M icrostructure and Mechanical Properties of Magnesium Alloy Sheet by Friction Heating Single Point Incremental Form ing

WANG Jin(王进),WANG Hai(王海),LILi-hua(李丽华),JIANG Hu-sen(姜虎森)

1 School of Mechanical Engineering,Qingdao Technological University,Qingdao 266033,China

2 College of Electromechanical Engineering,Qingdao University of Science and Technology,Qingdao 266061,China

M icrostructure and Mechanical Properties of Magnesium Alloy Sheet by Friction Heating Single Point Incremental Form ing

WANG Jin(王进)1*,WANG Hai(王海)1,LILi-hua(李丽华)2,JIANG Hu-sen(姜虎森)1

1 School of Mechanical Engineering,Qingdao Technological University,Qingdao 266033,China

2 College of Electromechanical Engineering,Qingdao University of Science and Technology,Qingdao 266061,China

By friction heating single point incremental form ing,truncated square pyram id parts with different draw angles of a magnesium alloy AZ31B were formed at room tem perature.M etallurgical,tensile and m icro-hardness tests were carried out to obtain the effects of wall angle on m icrostructure and mechanical properties.The results show that grain in side wall of the formed parts becomes refined significantly.Furthermore,with the increase of draw angle,grain size increases,but strength,hardness and p lasticity decrease.In addition,surface roughness tests were performed on the formed surface to determ ine the influence of speed of form ing tool.The results show that surface roughness has a little increase with the increase of tool rotational speed.

friction heating;single point incremental forming;AZ31B; mechanical property

Introduction

Single point incremental forming(SPIF)is an attractive technology which has no die and is particularly suitable for production of sheetmetal parts in small batches[13].Complex sheetmetal parts can be formed on a commonmachining center or a specialized incremental form ing device by SPIF.With the development of aircraft and automobile industries,hard-to-form materials such asmagnesium alloy and titanium alloy that have poor formability attractmore andmore attentions.Heating SPIF process is always used to form sheet of hard-to-work materials.The common heating methods consist of laser heating[4],halogen lamp heating[5],heater band heating[6],electric heating[7-10],and friction heating[1113].Among them,friction heating SPIF,in which the heat is from the friction between forming tool with high rotational speed and sheetmetal,has a strong attraction because the method does not require an additional heating source.By controlling the rotational speed,feed speed,and vertical pitch of the form ing tool,sheetof hardto-form materials can be formed at room temperature.

So far,the studies on friction heating SPIF processes are still little.Durante et al.[14]indicated temperature and surface roughness of AA7050-T0 aluminum alloy sheet decreased as rotational speed of forming tool increased inthe speed range of0 -600 r/m in.Park et al.[13]formed box-shaped parts of magnesium alloy AZ31 sheetswith wall angles of 45°and 60° at room temperature by rotational incremental forming,and calculated the incremental forming limit curve(FLC)that can be used in prediction for failure of the sheet in forming process.Buffa et al.[12]analyzed the effect of sheet temperature rise caused by friction on formability of AA1050- O,AA1050- H24,and AA6082- T6 aluminum alloy in SPIF.The results showed thatmaximum wall angle increase of 7.5°,10°and 12.5°for the three materials were achieved in forming conical frusta parts,compared with the SPIFwithout tool rotation,and rise of temperature led to dynam ic recrystallization and improved the formability of the formed sheet.Xu et al.[11]studied the effect of tool rotational speed on AA5053- H32 alum inum alloy sheet in the range of 0- 7 000 r/min.Their research showed thatwith the increase of the rotational speed,the sheet metal had a significant increase in formability,but forming force had a noticeable decrease.They also found that temperatures of the experimental sheetswere above 150℃when the tool rotational speed was in the range of 3 000- 7 000 r/min,and material dynam ic recrystallization occured.

For the formed metal parts,people always concern about their m icrostructure and performance.However,studies about microstructure and mechanical properties of parts formed by friction heating SPIF are little,especially formagnesium alloy.The aim of this paper was to research the m icrostructure and mechanical properties of magnesium alloy sheet parts after friction heating SPIF process,and focused on the effects of wall angle.In addition,the effectof tool rotational speed on surface quality of the formed partwas analyzed.

1 Experimental Procedure

The material used in the present research was AZ31B magnesium alloy with 1.3 mm thickness.The initial sheet was cut into 150 mm×150 mm square test samples which were formed to truncated square pyramid parts with wall angles of 30°,45°and 60°,respectively,and opening side of 112 mm.Forming process parameters except rotational speed of the tool were shown in Table 1.The hemisphere-shaped tool with a diameter of 12 mm was selected in all SPIF experiments.The rotational speed of the forming tool was 4 500 r/min which could generate enough friction heat to form AZ31B parts with differentwall angles at room temperature.Lubricant is the key to form AZ31B at room temperature,which should ensure the forming process avoids milling and the formed part has good surface quality.Through a variety of experiments of lubricants,a high-temperature lithium grease could meet the demand and was used for all experiments.

After forming,test samples were cut from the side deformation zone and the non-deformation zone at the bottom of the parts by w ire-electrode cutting,which were used for metallographic observation,tensile tests and hardness tests.Metallographic observation samples were ground by abrasive paper for metallograph,polished,and etched for 20 s in a mixed solution(100 m L ethanol+6 g picric acid+5 m L acetic acid+10 m L pure water)in turn,and then observed and photographed by an optical m icroscopy.Figure 1 shows the sketch of the sample for tensile test,in which R1 represents that the fillet radius of the tensile sample is 1 mm.WDW300KN electronic universal testing machine was used for tensile tests with a speed of 0.5 mm/min.FM-700-type m icro-hardness tester was employed to test at twelve locations on each sample for micro-hardness tests.For comparison,experiments werealso carried out on samples thatwere cut from original sheet.

Fig.1 Sketch of the sample for tensile test(unit:mm)

In order to analyze the effect of tool rotational speed on surface roughness of the formed parts,truncated square pyramid partswith draw angle of 40°were formed using tool rotational speeds of 3 000,4 000 and 5000 r/m in,respectively.Other process parameters were selected and also shown in Table 1.The roughness tester TR100 was employed to test the formed surfaces.

Table 1 Process parameters selectedin SPIF

2 Results and Discussion

2.1 Formed parts and microstructure

Figure 2 shows the formed square pyramid parts of magnesium alloy AZ31B with different draw angles of 30°,45° and 60°,respectively.The depth of the 30°part is32 mm,and the others are 40 mm.All parts did not fracture in SPIF process.

Fig.2 The formed AZ31B parts

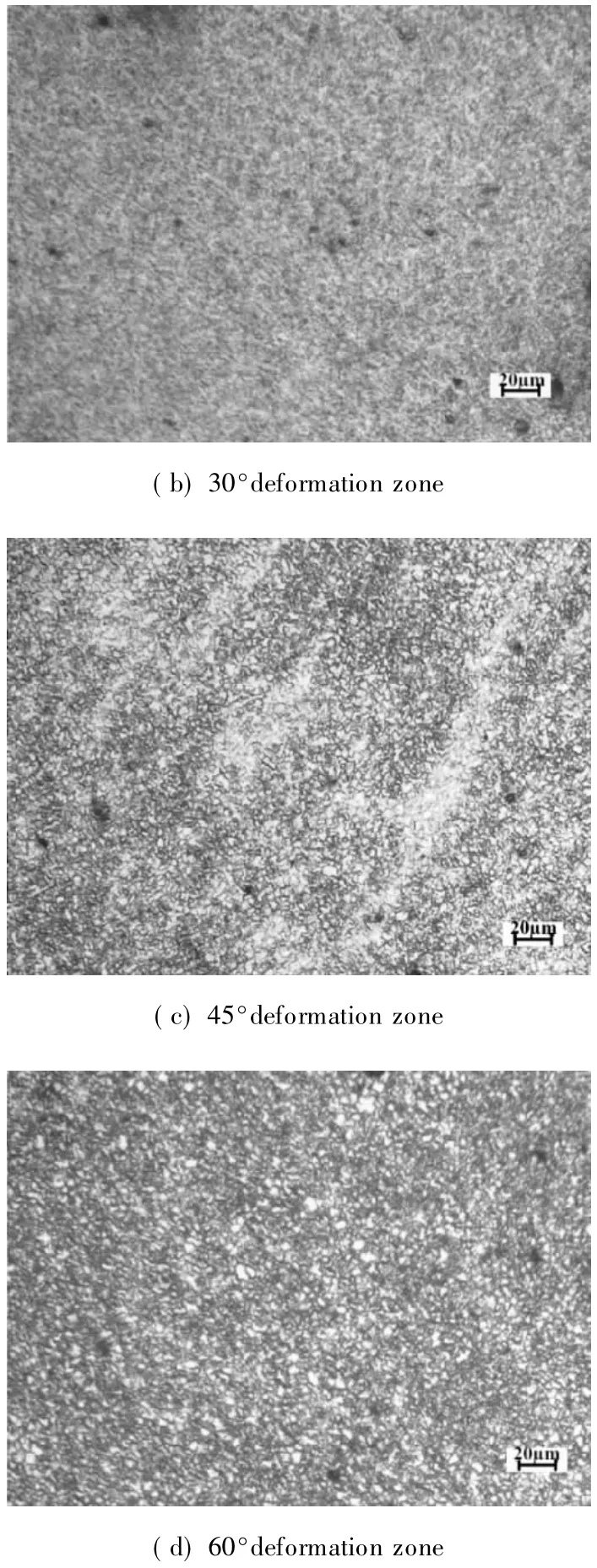

Respectively,the metallographic photos for the original sheet and the deformation zone at the location of sides of the formed 30°,45°and 60°parts are shown in Fig.3.Grain size of the original sheetwas about10.6μm(shown in Fig.3(a)),and the grains in sides of the formed parts were significantly refined.with the increase of draw angle,grain size increases.Among the formed parts,grain size of the 30°part was about 2.1μm(as in Fig.3(b)),and grain sizes of the 45°and 60° partswere about3.6μm and 4.7μm,respectively(as in Figs.3(c)and(d)).The reason of significant refinement of grain after deformationmay be due to dynamic recrystallization inside the deformed sheet.In SPIF with high rotational speed of tool,the contact area between tool and sheet is small,leading to high contact pressure.Thismay bring about high shear deformation along the rotational direction of tool to the surface of sheetat the contact area.After forming,initial grains are replaced by dynam ic recrystallization grains.Occurrence of dynamic recrystallization is determined by deformation,and dynamic recrystallization grain size is determ ined by deformation temperature and strain rate[15].High shear deformation makes occurrence of dynamic recrystallization ata low temperature.In the present experiments,low temperature of dynamic recrystallizaiton and high shear deformation rate led to very fine grain.As deformation temperature increases or strain rate decreases,grain size increases.In forming the three parts with different draw angles,deformation strain rates were not significantly different because of the same tool rotational speed and feed speed.Because draw angles of the parts are different,contact areas between the tools and the sheets are different.As contact area enlarges,more frictional heat could be generated per unit time,and temperature of formed sheet was higher.Therefore,grain size of the 60°part at deformation zone was bigger.

Fig.3 Metallographic photos of original sheet and formed parts

Figure 4 shows themetallography of non-deformation zone at the bottom of the formed 60°part.Comparing with Fig.3 (a),there has no significant difference between them in grain size.This is because the frictional heat actsmainly on contact area between sheet and tool,and temperature rise at bottom of sheet is not significant.Therefore,dynamic recrystallization did not occur at bottom of sheet,leading to unchanged grain there.

Fig.4 Metallography of 60°non-deformation zone

2.2 M echanical property

Figure 5 shows the results of tensile tests.The original AZ31B sheet has the tensile strength of 278 MPa and the maximum elongation of 22.2%,which is the indicator of plasticity ofmaterial.Comparing with the original sheetmetal,strength of the side walls of the formed parts ascended significantly.Among them,the strength of the 30°part increasedmost significantly,which was 325 MPa and increased by 17%compared with the original sheetmetal.In addition,the strength of the 30°partwas higher than those of the 45°and 60°parts.According to Hall-Petch relationship[16],finer grain material has higher strength,so the deformation zone of the 30° part has the highest strength because of the finest grain.However,Fig.5 also shows that the plasticity of the original sheet is better than those of the deformed sheets,and plasticity of experimental sheets decreases with the increase of draw angle.This may be due to the influence of thickness of samples.The samples for tensile tests were cut from side walls of the formed parts and the original sheet.Thickness of them decreaseswith the increase of draw angle.Sampleswith thinner thicknesses are easier to fracture in tensile tests.So plasticity of the original sheetwas themaximum in all tensile tests,and with the increase of draw angle,plasticity of the formed parts decreased.From tensile strength(Rm)and elongation(A)as shown in Fig.6,the same rule could be obtained.

Fig.5 True stress vs.true strain curves

Fig.6 Strength and elongation of the test sample

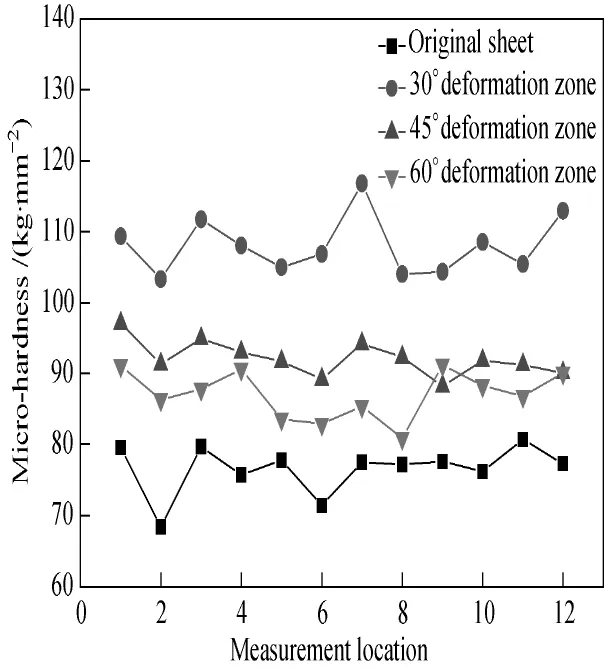

As shown in Fig.7,micro-hardness test results show the same tendency as strength in Fig.6.Hardnesses of the formed parts are larger than that of the original sheetmetal,and with the increase of draw angle,micro-hardness decreases.

Fig.7 M icro-hardness of original sheet and the formed parts

2.3 Surface roughness

Internal surfaces of the frustum pyram id shapes formed by different rotational speeds are shown in Fig.8.All parts had no obviousmilled trace and did notshow“fish-scale pattern”like1 060 alum inum alloy formed in SPIF[17].Roughness of the parts formed with different rotational speeds are shown in Fig.9,which points out roughness increases from 0.34μm to 0.49μm as the tool rotational speed increased.This is due to tool rotational speed increases,Milling of sheet surface increases,resulting in increased roughness[13].However,in general,the increase of roughness is not significant.

Fig.8 Internal surface of the formed parts

Fig.9 Relationship between rotational speed and roughness

3 Conclusions

By friction heating single incremental forming,parts of frustum pyramid shape with different wall angles of AZ31B magnesium alloy were formed at room temperature.By metallographic and mechanical properties experiments,follow ingmain conclusions can be obtained.

(1)For the formed 30°,45°and 60°parts,material dynam ic recrystallization occurred in the deformation zone,resulting in significantgrain refinement.With wall angle of part increases,grain size in deformation zone increases.Otherw ise,grain size in the non-deformation zone such as the bottom of part keeps an original size.

(2)As form ing angle increases,strength,hardness and plasticity of parts in deformation zone decrease.Compared with original sheet,strength and hardness in deformation zone is higher,while elongation is lower.

(3)With the increase of tool rotational speed,roughness of contact surface of sheet has a little increase.

[1]Echrif S B M,Hrairi M.Research and Progress in Incremental Sheet Forming Processes[J].Materials and Manufacturing Processes,2011,26(11):1404-1414.

[2]Jesw iet J,M icari F,Hirt G,et al.Asymmetric Single Point Incremental Form ing of Sheet Metal[J].CIRP Annals-Manufacturing Technology,2005,54(2):88-114.[3]Araujo R,Teixeira P,Montanari L,et al.Single Point Incremental Form ing of a Facial Implant[J].Prosthetics and Orthotics International,2014,38(5):369-378.

[4]Duflou J R,Callebaut B,Verbert J,et al.Laser Assisted Incremental Form ing:Formability and Accuracy Improvement[J].CIRP Annals-Manufacturing Technology,2007,56(1): 273-276.

[5]Kim SW,Lee Y S,Kang S H,et al.Incremental Forming of Mg Alloy Sheet at Elevated Temperatures[J].Journal of Mechanical Science and Technology,2007,21(10):1518-1522.

[6]Ambrogio G,Filice L,Manco G.Warm Incremental Form ing of Magnesium Alloy AZ31[J].CIRP Annals-Manufacturing Technology,2008,57(1):257-260.

[7]Ambrogio G,Filice L,Gagliardi F.Formability of Lightweight Alloys by Hot Incremental Sheet Form ing[J].Materials and Design,2012,34:501-508.

[8]Fan G,Gao L,Hussain G,et al.Electric Hot Incremental Form ing:a Novel Technique[J].International Journal of Machine Tools and Manufacture,2008,48(15):1688-1692.

[9]Fan G Q,Gao L.Numerical Simulation and Experimental Investigation to Improve the Dimensional Accuracy in Electric Hot Incremental Form ing of Ti-6Al-4V Titanium Sheet[J]. International Journal of Advanced Manufacturing Technology,2014,72(5/6/7/8):1133-1141.

[10]Sy L V,Nam N T.Hot Incremental Forming of Magnesium and Alum inum Alloy Sheets by Using Direct Heating System[J]. Journal of Engineering Manufacture,2013,227(8):1099-1110.

[11]Xu D K,Wu W C,Malhotra R,et al.Mechanism Investigation for The Influence of Tool Rotation and Laser Surface Texturing (LST)on Formability in Single Point Incremental Forming[J]. International JournalofMachine Tools&Manufacture,2013,73: 37-46.

[12]Buffa G,Campanella D,Fratini L.On the Improvement of Material Formability in SPIF Operation through Tool Stirring Action[J].International Journal of Advanced Manufacturing Technology,2013,66(9/10/11/12):1343-1351.

[13]Park J,Kim J,Park N,et al.Study of Form ing Lim it for Rotational Incremental Sheet Form ing of Magnesium Alloy Sheet[J].Metallurgical and Materials Transactions A,2010,41(1): 97-105.

[14]Durante M,Form isano A,Langella A,et al.The Influence of Tool Rotation on an Incremental Form ing Process[J].Journal of Materials Processing Technology,2009,209(9):4621-4626.

[15]Sellars C M,Whiteman JA.Recrystallization and Grain Grow th in Hot Rolling[J].Metal Science,1979,13(3/4):187-194.

[16]Bata V,Pereloma E V.An Alternative Physical Explanation of the Hall-Petch Relation[J].Acta Materialia,2004,52(3):657-665.

[17]Jiang H S,Wang J,Wang T H,etal.Effectof Spindle Speed on Workpiece Surface Roughness in Single Point Incremental Forming[J].Forging&Stamping Technology,2011,36(3): 33-36.(in Chinese)

TG386.4

A

1672-5220(2015)04-0654-04

date:2015-01-04

National Natural Science Foundation of China(No.51205217)

*Correspondence should be addressed to WANG Jin,E-mail:jinwangqtech@163.com

Journal of Donghua University(English Edition)2015年4期

Journal of Donghua University(English Edition)2015年4期

- Journal of Donghua University(English Edition)的其它文章

- Empirical Analysis of Binary Logistic Model for the Influencing Factors of the Chinese Urban and Rural Residents'Woolen Products Consumption—Based on Questionnaires of 513 Urban and Rural Residents in 16 Provinces

- Analysis of Satisfaction with Business Cost in Shanghai Using Structural Equation Modeling Approach

- Ontology Mapping Based on Bayesian Network

- Diurnal and Seasonal Variations in Particulate Matter at Shanghai during the Heavy Haze and Non-haze Periods

- Swept-Volume Display System Based on Cylindrical Space Projection and Curved Reflectors

- Existence of Solutions for Infinity-Point Nonlinear Fractional Boundary Value Problem at Resonance