关门岩电站受油器故障分析及处理

李志坚(湖南澧水公司江垭水电站,湖南 慈利 427221)

关门岩电站受油器故障分析及处理

李志坚

(湖南澧水公司江垭水电站,湖南 慈利 427221)

摘要:受油器在灯泡贯流式机组中是一个非常重要的部件,直接影响着机组的大修周期及整个值班模式,本文具体分析了受油器常见故障的原因,重点分析了受油器中管摆度大的原因,并提出了很好的解决处理方案。

关键词:受油器;同心限位环;大轴内径最小点

受油器是灯泡贯流式机组的一个重要的部件,将静止的压力油传输到旋转的转轮轮毂内以推动桨叶开关,高压油在动静传递过程中的密封要求高,旋转密封是世界难题,何况水轮发电机组的旋转线速度大、振动摆度大且操作油压高。

1 受油器故障特征

关门岩电站位于湖南省慈利县,澧水一级支流娄水中下游,电站安装3台单机容量为11MW的灯泡贯流式机组,为已建成的江垭水利枢纽的反调节电站。三台机组于2007年全部投产发电,一直以来调速器压力油泵启动频繁,受油器漏油严重,浮动瓦容易磨损,每年必须更换浮动瓦,检查发现浮动瓦轴向方向出现许多深度约为0.1mm左右的环形沟槽和拉伤痕迹,浮动瓦的径向边也存在明显的摩擦痕迹,浮动瓦轴向和径向方向都存在偏磨的现象。

2 受油器结构

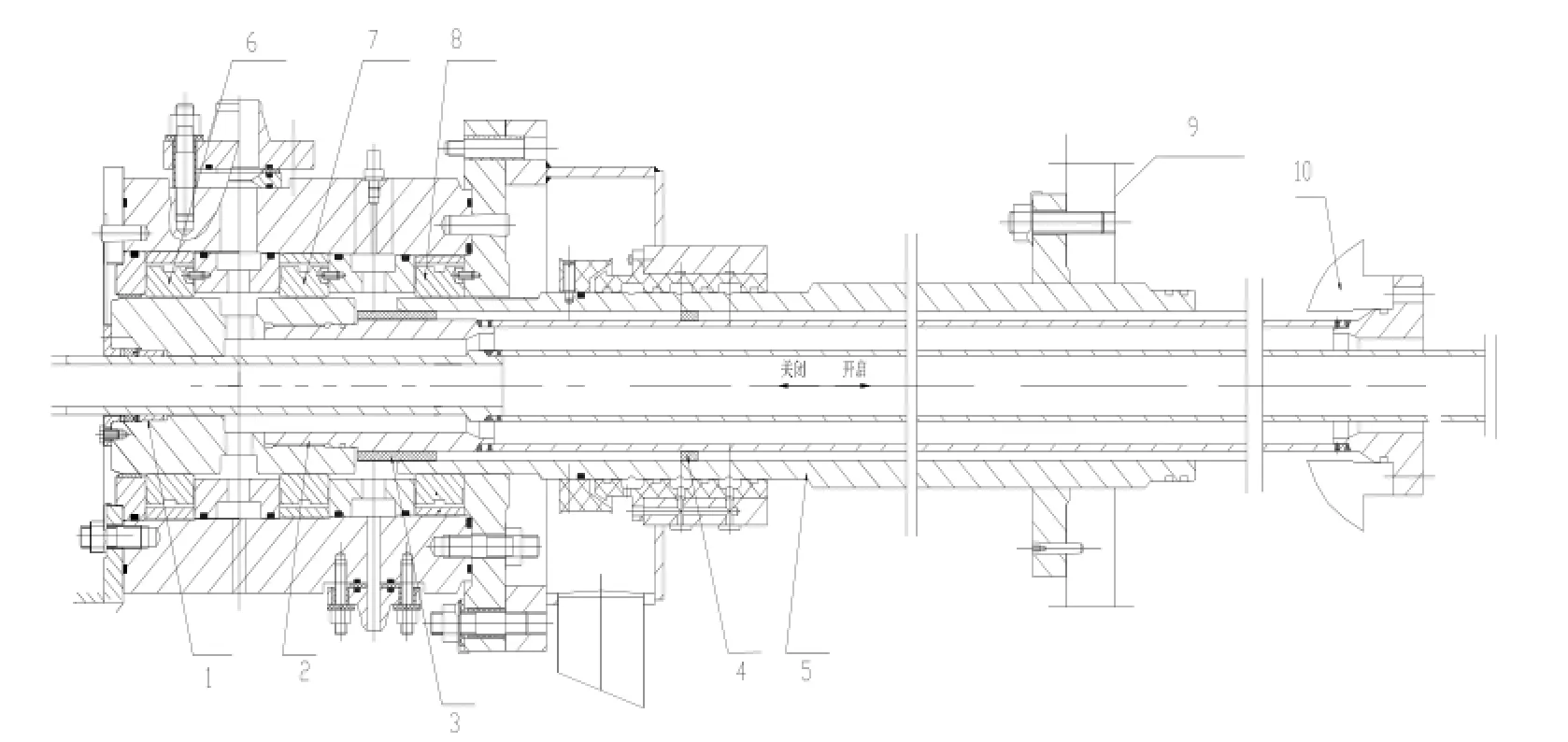

关门岩电站的受油器是一种比较典型的结构设计,由三块浮A、B、C动瓦形成两个密封压力油腔,操作油外管安装在转子中心体法兰上,中管套装在机组大轴和外管内腔,中管外壁上均布有8条60mm×12mm的滑块定位,保证中管和外管的同心度,导向头以螺纹(M130×4)的方式左旋入中管的端部(见下页图1)。

3 运行中存在的问题及分析

(1)调速器压力油泵启动频繁,浮动瓦运行时间2500h左右必须更换,每次检修发现浮动瓦磨损严重,浮动瓦与导向头及外管接触面上有许多深浅不一的划痕,且明显存在偏磨的现象,而且与导向头配合的B、C两块浮动瓦侧面磨损很严重,这说明浮动瓦在运行过程中径向摆度很大,中管与外管间隙较大,设计间隙为0.5mm左右,实际测量中管与外管间隙竟达到5mm左右,也许大家会认为这是安装的原因,其实有更深层次的原因,后面处理方案中有详细分析。

(2)与外管配合的A瓦也有许多划痕,实测外管摆度为0.08mm左右,摆度较好。这说明油质较差,管路安装过程中清理不干净。

(3)导向头端盖严重偏磨,每年必须换向或更换,这主要是导向头摆度过大引起,同时受油器外管与受油器本体不同心也有一定关系。

(4)桨叶接力器抽动,桨叶主配压阀配油频繁,这一般出现在浮动瓦运行时间快一年的时候。这说明主要也是浮动瓦漏油引起,同时桨叶接力器密封不好也会产生同样的后果。

4 处理措施

对受油器存在的问题进行分析,浮动瓦的磨损而引起密封不严漏油是故障的主要象征,其主要原因就是中管摆度过大,而油质不好、桨叶接力器密封不好、受油器同心度偏差等是次要原因。

4.1中管摆度过大处理

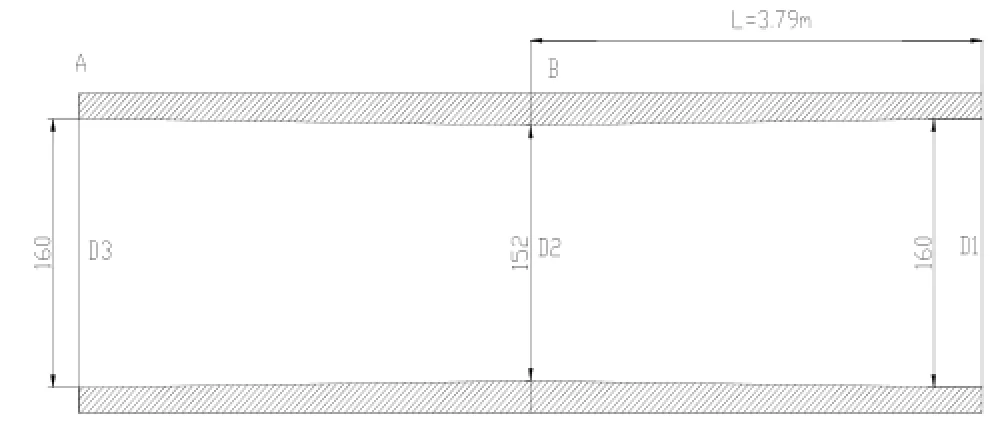

浮动瓦摆度过大主要是因为中管与外管间隙过大,我站实测单边间隙达到5mm左右,中管上有8条定位滑块以保证中管与外管的同心度,设计间隙为0.5mm,是否可以将外管上的定位滑块加大再与外管精细配合即可,实际操作根本不可行。机组大轴内孔内径呈现两头大中间小,呈喇叭口(如图2),D1=D3>D2,这主要是由于机组大轴内孔在加工过程中由于车床悬臂饶度引起内孔尺寸的不一致。

中管安装是由尾水管转轮处往大轴内插入,所以定位滑块外径最大不能超过D2,否则中管无法插入,这样中管与外管的单边最小间隙为(D3-D2)/2=4mm,无法达到厂家0.5mm的要求,所以单纯只增大定位滑块的尺寸是无法彻底解决中管与外管间隙过大的问题,这也是国内同类机组无法根除此问题的重要原因之一。

仅通过加大限位滑块的尺寸无法解决此问题,于是在外管圆周方向钻三个沉头定位螺栓来固定中管,第一台机组A级检修中按此方案实施,但实际效果不是令人很满意。此方案主要存在如下缺陷:1)在外管上钻孔攻丝,影响外管强度,定位螺栓调整完毕后必须用盖板焊接,容易产生焊接变形;2)不便于具体实施操作。首先中管与外管的同心定位没有合适的基准,同时每次调整定位螺栓会引起外管的盘车数据也发生改变,盘车时间长,盘车数据基准易变。开机运行后,出现过定位螺栓漏油的现象,外管摆度达到0.2mm左右(机组在线监测数据),并有增大的趋势,效果不能令人满意。

图1受油器结构图

1、导向头;2、中管;3、同心限位套(改造制作);4、定位滑块;5、外管;6、浮动瓦A;7、浮动瓦B;8、浮动瓦C;9、转子支架;10、桨叶接力器活塞

通过第一台机组受油器检修处理,对整个处理方案有了更深刻的认识,吸取了前次检修的经验,终于完美的解决了中管摆度过大的问题,主要过程如下:

(1)制作大轴内孔测量专用工具,测出最小内径D2和最小点B点到桨叶接力器活塞端面的长度L的具体数值。将一个直径为130mm的法兰盘,在圆盘四周钻孔攻丝安装四个均布的调节螺栓,螺栓头部焊接圆珠,法兰盘固定在镀锌钢管上,将法兰盘插入机组大轴内,通过调整法兰盘上的调节螺栓,最终可测出大轴内径最小值D2为152mm,L值为3.79m,而D1为160mm,然后在中管的对应位置焊接定位滑块精确配合,确保中管与大轴内孔间隙几乎为零。

图2中筐

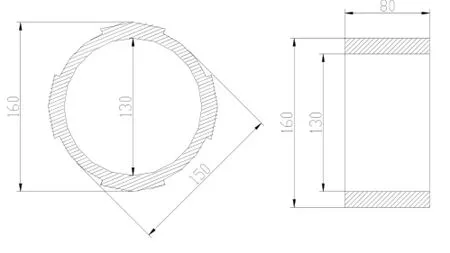

(2)制作外管与中管之间的同心限位环。前面提到,中管前端与外管有很大间隙,最小也有(D3-D2)/2=4mm,而第一次检修中用定位螺栓的方案效果不很理想,于是想到在中管与外管之间嵌入一个同心限位环。首先将中管外径上车削一个台阶,直径为130mm,公差为(-0.05,0),长度为8mm,用内径量表测得外管内径为160mm,公差(0.03,0.05),于是加工限位环(如图3),保证限位环内径公差与中管相配,外径公差与外管相配,最终限位环具体尺寸如下:内径为130mm,外径为160mm,长度为80mm,同时在定位环上刨出四个槽让油流通过,注意过流面积必须保证轮叶开关机时间。

图3限位环

这样中管通过端部法兰螺栓、大轴最小点B点处定位滑块,以及同心限位环三点完全固定死,中管与外管及大轴间的间隙几乎为零。

4.2其他次要原因的处理

(1)确保透平油过滤干净,管路安装前全部用白棉布进行抽拉,清洁管路不留死角,做到一丝不苟。

(2)外管与浮动瓦接触的部位进行镀铬处理,先将外管磨小0.1mm左右,再热镀同样厚度的铬层,大大提高外管的光洁度及硬度,减少对浮动瓦A瓦的磨损。

(3)将转轮体芯与桨叶接力器油缸密封更换为两道车氏密封,第一道密封为聚四氟乙烯滑环加O型圈组合,第二道密封为聚氨酯加O型圈组合,这种密封设计压力可达到60MPa,安装完毕后我们现场打压6.3MPa,保压2h,几乎没有渗漏,效果很好。

(4)严格盘车数据,外管盘车时应注意连接螺栓的憋劲,确保外管摆度不大于0.1mm,我站外管盘车摆度最终为0.08mm。

(5)保证受油器本体与外管同心。用内径量表测量受油器本体与外管的内径大小,调节受油器本体与外管同心度,偏差不大于0.1mm,同时将受油器连接管路全部更换成软管。

5 结论

受油器回装完成后,机组投入正常运行,外管摆度为0.05~0.06mm(机组在线监测数据),调速器压力油泵启停时间达到了1.5h,机组已正常运行一年时间油泵启停时间几乎没变化,整个受油器改造效果非常完美。

Abstract: Guide vane apparatus is one of key parts for a set of hydropower unit. In China, the installation of guide vane apparatus for Francis turbine should be carried out after pre-assembly normally. Taking other hydropower stations into consideration, the none field pre-assembly of guide vane apparatus is discussed and provided to peers.

Key words: guide vane apparatus; hydroturbine; pre-assembly; field

中图分类号:TV738

文献标识码:B

文章编号:1672-5387(2015)01-0060-03

DOI:10.13599/j.cnki.11-5130.2015.01.020

收稿日期:2014-08-28

作者简介:李志坚(1973-),男,工程师,从事电厂运行及检修管理工作。

Vibration characteristic analysis of mixed flow hydroturbine runner based on fluid structure interaction

ZHANG Xin1, ZHENG Yuan1,2, ZHANG De-hao3, WANG Zhong-feng3, WEI Qing-lian3

(1. College of Energy and Electrical Engineering, Hohai University, Nanjing 211100, China; 2.National Engineering Research Center of Water Resources Efficient Utilization and Engineering Safety, Hohai University, Nanjing 21098, China; 3. Baishan Power Factory, Xinyuan(Holdings) Company Limited, State Grid, Jilin 132400,China)

Abstract:The resonance of turbine will cause resonance crack on the turbine blade,so it is necessary to calculate the natural frequency of turbine to avoid external excitation frequency. The fluid structure interaction (FSI) method which combines CFD software CFX and finite element software ANSYS Workbench is introduced in the present paper. The finite element modal analysis is made on a domestic Francis turbine to calculate the modal of the turbine with and without considering the pre-stress respectively. Natural frequencies and mode shapes of the turbine are calculated in the air and water respectively. The results show that the natural frequencies of the turbine will increase by considering the pre-stress. However,the increasing ratio is less than 0.5%, so the effects of pre-stress can be ignored. Natural frequencies in water are reduced significantly than that in air, and the declined degrees vary in different frequency order. The general trend of drop coefficient is reduced with the increase of frequency order.

Key words:Turbine; modal analysis; FSI; pre-stress

Research and application of self-adjusting forced thrust bearing supported by elastic cushion

WANG Huan-dong

(Zhejiang FF Electrical Power Equipment CO., Ltd, Hangzhou 311201, China)

Abstract: The synthetic rubber elastic cushion which is installed under the thrust pad will generate self-adjusting for the forced thrust bearing. It has simple structure, excellent self-adjusting performance, low temperature difference in bearing shell and stable operation. The self-adjusting function of axis for thrust bearing makes the jigger without scraping and the axial line without dealing. It is the best choice for the medium and small type of generator unit to change the rigidity thrust bearing into elastic cushion thrust bearing.

Key words: rigidity thrust bearing; synthetic rubber elastic cushion; elastic cushion thrust bearing

Discussion of DC system operation for large station based on a DC grounding fault

XU Peng

(Longtan Hydropower Development Co., Ltd., Tian’e 547300, China)

Abstract: Based on the analysis of an instantaneous direct current (DC) system ground fault, it is found that the parasitic circuit brings about the ground fault in two completely independent DC system simultaneously. The wide use of devices such as microprocessor-based insulation monitoring device, static type protection device, filtering circuit, long cables and so on in large plant station makes DC system operation have some new problems. The operation of large-scale plant station with DC system under the new situation is discussed.

Key words: DC system; ground fault; insulation monitoring device; equivalent capacitance

Feasibility study of field pre-assembly and none pre-assembly for guide vane apparatus

TANG Zhi-an, LI Zhi-hui

(

Toshiba Hydro Power (Hangzhou) Co., Ltd, Hangzhou 311504, China)