A fault diagnosis method of reciprocating compressor based on sensitive feature evaluation and artificial neural network①

Xing Chenghong (兴成宏), Xu Fengtian

(*Diagnosis and Self-Recovery Engineering Research Center, Beijing University of Chemical Technology, Beijing 100029, P.R.China)(**PetroChina Beijing Gas Pipeline Co., Ltd., Beijing 100101, P.R.China)(***PetroChina Fushun Petrochemical Company Detergent Chemical Plant, Fushun 113005, P.R.China)

A fault diagnosis method of reciprocating compressor based on sensitive feature evaluation and artificial neural network①

Xing Chenghong (兴成宏)*, Xu Fengtian②

(*Diagnosis and Self-Recovery Engineering Research Center, Beijing University of Chemical Technology, Beijing 100029, P.R.China)(**PetroChina Beijing Gas Pipeline Co., Ltd., Beijing 100101, P.R.China)(***PetroChina Fushun Petrochemical Company Detergent Chemical Plant, Fushun 113005, P.R.China)

A method combining information entropy and radial basis function network is proposed for fault automatic diagnosis of reciprocating compressors. Aiming at the current situation that the accuracy rate of reciprocating compressor fault diagnosis which depends on manual work in engineering is very low, we apply information entropy evaluation to select the sensitive features and make clear the corresponding relationship of characteristic parameters and failures. This method could reduce the feature dimension. Then, a complete fault diagnosis architecture has been built combining with radial basis function network which has the fast and efficient characteristics. According to the test results using experimental and engineering data, it is observed that the proposed fault diagnosis method improves the accuracy of fault automatic diagnosis effectively and it could improve the practicability of the monitoring system.

information entropy, radial basis function network, fault automatic diagnosis, reciprocating compressor, sensitive feature

0 Introduction

Reciprocating compressors are widely used in process industries of oil refining and chemical, which are the core equipments of process plant. Most of the operation media of reciprocating compressors are combustible and explosive vapors, such as hydrogen, natural gas, methane gas and ethylene gas. In case of serious faults, dangerous gas is liable to leak, causing serious accidents such as fire even explosion[1]. Currently, part of domestic reciprocating compressors have installed the online monitoring system, which makes real-time monitoring of operation status possible. With the development of computer processing in intelligent classification technology, fault early-warning and automatic diagnosis have been an inevitable trend. But reciprocating compressor has multiple vibration sources, complex structures and poor working conditions. These make signal acquisition, condition monitoring and fault automatic diagnosis very difficult.

1 Related work

In recent years, many scholars have always concerned about fault diagnosis of reciprocating compressors. Feng, et al. applies support vector machines in fault classification of reciprocating compressor[2]. Ma, et al. used acoustic emission technology on reciprocating compressors for early-warning of piston rods fracture[3]. Ahmed, et al. uses neural networks, support vector machines and principle component analysis in reciprocating compressors fault diagnosis[4,5]. Qu, et al. proposes a fault diagnosis model based on multi-wavelet packet and neighborhood rough set, which enables automatic recognition of the different status of the device[6].

However, these monitoring and diagnosis methods are seldom used in practical engineering. There are three main aspects as follows:

• Reciprocating compressor’s practical working situation is complicated and the utility of fault diagnosis method in lab remains to be tested.

• For single fault, laboratory extracts a smaller number of features. But in the actual diagnosis of typical faults, there are dozens of or even hundreds of extracted features. Diagnosis for real-time processing is difficult.

• Part of the diagnosis methods slip from the target for fault early warning does not blended into online monitoring system.

Therefore, the capability of fault early-warning and automatic diagnosis in the online monitoring system is weak at present.

This paper applies feature selection technology in machine learning to the field of diagnosis for reciprocating compressor and extracts various kinds of fault features basing on online monitoring data, using information entropy technology to complete feature sensitivity analysis. The method achieves fault sensitive features to establish new alarm parameters.

Information entropy is the calculated information content on the basis of original data, which has strong objectivity as a measure of system’s uncertainty[7]. For the moment, information entropy is mainly applied to the aspects of feature analysis and selection in fault diagnosis. Xia, et al. uses it for rolling bearing friction analysis[8], Cabal-Yepez, et al. uses it in induction motors fault identification[9,10], Ai, et al. uses it in crack-rubbing coupled fault diagnosis[11].

There are few reports about the application of information entropy for fault diagnosis of reciprocating compressor.

On the basis of extraction of fault sensitive features by using information entropy, a new fault early-warning and diagnosis architecture combining fault-sensitive features and artificial neural network has been constructed and applied to practical fault diagnosis. Experimental and practical data have proved that the method in this paper obtains a higher diagnosis accuracy and timeliness of early warning compared to the method without feature selection.

2 Sensitive feature evaluation and diagnosis

2.1 Sensitive feature evaluation based on information entropy

Feature selection in machine learning can be defined as selecting a subset which has the optimal result of evaluation criteria from a set of features[12]. It is an algorithm that selects N features from given M features by a learning algorithm L to make a certain evaluation criterion J=J(L,S) optimal.

Information entropy evaluation criterion can quantify the uncertainty between features and fault mainly by using information entropy to determine the classification information that features contain. It is a non-parametric and nonlinear evaluation criterion. Among the methods of information entropy evaluation criterion, information gain and mutual information are widely applied. For illustration, the definition of entropy and conditional entropy is given first.

In information theory and probability and statistics, entropy is a measure of the uncertainty of a random variable. It sets X as a discrete random variable, if its probability distribution is P(X=xi)=pi, i=1,2,…,n, the entropy of the random variable X can be defined as

(1)

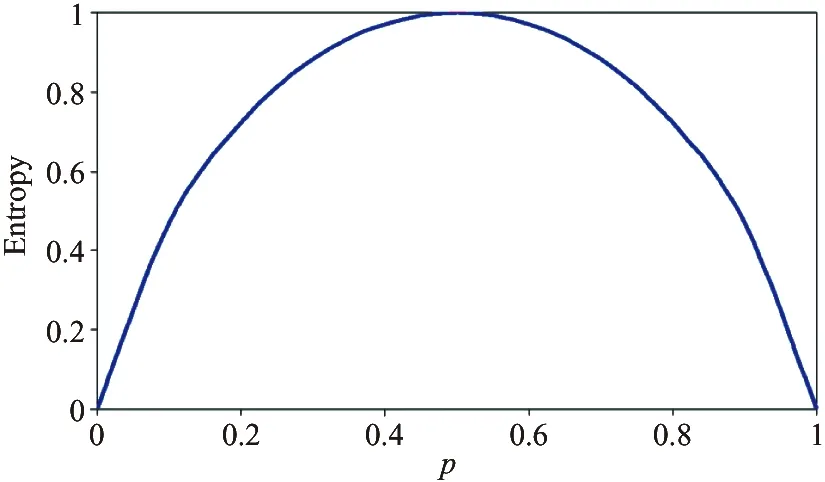

if pi=0, then 0log2(0)=0. By definition, X depends on the entropy distribution and has nothing to do with the value of X, so the entropy of X can be denoted as H(p). The greater the entropy, the greater the uncertainty of a random variable. When there are only two random variable values as 0 or 1, the distribution of X is H(X=1)=p and H(X=0)=1-p, 0≤p≤1, and the entropy is

H(p)=-plog2p-(1-p)log2(1-p)

(2)

At this point, the curve of the entropy with probability is shown in Fig.1. It could be known from Fig.1 that when p=0 or p=1, H(p)=0. That means the random variable has no uncertainty.

Fig.1 The relationship between entropy and probability

(3)

In Eq.(3), P(xi) is the priorprobability that the value of feature X is xi, and P(xi|yj) is the posterior probability that the value of feature X is xiin the given value yiof feature Y. Therefore, information gain is

IG(X|Y)=H(X)-H(X|Y)

(4)

According to the definition of information gain, if IG(X|Y)>IG(Z|Y), the correlation coefficient of feature Y and feature X is higher than that of feature Z and feature X. And IG(X|Y) can be normalized to

(5)

SU(X,Y) is called Symmetric Uncertainty, whose value is in [0, 1]. SU(X,Y)=1 when feature X and Y are completely dependent, and SU(X,Y)=0, when they are completely independent.

There have been symmetric uncertainty SU(X,Y) which can calculate the correlation coefficient of two features, also symmetric uncertainty SU(X,C) can be oblained which can calculate the correlation coefficient of one feature and fault classes with fault classes C to take the place of feature Y.

A relatively simple and straight forward calculation method of symmetric uncertainty is the histogram method[13]. Specific steps are as follows:

Step 1 Given n values x1,x2,…,xnof feature X, the value range of X is divided into n-1 disjoint intervals (xi, xi+1](i=1,…,n-1). Supposing A(xi) is a function that counts the number of sample data of feature X in the interval (xi, xi+1], probability function P(xi)=A(xi)/m would be got approximately in which m is the total number of sample data and information entropy of feature X namely:

(6)

Step 2 According to the fault classes, the sample data of feature X is classified. If A(cj) is the number of the sample data under fault class cj, and P(cj)=A(cj)/m is approximately probability function of fault class cj, then information entropy of fault class cjis calculated by

(7)

(8)

Step 4 Finally, it turns to calculate symmetry uncertainty:

(9)

After Step 4, calculating the next feature, then repeating computation steps of “1~4”. After all the features of symmetry are calculated, the uncertainty coefficients are normalized. It needs to set a threshold for the coefficients normalized. Then the sensitive features are selected whose coefficient is greater than the threshold for different faults. The provisions of this paper is that for a single fault, the feature whose normalized symmetrical uncertainty coefficient is greater than 0.6 will be selected as the sensitive feature of the fault.

2.2 Fault diagnosis of reciprocating compressor

Artificial neural network as an intelligent classifier has been widely used in fault diagnosis of reciprocating compressor. Radial basis function (radial basis, function, RBF) neural network is a typical local three layer feed forward artificial neural network with good performance. It has good training speed and nonlinear ability which can approximate a nonlinear function with any precision globally. In the approximation ability, classification ability, convergence and learning speed etc, the RBF is superior to BP network. This enables RBF to obtain widespread application in many fields[14].

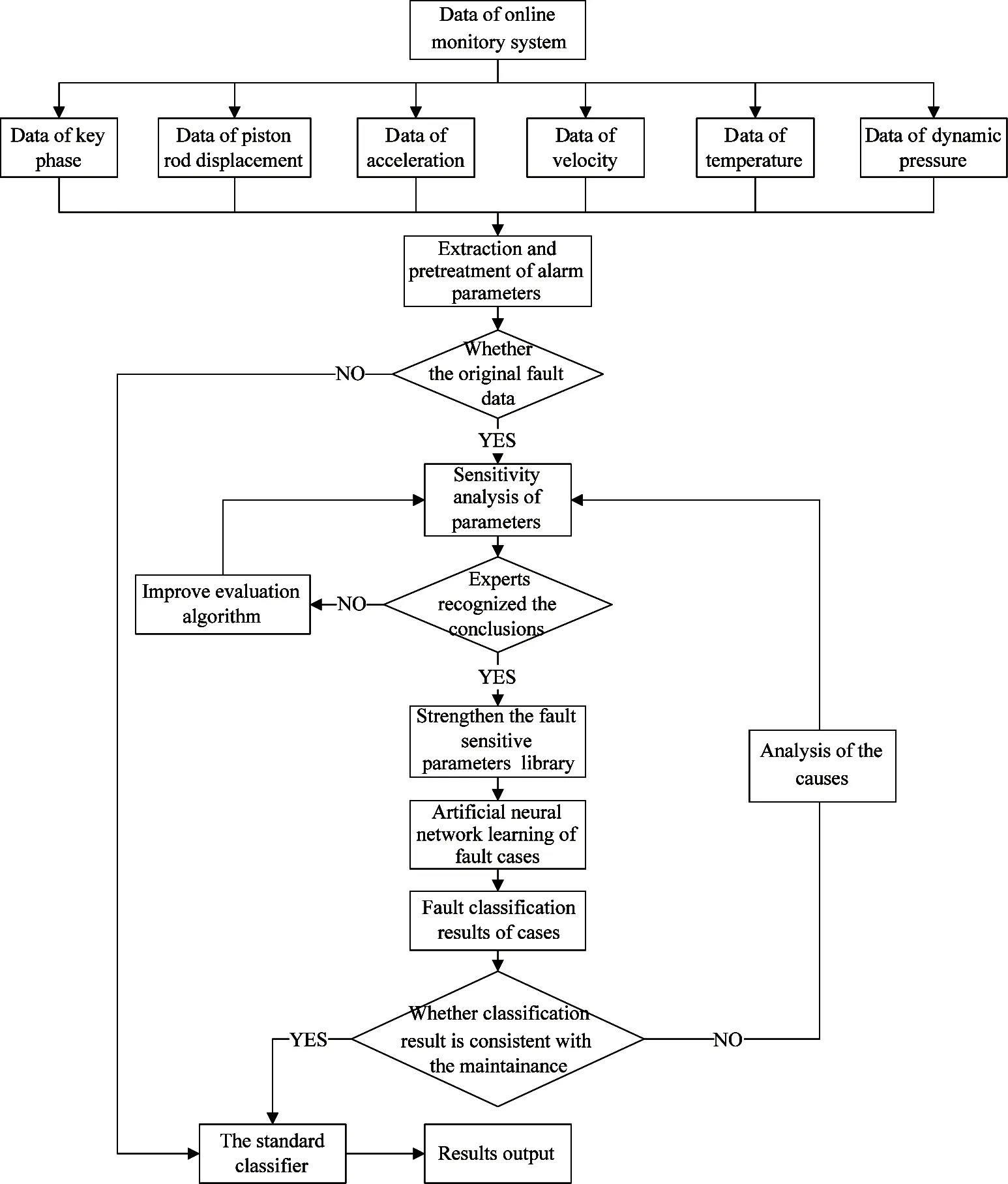

In this paper, an architecture is constructed combining with sensitive fault feature selection and artificial neural network for fault warning and diagnosis, as shown in Fig.2.

In Fig.2, based on the data of online monitoring system, the diagnostic parameters in time domain and frequency domain are calculated as the basis for the sensitive feature extraction. Through automatic learning a lot of data, a standard fault sensitive parameters library was built. The sensitive characteristics of the standard library can be used to improve the alarm parameters in the on-line monitoring system. Because the sensitive characteristics of every kind of fault are different, different neural network classifiers are set for different fault. By the learning of known faults history data, the neural network will be completed training. Then the trained neural network classifier can finish the fault automatic diagnosis. The architecture can be also improved by new type of faults, avoiding retraining of the neural network which has been trained.

3 Experimental investigation

To verify the effectiveness and practicability of the information entropy evaluation method applied in fault diagnosis of reciprocating compressors, two kinds of faults: fracture of piston rod and looseness of the piston rod nut, are used as validation examples. Both of the faults are difficult to be diagnosed in practice. The method will be verified based on data of fault simulation tests on a reciprocating compressor platform. The information of it is shown in Table 1 and the structure is shown in Fig.3.

Fig.2 Architecture of early-warning and fault diagnosis based on fault sensitive feature evaluation and artificial neural network

Based on the online monitoring system, 58 features have been extracted from time domain, frequency domain and time-frequency domain, including displacement peak-to-peak value, acceleration peak value, velocity RMS and so on. Table 2 and Table 3 show the normalized values of parts of features in different time of the failures.

Table1 The experimental compressor information

Fig.3 Structure of the reciprocating compressor

ClassNormalFaulttimetime1time2time3time4time5time6time1time2time3time4time5time6Displacementpeak-to-peak0.170.110.210.180.230.250.220.270.320.330.360.32Accelerationpeak0.080.050.110.100.130.150.340.420.380.410.510.47RMS0.200.270.320.250.220.330.660.820.840.720.810.79

Table 3 The value of parts of features for the looseness fault of piston rod nut

It is easy to see that there are varied differences between normal and fault of a certain feature for each kind of fault. Therefore, the information entropy evaluation method can be used to calculate and sort the sensitivity of different features. After normalized, the sensitivity coefficients of each feature of four groups of fault data are shown in Fig.4 and Fig.5. In Fig.4, it

Fig.4 Results of sensitive feature evaluation for the fracture failure of piston rod

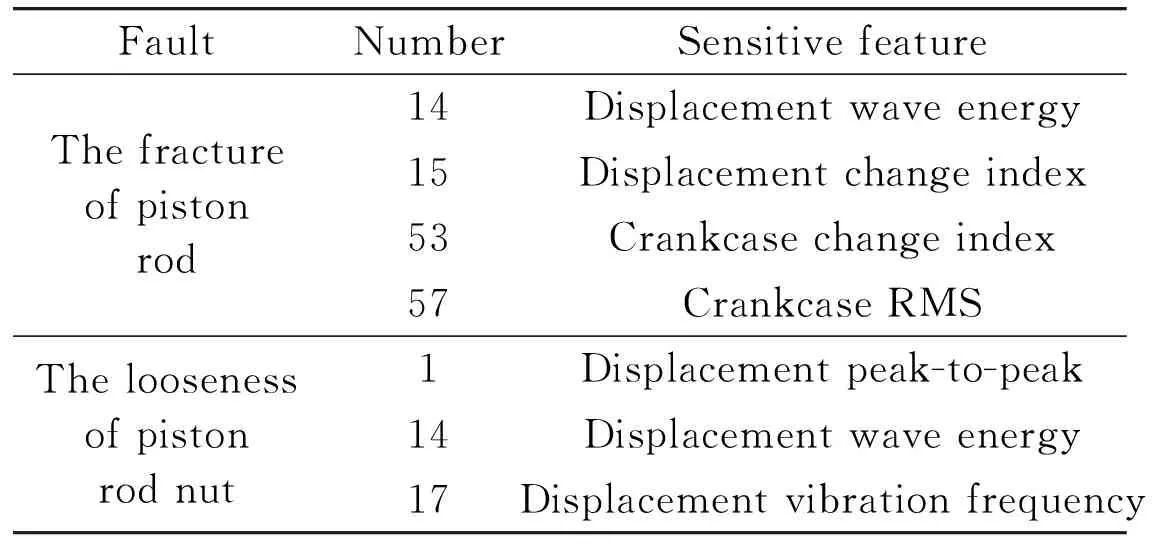

FaultNumberSensitivefeatureThefractureofpistonrod14Displacementwaveenergy15Displacementchangeindex53Crankcasechangeindex57CrankcaseRMSTheloosenessofpistonrodnut1Displacementpeak-to-peak14Displacementwaveenergy17Displacementvibrationfrequency

is the result of sensitive feature evaluation for the fracture failure of piston rods. And in Fig.5, it is for the looseness fault. The sensitive features for each fault are shown in Table 4.

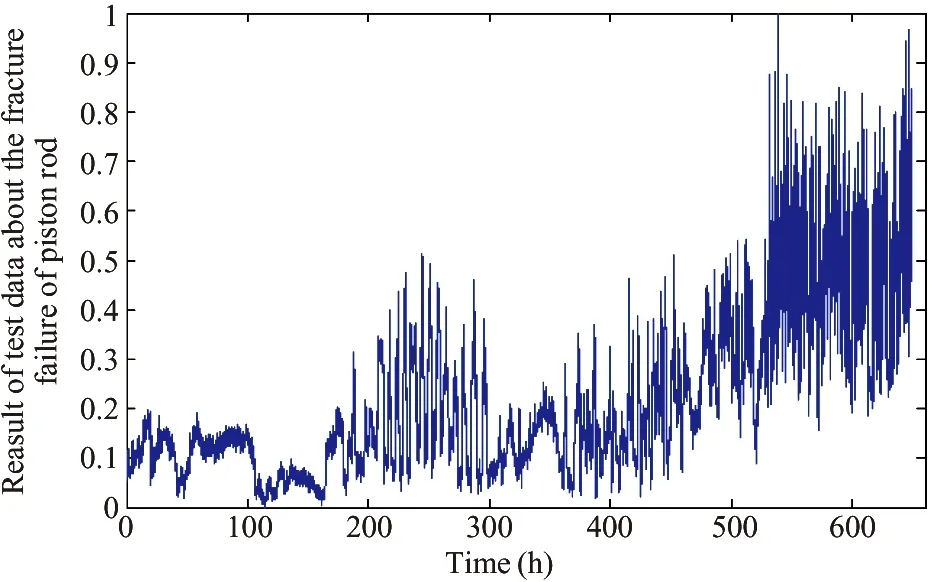

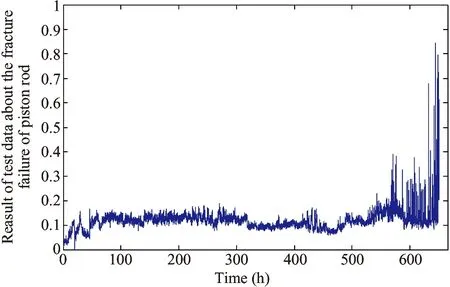

After the sensitive features are obtained, the sample data corresponding to the sensitive features will be used to train the artificial neural network as an intelligent classifier respectively for each kind of fault. Then one typical fault case for the fracture failure of piston rod is taken and one typical fault case for looseness fault to test the independent intelligent classifier. The results are shown in Fig.6 and Fig.7.

Fig.6 Output value of artificial neural network for the fracture failure of piston rod

Fig.7 Output value of artificial neural network for the looseness fault of piston rod nut

Fig.6 shows the output value of artificial neural network for the fracture failure of piston rod and it is easy to figure out that the trained classifier can do fault diagnosis. There is obviously the fault symptom in the early fault period. Similarly, Fig.7 shows the output value of artificial neural network for the looseness fault. And it is also easy to figure out that the trained classifier can do fault diagnosis, there is obviously the fault symptom in the early fault period.

After evaluation, the fault features not only make clear the relationship between the fault type and fault feature, but also improve the diagnosis accuracy. In order to illustrate it, this paper constructs an architecture of artificial neural network fault diagnosis without sensitive feature selection and just provides one neural network system for all kinds of fault. That is, the fault features for diagnosis are same for every fault. Before the early-warning and diagnosis of test data, it is required the use of a known fault data to train the neural network. One drawback of this layout is a new category of failure which will need to retrain the neural network.

Comparing and analyzing these experimental data, the test results of a typical fault case of the fracture failure for piston rod and a typical fault case for looseness fault are shown respectively in Fig.8 and Fig.9.

Fig.8 Output value of artificial neural network without sensitive feature selection for the fracture failure of piston rod

Fig.9 Output value of artificial neural network without sensitive feature selection for the looseness fault of piston rod

It shows the output results of artificial neural network of the fracture failure of piston rod and the looseness fault. It is easy to figure out that the trained classifier reduces the accuracy of fault diagnosis compared with the above and there is obviously no fault symptom in the early fault period.

4 Verification

In order to exam the practical value in engineering of the method proposed in this paper further, the actual fault case data from a domestic enterprise remote monitoring and diagnosis center of reciprocating compressor were carried to be analyzed. According to the faults including fracture of the piston rod failure, supporting ring wear failure and scuffing failure, 20 groups of the faults data were selected as training data; the other 100 groups fault were selected as test data.

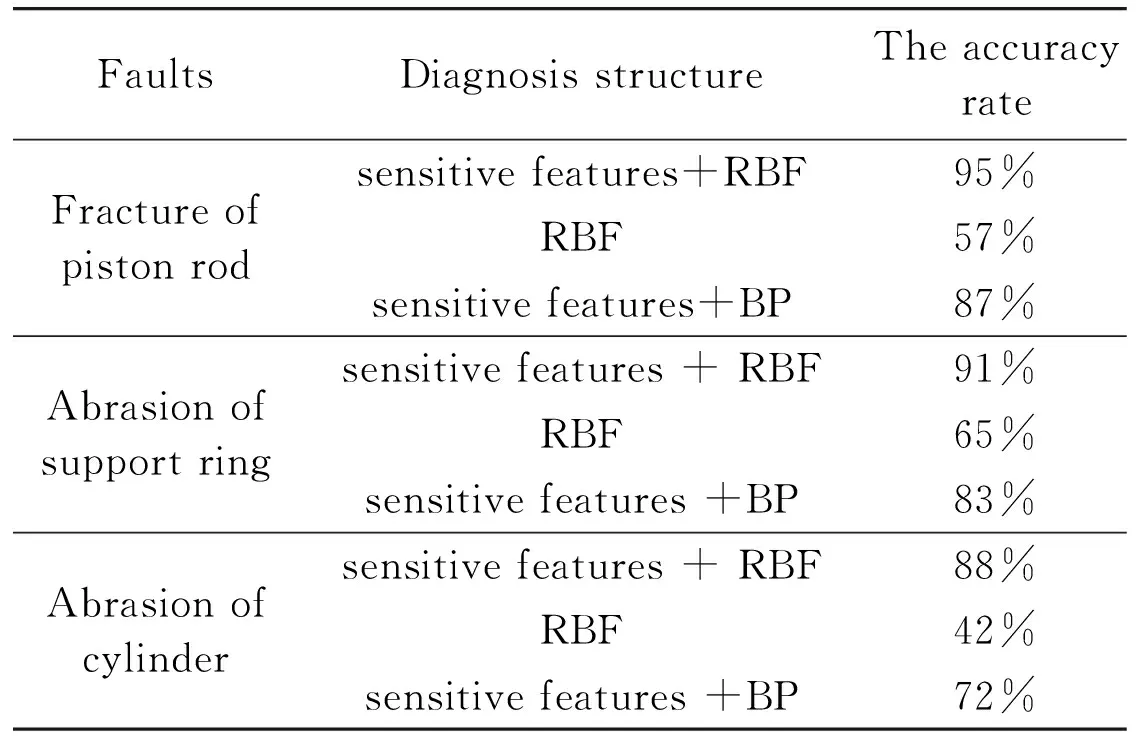

To comprehensively inspect the practicability and superiority of the method presented in this paper for fault diagnosis, the diagnosis structure of this paper was compared with that based on the sensitive feature selection and BP artificial neural network in addition to the structure that based on radial basis function artificial neural network only.

In Table 5, it is clear that the accuracy rate of RBF with sensitive features is higher than those of RBF only and BP with sensitive features.

After sensitive features selection through information entropy evaluation, the dimension of the feature set was greatly reduced from 58 to 4 or 3. Meanwhile, the computational complexity is significantly reduced and the fault diagnosis accuracy is greatly improved. More important, it is clearly to grasp the sensitive features for the compressor operators in application of online monitoring and diagnosis system.

Table 5 The validation results of actual faults data

5 Conclusions

According to the problems that the sensitivity of alarm parameters is very low and it is difficult to take automatic diagnosis in realistic, this paper proposes a new method that applies the information entropy evaluation to select the sensitive features of different faults based on the data in online monitory system. It makes clear the relationship of fault and features, reduces the dimension of data. The sensitive features can be used to improve the alarming system, increase the pertinence and validity of alarming parameters.

Based on the selection of sensitive features, a new diagnosis architecture combining sensitive features and artificial neural network is built which has been compared with other architectures by different fault cases data. The diagnosis results obtain test data from faults simulation and actual faults, the diagnosis architecture proposed in this paper improves the accuracy of fault diagnosis significantly.

The study of this paper is closely related to the requirements of realistic fault diagnosis of reciprocating compressor. The method has good application value. The next step will be integrating the diagnosis architecture into the online monitoring system to improve the training and studying through mass of data, and increasing the practicability and automatic diagnosis accuracy of the monitoring system.

[ 1] Yu L J. Review on fault diagnosis technology for reciprocation compressors. Fluid Machinery, 2014,41(1): 36-37

[ 2] Feng K, Jiang Z N, He W, et al. A recognition and novelty detection approach based on Curvelet transform, nonlinear PCA and SVM with application to indicator diagram diagnosis, Expert Systems with Applications, 2011, 38:12721-12729

[ 3] Ma B, Gao J J, Jiang Z N. Research on the piston rod fracture early warning technique of reciprocating compressor. Journal of Mechanical Strength, 2008, 30(3) : 445- 449

[ 4] M Ahmed, F Gu, A D Ball. Fault Detection of Reciprocating Compressors using a Model from Principles Component Analysis of Vibrations. Journal of Physics: Conference Series, 2012. 364, p. 012133

[ 5] Ahmed M, Abdusslam S, Baqqar M, et al. Fault Classification of Reciprocating Compressor Based on Neural Networks and Support Vector Machines. In: Proceedings of the 17th International Conference on Automation & Computing, Huddersfield, UK, 2011. 213-218

[ 6] Qu J X, Zhang Z S, He Z J. Fault diagnosis model based on multi- wavelet packet and rough neighborhood sets. Journal of Vibration, Measurement & Diagnosis, 2013, 33(1): 137-140

[ 7] Liu H, Yu L. Toward Integrating Feature Selection Algorithms for Classification and Clustering. IEEE Transactions on Knowledge and Data Engineering, 2005, 17(4): 491-502

[ 8] Xia X T, Chen L, Meng F N. Information Entropy of Rolling Bearing Friction Torque as Data Series. Applied Mechanics and Materials, 2010, 44- 47:1115-1119

[ 9] Cabal-Yepeza E, Romero-Troncosoa R J, Garcia-Pereza A, et al. Single-parameter fault identification through information entropy analysis at the startup-transient current in induction motors. Electric Power Systems Research, 2012, 89: 64-69

[10] Romero-Troncoso R J, Saucedo-Gallaga R, Cabal-Yepez E, et al. FPGA-Based Online Detection of Multiple Combined Faults in Induction Motors Through Information Entropy and Fuzzy Inference. IEEE Transactions on Industrial Electronics, 2011,58(11):5263-5270

[11] Ai Y T, Fu Q, Tian J, et al. Diagnosis method for crack-rubbing coupled fault in rotor system based on integration of information entropy distance. Journal of Aerospace Power, 2013,28(10): 2161-2166

[12] Liu H, Yu L. Toward Integrating Feature Selection Algorithms for Classification and Clustering. IEEE Transactions on Knowledge and Data Engineering, 2005, 17(4): 491-502

[13] Liu H W. A study on feature selection algorithms using information entropy: [Ph.D dissertation]. Jilin: Jilin University, 2010. 17-20

[14] Leng J F, Jin S X, Wu Z Q. Fault diagnosis for gearbox based on RBF neural network. Journal of Mechanical Strength, 2010, 32(1): 017-020

Xing Chenghong, born in 1972, is studying for his Ph.D degrees in Diagnosis and Self-recovery Engineering Research Center of Beijing University of Chemical Technology. His research interests in mechanical fault diagnosis and expert system.

10.3772/j.issn.1006-6748.2015.04.007

①Supported by the National Basic Research Program of China (973 Program) under Grant (No. 2012CB026000), and the National High Technology Research and Development Program of China (No. 2014AA041806).

②To whom correspondence should be addressed. E-mail: 2012210152@grad.buct.edu.cn Received on July 7, 2014*, Yao Ziyun**, Li Haifeng***, Zhang Jinjie*

High Technology Letters2015年4期

High Technology Letters2015年4期

- High Technology Letters的其它文章

- Effect of laser heating on the microstructure and hardness of TRIP590 advanced high strength steel used for roll forming①

- Design of bilayer lengthened LDPC codes over expanded graph for relay channels①

- Secure planar convex hull protocol for large-scaled point sets in semi-honest model①

- Magnetometer calibration algorithm based on ellipsoid constraint①

- Motion mechanism analysis of two contacting rollers①

- Service optimization in programmable cloud network①