Experimental study on the time-dependent dynamic mechanical behaviour of C60 concrete under high-temperatures

LI Hong-chao(李洪超), LIU Dian-shu(刘殿书) ZHAO Lei(赵磊),Greg YOU, LIANG Shu-feng(梁书锋) WANG Yu-tao(王宇涛)

(1.School of Mechanics and Civil Engineering, China University of Mining and Technology (Beijing), Beijing 100083, China;2.Faculty of Science and Technology, Federation University Australia, University Drive, Mt Helen, Ballarat,Victoria 3353, Australia)

Experimental study on the time-dependent dynamic mechanical behaviour of C60 concrete under high-temperatures

LI Hong-chao(李洪超), LIU Dian-shu(刘殿书)1, ZHAO Lei(赵磊)2,Greg YOU2, LIANG Shu-feng(梁书锋)1, WANG Yu-tao(王宇涛)1

(1.School of Mechanics and Civil Engineering, China University of Mining and Technology (Beijing), Beijing 100083, China;2.Faculty of Science and Technology, Federation University Australia, University Drive, Mt Helen, Ballarat,Victoria 3353, Australia)

To study the dynamic mechanical behavior of C60 concrete at high temperatures, impact tests under different steady-state temperature fields (100, 200, 300, 400 and 500 ℃) were conducted under a variety of durations at the corresponding constant high temperature, namely 0, 30, 60, 90 and 120 min, employing split Hopkinson pressure bar (SHPB) system. In addition, the impact tests were also conducted on the specimens cooled from the high temperature to the room temperature and the specimen under room temperature. From the analysis, it is found that C60 concrete has a time-dependent behavior under high-temperature environment. Under 100, 200, 300, 400 and 500 ℃ steady-state temperature fields respectively, as the duration at the corresponding constant high temperature increases, the dynamic compressive strength and the elastic modulus decrease but the peak strain generally ascends. After cooling to the room temperature, the dynamic compressive strength and the elastic modulus descend as well, but the peak strain increases first and then decreases slightly, when the duration increases. For specimens under and cooled from the high-temperature, as the temperature increases, the dynamic compressive strength and the peak strain raise first and then reduce gradually,and the dynamic compressive strength of specimen under high temperature is higher than that of the specimen cooled from the same high temperature.

concrete; SHPB; high temperature; dynamic mechanical behavior

Concrete-like material has been widely used in the construction industry as one of the most important building materials. Buildings collapse frequently due to fire hazards[1-3]. Moreover, fire disaster has become more dangerous in urban area due to high-density zones and high-rise buildings. Furthermore, progressive structure collapse could occur accompanied with explosion and fire caused by unexpected events, such as accidents in chemical plants or terrorists’ attacks[4]. It has been realised that steel structures have a low thermo tolerance, especially since the 9/11 Attacks, and concrete has been attracting more and more attentions for its superior thermo tolerance[5].

Numerous studies on mechanical properties of concrete have been done in the world, and split Hopkinson pressure bar (SHPB) technique has been used widely to measure the dynamic strength of concrete-like materials at high strain-rate between 10-1and 10-3s-1[6]. Wang et al.[7]fabricated three types of steel fiber reinforced concrete (SFRC) specimens with 0, 3.0% and 6.0% (percentage by volume) of ultrashort steel fiberand employed the SHPB system to impacted the specimens, and found that both the volume fraction of steel-fiber and strain-rate of loading exert significant influences on the SFRC strength. Li et al.[8], Jia et al.[9-10]employed the SHPB system to conduct concrete impact-compression tests under different temperatures, finding the effects of strain rate and temperature on the mechanical properties of concrete. Su et al.[11]studied the dynamic compressive mechanical properties of concrete under high temperature by SHPB system, and found that the dynamic compressive strength and specific energy absorption of concrete increase with the strain rate under different temperatures and at 400 ℃ it is increased by 14%, but at 200, 600, 800 ℃, it is decreased by 20%, 16% and 48% respectively, comparing with that at room temperature. Li et al.[12]tested concrete’s dynamic mechanical property under comparative conditions between room temperature and post-high temperature using SHPB equipment, and found that between 400 ℃-800 ℃, the dynamic compressive strength drops and critical strain raised dramatically. Yang et al.[13]did some impact tests on steel fiber reinforced reactive powder concrete specimens under the temperature between 400 ℃-800 ℃, as a result, the dynamic compressive strength decreases to 62% and 27% and the elastic modulus reduces to 83% and 35.6% respectively. Kim et al.[14]found there is a close relationship between the increase of dynamic compressive strength and the strain rate through SHPB equipment.

Above studies increase our understanding of the mechanical property of concrete, however, there is insufficient research on the dynamic mechanical behavior under different high temperatures and especially the effect of durations maintaining constant elevated temperature. This paper thereby discussed the law of dynamic mechanical properties by conducting impact tests on C60 concrete specimens through Φ75 mm SHPB equipment under a set of elevated temperatures and various durations of the specific constant temperature.

1 Experiment

1.1 Experimental apparatus and data processing

The experimental apparatus was Φ75 mm SHPB system consisting of power unit, pressure bar and data acquisition unit (Fig.1). A ceramic fiber resistance furnace was used for heating with a rated temperature of 1 300 ℃.

Fig.1 Illustration of the Φ75 mm SHPB test apparatus

Experimental data were processed employing the simplified three-wave equations[15]shown below, resulting in the strain-stress relation of concrete (strain rate range 73-117 s-1).

(1)

(2)

(3)

whereεi(t), εr(t)andεt(t)representthestrainsofincidentwave,reflectedwaveandtransmittedwaverespectively; A0iscross-sectionalarea; E0andC0areYoung’smodulusandelasticwavevelocityofrod’smaterial; AsandLstandfortheoriginalcross-sectionalareaandlengthofspecimen.

1.2Testspecimenpreparation

AccordingtothestudybyLietal.[16],foralargeΦ75 mm SHPB equipment, experimental data can accurately reveal the mechanical property of concrete specimen when the length of specimen is in the range of 30-75 mm (length-to-diameter ratio rangeL/D=0.4-1.0). C60 concrete specimens with a standard formulation (Tab.1) were placed in a standard curing room once the specimens were prepared. After 28 days’ standard curing, the concrete specimens were made into standard Φ75 mm×50 mm cylindrical specimens.

Tab.1 C60 concrete formulation kg/m3

1.3 Experimental procedure

There were six different experimental temperatures, e.g. room temperature, 100, 200, 300, 400, and 500 ℃. To make internal and external temperature of specimen’s uniform by homogeneous heating, ANSYS software was used to calculate and analyze the temperature field in the furnace and to calculate the required heating time. SOLID70 Unit of ANSYS was employed to calculate steady-state temperature field of the specimen with the following settings: specimen radius of 37.5 mm; length of 50 mm; heat exchange coefficientkof 50 W(m2·K); 20 ℃ initial temperature and 500 ℃ target temperature;concrete heat conduction coefficient of 1.335 when below 293 ℃ and 0.001 241T+1.716 2 when above 293 ℃; concrete density of 2 300 kg/m3, concrete specific capacity of 840+420T/85.

From above result, the heating-up time to reach the steady-state temperature fields of 100, 200, 300, 400, 500 ℃ in fire-port, are 50, 60, 75, 80, 130 min, respectively. To study how the maintaining duration at constant temperature influence the mechanical property of concrete, five durations, namely 0, 30, 60, 90 and 120 min,are used and designated as 0, 1, 2, 3, 4 in Tab.2. Shown in Tab.2 is the total time including both the heating-up time and the maintaining duration at constant temperature.

Tab.2 Heating period allocation table min

2 Experimental result analysis

2.1 Impact wave curves and failure pattern of concrete specimens under different temperature conditions

According to Ref.[17], the measurement error of SHPB equipment is no more than 3%. Besides the temperature drop is below 10% during the period between after heating and impacting experiment due to the thermal transmission.

Fig.2a is the incident wave and reflected wave curves tested three times cooled from 100 ℃ with duration of 120 min at 100 ℃ constant temperature. The incident waves are steady and approximate rectangle. The reflected waves of broken specimens are approximate ‘W’ shape. Fig.2b is the transmitted wave curves tested three times cooled from 100 ℃ with duration of 120 min at 100 ℃ constent temperature. The more serious the damage degree of specimen is; the deeper the wave trough is; the higher the energy of reflected wave is; the lower the energy of transmitted wave is.

Under each experimental condition, test was done three times (Fig.3). Here only take the tests cooled from 100 ℃.

Fig.2 Incident wave and reflected wave curves and transmitted wave curves of specimens cooled from 100 ℃ constant temperature with duration of 120 min at 100 ℃ constant

Fig.3 Failure patterns of specimens cooled from 100 ℃ with duration of 120 min at 100 ℃ constant temperature

2.2 Dynamic mechanical property analysis under and cooled from high temperature of different durations

2.2.1 Under and cooled from 100 ℃ steady-state temperature field of different durations at 100 ℃

From Fig.4, for the specimens under 100 ℃ steady-state temperature field as the duration at 100 ℃ increases, the dynamic compressive strength decreases; the elastic modulus goes down; and the peak strain ascends overall. At the durations of 0, 30 and 60 min at 100 ℃ constant temperature, the dynamic compressive strength is higher than that under the room temperature; in contrast it is lower at durations of 90 min and 120 min.

In Fig.5, for the specimens cooled from 100 ℃ constant temperature field, as the increase of the duration at 100 ℃, the dynamic compressive strength decreases; the elastic modulus goes down; and the peak strain ascends. In this case, the dynamic compressive strength is higher than that under room temperature for all durations except for 60 min.

Fig.4 Stress-strain curves of specimens with different durations at 100 ℃ constant temperature field

Fig.5 Stress-strain curves of specimens cooled from 100 ℃ to the room temperature, with different durations at 100 ℃

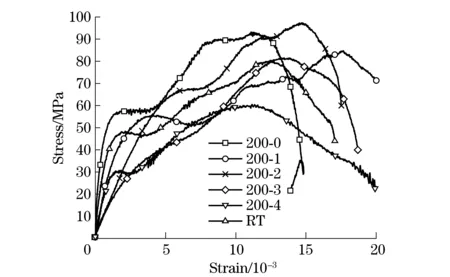

2.2.2 Under and cooled from 200 ℃ steady-state temperature field of different durations at 200 ℃

From Fig.6, for the specimens in 200 ℃ constant temperature field as the duration at 200 ℃ increases, the dynamic compressive strength goes down; the peak strain generally ascends; the elastic modulus decreases. The dynamic compressive strength is higher than that under the room temperature for all durations at 200 ℃.

In Fig.7, for the specimens cooled from 200 ℃ constant temperature field, as the increase of the duration at 200 ℃, the dynamic compressive strength and elastic modulus reduce, but peak strain generally increases. For the cooled specimens undergone the durations of 0 min, 30 min, 60 min and 90 min at 200 ℃, the dynamic compressive strength is higher than that under the room temperature, while it is lower at the duration of 120 min at 200 ℃.

Fig.6 Stress-strain curves of specimens with different durations at 200 ℃ constant temperature field

Fig.7 Stress-strain curves of specimens cooled from 200 ℃ to the room temperature, with different durations at 200 ℃

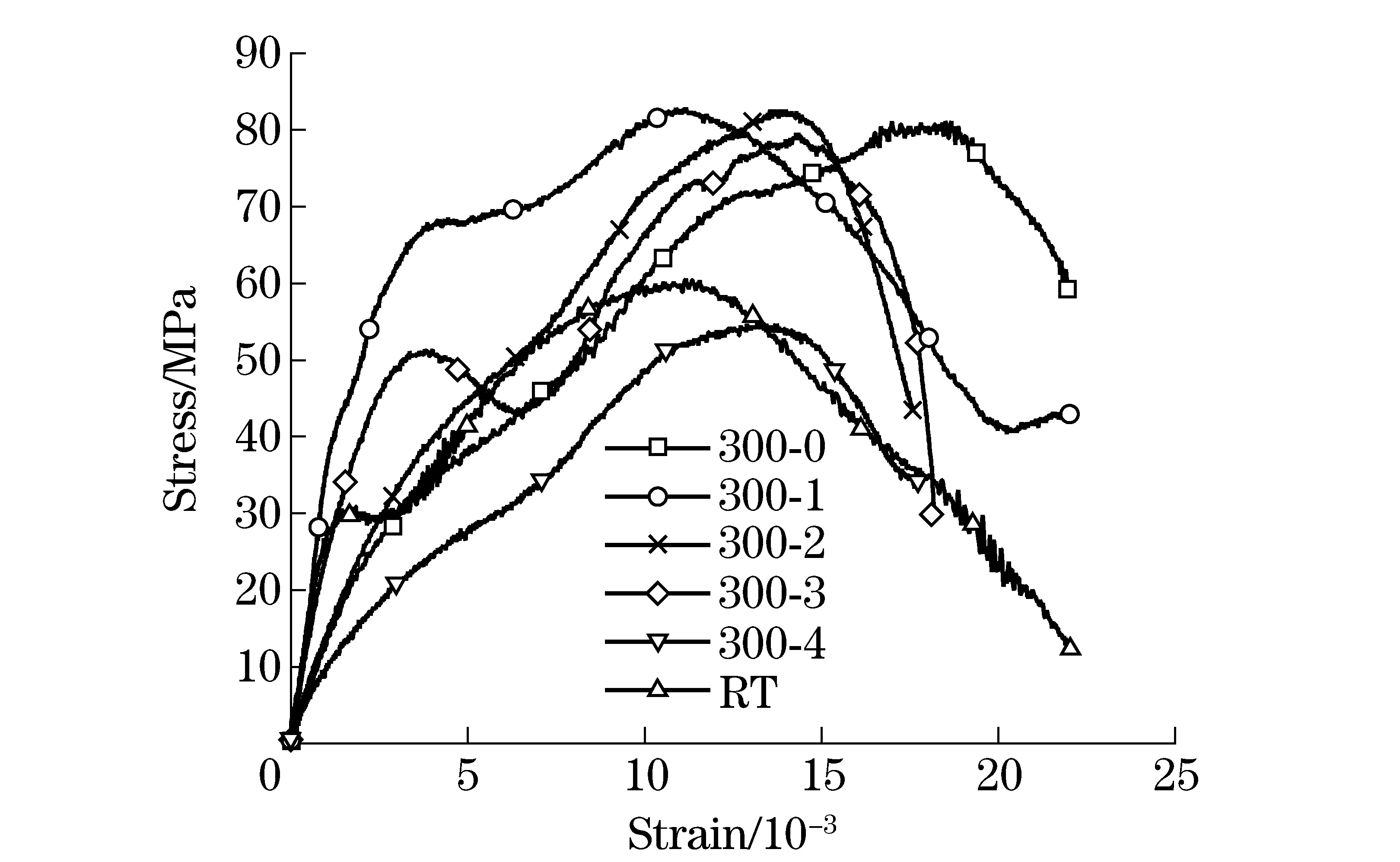

2.2.3 Under and cooled from 300 ℃ steady-state temperature field of different durations at 300 ℃

From Fig.8, for the specimens under 300 ℃ steady-state temperature field, as the duration at 300 ℃ ascends, the dynamic compressive strength and the elastic modulus decreases but the peak strain increases. In this case, the dynamic compressive strength is higher than that under the room temperature for all durations at 300 ℃.

From Fig.9, for the specimen cooled from 300 ℃, as the increase of the duration at 300 ℃, the dynamic compressive strength and the elastic modulus decrease; the peak strain increases first and then decreases. The dynamic compressive strength of the cooled specimens at the durations of 0, 30, 60 and 90 min at 300 ℃ is higher than that under room temperature, by contrast it reverses at the duration of 120 min at 300 ℃.

Fig.8 Stress-strain curves of specimens with different durations at 300 ℃ constant temperature field

Fig.9 Stress-strain curves of specimens cooled from 300 ℃ to the room temperature, with different durations at 300 ℃

2.2.4 Under and cooled from 400 ℃ steady-state temperature field of different durations at 400 ℃

From Fig.10, for the specimens under 400 ℃ steady-state temperature field as the duration at 400 ℃ rises, the dynamic compressive strength and the elastic modulus reduce, but the peak strain increases. At the durations of 0, 30 and 60 min under 400 ℃ constant temperature field, the dynamic compressive strength is higher than that under room temperature, but it is lower at the durations of 90 min and 120 min at 400 ℃.

From Fig.11, for the specimens cooled from 400 ℃, as the duration at 400 ℃ increases, the dynamic compressive strength and the elastic modulus decrease, and the peak strain increases first and then decreases lightly. For the cooled specimens at the durations of 30 min and 60 min at 400 ℃, the dynamic compressive strength is higher than that under the room temperature, but the trend reverses at the durations of 0, 90 and 120 min at 400 ℃.

Fig.10 Stress-strain curves of specimens with different durations at 400 ℃ constant temperature field

Fig.11 Stress-strain curves of specimens cooled from 400 ℃ to the room temperature, with different durations at 400 ℃

2.2.5 Under and cooled from 500 ℃ steady-state temperature field of different durations at 500 ℃

From Fig.12, for specimens in 500 ℃ steady-state temperature field as the duration at 500 ℃ increases, the dynamic compressive strength decreases first and then tends to stable; the elastic modulus reduces; the peak strain increases first and then maintains stable. The dynamic compressive strength of specimen without duration under 500 ℃ constant temperature is higher than that under room temperature, but it is opposite for the other durations at 500 ℃ constant temperature, e.g. 30, 60, 90 and 120 min.

From Fig.13, for specimens cooled from 500 ℃ as the duration at 500 ℃ constant temperature increases, the dynamic compressive strength and the elastic modulus decrease,and the peak strain reduces first and then goes up. The dynamic compressive strength of specimens cooled is lower than that under the room temperature for all durations at 500 ℃.

Fig.12 Stress-strain curves of specimens with different durations at 500 ℃ constant temperature field

Fig.13 Stress-strain curves of specimens cooled from 500 ℃ to the room temperature, with different durations at 500 ℃

2.3 Dynamic mechanical property analysis under and cooled from high temperature without temperature maintaining time

Fig.14 is a comparison of specimens under and cooled from high-temperature without temperature maintaining time, as the temperature increases (before cooling), the dynamic compressive strength increases till about 200 ℃ where the maximum value occurs, and then it decreases. The above phenomenon is resulted from the loss of free water of inside concrete at 200 ℃ which enhances the interlock capacity of concrete and lead the strength of concrete to reach the top. The dynamic compressive strength of specimen under higher temperatures is higher than that cooled from that high temperature, except at 500 ℃ where they are about same.

Fig.15 is a comparison of specimens under and cooled from high-temperature without temperature maintaining time, the peak strain rises firstly and then descends as temperature increase and the peak strain are same at about 270 ℃. Before 270 ℃ the peak strain under high temperature is higher than that cooled, which reverses after 270 ℃.

Fig.14 Dynamic compressive strength- temperature curves of specimens under and cooled from high temperature

Fig.15 Peak strain-temperature curves of specimens under and cooled from high temperature

3 Conclusions

This impact tests on C60 concrete specimens were conducted under different steady-state temperature fields (room temperature, 100, 200, 300, 400 and 500 ℃) after the specimen was maintained for a duration of 0, 30, 60, 90 or 120 min, respectively and after the specimen was cooled from the elevated temperatures to the room temperature, using Φ75 mm split Hopkinson pressure bar (SHPB) system. From the experimental data, the following conclusions can be made:

① Under the same steady-state temperature field, when the duration for maintaining the elevated temperature rises, the dynamic compressive strength of concrete specimen decreases. Under the 500 ℃ steady-state temperature field, when the total time exceeds 190 min, the dynamic compressive strength stops to descend and tends towards stable. For specimens cooled from the elevated temperature, as total time increases, the dynamic compressive strength decreases.

② Under the same steady-state temperature field of different temperature maintaining durations, as the duration increases, the peak strain of specimen generally rises; the elastic modulus reduces; and the toughness becomes stronger. For specimens cooled from the elevated temperature, with the increase of total time, the peak strain typically increases first and then decreases slightly, and the elastic modulus decreases.

③ For both specimens under and cooled from high-temperature without temperature maintaining time, as the temperature increases (before cooling),the dynamic compressive strength raises slightly till around 200 ℃ where the maximum point occurs and then descends after 200 ℃, and the peak strain ascends first and then goes down. The dynamic compressive strength of specimens under high temperature is higher than that of specimens cooled from that high temperature, except at 500 ℃ where they are nearly the same.

[1] Majid A, Li Xiaoyang, Nawawi C. Experimental investigations on bond strength between coconut fibre and concrete[J]. Material and Design, 2013, 44: 596-605.

[2] Le T T, Austin S A, Lim S, et al. Hardened properties of high-performance printing concrete[J]. Cement and Concrete Research, 2012, 42(3): 558-566.

[3] Toledo Filho R D, Koenders E A B, Formagini S, et al. Performance assessment of ultrahigh performance fiber reinforced cementitious composites in view of sustainability[J]. Material and Design, 2012, 36: 880-888.

[4] He Yuanming, Huo Jingsi, Chen Baisheng, et al. Impact tests on dynamic behavior of concrete at elevated temperature[J]. Engineering Mechanics, 2012, 29(9): 200-208. (in Chinese)

[5] Li Zhiwu, Xu Jinyu, Bai Erlei, et al. SHPB test for post-high-temperature concrete[J]. Journal of Vibration and Shock, 2012, 31(8): 143-147. (in Chinese)

[6] Li Qingming, Meng H. About the dynamic strength enhancement of concrete-like materials in a split Hopkinson pressure bar test[J]. International Journal of Solids and Structures, 2003, 40(2): 43-360.

[7] Wang Zhiliang, Liu Yongsheng, Shen R F.Stress-strain relationship of steel fiber-reinforced concrete under dynamic compression[J]. Construction and Building Materials, 2008, 22(5): 1-819.

[8] Li Kui, Tao Junlin. Research on impact compressive experiment and dynamic mechanic behavior of cement mortar at high temperature[J]. Journal of Wuhan University of Technology, 2010, 32(24): 2-27. (in Chinese)

[9] Jia, Bin, Li, Zhengliang, Tao Junlin, et al. SHPB test on high temperature dynamical mechanical behavior of concrete[J]. Journal of Wuhan University of Technology, 2010, 32(21): 34-37. (in Chinese)

[10] Jia Bin, Yang Fang, Sun Kunlin, et al. SHPB test on dynamical mechanical behavior of concrete with high temperature[J]. Applied Mechanics and Materials, 2014, 528: 61-69.

[11] Su Haoyang, Xu Jinyu, Ren Weibo. Experimental study on the dynamic compressive mechanical properties of concrete at elevated temperature[J]. Materials and Design, 2014, 56: 579-588.

[12] Li Zhiwu, Xu Jinyu, Bai Erlei. Static and dynamic mechanical properties of concrete after high temperature exposure[J]. Materials Science and Engineering A, 2012, 544: 27-32.

[13] Yang Shaowei, Liu Limei, Wang Yongwei. SHPB experiment of steel fiber reactive powder concrete exposed to high temperature[J]. Journal of Sichuan University, 2010, 42(1): 25-34. (in Chinese)

[14] Kim D J, Sirijaroonchai K, EI-Tawil S, et al. Numerical simulation of the split Hopkinson pressure bar test technique for concrete under compression[J]. International Journal of Impact Engineering, 2010, 37: 141-149.

[15] Hu Shisheng. Experimental techniques for studying dynamic mechanical behaviors of concrete[J]. Journal of University of Science and Technology of China, 2007, 37(10): 312-1319. (in Chinese)

[16] Li Shenglin, Liu Dianshu, Li Xianglong, et al. The effect of specimen length in Φ75 mm split Hopkinson pressure bar experiment[J]. Journal of China University of Mining & Technology, 2010, 39(1): 93-97. (in Chinese)

[17] Shi Shaoqiu, Gan Sun. The error analysis of resistance strain measure system on SHPB test unit[J]. Journal of Ningbo University, 1989, 2(2): 48-58. (in Chinese)

(Edited by Wang Yuxia)

10.15918/j.jbit1004-0579.201524.0305

O 347; TU 528.1 Document code: A Article ID: 1004- 0579(2015)03- 0313- 08

Received 2015- 03- 15

E-mail: l_hongchao@yahoo.com

——画家赵磊博采众长成大道

Journal of Beijing Institute of Technology2015年3期

Journal of Beijing Institute of Technology2015年3期

- Journal of Beijing Institute of Technology的其它文章

- High-rise building fire pre-warning model based on the support vector regression

- Dynamic modeling and simulation for the flexible spacecraft with dynamic stiffening

- Experimental study on compression stroke characteristics of free-piston engine generator

- Numerical simulation and optimization of the cylinder head water jacket based on the two-phase flow boiling heat transfer

- Multi-action-based approach for constructing knowledge map

- Slow driving control of tracked vehicles with automated mechanical transmission based on fuzzy logic