transverse and longitudinal directions fluctuates slightly and it is deduced that themicrostructures in weld central region aremore uniform,re-sulting in optimum hardness characteristics.

Fig.4 Transverse G distribution in WZ

Fig.5 Longitudinal G distribution in WZ

Fig.6 Microstructure in WZ

Opticalmicrographs of weld metal for some samples are shown in Fig.6.A mixture of fine equiaxed non-den-drite grains and coarse equiaxed dendrite grains was observed with the action of pulsed arc.As shown in Fig.4 and Fig.5,the G of samples No.3 and No.8 in the two directions both change slightly.According to the corresponding weld metal structures as shown in Fig.6a and Fig.6b,the grains are significantly refined with 35 kHz and 60 kHz frequency and the finer grains distribute uniform ly among the weld centre.In contrast,the G of samples No.7 and No.10 in the two directions fluctuate largely.It can be seen from Fig.6c and Fig.6d that finer equiaxed grains are observed distributing within the equiaxed dendrites,resulting in the poor uniformity.

2.2Microhardness characteristics in fusion zone

Fig.7 illustrates the Microhardness distribution in FZ with different pulse frequency.It is evident that the trends ofmicrohardness in FZ are similar for each pulse frequency.The maximum for the region close to WZ is less than 80 HV,while that for the region close to heat affected zone(HAZ)ismore than 90 HV.The G in FZ is shown in Fig.8.Maximum G for samp le No.5 is 107.5 HV/mm,and that for No.8 is only 27.4 HV/ mm.It can be explained that the hardness characteristics in FZ has a close relationship with its Microstructure,which presents a poor uniformity due to the transition from coarse columnar grains to partially melting grainswith severe solute segregation,then resulting in the obvious fluctuation of G.

Fig.7 Microhardness distribution in FZ

2.3 Discussion

Weld hardness characteristics have a close relationship with the weld structure.Previous literature had proved that in the HPVP-GTAW process for aluminum alloy,ultrahigh pulse electromagnetic field was generated in the weld pool with themodulation of high frequency pulse current[5].Influenced by the external arc force and contribution from the internal induced electromagnetic force,a strong and complex flow formeltingmetal in weld poolwas produced[6].The grain structurewas predominantly affected by the flow state ofmelting metal.With the enhancement of metal flowing,an even heat distribution in weld pool was promoted and a greater extent of constitutional supercooling in front of solidification interface was also produced[7].According to prior study,cellular dendrite and dendritic solidification interface could be used as high efficiency heterogeneous nucleation particles to promote the process of heterogeneous nucleation,which was responsible for transforming from coarse dendrite grains to fine equiaxed grains and improving the structure uniformity[8-9].The actual results revealed thatmicrostructure in the central region of WZ mainly consist of fine equiaxed non-dendrite grains and equiaxed dendrite grains,which alternately distribute throughout the region[10].Themicrohardness in WZ fluctuated ata certain level just due to the effective refinement of weld metal.

FZ is a transition area between WZ and HAZ with narrow width and heterogeneous structure.In this zone,microstructure at the area close to WZ mainly consists of coarse columnar grains,while the other area close to HAZ is partiallymelted zone(PMZ).Severe solute segregation occurs in the PMZ,then resulting in a weakmicrostructure and poor properties[11].Due to the variation in FZ,the microstructure uniformity is very poor then leading to the obvious fluctuation ofmicrohardness and its gradient.

Fig.8 G distribution in FZ

3 Conclusions

(1)Pulse frequency influences the microhardness and its gradient in the central region of AA 2219-O alloy welded joints.The gradient fluctuates slightly with pulse frequency of 35 kHz and 60 kHz.

(2)Themicrohardness and its gradient in the fusion zone of AA 2219-O alloy welded joints have great fluctuation influenced by pulse current frequency.Themaximum value of gradient at 60 kHz is only 25.5%of that at 45 kHz.

(3)The optimized pulse frequency of 60 kHz is suitable for AA 2219-O alloy HPVP-GTAW process.

References

[1] Fang C F,Yu JJ,Chen S J,et al.Effects of VPTIG welding current parameters on arc shape and weld quality.Transactions of the ChinaWelding Institution,2007,28(12):21-25.(in Chinese)

[2] Qiu L,Yang C L,Lin SB,et al.Effect of pulse current on microstructure and mechanical properties of variable polarity arc weld bead of2219-T6 aluminium alloy.Materials Science and Technology,2009,25(6):739-742.

[3] Cong B Q.Research on ultrafast-convert hybrid ultrasonic pulse VPTIG arc welding technique for high strength aluminum alloy.Beijing:Beihang University,2009.(in Chinese)

[4] Cong B Q,Qi B J,Li W,et al.Effect of pulse current frequency on microstructure and mechanical properties of 2219 aluminum alloy weld joints.Transactions of the ChinaWelding Institution,2010,31(9):37-40.(in Chinese)

[5] Cong BQ,Qi B J,LiW,et al.A novel ultrafast-convert hybrid pulse square-wave VP-GTAW process for aluminum alloys.ChinaWelding,2010,19(2):32-36.

[6] Ando K,Hasegawa M.The phenomena of welding arc.Beijing:China Machine Press,1985.(in Chinese)

[7] Kostrivas A,Lippold JC.A method for studying weld fusion boundary microstructure evolution in aluminum alloys.Welding Journal,2000,79(1):1s-8s.

[8] Kou S,Le Y.Welding parameters and the grain structure of weld metal-a thermodynamic consideration.Metallurgical Transaction A,1988,19(4):1075-1082.

[9] Dvornak M J,Frost R H,Olson D L.Influence of solidification kinetics on aluminum weld grain refinement.Welding Journal,1991,70(10):271s-276s.

[10] Cong B Q,Qi B J,Zhou X G,et al.Influences of ultrasonic pulse square-wave current parameters on microstructures and mechanical properties of 2219 aluminum alloy weld joints.Acta Metallurgica Sinica,2009,45(9):1057-1062.(in Chinese)

[11] Huang C,Kou S.Partiallymelted zone in aluminum welds:Solute segregation and mechanical behavior.Welding Journal,2001,80(1):9s-17s.

*The research is supported by the National Natural Science Foundation of China(No.51005011);the Fundamental Research Funds for the Central Universities.

**Ouyang Ruijie,Cong Baoqiang,Yang Mingxuan and Qi Bojin,School of Mechanical Engineering and Automation,Beihang University,Beijing,100191. Cong Baoqiang,Corresponding author,E-mail:congbq@buaa.edu.cn

- China Welding的其它文章

- Stress-strain characteristics of linear friction welding of TC11 and TC17 alloys*

- Effects of C/B4C ratio on Microstructure and property of Fe-based alloy coatings reinforced w ith in situ synthesized TiB2-TiC*

- Effects of Bi and rare earth metal on theMicrostructure and properties of Zn-based high-tem perature solder*

- Numerical analysis of keyhole establishment time in keyhole p lasma arc welding*

- Automatic defect detection in ultrasonic TOFD D-scan data using image processing m ethods*

- Analysis of grain grow th in hybrid weld HAZ based on the coupled thermo-fluid model